Professional Documents

Culture Documents

THERMOBREAK CLASS 0 Vs PVC Nitrile NBR Foam (2019)

Uploaded by

Hamzeh TarteerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

THERMOBREAK CLASS 0 Vs PVC Nitrile NBR Foam (2019)

Uploaded by

Hamzeh TarteerCopyright:

Available Formats

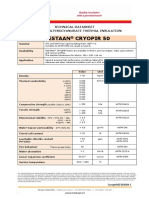

Technical Comparison

Thermobreak Class “0” Tube

©

Vs Elastomeric Foam Tube (PVC Nitrile)

PROPERTY TEST THERMOBREAK PVC Nitrile –NBR Foam

Physically CROSSLINKED , CLOSED CELL Polyolefin FR

foam composite, with flame bonded REINFORCED Extruded PVC Nitrile /NBR rubber composite.

MATERIAL CONSTRUCTION NA 9 um ALUMINIUM FOIL ( 110 um ). No foil facing or covering

Very fine cells with completely closed cell structure.

STRUCTURE NA No loose fibres Closed cell material.

DENSITY 25 Kg / m3 ( foam core only) 65-80 Kg /m3

THERMAL CONDUCTIVITY (k) ASTM C518 0.032 W/mK ( 23 Deg. C) 0.036-0.040 W/mK ( 24 Deg. C)

British Standard BS 476 Part Class “O” Class “O”

6&7

Spread of Flame index : 0 Spread of Flame index : 0

Australian /NZ Standard Smoke Develop index : 3

FIRE RATINGS AS1530.3 (1998) Smoke Develop index : 0-1

Heat Evolved index : 0 Heat Evolved index : 0

Ignability index : 0 Ignability index : 0

20/45 Pass

ASTM E84

FM Approved YES YES

UL 94 HF-1 ( UL Listed Product) No Data

NFPA 90A and 90B Compliance ASTM E84 and ASTM C411 Yes Yes

Meets and exceeds Standard’s threshold limits.

ISO 5956-2 Smoke density Dm<200 Not tested/no data

SMOKE DENSITY & TOXICITY with gas analysis

to IMO MSC 61(67) Gases concentration below threshold limits

CO, HCL, HF, NOx ,HBR, HCN, SO2

PERMEANCE ASTM E96-90 3.28 X 10-10 g/Pa.s.m2

WATER VAPOUR 8.19 X 10-15 K g/ Pa.s.m 1.16 X 10-13 Kg / Pa.s.m

PERMEABILITY* ASTM E-96-90

WATER VAPOUR RESISTANCE ≥ 40,000 ≥ 7000

FACTOR ( )

WATER ABSORPTION Less than 0.8% No data

TEMPERATURE RANGE -80 TO +100 C -40 to 82C ( flat sheets)

CFC COMPOUNDS NO NO

ENVIRONMENTAL & HEALTH

CONCERNS HCFC COMPOUNDS NO NO

CHLORINATED COMPOUNDS NO YES

CHEMICAL RESISTANCE NA Inert to most acids, alkalis, alcohols, esters, ketones, Inert to most acids, alkalis, alcohols, esters, ketones,

water, soaps and detergents water, soaps and detergents

UV RESISTANCE Excellent. Poor.

No coverings or additional UV coatings required Requires coating or special grade

GREEN BUILDING Green Star (VOC) Certified

ANTI MICROBIAL ASTM G21 No bacterial growth after 28 days incubation No ( Standard grade)

SUPPLY & INSTALLATION PREFORMED SIZE RANGE ½” TO 10” IPS Factory Preformed Up to 3” , then sheets need to be used.

NOTES

* Permeability values should only be compared in the Test Methods used are the same. Different procedures will give different results depending upon conditions of test.

Information given above is given in good faith and to the best of our knowledge. Data for other products are taken from common publications. However, due to the large number of manufacturers, some data may be vary slightly. It is recommended that

the data are verified by the interested parties before any decisions as to their suitability are made.

You might also like

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Precision Thin Film Chip ResistorsDocument3 pagesPrecision Thin Film Chip ResistorsJaPan LifeNo ratings yet

- Sekisui Thermobreak Thermaloc 2017 Brochure - OptDocument4 pagesSekisui Thermobreak Thermaloc 2017 Brochure - OptengineerhamzehNo ratings yet

- Hazardous Gas Monitoring, Fifth Edition: A Guide for Semiconductor and Other Hazardous OccupanciesFrom EverandHazardous Gas Monitoring, Fifth Edition: A Guide for Semiconductor and Other Hazardous OccupanciesNo ratings yet

- Roxul Comfortboard 80: Insulated SheathingDocument1 pageRoxul Comfortboard 80: Insulated SheathingMark RauNo ratings yet

- 2015EHCNDocument3 pages2015EHCNsvvsnrajuNo ratings yet

- 1.8 Thong So Ky Thuat Bao On AeroflexDocument1 page1.8 Thong So Ky Thuat Bao On AeroflexDatNo ratings yet

- Insuflex CatalogDocument15 pagesInsuflex Catalogmarceilinus devaluanto100% (1)

- Foam Glass Data SheetDocument2 pagesFoam Glass Data SheetMohamed KareemNo ratings yet

- THERMOBREAK CLASS 0 Vs Chemically Crosslinked (CXL) Foam 180912Document3 pagesTHERMOBREAK CLASS 0 Vs Chemically Crosslinked (CXL) Foam 180912Hamzeh TarteerNo ratings yet

- Tds Px439xs BK Vs Np1025Document3 pagesTds Px439xs BK Vs Np1025neil minnisNo ratings yet

- PBA Therm Clad BrochureDocument2 pagesPBA Therm Clad BrochureJames DickinsonNo ratings yet

- Rti Prorox WM 940 Es ExpDocument1 pageRti Prorox WM 940 Es ExpMadiaw NajaNo ratings yet

- Acetone: Shell ChemicalsDocument3 pagesAcetone: Shell ChemicalsUzair BukhariNo ratings yet

- Bao On AmazonDocument4 pagesBao On AmazonTrần ChâuNo ratings yet

- Shellsol A150 q7493 Eu 18042016Document3 pagesShellsol A150 q7493 Eu 18042016Henry FloresNo ratings yet

- Sekisui AcoustiPlus 2018 Brochure - WEBDocument4 pagesSekisui AcoustiPlus 2018 Brochure - WEBĐặng Văn SiêuNo ratings yet

- Eifs Product Catalogue KsaDocument8 pagesEifs Product Catalogue KsaRaihan AhmedNo ratings yet

- Searox SL 328: Technical InsulationDocument1 pageSearox SL 328: Technical InsulationAnh Le NgocNo ratings yet

- Ottocool Catalog enDocument40 pagesOttocool Catalog enBrian ReyesNo ratings yet

- Curtainrock 40 Curtain Wall Thermal Insulation TechdataDocument2 pagesCurtainrock 40 Curtain Wall Thermal Insulation TechdataBrian MabenNo ratings yet

- Isoparaffins Shellsolt EuropeDocument3 pagesIsoparaffins Shellsolt EuropeSaman ZehraNo ratings yet

- Rockboard 40Document2 pagesRockboard 40zaidg9876553No ratings yet

- Shellsol T q7412 AmDocument3 pagesShellsol T q7412 AmRagavendra Prabu GovindarajuNo ratings yet

- Able UCT S: Wiring ChannelsDocument8 pagesAble UCT S: Wiring ChannelsberdinsonNo ratings yet

- Shellsol T q7412 PDFDocument3 pagesShellsol T q7412 PDFmeNo ratings yet

- Modulatus Ornans Abstract Technical Brochure 2021 Rev00 IntlDocument48 pagesModulatus Ornans Abstract Technical Brochure 2021 Rev00 IntlRamses TorrealbaNo ratings yet

- Acetone SHELL SPEC 2010 PDFDocument3 pagesAcetone SHELL SPEC 2010 PDFLuka BraciNo ratings yet

- TDS - CRYOPIR50f - 202004-1Document1 pageTDS - CRYOPIR50f - 202004-1Nguyen Thi Bich ThuyNo ratings yet

- Peralatan & Perlengkapan Peledakan 3Document78 pagesPeralatan & Perlengkapan Peledakan 3Nurma Fitta SariNo ratings yet

- Shellsol A150 ND q7497 Eu 18042016Document3 pagesShellsol A150 ND q7497 Eu 18042016sizmaruNo ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- KLINGERSIL C-4430 SPEC SHEETDocument2 pagesKLINGERSIL C-4430 SPEC SHEETDailton SantosNo ratings yet

- Technical data for Kooltherm pipe insulationDocument7 pagesTechnical data for Kooltherm pipe insulationkuraimundNo ratings yet

- Methyl Ethyl Ketone: Shell ChemicalsDocument3 pagesMethyl Ethyl Ketone: Shell ChemicalssyamlokNo ratings yet

- TCS610-10-k-thermistorDocument10 pagesTCS610-10-k-thermistordaniel.liontecNo ratings yet

- Technical Information ASSET DOC LOC 1541021Document1 pageTechnical Information ASSET DOC LOC 1541021Henry PonceNo ratings yet

- Iig - ENERWRAP - MA - 960DataSheetDocument1 pageIig - ENERWRAP - MA - 960DataSheettmp_rootsNo ratings yet

- Datasheet Isoparaffinsshellsoltdeurope PDFDocument3 pagesDatasheet Isoparaffinsshellsoltdeurope PDFmeNo ratings yet

- ResinTek RTS 075FR-1Document2 pagesResinTek RTS 075FR-1vishal089No ratings yet

- FSL 960 (2305843009232006947)Document1 pageFSL 960 (2305843009232006947)luis angel armadilloNo ratings yet

- Wire Mesh Rock Wool Blanket HlywmblDocument2 pagesWire Mesh Rock Wool Blanket HlywmblENG ALAmireyNo ratings yet

- AZURINSULATIONDocument20 pagesAZURINSULATIONtitaNo ratings yet

- Calumet Calsia BrochureDocument2 pagesCalumet Calsia BrochureRishi DhimanNo ratings yet

- Nominal Engineering Properties of Ryton R-4: Data SheetDocument4 pagesNominal Engineering Properties of Ryton R-4: Data SheetRakeshNo ratings yet

- 2017 Kynar Wire and Cable SolutionsDocument8 pages2017 Kynar Wire and Cable SolutionsKaarthicNatarajanNo ratings yet

- Arnitel® EM550, TPC-ET - DSM Engineering Plastics - Plastics FinderDocument5 pagesArnitel® EM550, TPC-ET - DSM Engineering Plastics - Plastics FinderFaiz AnsariNo ratings yet

- Technical Data Sheet CPVC: (Chlorinated Polyvinyl Chloride)Document1 pageTechnical Data Sheet CPVC: (Chlorinated Polyvinyl Chloride)Nam NguyenNo ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- Shell Saraline 185V TDSDocument3 pagesShell Saraline 185V TDSYanu Ismadi100% (2)

- ETERSET 2960 Data SheetDocument2 pagesETERSET 2960 Data Sheetahmed mahmoudNo ratings yet

- Conathane En-1556 2e12Document3 pagesConathane En-1556 2e12scorpionbadshahNo ratings yet

- Pinnacle Alloys E8018 C3Document2 pagesPinnacle Alloys E8018 C3Sajeev SivanandanNo ratings yet

- Texanol - Tds (en)Document3 pagesTexanol - Tds (en)Pool Icanaque EspinalNo ratings yet

- 2017 - 06 - Armaflex FRV PDFDocument8 pages2017 - 06 - Armaflex FRV PDFNaqqash SajidNo ratings yet

- Eccoh 5836 TDS01 2018-10Document2 pagesEccoh 5836 TDS01 2018-10bobNo ratings yet

- Hexane Polymerisation: Data SheetDocument3 pagesHexane Polymerisation: Data SheetHamid Vahedi LarijaniNo ratings yet

- Solvesso™ 100: Aromatic FluidDocument1 pageSolvesso™ 100: Aromatic FluidSatish PeruriNo ratings yet

- Presentation Transformer OilDocument44 pagesPresentation Transformer Oilravi_bagga2000100% (3)

- THERMOBREAK CLASS 0 Vs Fglass (2010)Document2 pagesTHERMOBREAK CLASS 0 Vs Fglass (2010)Hamzeh TarteerNo ratings yet

- Technical Information Bulletin - Density Insulation PropertDocument3 pagesTechnical Information Bulletin - Density Insulation PropertHamzeh TarteerNo ratings yet

- Technical Bulletin - Additional Coatings and Vapour BarriersDocument1 pageTechnical Bulletin - Additional Coatings and Vapour BarriersHamzeh TarteerNo ratings yet

- G60 Psa 2010Document2 pagesG60 Psa 2010Hamzeh TarteerNo ratings yet

- Bulletin - Controlling Surface TemperatureDocument1 pageBulletin - Controlling Surface TemperatureHamzeh TarteerNo ratings yet

- ( (34.0L×16.0W) + (26.0L×12.0W) ) ×5.0H: Y. J Lee Y. J Lee Y. J LeeDocument1 page( (34.0L×16.0W) + (26.0L×12.0W) ) ×5.0H: Y. J Lee Y. J Lee Y. J LeeHamzeh TarteerNo ratings yet

- AcosutiPLus V Fibreglass Absorption and NRCsDocument2 pagesAcosutiPLus V Fibreglass Absorption and NRCsHamzeh TarteerNo ratings yet

- AsbestosDocument3 pagesAsbestosHaslayati HashimNo ratings yet

- Casey Jones Mask TemplateDocument3 pagesCasey Jones Mask TemplateChrisNo ratings yet

- صلاحية الفومDocument3 pagesصلاحية الفومabdo aliNo ratings yet

- 3M Automotive Products 2011Document621 pages3M Automotive Products 2011marsauto2No ratings yet

- Ramcharan Product ListDocument2 pagesRamcharan Product ListErwin ErwinNo ratings yet

- Desmopan TPU ProcessingDocument48 pagesDesmopan TPU ProcessingA Mahmood100% (1)

- Warranty Claim Procedure ManualDocument28 pagesWarranty Claim Procedure ManualjorgegachaNo ratings yet

- A Designer' S Guide To Rotational MoldingDocument11 pagesA Designer' S Guide To Rotational MoldinglamoNo ratings yet

- Rust Oleum WikipediaDocument3 pagesRust Oleum Wikipediaramthecharm_46098467No ratings yet

- Control of The Mat Gloss BalanceDocument3 pagesControl of The Mat Gloss Balancejulio100% (1)

- Affidavit of Support Assistantship Form) - Documents in Green Only If Required Immunization Form ResumeDocument4 pagesAffidavit of Support Assistantship Form) - Documents in Green Only If Required Immunization Form ResumeShyam Ramanath ThillainathanNo ratings yet

- Toyo Butterfly Valve PDFDocument20 pagesToyo Butterfly Valve PDFJimmy Adi100% (2)

- 147 Scu RadaflexDocument8 pages147 Scu RadaflexMartin R NilssonNo ratings yet

- Blowmolding 120209032429 Phpapp01Document16 pagesBlowmolding 120209032429 Phpapp01luan_baNo ratings yet

- Instruction Manual - Unique Single Seat Valve ATEX - en - 2Document40 pagesInstruction Manual - Unique Single Seat Valve ATEX - en - 2Duy NguyenNo ratings yet

- Loctite Product SelectionDocument158 pagesLoctite Product SelectionRiki Nurzaman100% (1)

- Ban on Use and Throw Away Plastics in Tamil NaduDocument56 pagesBan on Use and Throw Away Plastics in Tamil NaduDhivya SelvamNo ratings yet

- FM 1610 DI Pipe and Fittings, Flexible Fittings and Couplings 2016Document23 pagesFM 1610 DI Pipe and Fittings, Flexible Fittings and Couplings 2016andyNo ratings yet

- Anti-friction Fire Hydrant FeaturesDocument4 pagesAnti-friction Fire Hydrant FeaturesYury Isasi RosasNo ratings yet

- Unit 2 PlasticsDocument18 pagesUnit 2 PlasticsNivedhaNo ratings yet

- Environmental Reporting of Plastics and Synthetic Textile FibreDocument62 pagesEnvironmental Reporting of Plastics and Synthetic Textile FibreNguyễn Tiến DũngNo ratings yet

- AVK Water Supply BrochureDocument52 pagesAVK Water Supply BrochureHARSHANo ratings yet

- Diaphragm Valves - Typical Failure ModesDocument3 pagesDiaphragm Valves - Typical Failure ModesGustavioNo ratings yet

- HSE 10 Excavation PermitDocument1 pageHSE 10 Excavation PermitBa N Nhim100% (1)

- Price List: Flange GasketsDocument4 pagesPrice List: Flange GasketsAiskel PazNo ratings yet

- Leoni CableDocument44 pagesLeoni CableOzanNo ratings yet

- 9868 Rubber Mill LiningsDocument8 pages9868 Rubber Mill LiningsJames JhonsonNo ratings yet

- A Study on Effectiveness of Training & Development in RubcoDocument83 pagesA Study on Effectiveness of Training & Development in Rubcojayakrishnan100% (2)

- Anti Vibration Mount: Product CatalogDocument29 pagesAnti Vibration Mount: Product Catalogramsey222No ratings yet

- Product Overview: A Range of Metal Detectable Elastomers For The Ultimate Contamination Detection and ContainmentDocument3 pagesProduct Overview: A Range of Metal Detectable Elastomers For The Ultimate Contamination Detection and ContainmentSérgio GomesNo ratings yet