Professional Documents

Culture Documents

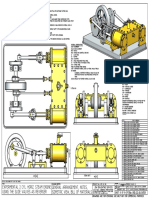

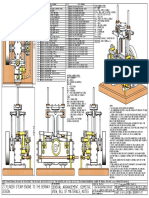

General Arrangement, Isometric Views, Notes, Bill of Materials A Simple Vertical Steam Engine BORE 24mm STROKE 24mm

Uploaded by

TIMEPASS CAPTUREOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Arrangement, Isometric Views, Notes, Bill of Materials A Simple Vertical Steam Engine BORE 24mm STROKE 24mm

Uploaded by

TIMEPASS CAPTURECopyright:

Available Formats

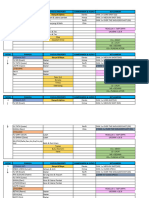

176 6.

93

OTHER ABBREVIATIONS

MATERIAL ABBREVIATIONS: DP = DEEP

ALU = ALUMINIUM DAA= DRILL AFTER

HALU= HARD ALUMINIUM ASSEMBLY

BRS = BRASS D&TAA= DRILL AND TAP

BRZ = BRONZE OR AFTER ASSEMBLY

GUNMETAL (BRZ/GM) CF = CLOSE FIT (SIZE

CI = CAST IRON FOR SIZE)

CU = COPPER PF = PRESS FIT

GRA = GRAPHITE PFAA= PRESS FIT AFTER

MS = MILD STEEL/BRIGHT ASSEMBLY

MILD STEEL PCD = PITCH CIRCLE

SS = SILVER STEEL OR DIAMETER

STAINLESS STEEL RM = REAM

SPS = SPRING STEEL HEX = HEXACON, 6SIDED

PEEK= POLYETHER ETHER CP = COMPRESSED

KETONE KNL = KNURLED

SYN = SYNTHETIC CSK = COUNTERSINK

MATERIAL SUCH AS PL = PLACES

VETON, NYLON, TEFLON OR DWL= DOWEL

RUBBER SPF= SPOTFACE

110 4.33 80 3.15 IN GENERAL (T)HESOP=(TAPPED)HOLES

SYNTHETIC EQUALLY SPACED ON

THE OFF SET ANGLE OF THE MATERIALS SOULD PCD

ECCENTRIC IN RELATION TO NOTES: BE ABLE TO (T)HESOC=(TAPPED)HOLES

THE CRANK AXIS TO BE 0. ALL DRAWINGS ARE IN METRIC MEASUREMENTS WITHSTAND THE EQUALLY SPACED ON

EXPERIMENTALLY DETERMINED 1. ALL ENGINEERING PRACTICES SHALL BE APPLIED WITH REGARDS TO HOLE HEAT AND CIRCUMFERENCE

FOR THE SMOOTH RUNNING OF AND SHAFT TOLERANCES. PRESSURE(S) OD = OUTSIDE DIAMETER

THE ENGINE AND 2. WHERE SCREWS OR BOLTS ARE USED THE CLEARANCE HOLES SHALL BE APPLIED TO THEM. ID = INSIDE DIAMETER

SATISFACTION OF THE BUILDER APPROXIMATELY 5% TO 8% LARGER THAN THE MATCHING TAPPED HOLE. nnn/nnn MEANS THAT SA-xxx = SUB

CRANK 3. PREFERABLY ALL TAPPED HOLES AND MATCHING SCREWS AND/OR BOLTS EITHER MATERIAL CAN BE ASSEMBLY-xxx

PIN TO BE METRIC FINE (MF) USED

CRANK 4. MATERIALS SPECIFIED ON THE DRAWINGS ARE INDICATIVE ONLY. THE

DISC BUILDER CAN MAKE HIS/HER OWN MATERIAL CHOICE. QTY. PART NUMBER

5. ALL CONNECTIONS/JOINTS WHICH HAVE STEAM PRESSURE APPLIED TO IT 1 09C-43-00-1-01-BED PLATE

SHALL BE SILVER/HARD SOLDERED.

6. COMPRESSION SPRINGS ARE DRAWN IN COMPRESSED STATE (CP), 2 09C-43-00-1-02-CRANK SHAFT BEARING

ECCENTRIC UNCOMPRESSED STATE IS APPROX 40% TO 60% LONGER THEN COMPRESSED 1 09C-43-00-1-03-CYLINDER+VALVE CHEST

X STATE. 1 09C-43-00-1-04-CYLINDER TOP COVER

7. WHERE PREFERRED SCREW OR RIVETED CONNECTIONS CAN BE OMITTED AND

PARTS CAN BE BONDED TOGETHER BY USING EITHER HIGH STRENGTH GLUE,

1 09C-43-00-1-05-CROSSHEAD GUIDE

EPOXY RESIN, OR SOLDER. 1 09C-43-00-2-01-CRANK SHAFT

8. PARTS WHICH ARE DIRECTLY EXPOSED TO STEAM AND/OR WATER SHOULD 1 09C-43-00-2-02-PISTON+CROSSHEAD

BE CONSTRUCTED USING NON-FERROUS OR NON CORROSIVE MATERIAL SUCH AS 1 09C-43-00-2-03-CON-ROD

BRASS, BRONZE, GUNMETAL, STAINLESS STEEL, COPPER OR MONEL. 1 09C-43-00-2-04-ECCENTRIC SHEAVE

9. THE ORDER IN WHICH THE PARTS/COMPONENTS ARE MANUFACTURED AND 1 09C-43-00-2-05-ECCENTRIC STRAP

THE MODEL IS ASSEMBLED IS ENTIRELY LEFT TO THE BUILDER/MODEL MAKER.

10. A COLOUR SCHEME FOR THIS PROJECT IS ENTIRELY LEFT UP TO THE MODEL 1 09C-43-00-2-06-SLIDE VALVE

MAKER. 6 09C-43-00-M3 NUT

11. THE MANNER IN WHICH THE PARTS/COMPONENTS ARE MANUFACTURED IS 5 09C-43-00-M3 WASHER-BRASS

ENTIRELY LEFT UP TO THE BUILDER. 2 09C-43-00-M3x3 A-K GRUB SCREW

12. USE LOCTITE, ON SCREW OR PRESS FIT CONNECTIONS OR SURFACES, WERE

DEEMED NECESSARY TO PREVENT PARTS FROM LOOSENING. 5 09C-43-00-M3x6 A-K CYL HEAD SCREW

13. WASHERS AND/OR SPRINGWASHERS SHALL BE USED WHERE DEEMED 12 09C-43-00-M4x10 A-K CYL HEAD SCREW

NECESSARY. 4 09C-43-00-M4x16 A-K CYL HEAD SCREW

XX. ERRORS AND/OR OMISSIONS MAY OCCUR IN THE DRAWINGS, DO NOT 4 09C-43-00-M4x24 A-K CYL HEAD SCREW

HESITATE TO CONTACT ME SO THAT THE ERRORS/OMISSIONS CAN BE

RECTIFIED. 5 09C-43-00-M5 DOME NUT

6 09C-43-00-M5 NUT

NOTES: THIS DESIGN IS BASED ON DRAWINGS WHICH WERE GIVEN TO ME. THE ORIGINAL DESIGN AND DRAWINGS WERE BY RAYMOND YATES. MAGAZINE AND DATES UNKOWN (FIG. 103, FIG. 104A & FIG. 104)

TITLE DRAWING CONTENTS PROJECT No 09C-43-00 PROJECTION

MODEL SCALE: 1:1

JDWDS

A SIMPLE VERTICAL STEAM ENGINE GENERAL ARRANGEMENT, ISOMETRIC JDW DRAUGHTING SERVICES

J.A.M. DE WAAL. 12 BRIGHTWELL STREET PAPAKURA

DATE

NOVEMBER 2019

DWG SCALE: 1:1 @A3 OR AS SHOWN

J.A.M. DE WAAL PAPAKURA NZ

Copyright ©

BORE=24mm STROKE=24mm VIEWS, NOTES, BILL OF MATERIALS SHEET: 01 OF 03 A3 No: 09C-43-00-SHT01

2110. NEW ZEALAND. PHONE: OO64 09 2988815. MOB:

0211791000 E-MAIL: dewaal@xtra.co.nz.

DRAWINGS ARE FOR PERSONAL USE ONLY NOT FOR COMMERCIAL PURPOSES

You might also like

- Structural General NotesDocument1 pageStructural General Notesjuan camiloNo ratings yet

- Lamellar Graphite Cast Irons FGL 175HB - FGL 215HB - FGL 240HB Technical SpecificationsDocument4 pagesLamellar Graphite Cast Irons FGL 175HB - FGL 215HB - FGL 240HB Technical Specificationsyusuf tolga öksüz100% (1)

- 09D 22 00 A3 Sheet 01Document1 page09D 22 00 A3 Sheet 01RobsNo ratings yet

- 09B 28 00 A3 Sheet 01Document1 page09B 28 00 A3 Sheet 01Abdul MannanNo ratings yet

- Muncaster 11 A3 Sheet 02Document1 pageMuncaster 11 A3 Sheet 02Juan PastorNo ratings yet

- C-01-PS8-1 - REINF-ModelDocument1 pageC-01-PS8-1 - REINF-ModelErection DepartmentNo ratings yet

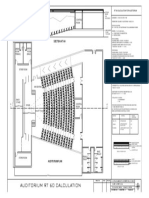

- Auditorium RT60 CalculationDocument1 pageAuditorium RT60 CalculationAniket WayalNo ratings yet

- Pole InformationDocument2 pagesPole InformationEliasNo ratings yet

- 01.12. Single Line DiagramDocument1 page01.12. Single Line DiagramreinaldiekaNo ratings yet

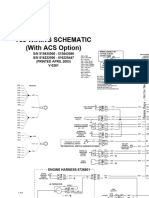

- Wiring Schematic (Without ACS Option)Document6 pagesWiring Schematic (Without ACS Option)alexandrNo ratings yet

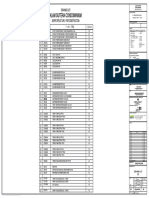

- Drawing List (II) : Alam Sutera CondominiumDocument1 pageDrawing List (II) : Alam Sutera CondominiumDenyNo ratings yet

- Drawing List (I) : Alam Sutera CondominiumDocument1 pageDrawing List (I) : Alam Sutera CondominiumDenyNo ratings yet

- Drawing List (III) : Alam Sutera CondominiumDocument1 pageDrawing List (III) : Alam Sutera CondominiumDenyNo ratings yet

- Drawing List (II) : Alam Sutera CondominiumDocument1 pageDrawing List (II) : Alam Sutera CondominiumDenyNo ratings yet

- Filter Berms Detail For Spacing BetweenDocument1 pageFilter Berms Detail For Spacing Betweenshafiullah NaseriNo ratings yet

- Drawing List (II) : Alam Sutera CondominiumDocument1 pageDrawing List (II) : Alam Sutera CondominiumDenyNo ratings yet

- Drawing List (I) : Alam Sutera CondominiumDocument1 pageDrawing List (I) : Alam Sutera CondominiumDenyNo ratings yet

- 864 Wiring Schematic: S/N 518913001-14999 S/N 516812001-14999 S/N 517512001-14999 (Printed March 2001) V-0072Document6 pages864 Wiring Schematic: S/N 518913001-14999 S/N 516812001-14999 S/N 517512001-14999 (Printed March 2001) V-0072Ataa AssaadNo ratings yet

- ETUDE DE DEDOUBLEMENT RN88 LOT 01-02 SUR 14 KM (1) - ObjetDocument1 pageETUDE DE DEDOUBLEMENT RN88 LOT 01-02 SUR 14 KM (1) - ObjetOussama AggounNo ratings yet

- 753 Wiring Schematic (With ACS Option) : S/N 515835000 - 515843086 S/N 516222000 - 516225447 (Printed April 2003) V-0261Document6 pages753 Wiring Schematic (With ACS Option) : S/N 515835000 - 515843086 S/N 516222000 - 516225447 (Printed April 2003) V-0261Iliyan VasilevNo ratings yet

- Adhea Ppktugasweek5 PDocument1 pageAdhea Ppktugasweek5 PAdhea SeftiNo ratings yet

- Chute Drain - R0Document4 pagesChute Drain - R0Manish PandeyNo ratings yet

- ConnectingsDocument5 pagesConnectingsPhillipos 19No ratings yet

- Al-Arifi Villas: Structural Drawings List (VILLA 1 & 2)Document26 pagesAl-Arifi Villas: Structural Drawings List (VILLA 1 & 2)LeMasters ArabiaNo ratings yet

- Ramp Plan: Alam Sutera CondominiumDocument1 pageRamp Plan: Alam Sutera Condominiumicih carilineNo ratings yet

- Ideal Home For Steel Fabrication: NotesDocument9 pagesIdeal Home For Steel Fabrication: Notesomar mahmoudNo ratings yet

- 01 Vestido de Noiva Tomara Que Caia MoldesDocument1 page01 Vestido de Noiva Tomara Que Caia MoldesAna CristinaNo ratings yet

- Kualat Exe Rev2Document6 pagesKualat Exe Rev2acasasasalsabila9024No ratings yet

- Wiring Schematic: 331 (S/N 232511001 AND ABOVE) (S/N 232711001 AND ABOVE) 334 (S/N 232611001 AND ABOVE)Document6 pagesWiring Schematic: 331 (S/N 232511001 AND ABOVE) (S/N 232711001 AND ABOVE) 334 (S/N 232611001 AND ABOVE)Willyas AsNo ratings yet

- Seleccion de Partes CumminsDocument2 pagesSeleccion de Partes CumminsSenterver Equipos IndustrialesNo ratings yet

- Opening Systems For Flap and Drop Down DoorsDocument24 pagesOpening Systems For Flap and Drop Down DoorsPedro Alexander Alfonso AceroNo ratings yet

- Site Plan Terminal Terpadu Kabupaten Pidie: Dinas Perhubungan Pemerintah Provinsi AcehDocument1 pageSite Plan Terminal Terpadu Kabupaten Pidie: Dinas Perhubungan Pemerintah Provinsi AcehZaeri TahriziNo ratings yet

- Checklist Patrol Crusher, Storage&proportionDocument10 pagesChecklist Patrol Crusher, Storage&proportionNova HeriNo ratings yet

- Albay - 3ar3 - Es2 SWDocument1 pageAlbay - 3ar3 - Es2 SWninayra.albay.archiNo ratings yet

- Foundation Formulas PDFDocument12 pagesFoundation Formulas PDFsayma saraNo ratings yet

- Wiring Schematic: 335 (S/N A16U11001 AND ABOVE)Document6 pagesWiring Schematic: 335 (S/N A16U11001 AND ABOVE)Willyas AsNo ratings yet

- Drawing Weak Acid CoolerDocument1 pageDrawing Weak Acid CoolerbetojulioNo ratings yet

- Auditorium RT60 CalculationDocument1 pageAuditorium RT60 CalculationAniket WayalNo ratings yet

- As Built Plan: General NotesDocument1 pageAs Built Plan: General NotesBryll Jude Calaor MartinezNo ratings yet

- REKLAMASI 2018 NGS-ModelDocument1 pageREKLAMASI 2018 NGS-ModelAn IkhrandiNo ratings yet

- 1chseaw JDW CompletDocument4 pages1chseaw JDW CompletJesús Los ArcosNo ratings yet

- 1chseaw JDW Complet PDFDocument4 pages1chseaw JDW Complet PDFOrlando Rojas PintoNo ratings yet

- With Slide Valve 1 Cylinder Horizontal Steam Engine and Notes General ArrangementDocument4 pagesWith Slide Valve 1 Cylinder Horizontal Steam Engine and Notes General ArrangementJose Rafael Ramos ChiquilloNo ratings yet

- New Roof DesignDocument1 pageNew Roof DesignsandaNo ratings yet

- Drawing Grating 25mmDocument1 pageDrawing Grating 25mmEko Wahyu QrakerNo ratings yet

- Potongan JembatanDocument1 pagePotongan JembatanputuwidyatnaNo ratings yet

- Drilling Jigs Italiana FerramentaDocument34 pagesDrilling Jigs Italiana FerramentaOliver Augusto Fuentes LópezNo ratings yet

- Kraby System 2018Document22 pagesKraby System 2018soga010178No ratings yet

- Proiect Arhitectura Nr. 4 - Anul V Plan Parter: Zona BazineDocument1 pageProiect Arhitectura Nr. 4 - Anul V Plan Parter: Zona BazineAlexandra PopescuNo ratings yet

- Site Plan For The Proposed Residential Building in Rs No: 601/1 Ward No: 10 at Munduparamba of Malappuram MunicipalityDocument1 pageSite Plan For The Proposed Residential Building in Rs No: 601/1 Ward No: 10 at Munduparamba of Malappuram MunicipalityhaneefachgmailNo ratings yet

- Machine DesignDocument39 pagesMachine DesignJp G PeterosNo ratings yet

- Full Borehole Analysis and Soil ReplacementDocument1 pageFull Borehole Analysis and Soil ReplacementAfuye Oluyemi IbiyinkaNo ratings yet

- 46 Income Tax Calculator For Fy 2009 10 FinalDocument16 pages46 Income Tax Calculator For Fy 2009 10 Finalmysteryia007No ratings yet

- Detail A: STEEL BEAM (300x150x6.5x9)Document1 pageDetail A: STEEL BEAM (300x150x6.5x9)Aaris AdeNo ratings yet

- Osce RadiologiDocument3 pagesOsce RadiologiNadiyah SalsabilaNo ratings yet

- SCHUDULESDocument1 pageSCHUDULESAya Mahmoud ShedeedNo ratings yet

- Me 2Document1 pageMe 2Yusril HadiNo ratings yet

- Saeed Ahmad S/O Chiragh Din Plot No.39 Street No.3 Block-H Fazaia SchemeDocument1 pageSaeed Ahmad S/O Chiragh Din Plot No.39 Street No.3 Block-H Fazaia SchemeHelloNo ratings yet

- Plan Parter Propunere sc.1/100Document1 pagePlan Parter Propunere sc.1/100Moldovan Adrian NeluNo ratings yet

- MombasaSEZ - General - Plan-01 Dec 2021 - Temporary Yards-ModelDocument1 pageMombasaSEZ - General - Plan-01 Dec 2021 - Temporary Yards-Modelkandy saidNo ratings yet

- Advertisement Temporary PositionDocument3 pagesAdvertisement Temporary PositionTIMEPASS CAPTURENo ratings yet

- Design. 2 Cylinder Steam Engine To The Bernay View, Bill of Materials, Notes General Arrangement, IsometricDocument1 pageDesign. 2 Cylinder Steam Engine To The Bernay View, Bill of Materials, Notes General Arrangement, IsometricTIMEPASS CAPTURENo ratings yet

- Harish Vinayak Kuber: Glenmark Pharmaceuticals LTDDocument281 pagesHarish Vinayak Kuber: Glenmark Pharmaceuticals LTDTIMEPASS CAPTURENo ratings yet

- Dr. Adil Usman: Academic Qualification (Undergraduate Degree Onwards)Document16 pagesDr. Adil Usman: Academic Qualification (Undergraduate Degree Onwards)TIMEPASS CAPTURENo ratings yet

- Case Studies in Thermal EngineeringDocument17 pagesCase Studies in Thermal EngineeringTIMEPASS CAPTURENo ratings yet

- Kulkarni: BSE Listing PDocument1 pageKulkarni: BSE Listing PTIMEPASS CAPTURENo ratings yet

- Parts and Assemblies Direct Connected Engine (B 24Mm S 72Mm) An Experimental 2 Cylinder V-ShapedDocument1 pageParts and Assemblies Direct Connected Engine (B 24Mm S 72Mm) An Experimental 2 Cylinder V-ShapedTIMEPASS CAPTURENo ratings yet

- Parts and Assemblies A Simple Vertical Steam Engine BORE 24mm STROKE 24mmDocument1 pageParts and Assemblies A Simple Vertical Steam Engine BORE 24mm STROKE 24mmTIMEPASS CAPTURENo ratings yet

- ISO 9606-3 1999 Qualification Testing of Welders-Fusion Welding Part 3 Copper and Copper AlloysDocument30 pagesISO 9606-3 1999 Qualification Testing of Welders-Fusion Welding Part 3 Copper and Copper AlloysJames HurtadoNo ratings yet

- C3D1 - 1.1187 - SteelNumber - Chemical Composition, Equivalent, PropertiesDocument1 pageC3D1 - 1.1187 - SteelNumber - Chemical Composition, Equivalent, PropertiesSergiNo ratings yet

- Heat Treatment 7Document12 pagesHeat Treatment 7watersoul.nNo ratings yet

- TaegutecDocument52 pagesTaegutecErik MorenoNo ratings yet

- Comparison - SPEROTTO Vs COMPETITORSDocument4 pagesComparison - SPEROTTO Vs COMPETITORSFrancisco J. Arias M.No ratings yet

- What Is Term Applied To The Process of Separating Different Sizes of The Same Material? A. Screening D. FilteringDocument99 pagesWhat Is Term Applied To The Process of Separating Different Sizes of The Same Material? A. Screening D. FilteringJom BautistaNo ratings yet

- Galvanic Corrossion: by B. Anvitha Reddy 20951A0109 Civil EngineeringDocument11 pagesGalvanic Corrossion: by B. Anvitha Reddy 20951A0109 Civil EngineeringTarunNo ratings yet

- 331 Heat Treatment: ASME B31.3-2012Document4 pages331 Heat Treatment: ASME B31.3-2012Stephen RajNo ratings yet

- MDSP Ultimate Compliation Part 1Document139 pagesMDSP Ultimate Compliation Part 1Marc Citcian GatinaoNo ratings yet

- Soldering, Brazing & WeldingDocument52 pagesSoldering, Brazing & WeldingChandrakantha K100% (1)

- Year 7 MetalsDocument7 pagesYear 7 MetalsMissparish8No ratings yet

- Abrasive Wear Behavior of Austempered Ductile Iron With Niobium AdditionsDocument8 pagesAbrasive Wear Behavior of Austempered Ductile Iron With Niobium AdditionsEverton CostaNo ratings yet

- Me Law ReportDocument19 pagesMe Law ReportChristian Angelo AndoyNo ratings yet

- SS 316Document3 pagesSS 316Deepak SinghNo ratings yet

- Metallurgy, Corrosion, CP SystemDocument37 pagesMetallurgy, Corrosion, CP Systemsatish04No ratings yet

- Vertical Direct Chill Casting of Magnesium Alloys - Especially For Extrusion BilletDocument8 pagesVertical Direct Chill Casting of Magnesium Alloys - Especially For Extrusion Billetpedro 1No ratings yet

- Sae 1022Document1 pageSae 1022talebimahdi924No ratings yet

- Mil DTL 14072FDocument64 pagesMil DTL 14072FJader PetrucciNo ratings yet

- Velan Forged Steel ValvesDocument43 pagesVelan Forged Steel Valvesjacquesstrappe06No ratings yet

- Elements Pics 11x8.5Document1 pageElements Pics 11x8.5Ana Sophya Camelo RochaNo ratings yet

- The Influence of Microalloying With Boron On Properties of Austenite Stainless Steel X8crnis18-9Document6 pagesThe Influence of Microalloying With Boron On Properties of Austenite Stainless Steel X8crnis18-9IJAR JOURNALNo ratings yet

- Sm-309Lmo: Special Metal Korea Co., LTDDocument1 pageSm-309Lmo: Special Metal Korea Co., LTDWelli E SNo ratings yet

- FSW-Tech Handbook For Specialists and Engineers - enDocument172 pagesFSW-Tech Handbook For Specialists and Engineers - enkamal touilebNo ratings yet

- KP THMA Fe-Al-Ni-Co-CuDocument4 pagesKP THMA Fe-Al-Ni-Co-CuCésar GNo ratings yet

- AnnealingDocument9 pagesAnnealingRathne AbeynayakeNo ratings yet

- Time Temperature Transformation With ReferncesDocument12 pagesTime Temperature Transformation With ReferncesEllie BrooklynNo ratings yet

- Steel Making Using Open Hearth Furnace-1Document9 pagesSteel Making Using Open Hearth Furnace-1victorymusa45No ratings yet

- Acta Technica Corviniensis: - Bulletin of EngineeringDocument7 pagesActa Technica Corviniensis: - Bulletin of EngineeringCHONKARN CHIABLAMNo ratings yet

- Corrugated Galvanised Iron (Cgi) Specifications For RoofingDocument2 pagesCorrugated Galvanised Iron (Cgi) Specifications For RoofingYeshaswee VaidayNo ratings yet