Professional Documents

Culture Documents

QCP 050 Concrete Finishing (Zuluf Water Supply Facilities B.I. No. 10-12322) Submitted

Uploaded by

RAMAKRISHNAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QCP 050 Concrete Finishing (Zuluf Water Supply Facilities B.I. No. 10-12322) Submitted

Uploaded by

RAMAKRISHNACopyright:

Available Formats

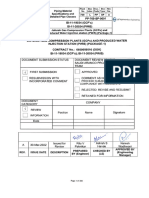

CONCRETE FINISHING

Document No. BQ-Zuluf- Rev. No Date Page

QCP-050 00 22-JUN-2022 Page 1 of 13

Project Title:

ZULUF AH DEVELOPMENT WATER SUPPLY FACILITIES

B.I. No..10-12322

Contract No.6600050536

Package 1 & Package 2

Confidentiality

This document is the property of Bin Quraya Limited Company. Neither the whole nor any part of this

document may be disclosed to others by reproduction, storage in a retrieval system, transmitted in any form

by means (electronic, mechanical, reprographic, mechanical, reprographic recording or otherwise) without

prior written consent of the Chief Executive Officer.

Prepared by Reviewed by Noted By Approved by

ARNALDO LUKKA RK Ferruccio Tata Nardini

DOCUMENT QA Manager Contractor SAPMT / PID

CONTROLLER Representative

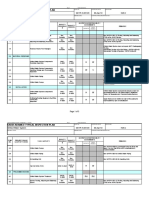

Concrete FINISHING Project Title B.I. No. 10 - 12322

BQ-Zuluf-QCP-050 Rev. 00 Zuluf Ah Development - Water Contract No. 6600050536

Supply Facilities Page: 2 of 13

REVISION HISTORY

Rev. Date Revision Description Prepared By Reviewed by Noted by Approved by

No. SAPMT

00 22-JUN-2022 Issued for Review and ARNALDO LUKKA RK Ferruccio Tata

Approval Nardini

© Bin Quraya Limited Company

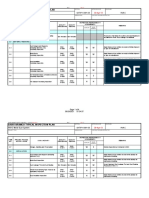

Concrete FINISHING Project Title B.I. No. 10 - 12322

BQ-Zuluf-QCP-050 Rev. 00 Zuluf Ah Development - Water Contract No. 6600050536

Supply Facilities Page: 3 of 13

Table Index

S/N Description Page

1 Purpose

2 Scope

3 References

4 Responsibilities

5 Tools and Materials

6 Manpower

7 Procedure

8 Quality

9 Safety, Health and Environment

1. Purpose

© Bin Quraya Limited Company

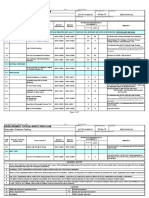

Concrete FINISHING Project Title B.I. No. 10 - 12322

BQ-Zuluf-QCP-050 Rev. 00 Zuluf Ah Development - Water Contract No. 6600050536

Supply Facilities Page: 4 of 13

To establish, implement and maintain a procedure for concrete placement and installation work to meet

the minimum quality requirement in accordance with the applicable Saudi Aramco and Industry

Standards and Specifications. This applies the CONCRETE FINISHING at the site of Zuluf Ah

Development Water Supply Facilities.

2. Scope

This procedure is applicable to all site CONCRETE FINISHING of Zuluf Ah Development Water

Supply Facilities BI no. 10-12322.

3. References

SAES-Q-001 – Criteria for Design and Construction of Concrete Structures

SAES-H-003 – Protective Coatings for Industrial Concrete Structures

ACI 301 – 16 & ACI 117 FINISHING OF CONCRETE

ACI 301 – Specifications for Structural Concrete

ACI 305R – Hot Weather Concreting

ACI 347 – Guide to Formwork for Concrete

ACI 309R - Guide for Consolidation of Concrete

ACI 308 - Standard Practice for Curing Concrete

ACI 308R – Guide to Curing Concrete

SATIP-Q-001 - Cast-In-Place Portland Cement Concrete

SATIP-H-003-01 - Coating Application on Concrete Surfaces

4. RESPONSIBILITIES:

4.1 The QA/QC Manager is responsible for ensuring that the materials to be used are as per the

approved materials submittals. He is also responsible for the continuous checking and

monitoring of all the QA/QC related requirements and procedures with respect to concrete

finishing procedure.

4.2 The Construction Manager shall be responsible to the Project Manager for all activities

performed by site personnel. Ensure that all site work is achieved in a timely manner, on

schedule and in compliance with Municipality and Saudi Aramco Standard requirements, the

approved procedures, specifications, drawings and all relevant documents. Coordinate with

Project Manager for determination of problems that may arise during construction.

© Bin Quraya Limited Company

Concrete FINISHING Project Title B.I. No. 10 - 12322

BQ-Zuluf-QCP-050 Rev. 00 Zuluf Ah Development - Water Contract No. 6600050536

Supply Facilities Page: 5 of 13

4.3 The Quality Control Inspector/s monitors daily activities verify/check compliance to Client’s

Specifications, IFC Drawings, Saudi Aramco Standard requirements and Applicable Codes and

accordingly prepare and submit RFI’s.

4.4 The Site Safety Officer check personnel and confirm compliance to all safety requirements,

such as wearing Personnel Protective Equipment (PPE). Identify & check work areas for any

unsafe conditions. Coordinate with Construction Manager and Supervisors to ensure work is

carried out in accordance with Project Safety Plan.

5 TOOLS AND MATERIALS:

5.1 Mason’s Trowels (various type)

5.2 Flat Bar

5.3 Spirit Level

5.4 Mason’s Bucket

5.5 Sponge

5.6 Brush

5.7 Carpenter’s Tools

5.8 Absorbent Mats: ASTM C171, Burlap & Polyethylene, minimum 270 gram/square meter

bonded to prevent separation during handling and placing.

5.9 Water: As per SAES-Q-001, Para, 10.2

5.10 Hessian: Weight 0.3 kg/m2, as approved by SAUDI ARAMCO

5.11 Bituminous Paint (APCS-10)

5.12 Approved Concrete Repair & Filler materials ( Cementitious / Epoxy )

6 MANPOWER:

6.1 Foreman

6.2 Masons

6.3 Carpenters

6.4 Labors

7 PROCEDURES:

© Bin Quraya Limited Company

Concrete FINISHING Project Title B.I. No. 10 - 12322

BQ-Zuluf-QCP-050 Rev. 00 Zuluf Ah Development - Water Contract No. 6600050536

Supply Facilities Page: 6 of 13

The following procedures described herein are intended specifically for the proper execution of the work

related to Concrete Finishing Procedure as per relevant specifications, guidelines and restrictions.

7.1 Concrete Finishing After Pouring

7.1.1 Care shall be taken for the lamination on the plywood form work not to get damaged.

7.1.2 Care shall be taken to avoid Deformation / movement of the form work during

concrete pouring which can cause poor finishing of concrete.

7.1.3 The elevations shall be marked on the form work as per the IFC drawing prior to start

the pouring and finishing shall be done accordingly.

7.1.4 The finishing of concrete shall be in accordance with ACI 301 - 05, and ACI 302.1R.

7.1.5 Upon completion of concrete pouring, skilled masons will be used to get the required

finishing on the top of the concrete according to the project requirement and company

specification.

7.1.6 Care shall be taken by the Site Engr. not to add water / sprinkle water on the top of the

concrete to get smooth finishing.

7.1.7 After vibration and screed-off to level have been completed in each area, an opaque

polyethylene sheet shall be placed over the concrete as soon as possible to avoid risk of

damage to the surface of the concrete. The Polyethylene sheet shall be placed closely to

prevent air circulation and loss of moisture.

7.1.8 As soon as the surface of the concrete has hardened sufficiently to enable it to do

finishing (if required) then the Polyethylene sheet shall be removed, area by area being

finished and the concrete finished as quickly as possible. No water may be added to

the surface for finishing.

7.1.9 Experienced Masons shall be used for the finishing work.

7.1.10 If the finishing operations can be commenced almost directly following the leveling

then the Polyethylene sheet between leveling and finishing shall be omitted. Under no

circumstances shall the fresh concrete surface be exposed to direct sunlight for a

cumulative period of more than one (1) hour.

7.2 Curing of Concrete

7.2.1 Make sure prior to start pouring all materials equipment and man power should ready

for curing.

7.2.2 Curing shall be done in accordance with the ACI-308 & 308 R.

7.2.3 Horizontal Surface

© Bin Quraya Limited Company

Concrete FINISHING Project Title B.I. No. 10 - 12322

BQ-Zuluf-QCP-050 Rev. 00 Zuluf Ah Development - Water Contract No. 6600050536

Supply Facilities Page: 7 of 13

7.2.3.1 As soon as concrete has taken its initial set (or in case not more than

12hours after completion of casting) the Polyethylene sheet shall be

removed, the concrete surface shall be poured with tested water and

overlaid with saturated hessian. The hessian is to be laid in reasonably

close contact with the surface of the concrete and to be kept continuously

wet. The hessian shall be totally covered with polythene sheet which shall

be in as close contact with the hessian as is necessary to prevent wind

getting into the hessian. Water shall be tested prior to use.

7.2.3.2 Moisture loss from surfaces placed against wooden forms or metal forms

exposed to heating by the sun shall be minimized by keeping the forms

thoroughly wet until they can be safely removed.

7.2.4 Vertical Surface

7.2.4.1 Immediately after each area of the formwork is removed, the surface of the

concrete shall be thoroughly wetted and saturated hessian placed over the

whole area. The hessian is to be laid so as to be in close contact with the

surface of the concrete as it is practicable and to be kept continuously wet.

7.2.4.2 The hessian shall be totally covered with polythene sheets which shall be in

close contact with the hessian as it is necessary to prevent wind getting into

the hessian.

7.2.4.3 Water curing shall be done continuously for 7 days minimum.

7.2.5 Surface Preparation

7.2.5.1 If the moisture content is within the limit, surface preparation shall be

started.

7.2.5.2 The surface to be treated must be sound and perfectly clean. Remove

cement laitance, loose and crumbling parts and all traces of dust, grease, oil

and form release compounds.

7.2.5.3 Ensure that the surface is sufficiently even. Repair and smooth over any

rough areas. Patch and fill all blowholes and air void. All Surfaces shall be

clean and free of foreign matters before application of paint.

7.2.5.4 Cleaning shall be planned properly so that the dust and other contaminants

will not fall on wet and newly painted surfaces.

7.2.5.5 Cracks less than 10 mm wide and holes not exceeding 10 mm in diameter

shall be filled using a qualified epoxy filler or cementitious material before

applying primer/sealer to the surface.

© Bin Quraya Limited Company

Concrete FINISHING Project Title B.I. No. 10 - 12322

BQ-Zuluf-QCP-050 Rev. 00 Zuluf Ah Development - Water Contract No. 6600050536

Supply Facilities Page: 8 of 13

7.2.5.6 All the sharp edges shall be removed using power grinder with abrasive

discs or by abrasive papers etc.

7.2.6 Coating On Concrete

7.2.8.1 Coating on concrete shall be in accordance with the SAES-H -003.

7.2.8.2 Aramco approved coating materials shall be used.

7.2.8.3 Coating material manufacturer’s instructions shall be followed.

7.2.8.4 The underground and above ground coating shall be according to the

project specification, IFC drawing etc.

7.2.8.5 Surface shall be cleaned properly prior to start application.

7.2.8.6 Expansion and construction joints shall be cleaned and masked off prior to

coating.

7.2.8.7 All the coating surface shall be approved by the Company prior to apply

( relevant RFI shall be raised and signed off )

7.2.8.8 Surface temperature, humidity and due point shall be checked and

confirmed that it is within the allowable limit prior to coating.

7.2.8.9 Material Approval shall be taken for all the coating materials prior to

coating.

8 QUALITY:

8.1 All inspections (RFI) and relevant quality documents must be signed off after completion of

inspection jointly made by SENDAN and ARAMCO.

9 SAFETY, HEALTH AND ENVIRONMENT:

To prevent accidents and incidents at work site, proper implementation of safety procedures and requirements

shall be maintained throughout the course of concrete finishing activity.

9.1 Conducts safety orientation with specific subject on concrete finishing activity safety. Make all

involved workers aware of the responsible persons and make each personnel aware of their

specific jobs and their responsibilities for the safety of the entire work force. Safety precautions

shall be discussed and workers shall be made aware of the emergency procedures.

9.2 Provides personal protective equipment’s to all workers involved in the activity which are

necessary for the safe execution of the work as per the Manufacturer’s Recommendations.

9.2.1 General – Gloves must be worn for all work that may result in soiling.

Apron/Coveralls/Protective Clothing must be worn when soiling is so great that

© Bin Quraya Limited Company

Concrete FINISHING Project Title B.I. No. 10 - 12322

BQ-Zuluf-QCP-050 Rev. 00 Zuluf Ah Development - Water Contract No. 6600050536

Supply Facilities Page: 9 of 13

regular work clothes do not adequately protect skin against contact with the

product. Safety eyewear should be used when there is likelihood of exposure.

9.2.2 Eye/Face Protection – Safety Eyewear complying with approved standard should be

used when risk assessment indicates this is necessary to avoid exposure to liquid

splashes, mist gases or dust. If contact is possible, the following protection should be

worn, unless the assessment indicates a higher degree of protection, safety glasses

with side shields.

9.2.3 Hand Protection - Wear chemical-resistant gloves (tested to EN374) in combination

with basic employee training. The quality of the chemical-resistant protective gloves

must be chosen as a function of the specific workplace concentration and quantity of

hazardous substance.

9.3 Implements safety procedures and monitors the entire activity at all times by Safety Officer who

are designated at the site.

9.4 Ensures the safety of personnel, public and equipment must not be compromised and that the

work procedures are according to the approved safety plan.

9.5 Provides and installs warning signs to be posted in designated area of on-going application of

bituminous paint to warn other workers.

9.6 Assure the safety and protect the residents and property owners adjacent to the working area

during painting activity.

9.7 Erect and maintain signs, barricades and other warning control devices within the painting area

for as long as it may be required.

© Bin Quraya Limited Company

You might also like

- QCP 045 Field Engg Control Procedure (Zuluf Water Supply Facilities B.I. No. 10-12322) SubmittedDocument11 pagesQCP 045 Field Engg Control Procedure (Zuluf Water Supply Facilities B.I. No. 10-12322) SubmittedRAMAKRISHNANo ratings yet

- QCP 12 Project Inspection Record (Zuluf Water Supply Facilities B.I. No. 10-12322)Document6 pagesQCP 12 Project Inspection Record (Zuluf Water Supply Facilities B.I. No. 10-12322)RAMAKRISHNANo ratings yet

- Satr Nde 2002Document1 pageSatr Nde 2002nadeem shaikhNo ratings yet

- Saep 3101DDocument14 pagesSaep 3101DKhaja MoinNo ratings yet

- Concrete Finishing ProcedureDocument11 pagesConcrete Finishing ProcedureGaneshNo ratings yet

- APPENDIX A3 - Concrete Batching PlantDocument6 pagesAPPENDIX A3 - Concrete Batching PlantAymanEssamNo ratings yet

- 1-Cover GCC Rev. 0Document27 pages1-Cover GCC Rev. 0Mohammed Mujeeb Ali FathaanNo ratings yet

- Saep 14Document47 pagesSaep 14OMER ELFADILNo ratings yet

- SCH.Q - Contract No.6600044663 (IK)Document81 pagesSCH.Q - Contract No.6600044663 (IK)kamilNo ratings yet

- Saudi Aramco ERTQA Forum 2017Document7 pagesSaudi Aramco ERTQA Forum 2017Anupam NathNo ratings yet

- Saes Q 004Document24 pagesSaes Q 004AasimNo ratings yet

- Engineering ProcedureDocument50 pagesEngineering Procedure MohammedNo ratings yet

- Schedule B - Attachment IVDocument41 pagesSchedule B - Attachment IVwangruiNo ratings yet

- Schedule B - Attachment IV Project Facilities RequirementsDocument52 pagesSchedule B - Attachment IV Project Facilities Requirementsxue jun xiangNo ratings yet

- Saudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 30-Oct-17 MechDocument2 pagesSaudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 30-Oct-17 MechJagdishNo ratings yet

- Saes Q 001Document22 pagesSaes Q 001irfan hussainNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 31-Aug-11 WeldAnonymous 4e7GNjzGWNo ratings yet

- BSP Project Quality Awareness Trainings (New)Document22 pagesBSP Project Quality Awareness Trainings (New)amirrulasyrafNo ratings yet

- Schedule B - Attachment IVDocument29 pagesSchedule B - Attachment IVAbdul Ahad LoneNo ratings yet

- Saep 115Document12 pagesSaep 115Anonymous 4IpmN7OnNo ratings yet

- CSE 202.01 Materials and Their Impact On Concrete FailuresDocument63 pagesCSE 202.01 Materials and Their Impact On Concrete FailuresJellyn BaseNo ratings yet

- Saudi Aramco Supplier Registration & Qualification SeminarDocument15 pagesSaudi Aramco Supplier Registration & Qualification Seminaral arabiNo ratings yet

- Engineering Standard (SAES-A-100) Survy CoordDocument6 pagesEngineering Standard (SAES-A-100) Survy CoordPageduesca Rouel100% (2)

- SAEP-1150 Inspection Coverage On ProjectsDocument54 pagesSAEP-1150 Inspection Coverage On ProjectsUsman AliNo ratings yet

- Saep 397Document9 pagesSaep 397munnaNo ratings yet

- Saep 3103Document7 pagesSaep 3103Seeria FreNo ratings yet

- SAIC-Q-1041 Asphalt Pavement Prime Coat & Tack Coating InspectionDocument10 pagesSAIC-Q-1041 Asphalt Pavement Prime Coat & Tack Coating InspectionAbdul HannanNo ratings yet

- AE-036411-001 INDEX For Drawing and EquipmentDocument1 pageAE-036411-001 INDEX For Drawing and Equipmentnarutothunderjet216No ratings yet

- IP02-Bend Check List 01Document1 pageIP02-Bend Check List 01Laith SalmanNo ratings yet

- JGCP Pms PP 769 SP 0001Document398 pagesJGCP Pms PP 769 SP 0001Ahmed BoraeyNo ratings yet

- Saes A 120Document11 pagesSaes A 120Walid MegahedNo ratings yet

- SAES-W-012 - Google Search3Document1 pageSAES-W-012 - Google Search3fayceal0% (1)

- Fencing Handbook by Guardian Ind - Co.ltd.Document56 pagesFencing Handbook by Guardian Ind - Co.ltd.Kevin VillaramaNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerSelvakpm06No ratings yet

- Saudi Aramco Typical Inspection Plan: Pre-Engineered Metal Buildings SATIP-M-100-04 30-Apr-13 CivilDocument2 pagesSaudi Aramco Typical Inspection Plan: Pre-Engineered Metal Buildings SATIP-M-100-04 30-Apr-13 CivilJeffrey Lipata Jr.No ratings yet

- SATIP-Q-001-01 Portland Cement Concrete - Batch Plants ManagementDocument2 pagesSATIP-Q-001-01 Portland Cement Concrete - Batch Plants ManagementAbdul HannanNo ratings yet

- RFP Clause Q010 - LOCAL DELIVERY PO (NON-CONCURRENT)Document40 pagesRFP Clause Q010 - LOCAL DELIVERY PO (NON-CONCURRENT)SamiNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 30-Oct-17 MechDocument2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 30-Oct-17 MechJagdishNo ratings yet

- Saes R 004Document8 pagesSaes R 004Shahzad HussainNo ratings yet

- SAES-L-460 PDF Download - Pipeline Crossings Under Roads - PDFYARDocument7 pagesSAES-L-460 PDF Download - Pipeline Crossings Under Roads - PDFYARZahidRafiqueNo ratings yet

- Saes Q 010 PDFDocument4 pagesSaes Q 010 PDFRoger MallariNo ratings yet

- Saudi Aramco Inspection Checklist: FBE Rebar & Embedments Receiving Inspection SAIC-Q-1007 15-Nov-17 MAH-SA-CDocument3 pagesSaudi Aramco Inspection Checklist: FBE Rebar & Embedments Receiving Inspection SAIC-Q-1007 15-Nov-17 MAH-SA-CAbdul HannanNo ratings yet

- Iqwq-Ce1092-Cpzzz-00-0003 - 0 - Civil Work Construction Procedure PDFDocument12 pagesIqwq-Ce1092-Cpzzz-00-0003 - 0 - Civil Work Construction Procedure PDFNassim SabriNo ratings yet

- Saep 50Document33 pagesSaep 50Demac SaudNo ratings yet

- MAS Approval SheetDocument1 pageMAS Approval SheetmuneerpmhNo ratings yet

- Appendix A Architectural Interior Finishes Requirments: Floor Base Wall CeilingDocument9 pagesAppendix A Architectural Interior Finishes Requirments: Floor Base Wall CeilingEr Bishwonath Shah100% (1)

- 01 Samss 005Document5 pages01 Samss 005Moustafa BayoumiNo ratings yet

- Saudi Aramco Precast Concrete Installation PlanDocument10 pagesSaudi Aramco Precast Concrete Installation PlanNaushad AlamNo ratings yet

- 00 Saip 13Document12 pages00 Saip 13immuNo ratings yet

- Project Execution Guide for Automation SystemsDocument18 pagesProject Execution Guide for Automation SystemsDemac SaudNo ratings yet

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocument1 pageSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWNo ratings yet

- SATIP-K-001-11 - AC Split Systems DX TypeDocument3 pagesSATIP-K-001-11 - AC Split Systems DX TypeRAMAKRISHNANo ratings yet

- Request For Quote/Proposal (RFQ/RFP) : Method of SubmittalDocument7 pagesRequest For Quote/Proposal (RFQ/RFP) : Method of Submittalstewart raymondNo ratings yet

- 00-180000-4700000203-CH2-CIV-SPC-000002 Rev.02.00 - Pdf. (Geotech)Document41 pages00-180000-4700000203-CH2-CIV-SPC-000002 Rev.02.00 - Pdf. (Geotech)ahmad.suliman.saeedNo ratings yet

- Span Approved Vendor Category ADocument27 pagesSpan Approved Vendor Category AyongksNo ratings yet

- 08 - Method Statement For Tile WorkDocument5 pages08 - Method Statement For Tile WorkAnsar WarraichNo ratings yet

- Gul Ahmed's 50MW Wind Power Project Foundation ConstructionDocument9 pagesGul Ahmed's 50MW Wind Power Project Foundation ConstructionAnsar WarraichNo ratings yet

- Method Statement For Block PavingDocument7 pagesMethod Statement For Block Pavingjohng5697No ratings yet

- Job Procedure For Concreting: Petron Engineering Construction Ltd. JBF Mangalore Document No.: Pecl/Til - Msc-006Document11 pagesJob Procedure For Concreting: Petron Engineering Construction Ltd. JBF Mangalore Document No.: Pecl/Til - Msc-006mahesh naikNo ratings yet

- Welding Process Control - PR - 0XXDocument21 pagesWelding Process Control - PR - 0XXRAMAKRISHNA100% (2)

- Weld Repair Procedure SummaryDocument10 pagesWeld Repair Procedure SummaryRAMAKRISHNANo ratings yet

- BQ-ZUL-0XX10 Welding Consumable ControlDocument10 pagesBQ-ZUL-0XX10 Welding Consumable ControlRAMAKRISHNANo ratings yet

- Sockolet Gap Control Threaded Joints - PR - 0XXDocument14 pagesSockolet Gap Control Threaded Joints - PR - 0XXRAMAKRISHNANo ratings yet

- Weld Procedure Specification - PR - 0XXDocument7 pagesWeld Procedure Specification - PR - 0XXRAMAKRISHNANo ratings yet

- Shop and Field Fabrication - PR - 0XXDocument18 pagesShop and Field Fabrication - PR - 0XXRAMAKRISHNANo ratings yet

- Bin Quraya Holding Co. ةضباقلا هعيرق نب ةكرش: QCP-45 Quality Control Procedure Field Engineering Change Control ProcedureDocument5 pagesBin Quraya Holding Co. ةضباقلا هعيرق نب ةكرش: QCP-45 Quality Control Procedure Field Engineering Change Control ProcedureRAMAKRISHNANo ratings yet

- SATIP-K-001-11 - AC Split Systems DX TypeDocument3 pagesSATIP-K-001-11 - AC Split Systems DX TypeRAMAKRISHNANo ratings yet

- Saic Q 1017Document1 pageSaic Q 1017Hussain Nasser Al- Nowiesser100% (2)

- SATIP-K-001-09 Rev 07 - Through-The-Wall and Window-Mounted Air ConditionersDocument2 pagesSATIP-K-001-09 Rev 07 - Through-The-Wall and Window-Mounted Air ConditionersمحمداحمدحسنالفنجرىNo ratings yet

- Saudi Aramco Exhaust Fan Inspection ChecklistDocument3 pagesSaudi Aramco Exhaust Fan Inspection ChecklistRohit BassNo ratings yet

- QCP 02 Project Inspection - Testing of Purchased Materials (Zuluf Water Supply Facilities B.I. No. 10-12322)Document12 pagesQCP 02 Project Inspection - Testing of Purchased Materials (Zuluf Water Supply Facilities B.I. No. 10-12322)RAMAKRISHNA100% (1)

- AHU Inspection Plan for Saudi AramcoDocument3 pagesAHU Inspection Plan for Saudi AramcoRAMAKRISHNA100% (1)

- SATIP-K-001-05 - Chilled Water System Rev 7Document3 pagesSATIP-K-001-05 - Chilled Water System Rev 7RAMAKRISHNANo ratings yet

- SATIP-K-001-12 - TAB of HVAC SystemDocument2 pagesSATIP-K-001-12 - TAB of HVAC SystemRAMAKRISHNANo ratings yet

- Saudi Aramco PACU Inspection PlanDocument3 pagesSaudi Aramco PACU Inspection PlanRAMAKRISHNA100% (1)

- SATIP-K-001-01 Rev 7 Centrifugal FanDocument3 pagesSATIP-K-001-01 Rev 7 Centrifugal FanRAMAKRISHNANo ratings yet

- SATIP-K-001-09 Rev 07 - Through-The-Wall and Window-Mounted Air ConditionersDocument2 pagesSATIP-K-001-09 Rev 07 - Through-The-Wall and Window-Mounted Air ConditionersمحمداحمدحسنالفنجرىNo ratings yet

- SATIP-K-001-03 - HVAC Metal Duct System - Rev. 7Document4 pagesSATIP-K-001-03 - HVAC Metal Duct System - Rev. 7RAMAKRISHNANo ratings yet

- SAUDI ARAMCO HYDROSTATIC TESTING INSPECTION PLANDocument2 pagesSAUDI ARAMCO HYDROSTATIC TESTING INSPECTION PLANmohamedqcNo ratings yet

- Saudi Aramco Typical Inspection Plan: Pneumatic Pressure Testing SATIP-A-004-01 MechanicalDocument2 pagesSaudi Aramco Typical Inspection Plan: Pneumatic Pressure Testing SATIP-A-004-01 MechanicalRAMAKRISHNANo ratings yet

- LTTS Corporate BrochureDocument20 pagesLTTS Corporate BrochureshountyNo ratings yet

- AssemblyDocument26 pagesAssemblySahil GuptaNo ratings yet

- QB Naval September 2016Document1 pageQB Naval September 2016Vikram ChauhanNo ratings yet

- 17 - Industry 4.0 An Amanofacturing EcosysDocument28 pages17 - Industry 4.0 An Amanofacturing Ecosysorlando moraNo ratings yet

- Design Review QuestionsDocument14 pagesDesign Review QuestionsCrystal DuncanNo ratings yet

- EASA AD for inspection of landing gear selector valves on Airbus A318/19/20/21Document3 pagesEASA AD for inspection of landing gear selector valves on Airbus A318/19/20/21Sa Be MirNo ratings yet

- Documents Required For Registration of Free Zone CompaniesDocument2 pagesDocuments Required For Registration of Free Zone CompaniesbeybakNo ratings yet

- INventory Management at Health CareDocument33 pagesINventory Management at Health CareishabihNo ratings yet

- Cablevision Your Passport To Cable 1984Document20 pagesCablevision Your Passport To Cable 1984rivest266No ratings yet

- Asme B31-2Document71 pagesAsme B31-2mcpaoloniNo ratings yet

- Aluminium - Section G AcessoriesDocument43 pagesAluminium - Section G AcessoriestechgovindNo ratings yet

- Aerospace SEP2012Document80 pagesAerospace SEP2012maruka33No ratings yet

- Podany, J. Et Al. Paraloid B-72 As A Structural Adhesive Ans As A Barrier. 2001Document28 pagesPodany, J. Et Al. Paraloid B-72 As A Structural Adhesive Ans As A Barrier. 2001Trinidad Pasíes Arqueología-ConservaciónNo ratings yet

- F2611 1647076-1Document5 pagesF2611 1647076-1Sabu Abdul NoorNo ratings yet

- Ocean Cable Engineering Handbook Vol4 Compiled by Ian S. CooteDocument154 pagesOcean Cable Engineering Handbook Vol4 Compiled by Ian S. Cootemannydesousa52100% (1)

- Horizontal and Vertical MeasurementsDocument20 pagesHorizontal and Vertical MeasurementsPermana BadriNo ratings yet

- Self-Aligning Bearing Units NTN-SNRDocument125 pagesSelf-Aligning Bearing Units NTN-SNRDenis DavydovNo ratings yet

- Argenta: Ip66 Wall Mounting Metal CabinetsDocument18 pagesArgenta: Ip66 Wall Mounting Metal CabinetsMahmoud_EldeekNo ratings yet

- FEMA PA Pocket GuideDocument68 pagesFEMA PA Pocket GuideHerbert Paul GrayNo ratings yet

- EscalatorDocument10 pagesEscalatorsagrikakhandkaNo ratings yet

- October 2014 Line Blind ReportDocument70 pagesOctober 2014 Line Blind Reportr_chulinNo ratings yet

- Handbook H-28 (1957) Part-IDocument217 pagesHandbook H-28 (1957) Part-IPaulo Vicentin NetoNo ratings yet

- National Inventory Records Form - BlankDocument10 pagesNational Inventory Records Form - BlankAlgen S. GomezNo ratings yet

- Core Banking PDFDocument255 pagesCore Banking PDFCông BằngNo ratings yet

- 1767vol IIIDocument183 pages1767vol IIIKrishna ManandharNo ratings yet

- Business Process Reengineering: Chapter# 01 The Crisis That Will Not Go AwayDocument47 pagesBusiness Process Reengineering: Chapter# 01 The Crisis That Will Not Go AwayShaique SiddiqueNo ratings yet

- Fundamentals of SolenoidDocument9 pagesFundamentals of SolenoidArun BabuNo ratings yet

- Chapter 05Document13 pagesChapter 05irsyadiskandarNo ratings yet

- Management Information Systems and Dss Unit-Iv: Disha Technical CampusDocument17 pagesManagement Information Systems and Dss Unit-Iv: Disha Technical CampusBiplab BiswasNo ratings yet

- E Procurement A Guide To Buy Side ApplicationsDocument55 pagesE Procurement A Guide To Buy Side ApplicationsnishantvpatelNo ratings yet