Professional Documents

Culture Documents

Fazal Ur - Rehman

Uploaded by

F r0 ratings0% found this document useful (0 votes)

38 views3 pagesOriginal Title

Fazal Ur_Rehman

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

38 views3 pagesFazal Ur - Rehman

Uploaded by

F rCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

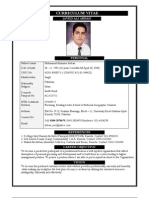

Fazal Ur Rehman

+971544424648

fazal648@yahoo.com

Al Ain, United Arab Emirates 15571

SKILLS 13rd JAN 1991

Time Management Skills Pakistan

Excels in team leadership

Team training and Married

development

Operation and maintenance

technical skills PROFESSIONAL SUMMARY

Team collaboration and

leadership Motivated Maintenance Team Leader & Planner with more than 12

Flexibility and versatility years of experience in FMCG recognized for assessing operational

Stress Management needs and developing solutions to save costs, improve revenues, and

Database maintenance and drive customer satisfaction. Resourceful and well-organized with

tracking excellent leadership and team-building record & collaborative,

High-value project cross-functional teamwork in different Middle East FMCG companies

management & Saving cost within high-pressure environments. Adept at project planning and

managing multiple accounts at once. Dedicated to improving

company sales goals and meeting business objectives.

EDUCATION WORK HISTORY

04/2013 11/2019 - Current

Preston University | Al Ain Dairy & Livestock Farm United Arab Emirates | Alain,

Faisalabad, Pakistan United Arab Emirates

Bachelor's: Mechanical Maintenance Team Leader and Planner

Production Leads line leaders in a production/packaging and Maintenance

department with a major impact on the success of the site’s

05/2010

Government Technical service levels, product quality, operation efficiency, and

College of Technology, financial performance.

Descon Engineering Systematically monitor and control production performance by

Diploma of Associate analyzing the SSQCDM indicators (safety, sustainability, quality,

Engineer: Mechanical cost, distribution, and moral), proposing the necessary action

plans to ensure compliance with the established goals and

objectives.

07/2010

Descon Engineering | Lahore, End to End Leadership – As a part of a management team

Pakistan member, participate with other managers in planning, sourcing,

Pipe Fabrication: Mechanical delivery, engineering, and strategic business roles in the

development and implementation of continuous improvement

strategies that will drive the overall supply pipeline.

Challenges status quo to improve overall performance via

continuous improvement tools.

Lead, coach, and develop team and organization based on Our

Leadership, Our Character, and Our responsibility according to

annual people processes.

Organizes resources and activities to ensure agreed deliverables

by the means of an optimal organization and production process.

EXPERTISE IN FMCG Leads the direction for the department and connects the Overall

EQUIPMENTS Alain farms group’s/site’s vision, mission, strategy, and values

Robot Palletization to local plans for the production/packaging department.

Tetra Pak TAD & UHT Executes business plans for own area of responsibility.

processing and Packaging Ensures that the department complies with Alain farms’

system standards, policies as well as applicable law and Health & Safety

SPX Processing Equipment’s procedures and mindset.

Lubrication, Hydraulic system Takes leadership in developing, anchoring, and role modeling a

Hydrogen Peroxide system lean culture.

Pure-Pack (ESL Combi filler) Cooperates with and ensures the required assistance from

Evergreen Filler (ECO-Pack) support functions, i.e., Maintenance, QEHS, Planning, PTD, and

Elopak Filling Equipment’s & Finance.

Feed roll. Stakeholder management: Site Director, Site leadership team,

Design control system Supply chain center of Excellence.

Filling control system

Sterile system and its

Saudia Dairy & Foodstuff Company SADAFCO | Dammam, Saudi

components

Arabia

Servo & Kinetic Drive systems

Maintenance Supervisor

PLC systems (GE-Fanuc,

Rockwell & TPMC) Worked with SISS (SADAFCO Integrated Service Solution) to

Tetra Pak induction heating improve machines mechanical efficiencies and reduce the losses

system Responsible for major installation or maintenance projects,

Frequency converters leading the team of Technicians assigned to the task

Temperature Controllers Provide a mechanical engineering advisory service to other

TMCC Cards (Tetra Pak multi sections

compact card) HACCP proficiency is required; this manager owns ongoing

DMC Cards (Digital module training and championing of quality goals and improvements at

card) the area level.

Technical Knowledge and Goal Setting and Measurement - Utilizing Operations teams,

Hands On experience establishing area performance standards and goals based on site

Programmable Logic goals and strategies; measure, control, take corrective action

Controllers and report results as appropriate in all areas of responsibility.

Allen Bradley - MicroLogix Annually assist in the development of area budgets and KPI

1000, GE - Fanuc - 90 -30 targets.

Allen Bradley - IN Touch & Financial understanding and work within the framework set by

Siemens S7 corporate finance.

Industrial Networks & Works with data-driven decision making and understands the

Communications analysis of data using SPC, OEE, or basis statistics.

Ethernet TCP/IP, Control Net, Leading role across the site in employee relations and union

Device Net, Profibus, ASIBUS, collaboration.

MODBUS, RS232, RS 485 Manage and control the entire production process with Peer

Proxxon Lathe machine for Production Manager.

tooling & modification Own maintenance production section budget: Approve and

ensure proper execution.

05/2013 - 10/2014

Awal Food Dairy Company | Manama, Bahrain

Maintenance Shift Technician

ACCOMPLISHMENTS

Develop a work environment that encourages compliance with

ISO 9001:2008/ ISO company, state and safety and employment guidelines

22000:2005/ ISO Discover training needs and provide coaching

14001:2004 Listen to team members' feedback and resolve any issues or

SAP-ERP implementation conflicts

Robot Palletization Project Recognize high performance and reward accomplishments

in Alain Farms(on-going) Encourage creativity and risk-taking

SPX-Flex UHT Long-life Assist in troubleshot Mechanical, electrical instruments,

Mixer (9000 L/H) in Alain conducted preventive and corrective maintenance aimed at

Dairy & Farms & Cost maintaining seamless operations

Saving. TPMS & Mechanical maintenance of Tetra Pak Filling, Packaging

Milk UHT by GEA 30000 & DE Equipment's

Liters/Hr. in Shakarganj Responsible for smooth run-on thick products like Tomato paste

FOODS, Pakistan Worked on different types of FMCG machinery including -

Tomato Paste Pasteurizer TETRA PAK (Milk Pasteurizer, Cream Pasteurizer, UHT & CIP

by GEA in SADAFCO, Saudi systems)

Arabia, 5 Ton boiler Sleeve applicator and Shrink Wrapper)

commissioning. GEA (FETA Cheese processing & CIP systems)

Water line project with RO Optimized team training and staff development.

plant. Maximized customer engagement and satisfaction by delivering

Tetra Pak A1 Fino excellent customer service.

Commissioning and Start-up Developed excellent working knowledge of industry trends and

Tetra Pak Cap30 Flex improvements in processes.

Commissioning and Tetra Prepared accurate budgets, receivables reports and profit and

Pak A3 Filling Machine loss reports.

Improved team efficiency by training and mentoring individuals

and setting achievable performance goals.

06/2010 - 05/2013

Shakarganj Food dairy Jaranwala | Faisalabad, Pakistan, Pakistan

Maintenance & Production Trainee

Accountable for troubleshooting Mechanically, electrical

instruments

Developed maintenance plans for production and electrical

equipment

Conducted preventive and corrective maintenance for ensuring

seamless operations

Performed the TPMS of the machines with Tetra Pak Engineer's

Performed the commissioning of the machines with Tetra Pak

Engineer's

By doing CBM (Condition Base Maintenance) saving maintenance

cost by increasing life cycles of the Equipment's

Reviews planning and scheduling documentation and identifies

ambiguities, risks, and key issues to be considered by the

project team.

You might also like

- Fazal Ur - Rehman CVDocument3 pagesFazal Ur - Rehman CVF rNo ratings yet

- Naukri RAJESHMAKWANA (12y 0m)Document4 pagesNaukri RAJESHMAKWANA (12y 0m)Piyush SinghalNo ratings yet

- Samir S. Al Yasen - CVDocument3 pagesSamir S. Al Yasen - CVMoh MohNo ratings yet

- Ahmad Junaid Anwar Samdani: Key Skills Brief IntroDocument2 pagesAhmad Junaid Anwar Samdani: Key Skills Brief IntroNoman JavaidNo ratings yet

- Taha Saleem MughalDocument4 pagesTaha Saleem MughaltahaNo ratings yet

- Manufacturing Leader with 12+ years of experience seeks new opportunitiesDocument3 pagesManufacturing Leader with 12+ years of experience seeks new opportunitiesFinQuest Consulting ServicesNo ratings yet

- BTech Electronics Manager 7 Years Logistics OperationsDocument3 pagesBTech Electronics Manager 7 Years Logistics OperationsBhuvanesh M.PNo ratings yet

- Asad AliDocument5 pagesAsad AliMisbhasaeedaNo ratings yet

- CMRP Mumbai May 2022Document9 pagesCMRP Mumbai May 2022shan5144342No ratings yet

- Pankaj NaikDocument4 pagesPankaj NaikPankaj.S.NaikNo ratings yet

- Murugesan-Operations ManagerDocument4 pagesMurugesan-Operations ManagerSoundhara Pandian SamuvelNo ratings yet

- Gaurav Pathak CV Opex 20.11.2022Document2 pagesGaurav Pathak CV Opex 20.11.2022Abhishek KumarNo ratings yet

- Mark Knofler: Career OverviewDocument2 pagesMark Knofler: Career OverviewknoflerNo ratings yet

- Bilal Hameed-Manager ProductionDocument2 pagesBilal Hameed-Manager ProductionSehba NaseemNo ratings yet

- Resume: Saad Iqbal / Business Development & OperationsDocument5 pagesResume: Saad Iqbal / Business Development & OperationsSaad IqbalNo ratings yet

- Rateek Awhney E Q: EY KillsDocument2 pagesRateek Awhney E Q: EY KillsMeer Hassan FarhadNo ratings yet

- CV of Ernesto F. Manuel JRDocument3 pagesCV of Ernesto F. Manuel JRIron Man-tcpNo ratings yet

- Ronan C. Verdejo, PMP: CertificationsDocument4 pagesRonan C. Verdejo, PMP: CertificationsRonan VerdejoNo ratings yet

- Drilling Operations Manager ProfileDocument6 pagesDrilling Operations Manager ProfilekanNo ratings yet

- Latest Resume Yogesh CharatkarDocument4 pagesLatest Resume Yogesh CharatkarYogesh CharatkarNo ratings yet

- Adarsh Kumar-Resume2021Document3 pagesAdarsh Kumar-Resume2021Divyank AryaNo ratings yet

- Ahmed Hassan - : Chemical Engineer (PEC Registered)Document3 pagesAhmed Hassan - : Chemical Engineer (PEC Registered)Engr AhmedNo ratings yet

- Shoaib Ismail CVDocument5 pagesShoaib Ismail CVMisbhasaeedaNo ratings yet

- Engr - Mohsin October 2021Document4 pagesEngr - Mohsin October 2021AliNo ratings yet

- Data Overview - IT BUSINESS ANALYST (SAP SUCCESSFACTORS)Document2 pagesData Overview - IT BUSINESS ANALYST (SAP SUCCESSFACTORS)MafijulNo ratings yet

- Service Delivery Professional: Core CompetenciesDocument1 pageService Delivery Professional: Core CompetenciesGuru KguruNo ratings yet

- XLRI CV Manish KumarDocument2 pagesXLRI CV Manish KumarobvertNo ratings yet

- Abhijeet ResumeDocument2 pagesAbhijeet ResumeRaghunathNo ratings yet

- Field Service ManagerDocument6 pagesField Service ManagerkanNo ratings yet

- Ajay Kumar: Experience SummaryDocument4 pagesAjay Kumar: Experience SummarySAMSON GLOBALNo ratings yet

- Career Objective: Anoop Kumar P.M Phone:-9744753806Document7 pagesCareer Objective: Anoop Kumar P.M Phone:-9744753806Anoop KumarNo ratings yet

- Varun-Kumar 1209Document1 pageVarun-Kumar 1209kumaraiesecadityaNo ratings yet

- VK - 15 Years Exp in Process & Production EngineeringDocument1 pageVK - 15 Years Exp in Process & Production Engineeringjprabhu81No ratings yet

- Saswat Kumar Mohapatra: Profile SummaryDocument3 pagesSaswat Kumar Mohapatra: Profile SummarySAMSON GLOBALNo ratings yet

- Profile: Date of Birth: Nationality: Address: Phone Number: Email Address: VisaDocument2 pagesProfile: Date of Birth: Nationality: Address: Phone Number: Email Address: VisaMohammad MajidNo ratings yet

- Curriculum Vitae: Javed Ali AbbasiDocument4 pagesCurriculum Vitae: Javed Ali AbbasiirfankatparNo ratings yet

- Experience Summary: Fakhry NakiraDocument3 pagesExperience Summary: Fakhry NakirarecruiterkkNo ratings yet

- Salman Ahmed: Career ObjectiveDocument4 pagesSalman Ahmed: Career ObjectiveAtif Ahmad KhanNo ratings yet

- Sanjeev's ResumeDocument2 pagesSanjeev's ResumeSai GaneshNo ratings yet

- Ashfaq Ahmed Butt: Working As Maintenance and Automation Supervisor in Milla, AZFP Co, Baku, AzerbaijanDocument5 pagesAshfaq Ahmed Butt: Working As Maintenance and Automation Supervisor in Milla, AZFP Co, Baku, AzerbaijanF rNo ratings yet

- Venkatesan - Mohan - Resume (2) - 1Document3 pagesVenkatesan - Mohan - Resume (2) - 1Angel PriyaNo ratings yet

- Jayes 1Document2 pagesJayes 1NathanNo ratings yet

- Karen - Perez - Cazares - CV Eng 2018Document3 pagesKaren - Perez - Cazares - CV Eng 2018roccomtzsegoviaNo ratings yet

- CV KhirullahDocument6 pagesCV Khirullahkyle1991No ratings yet

- Naukri VishalVerma (17y 0m)Document3 pagesNaukri VishalVerma (17y 0m)Amit SinhaNo ratings yet

- Instrument Engineer FOR CAREER PORTALDocument2 pagesInstrument Engineer FOR CAREER PORTALNavin KumarNo ratings yet

- Process - Mohamed Rashad - CV 2015 - 1) - 1) - 1)Document12 pagesProcess - Mohamed Rashad - CV 2015 - 1) - 1) - 1)Hatem HusseinNo ratings yet

- Dairy Production Manager with 12+ years experience in UAEDocument2 pagesDairy Production Manager with 12+ years experience in UAEVenkata NagiNo ratings yet

- CV IEA - 2024 Rev BDocument3 pagesCV IEA - 2024 Rev BErdiansyah SeputroNo ratings yet

- Quality Assurance VinothDocument3 pagesQuality Assurance VinothThanh TranNo ratings yet

- Unmesh CV PDFDocument5 pagesUnmesh CV PDFUnmesh UnnikrishnanNo ratings yet

- VARUGHESEDocument3 pagesVARUGHESEMohammad MajidNo ratings yet

- SAP FSCM Sample Resume 3Document17 pagesSAP FSCM Sample Resume 3ASHOKA GOWDANo ratings yet

- Operations Manager Medical Device in Minneapolis ST Paul MN Resume Kevin RileyDocument2 pagesOperations Manager Medical Device in Minneapolis ST Paul MN Resume Kevin RileyKevin RileyNo ratings yet

- Ashish Gupta: Fleet Manager/Associate OperationDocument2 pagesAshish Gupta: Fleet Manager/Associate OperationPalikila SrikanthNo ratings yet

- Key Work Skills Work Experience: Sales AdministratorDocument2 pagesKey Work Skills Work Experience: Sales AdministratorMohammad MajidNo ratings yet

- Fishbone MechanicsDocument26 pagesFishbone MechanicsLester KhanNo ratings yet

- J I A J: Ilban Brahim L IlbanDocument3 pagesJ I A J: Ilban Brahim L Ilbanmedhat alnagarNo ratings yet

- Muhammad Asam Zia: ContactDocument4 pagesMuhammad Asam Zia: ContactSaad MasoodNo ratings yet

- Y825 Valve replacement kit detailDocument1 pageY825 Valve replacement kit detailF rNo ratings yet

- 8 Skills of SuccessfulDocument13 pages8 Skills of SuccessfulDaniel Valderrama GregorioNo ratings yet

- 11022eDocument4 pages11022eF rNo ratings yet

- To Whom It May Concern: Mr. Irfan KhanDocument1 pageTo Whom It May Concern: Mr. Irfan KhanF rNo ratings yet

- SafiDocument2 pagesSafiF rNo ratings yet

- Ashfaq Ahmed Butt: Working As Maintenance and Automation Supervisor in Milla, AZFP Co, Baku, AzerbaijanDocument5 pagesAshfaq Ahmed Butt: Working As Maintenance and Automation Supervisor in Milla, AZFP Co, Baku, AzerbaijanF rNo ratings yet

- Skills Professional Summary:, H UAEDocument2 pagesSkills Professional Summary:, H UAEF rNo ratings yet

- 6 Plus Price in Pakistan - Google SearchDocument1 page6 Plus Price in Pakistan - Google SearchZeeshan UmraniNo ratings yet

- MIS EndTerm MBA07032 DakshMalhotraDocument6 pagesMIS EndTerm MBA07032 DakshMalhotraDakshNo ratings yet

- Muhammad Umair Ismail Mechanical Engineer: Cell Phone: EmailDocument2 pagesMuhammad Umair Ismail Mechanical Engineer: Cell Phone: EmailUmairIsmailNo ratings yet

- Mumbai Development Plan 2034 SummaryDocument35 pagesMumbai Development Plan 2034 SummaryAnonymous Dsr8pmbNo ratings yet

- Popular Electronics 1963-10Document120 pagesPopular Electronics 1963-10Lemmy KilmisterNo ratings yet

- PTS 2000Document76 pagesPTS 2000John Jairo CárdenasNo ratings yet

- KTB-BD-003-F01 Customer Complaint Register 2013Document15 pagesKTB-BD-003-F01 Customer Complaint Register 2013info.glconsultinqNo ratings yet

- Ovation To Abb SystemDocument2 pagesOvation To Abb SystemAnderson Pisconte SoteloNo ratings yet

- Introduction To Microprocessors and ComputersDocument24 pagesIntroduction To Microprocessors and ComputershrrameshhrNo ratings yet

- AA 3201 Study Notes 3 - BALAGTAS FYDocument12 pagesAA 3201 Study Notes 3 - BALAGTAS FYFrancis Ysabella BalagtasNo ratings yet

- Avetmiss Student Management Software PDFDocument71 pagesAvetmiss Student Management Software PDFfastchennaiNo ratings yet

- Fundamentals of Information Systems-PPT-Chapter1Document77 pagesFundamentals of Information Systems-PPT-Chapter1jhawk75767% (3)

- CITIES 2015 - YoanitaDocument15 pagesCITIES 2015 - Yoanitayoanita eka rahayuNo ratings yet

- Linux Integration Services v4-2-7Document17 pagesLinux Integration Services v4-2-7Harish NNo ratings yet

- Edurific Curriculum BrochureDocument20 pagesEdurific Curriculum BrochurerupeshNo ratings yet

- ABB Spec MCB SH200Document2 pagesABB Spec MCB SH200Jirayu KhumwanichNo ratings yet

- Problem 5.4 The Product Gas From A LLLLLLCoal Gasificati...Document4 pagesProblem 5.4 The Product Gas From A LLLLLLCoal Gasificati...Victor Hugo Sanchez RosasNo ratings yet

- Activity Tracker User Guide 1.2Document19 pagesActivity Tracker User Guide 1.2ENo ratings yet

- Case Study 1Document3 pagesCase Study 1ramtwinsmeNo ratings yet

- Unit - IiiDocument41 pagesUnit - IiiJit Agg0% (1)

- Shakil e Zoitl - 2020 - Towards A Modular Architecture For Industrial HMIsDocument5 pagesShakil e Zoitl - 2020 - Towards A Modular Architecture For Industrial HMIsRodrigo Sanches MianiNo ratings yet

- Mathematical Performance Analysis (2021) : June 2021Document11 pagesMathematical Performance Analysis (2021) : June 2021Nandam VamsiNo ratings yet

- Servicemanual Fluorostar 2nd EDDocument386 pagesServicemanual Fluorostar 2nd EDalex lzgNo ratings yet

- NSN For XafpDocument25 pagesNSN For XafpTeget1975No ratings yet

- Empowerment Technology Quarter 1 Week 2Document12 pagesEmpowerment Technology Quarter 1 Week 2BananaNo ratings yet

- 2011 ScreamineagleDocument46 pages2011 Screamineaglesukarja hermanNo ratings yet

- LEACH HDocument13 pagesLEACH HAman VermaNo ratings yet

- Grabner MINIFLASH TOUCH Flash Point TesterDocument2 pagesGrabner MINIFLASH TOUCH Flash Point Testerbu7amudNo ratings yet

- Kiapregiorepairmanual 1 PDF FreeDocument2 pagesKiapregiorepairmanual 1 PDF FreeIlhamNo ratings yet

- Case Study 6 - INTELDocument8 pagesCase Study 6 - INTELNguyễn Thị Phong NhãNo ratings yet