Professional Documents

Culture Documents

05020-250-090-MDS-116-01-01 Rev.2 (090TK-001,002) DCU FEED TANKS

Uploaded by

Selim SelimCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

05020-250-090-MDS-116-01-01 Rev.2 (090TK-001,002) DCU FEED TANKS

Uploaded by

Selim SelimCopyright:

Available Formats

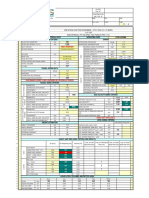

PAGE 1 OF 5

DATA SHEET

PROJECT TITLE : COKER COMPLEX REHABILITATION

PROJECT No. : 05020-250 DATA SHEET No. TAG No.

COMPANY : SUEZ OIL PROCESSING COMPANY (SOPC) 05020-250 - 090-MDS-116-01-01 090TK-001/002

SITE LOCATION : SUEZ - EGYPT MR No. MR ITEM No.

SUPPLIER : PETROJET 05020-250 - 116-01-01-P 4.0

This Data Sheet shall be read in conjunction with PO No. PO ITEM No.

the Specification No. : AS PER MR ATTACHMENTS LIST

PACKAGING , PREPARATION FOR SHIPMENT AND STORAGE SHALL BE IN ACCORDANCE:

JOB PACKAGING & SHIPMENT INSTRUCTION

SUPPLIER STANDARD

OTHERS :

EQUIPMENT : STORAGE TANKS

SERVICE : DCU FEED TANKS

10000-000-GE1-TMP-0005 (03/19)

2 29-Mar-21 RE-ISSUED FOR PURCHASE K.S F.A M.A.E

1 4-Mar-21 ISSUED FOR PURCHASE K.S F.A M.A.E

0 9-Jul-20 ISSUED FOR INQUIRY A.O F.A M.A.E

Rev. Date Revision Description By Checked Approved

PAGE 2 OF 5

DATA SHEET

COMPANY : SUEZ OIL PROCESSING COMPANY DATA SHEET No. : 05020-250 - 090-MDS-116-01-01

EQUIPMENT : STORAGE TANKS TAG No. : 090TK-001/002

LOCATION : SUEZ - EGYPT REV. No. : 2

DESIGN DATA

Rev

1

2 MAXIMUM CAPACITY 7,359 m³ NET WORKING CAPACITY 5,700 m³

3 DIAMETER 25,000 mm HEIGHT 16,000 mm

4 QUANTITY 2 Tanks FREE BOARD REQUIRED Yes, As Note-9

5 INT. DESIGN PRESSURE 0.005 kg/cm²g , at INT.DESIGN TEMP. 170 °C

6 VAC. DESIGN PRESSURE - kg/cm²g MIN.DESIGN TEMP. 4 °C

7 TEST PRESSURE. As per API DESIGN LIQUID LEVEL 14,100 mm

8 PWHT. (Note-23) As per API RADIOGRAPHY

9 FLUID & OPERATING CONDITIONS

10 OPERATING PRESSURE atm kg/cm²g at TEMPERATURE 140 °C

11 PRODUCT Vacuum Residue MAX S.G / AT 0.983 / 140 °C

12 RVP. 0.088 kg/cm²a FLASH PT. N/A °C SPECIAL SERVICE N/A

13 BLANKETING GAS N/A mbarg INFLOW NORMAL 24.6 m3/hr

3

14 MAX. FILLING RATE 145.0 m /hr MAX. EMPTYING RATE 80.0 m3/hr

15 MECHANICAL & CONSTRUCTION DATA

16 CODE API 650 ED. Latest SHELL DESIGN METHOD 1-FOOT

17 APPLICABLE APPENDICES □ A ■ B □ C ■ F □ G□ H ■ I □ J ■ L ■ M □ O ■ P □ S ■ U □ V□ W

18 ROOF TYPE Fixed Cone BOTTOM TYPE Coned up

19 ROOF SUPPORT TYPE Rafters BOTTOM SLOPE 1 : 100

20 ANCHORAGE TYPE Anchor Bolts DRIP RING No

21 LIFTING LUGS No STAIRWAYS Yes

22 EARTHING LUGS Yes (Note 15 ) WALKWAY & PLATFORM Yes

23 P & V VENT Yes SET. PRES. kg/cm²g LADDERS Yes

24 GA. HATCH Yes (Slot Dipping) GAUGER PLATFORM No

25 LOCAL LEVEL INDICATOR Mechanical Note 24 HANDRAIL Yes

26 HEATING COIL Yes (Note 26 ) PIPE GUIDES/SUPPORTS Yes

27 MIXER / AGITATOR Yes (Note 12 ) CLEAN OUT DOORS Yes

28 TANK SUPPORT Ground LEAK DETECTION Yes

29 FOUNDATION TYPE Ring Beam FIREFIGHTING SYSTEM Yes (Note 22 )

30 SIESMIC DESIGN WIND DESIGN

31 DESIGN CODE UBC 97, Zone 2A DESIGN CODE ASCE-7-05

32 DESIGN CRITERIA API 650 Appendix E WIND SPEED 140 Km/hr

33 SITE CLASS SC EXPOSURE FACTOR C

34 SIESMIC USE GROUP / IMP. FACTOR Group III / 1.5 TOP WIND GIRDER As Per Code

35 LATERAL ACCELERATION BASIS Other (Non-ASCE) INTERMEDIATE WIND GIRDER As Per Code

36 SS As Per Code S1 As Per Code IMPORTANCE FACTOR 1.15

37 VERTICAL EARTHQUAKE ACCEL. (AV) 0

38 PEAK GROUND ACCELERATION (SP) 0.15

39 MATERIALS (Notes 2, 20, 21 & 23)

10000-000-GE1-TMP-0005 (03/19)

40 SHELL A283 Gr. C GASKETS Compressed Non Asbestos Fiber (CNAF)

41 BOTTOM / ANNULAR A283 Gr. C EXTERNAL BOLTING A193-B7 / A194-2H

42 ROOF A283 Gr. C INTERNAL BOLTING A193-B8M / A194-Gr.8M

43 NOZZLE NECK A106-B FIXED INTERNALS A283 Gr. C

44 FLANGES A105-N REMOVABLE INTERNALS SS316L

45 STRUCTURAL (INT. /EXT.) A36 ANCHOR BOLTS A36 HDG

46 BOTTOM C A. 3 2 mm ROOF C.A. 3 2 mm 2

47 SHELL C A. 3 2 mm STRUCTURAL C.A. INT. / EXT. - / - mm 2

48 INTERNAL C. P. No EXTERNAL C. P. By Others

PAGE 3 OF 5

DATA SHEET

COMPANY : SUEZ OIL PROCESSING COMPANY DATA SHEET No. : 05020-250 - 090-MDS-116-01-01

EQUIPMENT : STORAGE TANKS TAG No. : 090TK-001/002

LOCATION : SUEZ - EGYPT REV. No. : 2

SURFACE PREPARATION & PAINTING (NOTE 7)

Rev

1

2 EXTERNAL PAINTING SYSTEM INTERNAL COATING SYSTEM

3 SYSTEM No. 4 SYSTEM No.

4 SURFACE PREP. Sa 2½ SURFACE PREP. **

5 PRIMER 75 μm Inorganic zinc silicate PRIMER **

6 INTER. COAT N/A TOP COAT **

7 TOP COAT 200 μm polyamide MIO epoxy LINING YES

8 FINAL COLOR N/A

9 INSULATION & FIRE PROOFING (NOTE 25)

10 INSULATION Yes TYPE Heat Conservation

Mineral fiber blankets ASTM C592 TYPE

11 MATERIAL THICKNESS (NOTE 25) 40 mm

II (NOTE 25)

12 INSUL. SUPPORTS Yes FIRE PROOFING SUPPORTS N.A.

13 FOUNDATION LOADS (Note 3)

14 EMPTY ** K(N) SEISMIC SHEAR ON BASE ** K(N)

15 OPERATING ** K(N) SEISMIC MOM. ON RING BEAM ** K(N.m)

16 TEST ** K(N) SEISMIC MOM. ON SLAB ** K(N.m)

17 WIND SHEAR ** K(N) WIND MOMENT ** K(N.m)

18 NOZZLES

19 FLANGE

MARK QTY SIZE SERVICE REMARKS

20 RATING TYPE FACING

21 N1 1 10" 300 lb WN RF VR INLET

22 N2 1 14" 150 lb WN RF VR OUTLET

23 N3 1 6" (HOLD) 300 lb WN RF SPILLBACK with internal pipe

24 N4 1 2" 300 lb WN RF LP STEAM INLET (to 090E-001) NOTE- 26

25 N5 1 2" 150 lb WN RF CONDENSATE OUTLET (from 090E-001) NOTE- 26

26 N6 (**) (**) 150 lb WN RF SIDE ENTRY PROPELLER MIXERS NOTE- 12

N7 1 (**) 150 lb WN RF VENT NOTE- 4

N8 1 4" 150 lb WN RF DRAIN with internal pipe

27 N9 1 4" 150 lb WN RF DRAIN with internal pipe

30 N10 1 4" 150 lb WN RF UTILITY CONNECTION

31 N11 (*) (*) 150 lb WN RF HEAT DETECTION NOTE-22

N12 1 24" API STD MECH. LEVEL GAUGE (Note-27) (NOTE-24)

N13 1 24"(HOLD) 300 lb WN RF LEVEL TRANSMITTER (Note-27) with stilling well

N14 1 4" (*) 300 lb WN RF LEVEL TRANSMITTER (Note-27) with stilling well

32 N15 1 2" (*) 300 lb WN RF TEMP. GAUGE (Note-27)

33 N16 1 2" (*) 300 lb WN RF TEMP. TRANSMITTER (Note-27)

34 N17 1 2" (*) 300 lb WN RF TEMP. TRANSMITTER (Note-27)

10000-000-GE1-TMP-0005 (03/19)

39 GH 1 8" API STD GAUGE HATCH NOTE- 28

40 EH (**) 24" API STD EMERGENCY HATCH NOTE- 4

44 M1/2 2 24" API STD ROOF MANWAY NOTE-11

45 M3/4 2 24" API STD SHELL MANWAY NOTE-11

46 M5 1 48"X48" API STD CLEAN OUT MANWAY NOTE-11

(*) Size is Hold

47

(**) By Supplier

PAGE 4 OF 5

DATA SHEET

COMPANY : SUEZ OIL PROCESSING COMPANY DATA SHEET No. : 05020-250 - 090-MDS-116-01-01

EQUIPMENT : STORAGE TANKS TAG No. : 090TK-001/002

LOCATION : SUEZ - EGYPT REV. No. :2

SKETCH

10000-000-GE1-TMP-0005 (03/19)

0 3-Mar-21 H.S. K.S.

Rev. Date By Checked

PAGE 5 OF 5

DATA SHEET

COMPANY : SUEZ OIL PROCESSING COMPANY (SOPC) DATA SHEET No. : 05020-250 - 090-MDS-116-01-01

EQUIPMENT : STORAGE TANKS TAG No. : 090TK-001/002

LOCATION : SUEZ - EGYPT REV. No. : 2

NOTES

Rev.

1 - All dimensions are in mm unless otherwise noted.

2 - Minimum ambient temperature is 4oC.

3 - Any missing data shall be completed by tank supplier. Tank supplier shall be responsible to determine the final thickness, weights and

foundation loads during detailed engineering phase.

4 - Total numbers of emergency hatches (24”) & Sizing of vent as per API 2000 latest edition shall be included in tank supplier scope of

supply.

5 - Nozzles elevation, orientation and projection shall be confirmed during detailed engineering phase.

6 - Flanges bolt holes shall evenly straddle vertical axis.

7 - Surface preparation and painting shall be according to project specification no. 05020-250-100-020. Tank shall be internally lined

with phenolic epoxy for bottom, sump and first 1m of shell, and also for shell courses above HHLL and roof surfaces.Coating system

shall be suitable for operating temperature. System details shall be specified by the vendor.

8 - All flanges shall be as per ASME B16.5 with smooth facing surface finish 125 AARH to 250 AARH. Nozzle flanges: ASME B16.5

up to 24" NPS, for NPS >24" use ASME B16.47 series A.

9 - The proposed tank height by PETROJET (16000) mm will be approved during detailed engineering considering freeboard (above

HHLL) necessary to contain liquid sloshing wave. This freeboard shall be sufficient to be fully contained within the shell, the sealing

ring and the secondary seal. Consequently; supplier shall consider this in tank design.

10 - Loads superimposed by platforms and brackets and loads resulting from connected piping shall be considered in the tank design.

11 - Manways & Cleanout doors shall be supplied with blind covers with hinges / davits, gasket, bolts and handles, Internal grab rungs

shall provide for manways (as applicable).

12 - Design, test, supply, and installation of Side-entry tank mixer located below low low liquid level complete with electric motor driver

and all accessories, as per datasheet no. 05020-250-090-MDS-136-02-01, mechanical mixer specification no. 05020-250-100-021,

motor data sheet no. 05020-250-090-EDS-500-08-02, and low voltage induction motor specification no. 05020-250-500-008.

Quantity of mixer is hold and to be indicated by tank supplier based on CFD calculations.

13 - Spare parts for commissioning and start up shall be:

■ Three complete set of gaskets for manways, blind connections.

■ 10% of bolting (min. 5 pieces of each size/ type) for manways, blind connections.

14 - Tank supplier shall provide list of recommend spares for two years (listed) continuous operation.

15 - Tank shall be provided with minimum three SS - 120 degree Earthing boss complete with all stainless steel fixation and termination

accessories (earthing lug suitable for bolt size M8 , washer ,nut etc..)

16 - Reinforcing pads and all other external attachement pads shall have rounded corners of minimum 50 mm (2 inch) radius. Pads that

cover shell seams shall be provided with a 6 mm telltale hole.

17 - Welding shall be according to project specification 05020-200-100-076.

18 - Supplier shall submit Tank allowable nozzle loads and nozzles stiffness (Forces and Moments). In case actual calculated piping loads

exceed the submitted allowable loads, Contractor shall submit the actual calculated nozzle piping loads for supplier execution.

19 - In case of piping need any Piping Bracket\Guide Supports will fabricated by supplier, then Piping Bracket\Guide Clip list will be

submitted during detailed engineering phase.

20 - External bolting shall be PTFE coated suitable for design temperature.

21 - PMI shall be according to project specification 05020-200-100-077.

22 - Tanks shall be equipped with a firefighting deluge system of water spray rings arranged to operate as two independent halves, each

half is covering half shell surface area and half roof surface area, the water spray system including design, supply, installation and

testing up to the tie-in flange (300mm Min. from grade level) shall be inside supplier scope battery limit. Two linear heat detectors

on each tank shall be covering top side area while of design, supply, installation, wiring, termination, fixation, and testing up to the

interposing junction box of those detectors shall be into supplier scope battery limit. Deluge Valve feeding the water spray system on

tanks is not part of supplier scope of supply.

23 - Process fluid physical properties are as follows:

Vacuum Residue Viscosity: 66 – 690 cP

Thermal Conductivity: 0.07 kcal/h-m-Oc CP: 0.5 kcal/kg-oC

24 - Mechanical level gauge to be float operated / guided wire type indicator with oil seal unit and to be readable from ground level.

25 - Heat Conservation Insulation shall be as project spec. no. 05020-250-400-005

26 - Tanks shall be equipped with inside steam heating coil (located below low low liquid level) to maintain the fluid temperature as

minimum at 140°C. Thermal/Mechanical Design , material supply, fabrication, inspection and installation of inside heating coil

complete with all supports shall be included in tank supplier scope of supply as per below data:

Low Pressure Steam Design Pressure = 25 kg/cm2g / FV Design Temperature = 350 oC

Operating Pressure = 8 kg/cm2g (min.) / 10 kg/cm2g (max.)

Operating Temperature = 220oC (min.) / 230oC (max.)

Design Steam Consumption= 400 kg/hr

10000-000-GE1-TMP-0005 (03/19)

Heater design duty is 0.27 MMkcal/h (calculated based on mineral wool with 40mm thickness tank insulation.)

27 - Nozzles instrumentation Tag No.s For TK-001/TK-002:

N12: 090-LG-001 for TK-001, 090-LG-002 for TK-002.

N13: 090-LT-001 for TK-001, 090-LT-003 for TK-003.

N14: 090-LZT-002 for TK-001, 090-LZT-004 for TK-002.

N15: 090-TG-001 for TK-001, 090-TG-002 for TK-002.

N16: 090-TT-001 for TK-001, 090-TT-003 for TK-002.

N17: 090-TZT-002 for TK-001, 090-TZT-004 for TK-002.

28 - Gauge hatch complete with flange, cover, stilling well, gasket, bolts and nuts shall be in scope of tank supplier.

You might also like

- SCR10-20PM Compressor ManualDocument36 pagesSCR10-20PM Compressor ManualTrinnatee Chotimongkol100% (2)

- LPG Blending Facilities Tender Documents ListDocument235 pagesLPG Blending Facilities Tender Documents ListManish MehtaNo ratings yet

- Engineering Services Related To Process Study: SRU RevampDocument16 pagesEngineering Services Related To Process Study: SRU RevampSiddiqui Muhammad AshfaqueNo ratings yet

- Annexure 2 - Requisition For Pipe 4inch & AboveDocument11 pagesAnnexure 2 - Requisition For Pipe 4inch & Abovefrankz89No ratings yet

- Simulation of Crude Distillation Unit of Eastern Refinery Limited (ERL) Using Aspen PlusDocument6 pagesSimulation of Crude Distillation Unit of Eastern Refinery Limited (ERL) Using Aspen PlusAndre BasantesNo ratings yet

- Bacnet® Fixed Function Thermostat: For Fan Coil/Heat Pump/Conventional SystemsDocument8 pagesBacnet® Fixed Function Thermostat: For Fan Coil/Heat Pump/Conventional Systemsamjadjaved033148100% (1)

- Harvia Sauna: Glass, light and beautiful contrast – read more about the new Harvia Claro sauna on page 11Document36 pagesHarvia Sauna: Glass, light and beautiful contrast – read more about the new Harvia Claro sauna on page 11Kadiri Olanrewaju100% (1)

- Anatomy of The PeriodontiumDocument46 pagesAnatomy of The PeriodontiumYunita Nitnot50% (2)

- Dodsal Engineering P&ID TransmittalDocument2 pagesDodsal Engineering P&ID TransmittalPriyam KmNo ratings yet

- PT Synergy Engineering Proposal for Detailed Engineering Support of Kerendan Field DevelopmentDocument7 pagesPT Synergy Engineering Proposal for Detailed Engineering Support of Kerendan Field DevelopmentmatsuruNo ratings yet

- 00 PR PH 00002 - 2 Service Definition PhilosophyDocument8 pages00 PR PH 00002 - 2 Service Definition PhilosophyStevanNikolicNo ratings yet

- 1961spm OILandGAS PDFDocument110 pages1961spm OILandGAS PDFvesgacarlosNo ratings yet

- Working at Height PolicyDocument7 pagesWorking at Height PolicyAniekan AkpaidiokNo ratings yet

- Skikda Training CDU (Basis - Process.EQ Modi. Interlock)Document48 pagesSkikda Training CDU (Basis - Process.EQ Modi. Interlock)Mohamed OuichaouiNo ratings yet

- Service Manual For High Efficiency High Ambient Amazon 20180726Document400 pagesService Manual For High Efficiency High Ambient Amazon 20180726Syedimam100% (1)

- Om Prakash Mohanty: Epc Project Management ProfessionalDocument5 pagesOm Prakash Mohanty: Epc Project Management Professionalsoumya19800000000No ratings yet

- IOCL Barauni Refinery BS-IV Project Pre-Feasibility ReportDocument35 pagesIOCL Barauni Refinery BS-IV Project Pre-Feasibility ReportSwastika DasNo ratings yet

- Unit 040 NHDS PresentationDocument35 pagesUnit 040 NHDS PresentationNguyễn Ngọc Tưởng100% (1)

- Engineering Design Documents for DHDS ProcessDocument37 pagesEngineering Design Documents for DHDS ProcessTaofiqNo ratings yet

- Anti FoamDocument7 pagesAnti FoamMohammad MohseniNo ratings yet

- 599ba9f5685ec58cc43993da9760b722Document65 pages599ba9f5685ec58cc43993da9760b722Cm SinghNo ratings yet

- (BMPS) : Bapco Modernization Program SpecificationsDocument35 pages(BMPS) : Bapco Modernization Program SpecificationschaitanyaNo ratings yet

- Cdu-Vdu Feed PropertiesDocument36 pagesCdu-Vdu Feed PropertiesYADAV ANIL KUMARNo ratings yet

- JERP Brief ProcessDocument14 pagesJERP Brief Processbikas_sahaNo ratings yet

- Process Flow DiagramDocument11 pagesProcess Flow DiagramNikhil UdainiyaNo ratings yet

- HYSYS-Report Ammonia PlantDocument21 pagesHYSYS-Report Ammonia PlantDouglas Ross HannyNo ratings yet

- Volume IIA Technical SpecificationDocument83 pagesVolume IIA Technical SpecificationSanjeev Kumar DasNo ratings yet

- Frequent Sulfuric Acid LeakagesDocument7 pagesFrequent Sulfuric Acid LeakagesMuhammad BilalNo ratings yet

- H2so4 SpillDocument4 pagesH2so4 SpilludayNo ratings yet

- Sulphuric AcidDocument1 pageSulphuric AcidMuhammad FarhanNo ratings yet

- Tank Lining Chart 1-26-10Document2 pagesTank Lining Chart 1-26-10Guatemalan1979No ratings yet

- 2018 UOP Course ScheduleDocument2 pages2018 UOP Course SchedulePRATEEK KUMAR DASNo ratings yet

- استاندارد ساپورتDocument323 pagesاستاندارد ساپورتoctobr.86No ratings yet

- Ethanol Plant Commissioning Startup and ShutdownDocument5 pagesEthanol Plant Commissioning Startup and Shutdowntsrinivasan5083No ratings yet

- Instrument Process Datasheet Control Valves Section 100: Technologies TechnologiesDocument13 pagesInstrument Process Datasheet Control Valves Section 100: Technologies TechnologiesMohamedNo ratings yet

- Boq of Ball Float ValveDocument1 pageBoq of Ball Float Valvem 418No ratings yet

- Syaukani Muhammad AliDocument6 pagesSyaukani Muhammad AlidotcomNo ratings yet

- Ligalub 50 PE - Peter Greven PDFDocument2 pagesLigalub 50 PE - Peter Greven PDFk2 polyNo ratings yet

- Final Report 2 PsDocument27 pagesFinal Report 2 PsNishant AsharNo ratings yet

- Eaton Pipeline Strainer Pressure Drop CalculationsDocument1 pageEaton Pipeline Strainer Pressure Drop Calculationsreborn_willyNo ratings yet

- Refinery Construcion Project KARBALA IRAQ 1609420219Document16 pagesRefinery Construcion Project KARBALA IRAQ 1609420219Clever RoseNo ratings yet

- 3PS Gaw 002Document6 pages3PS Gaw 002ravi00098No ratings yet

- Condenser and Cooler Inspection ReportsDocument6 pagesCondenser and Cooler Inspection ReportsSampatNo ratings yet

- Process Description of Superphosphate PlantDocument10 pagesProcess Description of Superphosphate PlantChirag JaniNo ratings yet

- HEI-IMS-CHEM-SOP10 Sodium Hypochlorite Plant OperationDocument8 pagesHEI-IMS-CHEM-SOP10 Sodium Hypochlorite Plant Operationrizwan chNo ratings yet

- Ione VP 14 P 102ab 001 - 1Document8 pagesIone VP 14 P 102ab 001 - 1ضياء محمدNo ratings yet

- Compressors How To Achieve High Reliability & Availability (Electronics)Document55 pagesCompressors How To Achieve High Reliability & Availability (Electronics)Anonymous IGtWHoi0No ratings yet

- PIPE CLASS SPECIFICATIONDocument138 pagesPIPE CLASS SPECIFICATIONbadelitamariusNo ratings yet

- Desalter DrumDocument4 pagesDesalter DrumHsein WangNo ratings yet

- PR Project UpdateDocument68 pagesPR Project UpdateAbdulaheemNo ratings yet

- Ammonia Plant Changeover StudyDocument14 pagesAmmonia Plant Changeover StudyJatinder Saini100% (1)

- PDE-EQS-3120-EC-00005 - 00 Technical Specification of Ammonia Flash VesselDocument9 pagesPDE-EQS-3120-EC-00005 - 00 Technical Specification of Ammonia Flash Vesselhgag selimNo ratings yet

- DcrerweDocument1 pageDcrerwesri9987No ratings yet

- PDE-EQS-3120-EC-00006 - 00 Technical Specification of Ammonia SeparatorDocument8 pagesPDE-EQS-3120-EC-00006 - 00 Technical Specification of Ammonia Separatorhgag selimNo ratings yet

- Nit 1005 Mab Amd 1Document95 pagesNit 1005 Mab Amd 1Pradeep KumarNo ratings yet

- AspenTech Course Catalog FY23 PDFDocument24 pagesAspenTech Course Catalog FY23 PDFvlananloNo ratings yet

- SPSP Certification Request Form - 20221003Document1 pageSPSP Certification Request Form - 20221003ali othmanNo ratings yet

- WPRK Pack Preparation PDFDocument42 pagesWPRK Pack Preparation PDFYusufNo ratings yet

- Khadimally RT011215Document33 pagesKhadimally RT011215jkj_13874No ratings yet

- YANBU REFINERY PROJECTDocument8 pagesYANBU REFINERY PROJECTJanakiraman MalligaNo ratings yet

- Solvent Deasphalting of Saudi Residue To Produce Hard AsphaltDocument7 pagesSolvent Deasphalting of Saudi Residue To Produce Hard AsphaltBahar MeschiNo ratings yet

- Clean Fuels: QuestionsDocument6 pagesClean Fuels: QuestionsErika de la RosaNo ratings yet

- FlowmeterDocument22 pagesFlowmeterAnandNo ratings yet

- Pump Data Sheet For Circulating Water PumpDocument2 pagesPump Data Sheet For Circulating Water PumpSherwin SabandoNo ratings yet

- Metric: 1 - Enter The Internal Pipe Diameter 2 - Enter The Flow Rate 3 - Review The ResultDocument2 pagesMetric: 1 - Enter The Internal Pipe Diameter 2 - Enter The Flow Rate 3 - Review The ResultSelim SelimNo ratings yet

- 05020-250-090-CFD-001 Rev.2 DCU Feed Tank (090-TK-001) Foundation Plan, Sections and DetailsDocument1 page05020-250-090-CFD-001 Rev.2 DCU Feed Tank (090-TK-001) Foundation Plan, Sections and DetailsSelim SelimNo ratings yet

- Dialogstart: Norsok M-506 Corrosion Rate Model, Rev. 2, June 2005Document40 pagesDialogstart: Norsok M-506 Corrosion Rate Model, Rev. 2, June 2005Selim SelimNo ratings yet

- MP Avt 303 15Document8 pagesMP Avt 303 15Selim SelimNo ratings yet

- Periodontal DiseaseDocument4 pagesPeriodontal Diseasemojako_badboysNo ratings yet

- Marketing Environment Analysis and Trends Impacting CompaniesDocument27 pagesMarketing Environment Analysis and Trends Impacting CompaniesSamoyed KalraNo ratings yet

- EVBAT00100 Batterij ModuleDocument1 pageEVBAT00100 Batterij ModuleSaptCahbaguzNo ratings yet

- ResiboDocument1 pageResiboAlex RespicioNo ratings yet

- Health Facilities and Services Regulatory Bureau: Republic of The Philippines Department of HealthDocument3 pagesHealth Facilities and Services Regulatory Bureau: Republic of The Philippines Department of Healthal gulNo ratings yet

- Welfare Schemes in TelanganaDocument46 pagesWelfare Schemes in TelanganaNare ChallagondlaNo ratings yet

- Admin, 085 - 799 - Ivan Master Worung - GalleyDocument5 pagesAdmin, 085 - 799 - Ivan Master Worung - GalleyM Ali AdrianNo ratings yet

- Research 1Document7 pagesResearch 1Rhea Mae ObligarNo ratings yet

- Veena Singh-176-189 - Findings, Implications and ConclusionsDocument14 pagesVeena Singh-176-189 - Findings, Implications and ConclusionsValerine SNo ratings yet

- Premium detergent market insights and Nirma case studyDocument32 pagesPremium detergent market insights and Nirma case studyBhavya ShahNo ratings yet

- Screenshot 2021-06-06 at 11.13.56Document1 pageScreenshot 2021-06-06 at 11.13.56Momina Ibrahim AhmedNo ratings yet

- Nurs478 Healthcaredelivery Audrey GohDocument12 pagesNurs478 Healthcaredelivery Audrey Gohapi-316372858No ratings yet

- Why encouraging entrepreneurship to boost economies is flawedDocument9 pagesWhy encouraging entrepreneurship to boost economies is flawedLaureanoNo ratings yet

- Glycerol PDFDocument3 pagesGlycerol PDFTushar GaikarNo ratings yet

- Optimized Die Steel Reference GuideDocument16 pagesOptimized Die Steel Reference GuideKeattikhun ChaichanaNo ratings yet

- Ergo in Workplace PDFDocument7 pagesErgo in Workplace PDFsightbdNo ratings yet

- Personal Development Course for Senior High StudentsDocument7 pagesPersonal Development Course for Senior High StudentsLucelle PalarisNo ratings yet

- AA3 My Favorite City - Comparing Places Ejercicio FinalDocument6 pagesAA3 My Favorite City - Comparing Places Ejercicio FinalCesar Augusto Triana AyalaNo ratings yet

- X80 Io PDFDocument446 pagesX80 Io PDFHATEM68No ratings yet

- Fault Tracing: FMI 3: Checking The Sensor CircuitDocument1 pageFault Tracing: FMI 3: Checking The Sensor Circuituser1No ratings yet

- FT-IR Analysis of Hock ProcessDocument4 pagesFT-IR Analysis of Hock ProcessmohsengolestanzadehNo ratings yet

- Action On Agricultural. Calculating Agricultural EmissionsDocument27 pagesAction On Agricultural. Calculating Agricultural EmissionsXoel UrriagaNo ratings yet

- Thermo Fluids LabDocument23 pagesThermo Fluids LabMuket AgmasNo ratings yet

- Mandaya: Presented By: Cutad, Ray Dag-Uman, Ely Mae Cortes, MaikoDocument24 pagesMandaya: Presented By: Cutad, Ray Dag-Uman, Ely Mae Cortes, MaikoAPPLE MAE AGOSTONo ratings yet