Professional Documents

Culture Documents

Wire Mesh Rock Wool Blanket Hlywmbl

Uploaded by

ENG ALAmireyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wire Mesh Rock Wool Blanket Hlywmbl

Uploaded by

ENG ALAmireyCopyright:

Available Formats

WIRE MESH ROCK WOOL

BLANKE HLY WMBL

Product introduction

Huali rock wool is made from natural stone , melting at 1450 ℃ , centrifugal injection to

kind of mineral fiber, add some thermosetting adhesives and additives etc, with the

performance of non-combustible, non-toxic, low thermal conductivity, hydrophobic, sound

absorption, etc. Wire mesh rock wool blanket is suitable for heat insulation, fire prevention

and sound absorption and noise reduction of large pipe network, large storage tanks,

containers, furnaces and air pipes, especially used for high temperature and vibration

places or places with high requirements on fire prevention.

Packing & installation

Wire mesh rock wool blanket is packed in heat shrinkage PE film or woven bags. It can be

cut into any length and tightly wrapped on the insulation equipment. The edges need to be

joined together, leaving no gaps, and held together with steel wire. HLY WMBL can be

fixed on the equipment with metal band/clip or wire.

Product specification

Thickness HLY WMBL60 HLY WMBL80 HLY WMBL100 HLY WMBL128

30-50mm 5mx600mm 5mx600mm 5mx600mm 5mx600mm

50-100mm 3mx600mm 3mx600mm 3mx600mm 3mx600mm

Wire mesh Galvanized or stainless steel 304/316 (1”x24# or 1”x22#)

Technical Data

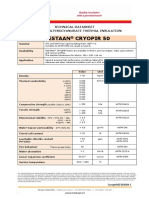

Item name Test Method Standard Value Test Value

Thermal 24℃ ASTMC592-16 ≤0.036 0.034

conductivity 93℃ ASTM C177-19 ≤0.049 0.042

W/(m·k) 204℃ ≤0.076 0.058

260℃ ≤0.092 0.070

371℃ ≤0.124 0.102

PH ASTM C795-08 <12.5 8.4

Non-Fibrous (Shot) content ASTMC592-16 ≤25% 14%

ω(CI-)% When ω(SiO32-)+ 0.0004

ω(F-)% ASTMC795-08 ω(Na+)=0.15%, 0.0045

ω(SiO32-)% ASTMC871-11 ω(CI-)+ω(F-)<0.019% 0.14

ω(Na+)% 0.0071

Maximum Flame Spread Index ASTM E84-18 ≤ 25 0

Maximum Smoke-developed Index ASTM E84-18 ≤ 50 0

Water Vapor Sorption by Weight ASTMC592-16 ≤5.0% 1.4%

Linear Shrinkage ASTMC592-16 ≤4.0% 2.28%

Resistance to Fungi ASTM C592-16 Growth no greater than No growth

ASTMC1338 that a comparative item apparent under

40 Times

magnification

Service Termperature ASTMC592-16 No warping, flaming, 650℃

glowing,Smoldering and

smoking

Corrosiveness to Steel ASTM C592-16 35

Corrosiveness to Aluminum ASTM C665-17 >21 27.5

Corrosiveness to Copper 24.5

Non-combustibility ASTM E136-16a The recorded non-combustibility

temperature rise shall

not exceed more than

30℃ with no flaming

and weight loss

exceeding 5%

Odor Emission ASTMC592-16 A detectable odor of None of 5

objectionable nature members

recorded by more than considered the

two of the five panel odor

members shall was objectionable

constitute rejection of and strong.

the material.

Company: Tianjin Huali Thermal Insulation Building Material Co., Ltd 300451

Tel: 86 22 25212423 Fax: 86 22 25211666 Email: info@hualibw.com

You might also like

- Fire Resistance UL 1709Document2 pagesFire Resistance UL 1709ednavilod100% (3)

- Industrial Insulation Rock Wool Board Hly SliDocument2 pagesIndustrial Insulation Rock Wool Board Hly SliTranLeTrungNo ratings yet

- Industrial Rock Wool Pipe Hlypi: Product IntroductionDocument2 pagesIndustrial Rock Wool Pipe Hlypi: Product IntroductionTranLeTrungNo ratings yet

- MTC Rockwool Board 80KDocument1 pageMTC Rockwool Board 80KAdrianNodaloNo ratings yet

- Technical Data Sheet: Stainless Steel: SuperausteniticDocument5 pagesTechnical Data Sheet: Stainless Steel: SuperausteniticSue EpicNo ratings yet

- Technical Datasheet Natura (3Mm) : Characteris C Standard Unit Requirement Values From Manufacturing ControlsDocument1 pageTechnical Datasheet Natura (3Mm) : Characteris C Standard Unit Requirement Values From Manufacturing Controlseromax1No ratings yet

- (UNS N08904) : NAS High Corrosion Resistant Stainless SteelDocument4 pages(UNS N08904) : NAS High Corrosion Resistant Stainless SteelMiguel Martinez GuerreroNo ratings yet

- SMS001R0Document1 pageSMS001R0PRASANTH PRASANTHNo ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- 70 - 80mm Mineral WoolDocument1 page70 - 80mm Mineral WoolniyasNo ratings yet

- Pamphlet (DW 2594)Document1 pagePamphlet (DW 2594)Irvansyah RazadinNo ratings yet

- ArmaGelDT - TDS - EN-Dual TempDocument4 pagesArmaGelDT - TDS - EN-Dual TempLee Kok RoyNo ratings yet

- Tds - Rockal Rockwool Boards - Kraft FacingDocument4 pagesTds - Rockal Rockwool Boards - Kraft FacingelkatebskeNo ratings yet

- Commercial Purity Aluminium1050Document1 pageCommercial Purity Aluminium1050HermanNo ratings yet

- Non Heat Treatable Commercial-Purity Aluminium 1050 A: Chemical Composition Limits (In %) Aluminium 99,5% MinimumDocument1 pageNon Heat Treatable Commercial-Purity Aluminium 1050 A: Chemical Composition Limits (In %) Aluminium 99,5% Minimumprivate 2No ratings yet

- Commercial-Purity Aluminium1050Document1 pageCommercial-Purity Aluminium1050SiyabulelaNo ratings yet

- 18nicrmo14-6: Steel GradeDocument4 pages18nicrmo14-6: Steel Gradesmith willNo ratings yet

- Al 99.5 AW 10-50 Aluminium A 1050 Technical Data Sheet RLSADocument2 pagesAl 99.5 AW 10-50 Aluminium A 1050 Technical Data Sheet RLSAAlex GăuruşNo ratings yet

- Technical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelDocument2 pagesTechnical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelManjunath UNo ratings yet

- TDS Nycogrease GN3058 1E10Document1 pageTDS Nycogrease GN3058 1E10Sameen Khan100% (1)

- Astm A516Document11 pagesAstm A516Kokoh Aji LesmanaNo ratings yet

- Specs of PU FoamDocument3 pagesSpecs of PU FoamJuan ValdiviesoNo ratings yet

- Christo Lube MCG 134 Tech DataDocument1 pageChristo Lube MCG 134 Tech Datarobertoalfaro492023No ratings yet

- Winpower International Limited: ApplicationDocument2 pagesWinpower International Limited: ApplicationAHMED YOUSEFNo ratings yet

- Acetone SHELL SPEC 2010 PDFDocument3 pagesAcetone SHELL SPEC 2010 PDFLuka BraciNo ratings yet

- TDS ATLANTIC CHT81Ni1Document1 pageTDS ATLANTIC CHT81Ni1Andi Baso Temalala STNo ratings yet

- ArmaGel - HT - TDS - English - HotDocument4 pagesArmaGel - HT - TDS - English - HotLee Kok RoyNo ratings yet

- Alloy 276 Spec SheetDocument3 pagesAlloy 276 Spec SheetermusatNo ratings yet

- Sekisui Thermobreak Thermaloc 2017 Brochure - OptDocument4 pagesSekisui Thermobreak Thermaloc 2017 Brochure - OptengineerhamzehNo ratings yet

- Shellsol A150 q7493 Eu 18042016Document3 pagesShellsol A150 q7493 Eu 18042016Henry FloresNo ratings yet

- BP Energrease LSDocument2 pagesBP Energrease LSsaddamNo ratings yet

- Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearDocument3 pagesMatmatch Is Trusted by 2 Million+ Engineers and Product Developers Each Yearhardeep SinghNo ratings yet

- API Test Data For Distribution 1 1Document6 pagesAPI Test Data For Distribution 1 1Avyan KelanNo ratings yet

- How To Get High Quality Boiler TubesDocument7 pagesHow To Get High Quality Boiler TubesYaneYangNo ratings yet

- Metallic Material Specification: Title: 2.25 Cr-1 Mo (ASTM A182, Grade F22 Mod), 85 KSI Min Yield Strength - Unified SpecDocument6 pagesMetallic Material Specification: Title: 2.25 Cr-1 Mo (ASTM A182, Grade F22 Mod), 85 KSI Min Yield Strength - Unified SpecReginaldo SantosNo ratings yet

- 1.8 Thong So Ky Thuat Bao On AeroflexDocument1 page1.8 Thong So Ky Thuat Bao On AeroflexDatNo ratings yet

- THERMOBREAK CLASS 0 Vs PVC Nitrile NBR Foam (2019)Document2 pagesTHERMOBREAK CLASS 0 Vs PVC Nitrile NBR Foam (2019)Hamzeh TarteerNo ratings yet

- CZLLCW511L TN enDocument4 pagesCZLLCW511L TN endrgilleNo ratings yet

- Rockinsul RB Slabs - 48 KG Per m3 75 MM - Technical Data SheetDocument1 pageRockinsul RB Slabs - 48 KG Per m3 75 MM - Technical Data SheetDushyant SharmaNo ratings yet

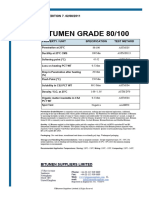

- 2017716154112bitumen 6070Document1 page2017716154112bitumen 6070lab copriNo ratings yet

- Certificate No. 00801-16A PDFDocument1 pageCertificate No. 00801-16A PDFPaulo MoraesNo ratings yet

- Bitumen Phenomenal Hau KauDocument5 pagesBitumen Phenomenal Hau Kautariq wazedNo ratings yet

- Steel Plates For Offshore Structural ApplicationsDocument12 pagesSteel Plates For Offshore Structural ApplicationsbsoyleyenNo ratings yet

- SMS002R0Document1 pageSMS002R0PRASANTH PRASANTHNo ratings yet

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- TDS Turbonycoil TN160 1E9Document2 pagesTDS Turbonycoil TN160 1E9HimalayaNo ratings yet

- Technical Datasheet: Co2 (High Pressure) 2 KG Fire ExtinguisherDocument1 pageTechnical Datasheet: Co2 (High Pressure) 2 KG Fire Extinguishershashi ranjanNo ratings yet

- 203 Super S Inhibited Transformer OilDocument2 pages203 Super S Inhibited Transformer OilHanderson PanjaitanNo ratings yet

- Searox SL 328: Technical InsulationDocument1 pageSearox SL 328: Technical InsulationAnh Le NgocNo ratings yet

- 20201002114953-DIWETEN 355+M 08 2020 E-AktuellDocument6 pages20201002114953-DIWETEN 355+M 08 2020 E-AktuellHAINo ratings yet

- 17 - Dcn8015enDocument4 pages17 - Dcn8015enJustice MachiwanaNo ratings yet

- Type 1 BricksDocument20 pagesType 1 Bricksprachi410No ratings yet

- Bao On AmazonDocument4 pagesBao On AmazonTrần ChâuNo ratings yet

- TDS - CRYOPIR50f - 202004-1Document1 pageTDS - CRYOPIR50f - 202004-1Nguyen Thi Bich ThuyNo ratings yet

- Penetration Bitumen 80 100 SpecificationsDocument1 pagePenetration Bitumen 80 100 Specificationsnnadoziekenneth5No ratings yet

- C 70 SuperthermDocument2 pagesC 70 SuperthermMandeep SinghNo ratings yet

- White Oil T-550 (2016)Document1 pageWhite Oil T-550 (2016)Kurnia KwankNo ratings yet

- Perno A325 HDG 5-8 X 1 1-4 (TKR+D7042279)Document1 pagePerno A325 HDG 5-8 X 1 1-4 (TKR+D7042279)Alexander Ortiz CarrionNo ratings yet

- Oil Analysis Report: PT Petrolab ServicesDocument1 pageOil Analysis Report: PT Petrolab ServicesJon HermanNo ratings yet

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- مذكرة تصميم أنظمة اطفاء الحريقDocument61 pagesمذكرة تصميم أنظمة اطفاء الحريقENG ALAmirey100% (3)

- Man Thickness Meter Pce TG 250 enDocument12 pagesMan Thickness Meter Pce TG 250 enENG ALAmireyNo ratings yet

- Building Insulation Rock Wool BoardDocument14 pagesBuilding Insulation Rock Wool BoardENG ALAmireyNo ratings yet

- JIS G5122 Grade SCH13: Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearDocument3 pagesJIS G5122 Grade SCH13: Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearENG ALAmireyNo ratings yet

- Quantitative: Analytical Chemistry (Qualitative and Chemistry)Document13 pagesQuantitative: Analytical Chemistry (Qualitative and Chemistry)Rizza OlivaNo ratings yet

- Conductor Dead-Ends - Sec14 EnergycatDocument32 pagesConductor Dead-Ends - Sec14 EnergycatCarlos CristoNo ratings yet

- prEN 10264-2 (2017) (E)Document5 pagesprEN 10264-2 (2017) (E)Nix100% (2)

- 11 - AASHTO Material Properties (2015)Document42 pages11 - AASHTO Material Properties (2015)mehdiNo ratings yet

- Revision Class Ix Mole ConceptDocument1 pageRevision Class Ix Mole Conceptvishal_bokaro0% (1)

- Microchannel Heat Exchanger As EvaporatorDocument11 pagesMicrochannel Heat Exchanger As EvaporatorAbhilash TilakNo ratings yet

- Hot-Rolled - Plate: Data SheetDocument2 pagesHot-Rolled - Plate: Data SheetRichard Vica CalvoNo ratings yet

- 103 V 105Document550 pages103 V 105Gaurav SavlaniNo ratings yet

- Interline 984C - Technical Data SheetDocument4 pagesInterline 984C - Technical Data SheetIleanaNo ratings yet

- Numeric Index TmsDocument13 pagesNumeric Index TmsScribdLibros11No ratings yet

- ReArm Bond EBADocument2 pagesReArm Bond EBARajesh GiriNo ratings yet

- Chapter 3Document20 pagesChapter 3Chin Fout LengNo ratings yet

- VWStrainGaugeManualV1 8Document46 pagesVWStrainGaugeManualV1 8Giovanni PrensNo ratings yet

- Catalogus 2014 Compleet - LR PDFDocument215 pagesCatalogus 2014 Compleet - LR PDFJacob ReedNo ratings yet

- Dow Corning 813 Silicone Sealant: Glazing and Construction SealantDocument2 pagesDow Corning 813 Silicone Sealant: Glazing and Construction SealantcandyamNo ratings yet

- UV-shielding Antimicrobial Zein Films Blended With Essential Oils For Active Food PackagingDocument10 pagesUV-shielding Antimicrobial Zein Films Blended With Essential Oils For Active Food PackagingVero ArellanoNo ratings yet

- Reinforced Concrete Structures Case StudiesDocument64 pagesReinforced Concrete Structures Case StudiesRevanth Local MokkapatiNo ratings yet

- Chapter 20: Magnetic Properties: Issues To Address..Document17 pagesChapter 20: Magnetic Properties: Issues To Address..HaroonNo ratings yet

- A Survey On Gas Metal Arc Welding (GMAW) - Review: January 2019Document7 pagesA Survey On Gas Metal Arc Welding (GMAW) - Review: January 2019Radhi NurvianNo ratings yet

- Glenair Micro-D & Nano Miniature CatalogueDocument292 pagesGlenair Micro-D & Nano Miniature CatalogueAmex Ammy100% (1)

- Study On Strength Properties of Coconut Shell ConcreteDocument9 pagesStudy On Strength Properties of Coconut Shell Concreteabdul imranNo ratings yet

- Operation and Maintenance of Hydro TunnelsDocument49 pagesOperation and Maintenance of Hydro TunnelsAbhushan NeupaneNo ratings yet

- 2925 Modeling of Anhydrite Swelling With FlacDocument9 pages2925 Modeling of Anhydrite Swelling With Flacjmhs31No ratings yet

- CH 20 - P&A ProceduresDocument7 pagesCH 20 - P&A ProceduresdimitryNo ratings yet

- Vulkan Blast Shot Technology: Material Safety Data SheetDocument3 pagesVulkan Blast Shot Technology: Material Safety Data Sheetpatt43No ratings yet

- Market Item RatesDocument2 pagesMarket Item RatesRana Muhammad TalhaNo ratings yet

- Comp Ins PDFDocument7 pagesComp Ins PDFramsesiNo ratings yet

- Optimizing Heat Transfer Fluid PerformanceDocument12 pagesOptimizing Heat Transfer Fluid PerformancedhavalmpNo ratings yet

- Omae2008 57495Document6 pagesOmae2008 57495Vinicius Cantarino CurcinoNo ratings yet