Professional Documents

Culture Documents

Construction of Water Absorbing Roads with Porous Asphalt

Uploaded by

Bharath Srinivasreddy0 ratings0% found this document useful (0 votes)

13 views4 pagesThis document discusses the construction of water absorbing roads using porous asphalt. It aims to address issues like temperature rise, waste management, and stormwater drainage. Porous asphalt allows water to drain through its surface and into the ground below. This reduces stormwater runoff and replenishes groundwater supplies. Tests on compressive strength of samples with different percentages of fly ash addition showed strength increases up to 10% fly ash content. While replacing bitumen is challenging, further research is needed to fully utilize this technique's benefits and overcome its issues.

Original Description:

Original Title

fin_irjmets1651679677

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses the construction of water absorbing roads using porous asphalt. It aims to address issues like temperature rise, waste management, and stormwater drainage. Porous asphalt allows water to drain through its surface and into the ground below. This reduces stormwater runoff and replenishes groundwater supplies. Tests on compressive strength of samples with different percentages of fly ash addition showed strength increases up to 10% fly ash content. While replacing bitumen is challenging, further research is needed to fully utilize this technique's benefits and overcome its issues.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views4 pagesConstruction of Water Absorbing Roads with Porous Asphalt

Uploaded by

Bharath SrinivasreddyThis document discusses the construction of water absorbing roads using porous asphalt. It aims to address issues like temperature rise, waste management, and stormwater drainage. Porous asphalt allows water to drain through its surface and into the ground below. This reduces stormwater runoff and replenishes groundwater supplies. Tests on compressive strength of samples with different percentages of fly ash addition showed strength increases up to 10% fly ash content. While replacing bitumen is challenging, further research is needed to fully utilize this technique's benefits and overcome its issues.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

e-ISSN: 2582-5208

International Research Journal of Modernization in Engineering Technology and Science

( Peer-Reviewed, Open Access, Fully Refereed International Journal )

Volume:04/Issue:05/May-2022 Impact Factor- 6.752 www.irjmets.com

CONSTRUCTION OF WATER ABSORBING ROADS WITH POROUS ASPHALT

Abhishek Kumar*1, Kunal Verma*2, Aman Singh Verma*3,Gaurav Yadav*4,Brijesh

Chauhan*5,Rajkumar Gupta*6,Om Prakash Pal*7,Shubhendu Mishra*8

*1,2,3,4,5UG Student, Civil Engineering Department, GITM, Lucknow, UP India.

*6Head of Department, Civil Engineering Department, GITM, Lucknow, UP India.

*7,8Assistant professor, Civil Engineering Department, GITM, Lucknow, UP India.

ABSTRACT

We know not only India but the whole world is suffering from temperature problem, plastic waste road

reconstruction or road construction waste and the sound of vehicle .It is considerable that the use of natural

aggregates for the road construction which makes the increase amount of the solid waste which makes,

attention to many researchers. The construction and the demolition of wastes including, Also the porous

Asphalt pavements is designed for the dual duty it provides the payments for parking on the roads and it also

serves the storm water storage and infiltration system. They are in demand because they offers the site

planners and the public works officially and the opportunity to maintain the storm water in an environment

friendly way and to improve the water quality.

Keywords: Storm Water, Waste Material, Payments, Reconstruction, Infiltration System.

I. INTRODUCTION

We all know the population of world is increasing continuously with this expanding world, the demand for

extensive Road networks. As available natural resources become drastic for us as the recycled material of

construction, including payments and construction over the past few centuries, increasing in the application of

waste materials in different layers of flexible pavement including porous asphalt surface layer now what is so

many waste material suggest porous pavement in a storm water drainage system, and it allows rain water, to

runoff and move through the pavements surface to store a layer below it. An eventually seeping in the

underlying soil. Permeable pavement is profitable to the environment because it reduce the storm water and

volume. To treat the storm water quality and replenish, the ground water supply with low temperatures on hot

days. Due to increase in the void ratio, and water to pass through the surface and it allows the infiltrate and

evaporate. While the conventional surfaces will not do it so. The porous pavement surface has become an active

participant of hydrological cycle. Rain fall is the run back through soil in ground water. This technology of

pavement creates an more efficient land use by removing the need of Retention ponds, other storm water

management devices. In doing so, the pervious concrete has the ability to lower the overall project costs on the

first-cost basis. The previous concrete, carefully controlled the amount of water and cementation material are

used to create a paste that form a thick coating around the aggregate particles. A pervious concrete mixture

contain a little or no sand, creating the substantial void content. The porous asphalt with near to no use of

bitumen was the quiet difficult task but we tried our best to innovate a road with no use of bitumen but it was a

difficult task which also shows many negative impact but we to will tried to overcome with this problem. Our

problem is that the roads will face drainage problem if we use bitumen and the cost will also increase and to

reduce the cost to road we have to think differently. This is the concept which is looking something impossible

but definitely this can work one day. We as engineers has to work on this .The good drainage system will be

accompanied with roads having this much less use of bitumen.

www.irjmets.com @International Research Journal of Modernization in Engineering, Technology and Science

[200]

e-ISSN: 2582-5208

International Research Journal of Modernization in Engineering Technology and Science

( Peer-Reviewed, Open Access, Fully Refereed International Journal )

Volume:04/Issue:05/May-2022 Impact Factor- 6.752 www.irjmets.com

Fig 1.1 Concrete mix

1.1Objective

It allows any water that accumulate on the road side to drain through the surface and enter into the ground.

It solves the problem of flooding roads at rainy season.

To collect rain water instead of wasting it.

II. CASE STUDY

Generally the compressive strength of the pervious concrete is less the conventional concrete to justify the

various compressive strength of cube with different fine fractions this test is conducted. Compressive strength

is the resistance of a material to breaking under compression.

Remove the specimen from water after 7 days curing time and wipe out excess water from the surface

Clean the bearing surface of the testing machine.

Place the specimen in the machine in such a manner that the load shall be applied to the opposite sides of

the cube cast.

Align the specimen centrally on the base plate of the machine.

Rotate the movable portion gently by hand so that it touches the top surface of the specimen.

Apply the load gradually without shock and continuously at the rate of 140 kg/cm 2 /minute till the

specimen fails.

Record the maximum load and note any unusual features in the type of failure.

Fig 2,1 Compression testing Machine

www.irjmets.com @International Research Journal of Modernization in Engineering, Technology and Science

[201]

e-ISSN: 2582-5208

International Research Journal of Modernization in Engineering Technology and Science

( Peer-Reviewed, Open Access, Fully Refereed International Journal )

Volume:04/Issue:05/May-2022 Impact Factor- 6.752 www.irjmets.com

As the percentage of fly ash increases the compressive strength of concrete tends to increase up to certain

percentage and then start’s decreasing with the increase of ash content. The strength of 10% fly ash concrete is

more than 5% fly ash concrete and strength of 5% fly ash concrete is more than normal concrete. This shows

that till 10% fly ash concrete the strength increases while percentage of sugarcane bagasse ash increases.

III. RESULTS AND DISCUSSION

As the concrete used in the formation of the road plays the major role. The concrete used is of uniform size and

it shows porous nature. The replacement of bitumen is also a controversial point to discuss and further deep

study on this point is needed. As till know we know that concrete is the most important material for the

construction of the road. But in this road construction we tried to fully replace the bitumen which shows

various problems which we are trying to overcome in the future. Further test will be performed .

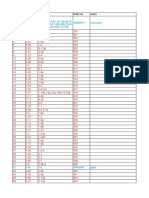

Compressive strength test result-:

Table 3.1 % of material vs & days compressive strength

%of material 7 days compressive strength

0 20.12mpa

5 22.83mpa

10 24.85mpa

15 21.63mpa

Fig 3.1 Concrete mixture

IV. CONCLUSION

1. This paper conclude the relation of the values of porous asphalt in the project.

2. Water quality control aspect and design maintenance are relevant to the practitioner. The most important

target is the pollutants hydrocarbon, heavy metals and nutrients.

3. New inventions highlight and explained the further research work which was outlined. The development of

cooling water treatment and recycling payment system is promising.

V. REFERENCES

[1] St. Paul, Minn, CTC & Associates Inc. (2012). Porous Asphalt Performance in Cold Regions. Report 2012-

12TS. Minnesota Department of Transportation,

[2] Nakayama, T.; Shizuka, H. Study on pavement performance of porous asphalt pavement with water

saving and cooling. Constr. Build. Mater 2015.

[3] Dr B V Kiran Kumar, Manjunatha S, Shiva Prasad N. “Porous asphalt pavement a tentative mix design

guideline” new generation open graded friction course approach.

www.irjmets.com @International Research Journal of Modernization in Engineering, Technology and Science

[202]

e-ISSN: 2582-5208

International Research Journal of Modernization in Engineering Technology and Science

( Peer-Reviewed, Open Access, Fully Refereed International Journal )

Volume:04/Issue:05/May-2022 Impact Factor- 6.752 www.irjmets.com

[4] Recycling of Asphalt Pavement. Missouri Asphalt Pavement Associa-tion, Jefferson City.

http://www.moasphalt.org/facts/environmental/recycling.htm. Accessed July 26, 2010.

[5] McGarrah, E. J. Evaluation of Current Practices of Reclaimed Asphalt Pavement/Virgin Aggregate as Base

Course Material. MS dissertation. University of Washington, Seattle, 2007.

www.irjmets.com @International Research Journal of Modernization in Engineering, Technology and Science

[203]

You might also like

- Cube Failure ReportDocument15 pagesCube Failure ReportVenu PrasadNo ratings yet

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsFrom EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsNo ratings yet

- Mathematics, Science and Technology - Module 1Document2 pagesMathematics, Science and Technology - Module 1Allysa Jean Tadlongan Alajan83% (6)

- Utilization of Non - Biodegradable Material For Repairing PotholesDocument7 pagesUtilization of Non - Biodegradable Material For Repairing PotholesIJRASETPublicationsNo ratings yet

- Minor Project - No Fine ConcreteDocument24 pagesMinor Project - No Fine ConcreteMr.Bhaskar WabhitkarNo ratings yet

- Porous Concrete As An Anti-Aquaplaning Building MaterialDocument11 pagesPorous Concrete As An Anti-Aquaplaning Building Materialraul.chiriacNo ratings yet

- Porous PavementDocument5 pagesPorous PavementInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- An Experimental Investigation of The Effect of Pervious Concrete by Various Shape and Sizes of AggregateDocument10 pagesAn Experimental Investigation of The Effect of Pervious Concrete by Various Shape and Sizes of AggregateIJRASETPublicationsNo ratings yet

- Fin Irjmets1630738104Document10 pagesFin Irjmets1630738104IRJMETS JOURNALNo ratings yet

- Concrete Project ReportDocument16 pagesConcrete Project ReportMayur Madhukar Mankar100% (1)

- A Study On Influence of Ldpe On Properties of Bitumen Pavement Under Submergence Condition IJERTV8IS060459Document6 pagesA Study On Influence of Ldpe On Properties of Bitumen Pavement Under Submergence Condition IJERTV8IS060459SyedBaqirNo ratings yet

- Pervious Concrete: New Era For Rural Road PavementDocument5 pagesPervious Concrete: New Era For Rural Road PavementseventhsensegroupNo ratings yet

- Use of Sewage Sludge Ash in Replacement of Stone Dust in Concrete PavementDocument45 pagesUse of Sewage Sludge Ash in Replacement of Stone Dust in Concrete PavementMukeshPatel100% (1)

- Investigation On Causes of Pavement Failure and Its Remedial MeasuresDocument5 pagesInvestigation On Causes of Pavement Failure and Its Remedial MeasuresIJRASETPublicationsNo ratings yet

- 34229-ArticleText-53314-1-10-20201214Document11 pages34229-ArticleText-53314-1-10-20201214Soham KatviNo ratings yet

- fin_irjmets1643966370Document11 pagesfin_irjmets1643966370mariacelestebanayoNo ratings yet

- ProcessDocument13 pagesProcessDuy Khanh HuynhNo ratings yet

- Construction of Water Absorbing Pavements by UsingDocument3 pagesConstruction of Water Absorbing Pavements by UsingAmmulu 123No ratings yet

- Evaluation of Design Mix Bituminous Concrete Using Plastic Waste in Road PavementDocument3 pagesEvaluation of Design Mix Bituminous Concrete Using Plastic Waste in Road PavementEditor IJTSRDNo ratings yet

- Article Text 463742 1 10 20190116 2Document7 pagesArticle Text 463742 1 10 20190116 2Jiu ShitzukiNo ratings yet

- Irjet V5i5381 PDFDocument4 pagesIrjet V5i5381 PDFAjay Kumar GantiNo ratings yet

- Use of Pervious Concrete in Pavement ConstructionDocument3 pagesUse of Pervious Concrete in Pavement ConstructionSaul Lopez MejiaNo ratings yet

- Recycled Materials in Concrete: Strength and Durability AnalysisDocument3 pagesRecycled Materials in Concrete: Strength and Durability AnalysisShreeshailNo ratings yet

- Study of Recent Trendes in Road ContructionDocument9 pagesStudy of Recent Trendes in Road Contructionfaizan shaikhNo ratings yet

- Report GroupDocument37 pagesReport GroupPrince TiwariNo ratings yet

- Review On Experimental Study Work On Partial Replacement of Cement With Waste Glass in Flexible or CC PavementsDocument7 pagesReview On Experimental Study Work On Partial Replacement of Cement With Waste Glass in Flexible or CC PavementsIJRASETPublicationsNo ratings yet

- Sustainability: 1.1.1. BackgroundDocument15 pagesSustainability: 1.1.1. Backgroundkumar AbhishekNo ratings yet

- A Partial Replacement of Cement and Fine Aggregate With MDP and GGBSDocument9 pagesA Partial Replacement of Cement and Fine Aggregate With MDP and GGBSIJRASETPublicationsNo ratings yet

- RohanDocument21 pagesRohanmansikakaniNo ratings yet

- Performance Assessment of Pervious Concrete Road On Strength and Permeability by Using Silica FumeDocument18 pagesPerformance Assessment of Pervious Concrete Road On Strength and Permeability by Using Silica FumeIJRASETPublicationsNo ratings yet

- Experimental Studies of Coconut Shell Ash Composites in ConcreteDocument4 pagesExperimental Studies of Coconut Shell Ash Composites in ConcreteaswathyNo ratings yet

- Easychair Preprint: Kamesh Bhise, Anu Murali and Kapil MauryaDocument6 pagesEasychair Preprint: Kamesh Bhise, Anu Murali and Kapil MauryaCivil StructureNo ratings yet

- Numerical Study of Two-Phase Flow in Centrifugal Dust CollectorsDocument6 pagesNumerical Study of Two-Phase Flow in Centrifugal Dust CollectorsResearch ParkNo ratings yet

- Some Aspects of The Effect of Porosity On Moisture Transfer in ConcreteDocument6 pagesSome Aspects of The Effect of Porosity On Moisture Transfer in ConcreteResearch ParkNo ratings yet

- Journal Printabs 4haug14esrDocument11 pagesJournal Printabs 4haug14esrBruno CarleteNo ratings yet

- Applications of Pervious Concrete in Road PavementsDocument15 pagesApplications of Pervious Concrete in Road PavementsIJRASETPublicationsNo ratings yet

- Research Paper Studies On Strength of Concrete by Partial Replacement of Sand With SawdustDocument3 pagesResearch Paper Studies On Strength of Concrete by Partial Replacement of Sand With SawdustjasimabdNo ratings yet

- Rizwan WordDocument46 pagesRizwan WordShubham YadavNo ratings yet

- A Study On Water AbsorbingDocument2 pagesA Study On Water AbsorbingInternational Journal of Innovative Science and Research Technology100% (1)

- Experimental Study On Properties of Concrete Using Industrial Waste Ceramic and Stone Dust With Partial Replacement of Cement and SandDocument4 pagesExperimental Study On Properties of Concrete Using Industrial Waste Ceramic and Stone Dust With Partial Replacement of Cement and SandEditor IJTSRDNo ratings yet

- Green Concrete Using Plastic Waste1Document3 pagesGreen Concrete Using Plastic Waste1sugunavidiyadar100% (1)

- AluminumDocument7 pagesAluminumcollenedesilvaNo ratings yet

- Structural Design of Interlocking Concrete Paving Block: E. Palanikumar Pothuganti Uday KumarDocument4 pagesStructural Design of Interlocking Concrete Paving Block: E. Palanikumar Pothuganti Uday Kumarivanhendriprasetyo 127No ratings yet

- 201509IOSRJMCEDocument12 pages201509IOSRJMCESreeja SadanandanNo ratings yet

- Pavan Savale Capstone 6I MY PROJECT (1) - OrganizedDocument28 pagesPavan Savale Capstone 6I MY PROJECT (1) - OrganizedSE-50 Yogesh KedarNo ratings yet

- Study On Breathe Bricks: International Research Journal of Engineering and Technology (IRJET)Document4 pagesStudy On Breathe Bricks: International Research Journal of Engineering and Technology (IRJET)Frida Faye LacsamanaNo ratings yet

- A Study On The Rigid Pavement Construction Joint and Crack FormationDocument6 pagesA Study On The Rigid Pavement Construction Joint and Crack FormationAjit P. SinghNo ratings yet

- Cost Optimization of Geopolymer Concrete PavementDocument11 pagesCost Optimization of Geopolymer Concrete PavementIJRASETPublicationsNo ratings yet

- A Study On The Suitability of Solid Waste Materials in Pavement Construction A ReviewDocument13 pagesA Study On The Suitability of Solid Waste Materials in Pavement Construction A Reviewaakash singhNo ratings yet

- Utilization of Basaltic Quarry Dust As A Partial Replacement of Cement For Hollow Concrete Block ProductionDocument13 pagesUtilization of Basaltic Quarry Dust As A Partial Replacement of Cement For Hollow Concrete Block Productionnajathahamed880No ratings yet

- Marble Powder in HmaDocument15 pagesMarble Powder in HmaRoshan GuptaNo ratings yet

- Waterproofing Method For Slab - A Comparative Effective Analysis For Ashta RegionDocument12 pagesWaterproofing Method For Slab - A Comparative Effective Analysis For Ashta RegionKiran KumarNo ratings yet

- Mini Project Advance PavementsDocument39 pagesMini Project Advance PavementsSD TECHNo ratings yet

- Water Absorbing Roads (WAR) : A New Construction Technique For Roads in IndiaDocument5 pagesWater Absorbing Roads (WAR) : A New Construction Technique For Roads in IndiaAmmulu 123No ratings yet

- Construction of Paving Blocks by Using Plastic WasteDocument8 pagesConstruction of Paving Blocks by Using Plastic WasteInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Eco-friendly Paver Blocks from Waste MaterialsDocument7 pagesEco-friendly Paver Blocks from Waste MaterialsGUGANATHAN ANo ratings yet

- Vacuum Dewaterimg: New Way For Concrete Flooring by Tremix MethodDocument9 pagesVacuum Dewaterimg: New Way For Concrete Flooring by Tremix MethodAPARNA V MURALINo ratings yet

- Study On Repairing of PotholesDocument6 pagesStudy On Repairing of PotholesVIVA-TECH IJRI50% (2)

- A Study of Concrete Paver Block Using Crumb Rubber in InterlockingDocument4 pagesA Study of Concrete Paver Block Using Crumb Rubber in InterlockingEditor IJTSRDNo ratings yet

- Comparative Study of Mix Proportioning of High Strength Concrete Using Doe and Aci Method IJERTCONV4IS30028Document3 pagesComparative Study of Mix Proportioning of High Strength Concrete Using Doe and Aci Method IJERTCONV4IS30028Hanan IbrahimNo ratings yet

- Advances in Concrete TechnologyDocument10 pagesAdvances in Concrete TechnologytusshaarpatilNo ratings yet

- What Is Problem SolvingDocument5 pagesWhat Is Problem SolvingBharath SrinivasreddyNo ratings yet

- RailwayDocument16 pagesRailwayBharath SrinivasreddyNo ratings yet

- Calculating moments of resistance for reinforced concrete sectionsDocument2 pagesCalculating moments of resistance for reinforced concrete sectionsBharath SrinivasreddyNo ratings yet

- Account Statement SummaryDocument2 pagesAccount Statement SummaryBharath SrinivasreddyNo ratings yet

- Board of Technical Education: "Design & Analysis of Highway Pavement"Document43 pagesBoard of Technical Education: "Design & Analysis of Highway Pavement"Bharath SrinivasreddyNo ratings yet

- Cej 4291fDocument10 pagesCej 4291fBharath SrinivasreddyNo ratings yet

- FIRSTDocument2 pagesFIRSTRose QuitilenNo ratings yet

- P&ID Water Treatment Unit-ColpalDocument2 pagesP&ID Water Treatment Unit-ColpalJoseph OlingaNo ratings yet

- Field Notes: Design Alaska Wild Arts Walk!Document8 pagesField Notes: Design Alaska Wild Arts Walk!Friends of Creamer's FieldNo ratings yet

- Substructure Preliminaries: T.O. ListDocument45 pagesSubstructure Preliminaries: T.O. ListDasun MahabadugeNo ratings yet

- Sds Ridomil - Gold - 480SL - 28474 - en - SDSDocument15 pagesSds Ridomil - Gold - 480SL - 28474 - en - SDSAzuan MABKNo ratings yet

- Fire Suppression Notes SummaryDocument3 pagesFire Suppression Notes SummarydomcristiniNo ratings yet

- Method of Statement For Site DemobilizationDocument11 pagesMethod of Statement For Site DemobilizationGameTasticNo ratings yet

- Method of Statement - Road Works For Katibas (Drainage Works) (16.5.2020)Document6 pagesMethod of Statement - Road Works For Katibas (Drainage Works) (16.5.2020)Dominic Chupong Joss BawingNo ratings yet

- The Global Arsenic Problem: Challenges For Safe Water ProductionDocument231 pagesThe Global Arsenic Problem: Challenges For Safe Water ProductionAna VlasceanuNo ratings yet

- KOBELCO Reference Plant 171102Document23 pagesKOBELCO Reference Plant 171102Bảo BáchNo ratings yet

- Hyflux Kristal MembranesDocument2 pagesHyflux Kristal MembranesNguyễn Bá ĐậuNo ratings yet

- I. Choose A, B, C, D For Each Gap in The Following SentencesDocument6 pagesI. Choose A, B, C, D For Each Gap in The Following SentencesThủy TrầnNo ratings yet

- WC - Bowl - Kohler K-4325-SsDocument2 pagesWC - Bowl - Kohler K-4325-SsEnak CenirNo ratings yet

- 1 s2.0 S0022030296766055 MainDocument6 pages1 s2.0 S0022030296766055 Mainfawad ahmadNo ratings yet

- Combi SchematicsDocument7 pagesCombi SchematicsMatt HullNo ratings yet

- Report Regarding Dehumidifier's For Indian MarketDocument5 pagesReport Regarding Dehumidifier's For Indian MarketNitin ShenoyNo ratings yet

- Comprehensive HVAC System Design and Maintenance TrainingDocument8 pagesComprehensive HVAC System Design and Maintenance TrainingSuresh Velu100% (1)

- The Development of Carbon Capture and Storage (CCS) in India: A CriticaDocument33 pagesThe Development of Carbon Capture and Storage (CCS) in India: A CriticacaesarchadmaNo ratings yet

- EIA Proposed Property Development Scheme Project On "Plot P" of Avalon Golf Estate at Bois SecDocument17 pagesEIA Proposed Property Development Scheme Project On "Plot P" of Avalon Golf Estate at Bois Secmelvin_12No ratings yet

- Group 4 Bsce 1-3 Position Paper Purcom FinalsDocument5 pagesGroup 4 Bsce 1-3 Position Paper Purcom FinalsAndrea CastilloNo ratings yet

- Geology Shaped LA Infrastructure DevelopmentDocument65 pagesGeology Shaped LA Infrastructure DevelopmentGabija PaškevičiūtėNo ratings yet

- Worksheet Soil and Water Conservation: Hello@edutap - Co.inDocument10 pagesWorksheet Soil and Water Conservation: Hello@edutap - Co.inSaurabh MishraNo ratings yet

- Nibe S2125 Brochure M12867-1Document4 pagesNibe S2125 Brochure M12867-1Dave Van DongenNo ratings yet

- Recommended For Areas Where TDS Is Below 300 MG/L (300 PPM) : Uv Range Water PurifierDocument2 pagesRecommended For Areas Where TDS Is Below 300 MG/L (300 PPM) : Uv Range Water PurifierpraveenNo ratings yet

- Victorville Bombing Range No. 6Document179 pagesVictorville Bombing Range No. 6CAP History LibraryNo ratings yet

- Soil Erosion PHD ThesisDocument8 pagesSoil Erosion PHD ThesisFindSomeoneToWriteMyPaperLowell100% (2)

- 1 5 20000509 Vamsadara 1-1p, 2p, 7p, 8,9,10,11l, 12p, 6p, 14 P, 15p, 13,16,17,18p, 20p, 21p, 8 - 1p, 2p, 7p, 8,9p, 10p, 17p, 18pDocument119 pages1 5 20000509 Vamsadara 1-1p, 2p, 7p, 8,9,10,11l, 12p, 6p, 14 P, 15p, 13,16,17,18p, 20p, 21p, 8 - 1p, 2p, 7p, 8,9p, 10p, 17p, 18pthamada saikumarNo ratings yet

- Mark Scheme (Results) Summer 2019: Pearson Edexcel International GCSE in Pakistan Studies (4PA1) Paper 02Document19 pagesMark Scheme (Results) Summer 2019: Pearson Edexcel International GCSE in Pakistan Studies (4PA1) Paper 02Muhammad SaleemNo ratings yet

- District Survey Report For Latur District FORDocument146 pagesDistrict Survey Report For Latur District FORINo ratings yet