Professional Documents

Culture Documents

Design. 2 Cylinder Steam Engine To The Bernay View, Bill of Materials, Notes General Arrangement, Isometric

Uploaded by

TIMEPASS CAPTUREOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design. 2 Cylinder Steam Engine To The Bernay View, Bill of Materials, Notes General Arrangement, Isometric

Uploaded by

TIMEPASS CAPTURECopyright:

Available Formats

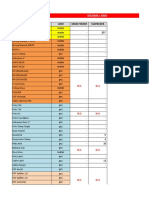

QTY. PART NUMBER QTY.

PART NUMBER

1 BERNAY-01-WOOD BASE 1 BERNAY-36-CROSSHEAD PIN OTHER ABBREVIATIONS

2 BERNAY-02-CYLINDER BLOCK SUPPORT FOOT 2 BERNAY-37-CONNECTING ROD SHAFT DP = DEEP

1 BERNAY-03-CYLINDER BLOCK 2 BERNAY-38-CONNECTING ROD DAA= DRILL AFTER ASSEMBLY

2 BERNAY-04-CRANK SHAFT BEARING 4 BERNAY-39-PISTON ROD SLIDER D&TAA= DRILL AND TAP AFTER ASSEMBLY

1 BERNAY-05-CYL. BEARING TOP BLOCK 1 BERNAY-40-ECCENTRIC STRAP CF = CLOSE FIT (SIZE FOR SIZE)

2 BERNAY-06-EXHAUST PIPE CONNECTOR 2 BERNAY-41-SLIDE VALVE PF = PRESS FIT

4 BERNAY-07-CYLINDER BLOCK GASKET 2 BERNAY-42-SLIDE VALVE ROD PFAA= PRESS FIT AFTER ASSEMBLY

2 BERNAY-08-CYLINDER LOWER COVER 4 BERNAY-43-VALVE ROD RETAINER BUSH PCD = PITCH CIRCLE DIAMETER

2 BERNAY-09-CYLINDER UPPER COVER 2 BERNAY-44-VALVE GEAR LINK #1 RM = REAM

2 BERNAY-10-PISTON ROD GLAND NUT 2 BERNAY-45-VALVE GEAR LINK #2 HEX = HEXACON, 6SIDED

1 BERNAY-11-CROSSHEAD GUIDE 1 BERNAY-46-VALVE GEAR LINK #3 CP = COMPRESSED

1 BERNAY-12-PISTON ROD GUIDE PLATE 1 BERNAY-47-VALVE GEAR LINK #4 KNL = KNURLED

2 BERNAY-13-PISTON ROD GUIDE BUSH 1 BERNAY-48-VALVE GEAR LINK #5 CSK = COUNTERSINK

2 BERNAY-14-STEAM CHEST 5 BERNAY-49-RETAINER RING PL = PLACES

2 BERNAY-15-SLIDE VALVE PORT PLATE 4 BERNAY-M2.5x3 A-K GRUB SCREW DWL= DOWEL

4 BERNAY-16-STEAM CHEST GASKET 16 BERNAY-M3 DOME NUT HESOP=HOLES EQUALLY SPACED ON PCD

2 BERNAY-17-STEAM CHEST COVER 4 BERNAY-M3x6 A-K GRUB SCREW SA-n-xxx = SUB ASSEMBL-n-xxx

237.5 9.35

2 BERNAY-18-INLET PIPE NIPPLE 16 BERNAY-M3x44 THREADED ROD

2 BERNAY-19-VALVE ROD GLAND NUT 8 BERNAY-M4 DOME NUT

1 BERNAY-20-RH-ROCKER ARM SUPPORT BRACKET 5 BERNAY-M4x13 A-K CYL HEAD SCREW

1 BERNAY-21-LH-ROCKER ARM SUPPORT BRACKET 20 BERNAY-M4x15 A-K CYL HEAD SCREW

2 BERNAY-22-STEAM INLET PIPE-1 5 BERNAY-M4x20 A-K CYL HEAD SCREW

1 BERNAY-23-STEAM INLET PIPE-2 4 BERNAY-M4x28 A-K CYL HEAD SCREW

1 BERNAY-24-STEAM INLET T-CONNECTOR 2 BERNAY-M5 DOME NUT

5 BERNAY-25-M8x6 PIPE NUT 2 BERNAY-M5 NUT

2 BERNAY-26-CRANK SHAFT END 8 BERNAY-M6 NUT

1 BERNAY-27-CRANK SHAFT CENTER 4 BERNAY-M6 WASHER

2 BERNAY-28-CRANK SHAFT PIN 4 BERNAY-M6x10 A-K CYL HEAD SCREW

4 BERNAY-29-CRANK SHAFT WEB 4 BERNAY-M6x24 A-K CYL HEAD SCREW

1 BERNAY-30-FLYWHEEL

1 BERNAY-31-ECCENTRIC SHEAVE

1 BERNAY-32-ECCENTRIC SHEAVE COVER

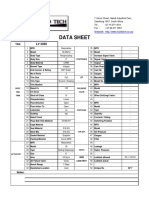

2 BERNAY-33-PISTON MATERIAL ABBREVIATIONS:

2 BERNAY-34-PISTON ROD ALU = ALUMINIUM

1 BERNAY-35-CROSSHEAD BRS = BRASS

BRZ = BRONZE OR GUNMETAL

170 6.69 (BRZ/GM)

CI = CAST IRON

CU = COPPER

GRA = GRAPHITE

MS = MILD STEEL/BRIGHT MILD STEEL

S/S = SILVER STEEL OR STAINLESS

STEEL

SPS = SPRING STEEL

PEEK= POLYETHER ETHER KETONE

SYN = SYNTHETIC MATERIAL SUCH AS

VETON, NYLON, TEFLON OR RUBBER NOTES:

IN GENERAL SYNTHETIC 0. ALL DRAWINGS ARE IN METRIC MEASUREMENTS

MATERIALS SOULD BE ABLE TO 1. ALL ENGINEERING PRACTICES SHALL BE APPLIED WITH REGARDS TO HOLE

WITHSTAND THE HEAT AND AND SHAFT TOLERANCES.

PRESSURE(S) APPLIED TO 2. WHERE SCREWS OR BOLTS ARE USED THE CLEARANCE HOLES SHALL BE

THEM. APPROXIMATELY 5% TO 8% LARGER THAN THE MATCHING TAPPED HOLE.

nnn/nnn MEANS THAT EITHER 3. PREFERABLY ALL TAPPED HOLES AND MATCHING SCREWS AND/OR

MATERIAL CAN BE USED BOLTS TO BE METRIC FINE (MF)

4. MATERIALS SPECIFIED ON THE DRAWINGS ARE INDICATIVE ONLY. THE

BUILDER CAN MAKE HIS/HER OWN MATERIAL CHOICE.

5. ALL CONNECTIONS/JOINTS WHICH HAVE STEAM PRESSURE APPLIED TO IT

263 10.35

SHALL BE SILVER/HARD SOLDERED.

6. COMPRESSION SPRINGS ARE DRAWN IN COMPRESSED STATE (CP),

UNCOMPRESSED STATE IS APPROX 40% TO 60% LONGER THEN

COMPRESSED STATE.

7. WHERE PREFERRED SCREW OR RIVETED CONNECTIONS CAN BE OMITTED

AND PARTS CAN BE BONDED TOGETHER BY USING EITHER HIGH STRENGTH

GLUE, EPOXY RESIN, OR SOLDER.

8. PARTS WHICH ARE DIRECTLY EXPOSED TO STEAM AND/OR WATER

SHOULD BE CONSTRUCTED USING NON-FERROUS OR NON CORROSIVE

MATERIAL SUCH AS BRASS, BRONZE, GUNMETAL, STAINLESS STEEL,

COPPER OR MONEL.

9. THE ORDER IN WHICH THE PARTS/COMPONENTS ARE MANUFACTURED

AND THE MODEL IS ASSEMBLED IS ENTIRELY LEFT TO THE BUILDER/MODEL

MAKER.

10. A COLOUR SCHEME FOR THIS PROJECT IS ENTIRELY LEFT UP TO THE

MODEL MAKER.

11. THE MANNER IN WHICH THE PARTS/COMPONENTS ARE MANUFACTURED

IS ENTIRELY LEFT UP TO THE BUILDER.

12. USE LOCTITE, ON SCREW OR PRESS FIT CONNECTIONS OR SURFACES,

WERE DEEMED NECESSARY TO PREVENT PARTS FROM LOOSENING.

XX. ERRORS AND/OR OMISSIONS MAY OCCUR IN THE DRAWINGS, DO NOT

HESITATE TO CONTACT ME SO THAT THE ERRORS/OMISSIONS CAN BE

RECTIFIED.

NOTES: FOUND ORIGINAL DRAWINGS ON THE INTERNET. THE DRAWINGS WERE DATED 30-07-2012. THE INPRINTED LOGO WAS CSEE (CLASSIC STEAM ENGINE ENGINEERING). NUMBER OF ORIGINAL DRAWINGS 44xA4 (ORIGINATOR UNKNOWN)

TITLE DRAWING CONTENTS PROJECT No 09E-19-00 PROJECTION

MODEL SCALE: 1:1

2 CYLINDER STEAM ENGINE TO THE BERNAY GENERAL ARRANGEMENT, ISOMETRIC JDW DRAUGHTING SERVICES DATE

JDWDS DWG SCALE: NTS @A3 OR AS SHOWN

J.A.M. DE WAAL. 12 BRIGHTWELL STREET PAPAKURA 2110. JULY-2016 J.A.M. DE WAAL PAPAKURA NZ

Copyright ©

DESIGN. VIEW, BILL OF MATERIALS, NOTES NEW ZEALAND. PHONE: OO64 09 2988815. MOB: 0211791000

E-MAIL: dewaal@xtra.co.nz. SHEET: 01 OF 04 A3 No: BERNAY-01

You might also like

- Steering Column Switch WiringDocument27 pagesSteering Column Switch WiringMM100% (3)

- EnardoDocument2 pagesEnardoDwi April YantoNo ratings yet

- SG Iron GradesDocument2 pagesSG Iron GradesSagarKBL100% (1)

- 2 Cylinder Steam Engine To The Bernay DesignDocument4 pages2 Cylinder Steam Engine To The Bernay DesignAxel Dominique100% (1)

- Hand Pump Service ManualDocument12 pagesHand Pump Service Manualblue wolfNo ratings yet

- Base de Product para Analizar en Power BiDocument52 pagesBase de Product para Analizar en Power BiebelnaisNo ratings yet

- Powertec wb-ft11Document12 pagesPowertec wb-ft11carlosNo ratings yet

- MRF 4547-23Document5 pagesMRF 4547-23Azmi MuhammadNo ratings yet

- 4 Cylindres Oscillant en Ligne PDFDocument3 pages4 Cylindres Oscillant en Ligne PDFJose Guadalupe AntonioNo ratings yet

- Pri IndexDocument2 pagesPri IndexKoppisetti KrishnaNo ratings yet

- Guadaña A Gasolina 43 CC Eje Rígido / Giratorio: Parte: ModeloDocument6 pagesGuadaña A Gasolina 43 CC Eje Rígido / Giratorio: Parte: ModelojuanglealpNo ratings yet

- Npgqa2 PDocument8 pagesNpgqa2 PleighNo ratings yet

- AXIS Catalogue 2018Document49 pagesAXIS Catalogue 2018Tran Quoc Thinh - M&ENo ratings yet

- ABA DS Catalogue enDocument68 pagesABA DS Catalogue enReza PramataNo ratings yet

- Spalding Fasteners Product CatalogueDocument95 pagesSpalding Fasteners Product CatalogueMarco NiNo ratings yet

- AXIS INDIA Earthing-and-Lightning-Protection-SystemDocument68 pagesAXIS INDIA Earthing-and-Lightning-Protection-Systemaminchhipa6892No ratings yet

- Mechanical Valves & Flexible Joints: Leading The Way in Piping NeedsDocument40 pagesMechanical Valves & Flexible Joints: Leading The Way in Piping NeedsTanveer AzizNo ratings yet

- EARTHING and LightningDocument68 pagesEARTHING and LightningAshish SutharNo ratings yet

- Catalog - Fastener Stainless 2011Document88 pagesCatalog - Fastener Stainless 2011Kenichi Domingo FanerNo ratings yet

- GRAFIK REPAIR 2x BOLAK BALIK JAN 2023Document4 pagesGRAFIK REPAIR 2x BOLAK BALIK JAN 2023Shaka ManiaNo ratings yet

- Contents PDFDocument5 pagesContents PDFDon BraithwaiteNo ratings yet

- Packing Plant Coupling Details: SL - No Equiment I/P Coupling O/P CouplingDocument3 pagesPacking Plant Coupling Details: SL - No Equiment I/P Coupling O/P Couplingsaravana kumarNo ratings yet

- Hy Hybc5210pro Despiece Es enDocument6 pagesHy Hybc5210pro Despiece Es enJuan ArdevolNo ratings yet

- Clamps Brochure r8 FINALDocument48 pagesClamps Brochure r8 FINALmasmunirNo ratings yet

- Din No With DrawingDocument9 pagesDin No With DrawingdurgeshwardNo ratings yet

- Speck Pump Installation and Maintenance InstructionsDocument3 pagesSpeck Pump Installation and Maintenance InstructionsSergei Kurpish0% (1)

- Ruger Rifle Parts ListDocument2 pagesRuger Rifle Parts ListPeter DavidsonNo ratings yet

- List Aset Banjir & CollapseDocument3 pagesList Aset Banjir & CollapseJosue JohnNo ratings yet

- ALKESS2Document1 pageALKESS2psychoengine6No ratings yet

- Inventory Spare Part Tb. TP2Document14 pagesInventory Spare Part Tb. TP2Rohmananda ValdaNo ratings yet

- SP - JB B340 - 17-01 - H - Teewb581a3Document48 pagesSP - JB B340 - 17-01 - H - Teewb581a3gatodarkNo ratings yet

- 1405 FastenersDocument77 pages1405 Fastenerskaniappan sakthivelNo ratings yet

- Trade Price List: September 2016Document28 pagesTrade Price List: September 2016Jhon SanfraNo ratings yet

- Earthing and Lightning Pr.9500335.PowerpointDocument24 pagesEarthing and Lightning Pr.9500335.PowerpointHimal SaubhagyaNo ratings yet

- Documentatie Tehnica Masina de Tuns Gazon RX20Document9 pagesDocumentatie Tehnica Masina de Tuns Gazon RX20Ionuț CojocariuNo ratings yet

- Selective Basic Ball Lock: Catalog 4000Document36 pagesSelective Basic Ball Lock: Catalog 4000tony nixNo ratings yet

- CLR07-02-000 - Sondakan RW 15 - MatrixDocument10 pagesCLR07-02-000 - Sondakan RW 15 - MatrixilhamNo ratings yet

- Vista B-B: Bocina de Piston SUP Material 1020 Cant X Tolva 2 PZDocument1 pageVista B-B: Bocina de Piston SUP Material 1020 Cant X Tolva 2 PZCristo PatricioNo ratings yet

- Daftar Kalkulasi Pipa Penstock, Bifurcation, Dan Pintu AirDocument1 pageDaftar Kalkulasi Pipa Penstock, Bifurcation, Dan Pintu Airyoyok isbanuNo ratings yet

- Atlas Steel Product-Catalogue-2017Document36 pagesAtlas Steel Product-Catalogue-2017Eshan Alawala100% (1)

- Inq. 4502Document27 pagesInq. 4502srave_k07No ratings yet

- PCB Manufacturing Table 1Document1 pagePCB Manufacturing Table 1Solomon AndreiNo ratings yet

- Norma JIC 37Document36 pagesNorma JIC 37guguimirandaNo ratings yet

- Area of Sand Blasting-1Document32 pagesArea of Sand Blasting-1MUHAMMAD WARIS SQNo ratings yet

- Detroit Diesel Parst ListDocument1 pageDetroit Diesel Parst ListMd chotuNo ratings yet

- A9-1&2 SL03,04-Street Lighting Feeder Pillar Detail-A9-1Document1 pageA9-1&2 SL03,04-Street Lighting Feeder Pillar Detail-A9-1amirul aizadNo ratings yet

- Rancangan Anggaran Belanja Electrical Power KAIKODocument21 pagesRancangan Anggaran Belanja Electrical Power KAIKOade barunaNo ratings yet

- ABA DS Catalogue enDocument68 pagesABA DS Catalogue enTan JaiNo ratings yet

- PAC Metal Roofing Wall and Trim Catalog 2023Document48 pagesPAC Metal Roofing Wall and Trim Catalog 2023THIS IS AWESOMENo ratings yet

- Simple Connection: B1 W10X26 (H-262x147x6.6x11.2) G1 W14X53 (H-354x205x9.4x16.8) G2 W16X40 (H-407x178x7.7x12.8)Document5 pagesSimple Connection: B1 W10X26 (H-262x147x6.6x11.2) G1 W14X53 (H-354x205x9.4x16.8) G2 W16X40 (H-407x178x7.7x12.8)Bißék ŚílwàlNo ratings yet

- Welcome Concert 2022Document7 pagesWelcome Concert 2022Kevin MaulanaNo ratings yet

- 1998 Sec 6-6.5L Engine MechanicalDocument192 pages1998 Sec 6-6.5L Engine MechanicalLuis TomboNo ratings yet

- HP227 Spare Parts Sheet PDF313201603810Document1 pageHP227 Spare Parts Sheet PDF313201603810Pedro SanchezNo ratings yet

- KI-191-1 (14V), KI-191-2 (28V) R44-Series HID Landing Lights Installation Kit InstructionsDocument8 pagesKI-191-1 (14V), KI-191-2 (28V) R44-Series HID Landing Lights Installation Kit Instructionsoscar cuevaNo ratings yet

- Grid Station Maintenance T&P LIST IN RESPECT OF AM (S) Circle NTDC Jamshoro Quantity RequiredDocument3 pagesGrid Station Maintenance T&P LIST IN RESPECT OF AM (S) Circle NTDC Jamshoro Quantity RequiredDeputy ManagerNo ratings yet

- Irrigation Catalogue 2024Document93 pagesIrrigation Catalogue 2024yafoor04No ratings yet

- Data Sheet: Website: HTTP://WWW - Fluidtech.co - ZaDocument1 pageData Sheet: Website: HTTP://WWW - Fluidtech.co - ZamohamedNo ratings yet

- Racoreria Manghidraulica BosadoDocument59 pagesRacoreria Manghidraulica BosadoOdicoNo ratings yet

- Advertisement Temporary PositionDocument3 pagesAdvertisement Temporary PositionTIMEPASS CAPTURENo ratings yet

- Harish Vinayak Kuber: Glenmark Pharmaceuticals LTDDocument281 pagesHarish Vinayak Kuber: Glenmark Pharmaceuticals LTDTIMEPASS CAPTURENo ratings yet

- Dr. Adil Usman: Academic Qualification (Undergraduate Degree Onwards)Document16 pagesDr. Adil Usman: Academic Qualification (Undergraduate Degree Onwards)TIMEPASS CAPTURENo ratings yet

- Parts and Assemblies Direct Connected Engine (B 24Mm S 72Mm) An Experimental 2 Cylinder V-ShapedDocument1 pageParts and Assemblies Direct Connected Engine (B 24Mm S 72Mm) An Experimental 2 Cylinder V-ShapedTIMEPASS CAPTURENo ratings yet

- General Arrangement, Isometric Views, Notes, Bill of Materials A Simple Vertical Steam Engine BORE 24mm STROKE 24mmDocument1 pageGeneral Arrangement, Isometric Views, Notes, Bill of Materials A Simple Vertical Steam Engine BORE 24mm STROKE 24mmTIMEPASS CAPTURENo ratings yet

- Technical Volume I I Go FiiDocument375 pagesTechnical Volume I I Go FiiRanjan KumarNo ratings yet

- Keyhole Gtaw & Other Gtaw VariantsDocument2 pagesKeyhole Gtaw & Other Gtaw VariantsThiago Ribeiro da SilvaNo ratings yet

- Innovative In-Situ Repair of A High Temperature Steam Super Heater CoilDocument13 pagesInnovative In-Situ Repair of A High Temperature Steam Super Heater Coilvaratharajan g r100% (1)

- Facial Mirror With Plywood BackingDocument65 pagesFacial Mirror With Plywood BackingVinod Mohan100% (1)

- BV224 Series DSDocument1 pageBV224 Series DSFAIYAZ AHMEDNo ratings yet

- Ellingham DiagramsDocument8 pagesEllingham DiagramschantaiahNo ratings yet

- SER - Tower Related Price RevisiedDocument270 pagesSER - Tower Related Price RevisiedTasew AberaNo ratings yet

- UL Design - S729Document3 pagesUL Design - S729souravrobinNo ratings yet

- Coordination System Piping ArrangementDocument29 pagesCoordination System Piping ArrangementAniekanNo ratings yet

- 25.Checklist-Metal Doors, Windows & VentilatorsDocument2 pages25.Checklist-Metal Doors, Windows & Ventilatorsajit karandikar50% (2)

- Connection Grade and Material ComparisionDocument16 pagesConnection Grade and Material ComparisionRajveer SinghNo ratings yet

- Turco 5351 TDSDocument3 pagesTurco 5351 TDSmiguelmosquerabNo ratings yet

- Atlas Specialty Metals: Stainless Steel Wire & BarDocument29 pagesAtlas Specialty Metals: Stainless Steel Wire & Barsattar12345No ratings yet

- ME1112 Engineers Guide To Corrosion Causes Protection and ControlDocument162 pagesME1112 Engineers Guide To Corrosion Causes Protection and ControlFarid TataNo ratings yet

- Astm F3125 - 2019 PDFDocument14 pagesAstm F3125 - 2019 PDFMark GuevarraNo ratings yet

- Usg Boral Product Catalogue: Metal Framing Substrates Gypsum Boards Ceilings CompoundsDocument9 pagesUsg Boral Product Catalogue: Metal Framing Substrates Gypsum Boards Ceilings CompoundsJane RoNo ratings yet

- ISO 8501 Surface PreparationDocument4 pagesISO 8501 Surface Preparationraseen pNo ratings yet

- Chattisgarh Industry MapDocument12 pagesChattisgarh Industry MapSurajPandeyNo ratings yet

- Soundness of Welds in Steel by Comparison To Graded ASTM E 390 Reference RadiographsDocument2 pagesSoundness of Welds in Steel by Comparison To Graded ASTM E 390 Reference RadiographsERNESTO ENRIQUE FERNANDEZ BAPTISTANo ratings yet

- LGKKCKTXFKDocument59 pagesLGKKCKTXFKRuwan PareraNo ratings yet

- Bushings: Grid SolutionsDocument4 pagesBushings: Grid SolutionsfelixokNo ratings yet

- Health and Safety FCX-HS33.1Document1 pageHealth and Safety FCX-HS33.1berry trisnamuktiNo ratings yet

- Materials Comparison DIN / EN / ASTM: Finished PartsDocument6 pagesMaterials Comparison DIN / EN / ASTM: Finished PartsBittuNo ratings yet

- Pipe Body Properties-CatalogueDocument118 pagesPipe Body Properties-CatalogueFredy NavasNo ratings yet

- B31.3 Schedule Calculator v1.1Document4 pagesB31.3 Schedule Calculator v1.1Saqib LaeeqNo ratings yet

- Astm D4138Document5 pagesAstm D4138ДмитрийNo ratings yet

- Customer Complaint RegisterDocument15 pagesCustomer Complaint RegisterKarthik MadhuNo ratings yet

- HE - PILBARA - BROCHURE - 17pp A4Document17 pagesHE - PILBARA - BROCHURE - 17pp A4Jorge VillalobosNo ratings yet

- Iso 16228 - 2017 - en PDFDocument11 pagesIso 16228 - 2017 - en PDFri.paoletto82No ratings yet