Professional Documents

Culture Documents

Diesel Engines Series 4000: Stationary Power Generation

Uploaded by

jesus_rs01Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Diesel Engines Series 4000: Stationary Power Generation

Uploaded by

jesus_rs01Copyright:

Available Formats

Diesel Engines Series 4000

Stationary Power Generation

SIM 05 167 (52 3E) 1/03 · Printed in Germany · SIMA 2003-09 L · Printed on chlorine-free bleached paper.

Subject to modification in the interest of technical progress.

DaimlerChrysler Off-Highway

MTU Friedrichshafen GmbH Detroit Diesel Corporation

88040 Friedrichshafen 13400 Outer Drive, West

Germany Detroit, Michigan 48239-4001, USA

Phone +49 7541 90 87 73 Phone +1 313 592 57 08

Fax +49 7541 90 81 35 Fax +1 313 592 51 58

powergen@mtu-online.com powergen@detroitdiesel.com

www.mtu-online.com www.detroitdiesel.com

DaimlerChrysler Off-Highway

We provide the Power You Need.

MTU Friedrichshafen in Germany and

Detroit Diesel Corporation in the USA, two

DaimlerChrysler companies, have combined

their off-highway operations.

With the joint product ranges of the MTU

and DDC brands – complemented by

Mercedes-Benz engines – a global leader

has been created in the engine and systems

engineering sector covering marine, rail

and power generation applications as well Your Benefits:

as heavy commercial and defense vehicles

and construction, mining and agricultural Very Low Assembly and Engineering

machinery. Expenditure

In the power generation field MTU system > Various accessories integrated (air filters,

solutions provide technical perfection axial compensators, engine and alternator

which is commercially viable. 100,000 MTU mounting etc.)

and DDC engines and gensets, delivered > Optimal interface arrangement

worldwide prove themselves daily in demand- > Flexible system and unit planning

ing operational conditions.

MTU has at it’s disposal a unique drive Optimal Operating Behaviour

system know how and excellent product > Low vibration operation

quality, which results from MTU’s innovative > Constant engine power available at intake

capabilities, reliability, as well as an immense air temperatures of up to 40°C and site

system competence. altitudes of up to 400 m above sea level

MTU’s complete product and customer > Excellent load acceptance behaviour

support will ensure that the highest availa- > High speed/frequency stability

bility is achieved, wherever you are.

A world wide network of affiliates, agencies Environmental Compatibility

and support centers with MTU trained per- > Complies with international emission rules

sonnel assures expert engine maintenance > Low fuel and lube-oil consumption

24 hours a day. > Low particle emissions

> Low noise and vibration levels

> Environmentally favourable paint finish

Model 20V 4000

Series 4000 High Availability and Reliability

> Long life-time

> 24 hour service

> World-wide customer service network with

2,250 support points

> electronic engine management system with

MTU engines are the basis for the realization effect of a considerably reduced planning self-diagnosis function

of reliable and economically efficient drive expenditure making the unit control easier

solutions. Apart from their reliability and and its price more reasonable. The operator Low Life Cycle Costs

long life-time the engines of the 4000 series benefits from the engines low fuel consumption > Competitive price

have low fuel consumption and emission and emission values, excellent load acceptance > Low fuel consumption

values at attractively competitive prices. behaviour and, not to forget, from the safety > Low lube-oil consumption

A large choice of integrated accessories, of a world-wide service network. > Easy to service

reduces the engineering expenses the unit Optimized for fuel consumption or exhaust > High TBO

producer would otherwise have to invest. emission, the switchable speed engines of > REMAN parts

The electronic engine management system the 4000 series cover a perfectly harmonized

has been designed to take over a variety of scope of performances and offer the optimal

control and monitoring functions to the solution to comply with any individual appli-

cation.

Superior Technology:

Module for Module.

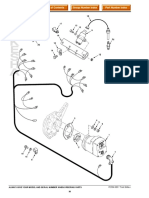

Intercooler

Engine and Generator Mounts Engine Management

Elastic engine and generator mounts with Electronic control and monitoring system

rubber elements for different generator with all-speeds or charging control and inte-

construction types grated safety and self-diagnosis functions

Coolant circulation

Benefits:

GRA-0209

pumps extendable by means of interface modules

Lube oil

with plug-in connections ready for plug in

> Also suitable for cost-advantageous base Thermostat

Radiator

heat exchanger

starting automatics and load profile recorder,

frames

Radiator

Thermostat engine optimally harmonized in regard to fuel

> Easy mounting consumption and emissions complete

> Effective solid-born noise silencing with engine sensory analysis and cabling,

> Highly efficient vibration damping suitable for combination with all common

power set control systems many additional

Dual-Circuit Cooling System with functions available (e.g. variable p-grade

Service Components and Water Charge Air Cooling adjustment, changeable speed etc.)

Connections System solution apt for separate installation

Benefits:

Easily accessible fuel and oil filters, pumps, of mechanically or electromotor driven fan

cooling water and fuel supply connections, all coolers, heat exchangers or desktop type > Optimal operating behaviour

arranged at the outlet side coolers. > Easy, fast and cost-advantageous

Benefits: connection possible to external systems

Benefits:

> Re-cooling system can be installed > Maintenance-free design

> Easy servicing through direct access

separately and located away from the

> Easy connecting capabilities

genset it serves Common Rail Injection System

> Units can be planned flexibly and individually Electronically controlled common rail

injection system with high-pressure pump,

Turbo-Charging and Exhaust pressure accumulator (rail) and individual

injectors

Gas System

Benefits:

Single stage exhaust gas turbo charging with

two (8V / 20V) or four (12V / 16V) highly > Optimal control of start of injection,

efficient turbo chargers, charge air cooling, injection volume and injection pressure

exhaust gas elbow with vertical discharge > Significant reduction of particle emissions

and dry exhaust gas lines, arranged inside > Low fuel consumption over the complete

the engine V-space capacity range

Benefits: > No mechanical adjustment needed

> High engine efficiency > Excellent acceleration behaviour and

> Optimal load acceptance excellent behaviour under instantaneous

loads

> Easy connection to external exhaust

gas system > High reliability

> Exceptionally smooth-running

> No power dissipation at high fuel

temperatures

Technical Data

Diesel Engine Series 4000 Application Group Standby Power Prime Power Prime Power Continuous Power

Configuration 8V, 12V, 16V 20V Limited

Bore mm 165/190 165/210 3D 3C 3B 3A

Swept volume I/cyl. 4.06 4.49 Mode of operation Standby with Standby with Contin. operation Contin. operation

Fuel specification EN 590; Grade Nr. 1-D /2-D, (ASTM D975-00) variable load variable load with variable load with 100 % load

Load factor < 85% < 75% < 75% ≤ 100%

Annual operating hours max. 500 max. 1000 unrestricted unrestricted

Application Group Standby Power Prime Power Prime Power Continuous Power Rating definition fuel stop power 10% overload 10% overload 10% overload

Limited DIN ISO 3046 ICFN capability ICXN capability ICXN capability ICXN

3D 3C 3B 3A

Mode of operation Standby with Standby with Contin. operation Contin. operation

variable load variable load with variable load with 100 % load

Engine Model Engine Power (kW) at 1500/1800 rpm (50/60 Hz switchable)

with Water Charge Air Cooling

Load factor < 85% < 75% < 75% ≤ 100%

Annual operating hours max. 500 max. 1000 unrestricted unrestricted

Optimization ⌧/ 햳 ⌧ or 햲 / 햳 ⌧ or 햲 / 햳 ⌧/ 햳

8V 4000 G61 1985 / 1050 1895 / 1955 1895 / 1955 1735 /1750

Rating definition fuel stop power 10% overload 10% overload 10% overload

12V 4000 G21 1330 / 1445 1205 / 1310 1205 / 1310 -

DIN ISO 3046 ICFN capability ICXN capability ICXN capability ICXN

12V 4000 G61 1465 / 1590 1330 / 1445 1330 / 1445 1095 /1120

16V 4000 G21 1760 / 1910 1600 / 1735 1600 / 1735 -

16V 4000 G61 1940 / 2100 1760 / 1910 1760 / 1910 1450 / 1495

Engine Model Engine Power (kW) at 1500 rpm (50 Hz) with Water Charge Air Cooling

20V 4000 G22 2420 / 2740 2200/ 2490 2200 /2490 -

Optimization ⌧ ⌧ or 햲 ⌧ or 햲 ⌧

20V 4000 G62 2670 / 3010 2420/ 2740 2420 /2740 2000/2060

18V 4000 G61 1985 1895 1895 1735

12V 4000 G21 1330 1205 1205 -

12V 4000 G61 1465 1330 1330 1095 Reference Conditions Standard Power Available up to

16V 4000 G21 1760 1600 1600 - Intake air temperature 25°C 40°C

16V 4000 G61 1940 1760 1760 1450 Altitude above sea level 100 m 400 m

20V 4000 G22 2420 2200 2200 - Charge-air coolant temperature 55°C 55°C

20V 4000 G62 2670 2420 2420 2000

Optimization 햲 Exhaust emission (TA-Luft/Edition 1986)

햳 Exhaust emission (EPA 40 CFR 89/ Tier 1)

Engine Model Engine Power (kW) at 1800 rpm (60 Hz) with Water Charge Air Cooling ⌧ Fuel consumption

Optimization 햳 햳 햳 Fan power requirement not considered.

8V 4000 G81 1100 - 1000 1750

12V 4000 G41 1490 - - -

12V 4000 G81 1640 - 1490 1120

16V 4000 G41 1990 - - -

16V 4000 G81 2190 - 1990 1495

20V 4000 G42 2740 - 2490 -

20V 4000 G82 3010 - 2740 2060

You might also like

- 5.3 Cruise Control: 5.3.1 OperationDocument9 pages5.3 Cruise Control: 5.3.1 OperationdinhvuNo ratings yet

- ID DCU IndustrialDocument4 pagesID DCU IndustrialRoozbeh BahmanyarNo ratings yet

- Tecumseh Hs50 67320hDocument6 pagesTecumseh Hs50 67320henjoytheride100% (1)

- Installation Instruction: Lubricating Oil Filter Bypass ValveDocument6 pagesInstallation Instruction: Lubricating Oil Filter Bypass ValveSean DuncanNo ratings yet

- C9 On-Highway Truck Engine Electrical System: Harness and Wire Electrical Schematic SymbolsDocument4 pagesC9 On-Highway Truck Engine Electrical System: Harness and Wire Electrical Schematic SymbolsRaffoNo ratings yet

- 4700 Operatior's ManualDocument74 pages4700 Operatior's ManualRidwan Praditya100% (1)

- Electronic Control System: Operación de SistemasDocument11 pagesElectronic Control System: Operación de SistemasAlberto PANo ratings yet

- 39MT 42MT 50MTDocument3 pages39MT 42MT 50MTsyamyyyNo ratings yet

- C-18 Caterpillar Engine For PM200 Cold Planer P1M00001-UP (MACHINE) POWERED BY C-18 Engine (KEBP0335 - 04) - Product StructureDocument4 pagesC-18 Caterpillar Engine For PM200 Cold Planer P1M00001-UP (MACHINE) POWERED BY C-18 Engine (KEBP0335 - 04) - Product Structurebasem elhosanyNo ratings yet

- Mack International MP8 Engine: Ingo TrossDocument31 pagesMack International MP8 Engine: Ingo TrossbrayamNo ratings yet

- Replace Cool Logic With Air Actuated Fan Drive: Installation & Service GuideDocument16 pagesReplace Cool Logic With Air Actuated Fan Drive: Installation & Service Guideraymond rizaNo ratings yet

- Diagrama CollageDocument14 pagesDiagrama CollageJuan del AngelNo ratings yet

- x15 Efficiency NavistarDocument2 pagesx15 Efficiency NavistarPablo Raigosa IdarragaNo ratings yet

- Shematic FalconDocument76 pagesShematic FalconknarfboyNo ratings yet

- Detroit Diesel 50 Engine Tech ManualDocument2 pagesDetroit Diesel 50 Engine Tech Manualayman akrabNo ratings yet

- Thermal Recirculation Valve Installation InstructionsDocument7 pagesThermal Recirculation Valve Installation InstructionsSean DuncanNo ratings yet

- Eaton T-905 Transmission Service ManualDocument72 pagesEaton T-905 Transmission Service ManualTawfiq ZidanNo ratings yet

- Cummins PDFDocument2 pagesCummins PDFCesar ZarateNo ratings yet

- Allison Serie 9800Document2 pagesAllison Serie 9800Anonymous TEbcqw5RbT100% (1)

- USB-Link™ Installation and Setup ManualDocument78 pagesUSB-Link™ Installation and Setup ManualDuy KhaNo ratings yet

- Abs BendixDocument44 pagesAbs BendixDavid GonzalezNo ratings yet

- Asc 4 Designer S Reference Handbook 4189341075 UkDocument128 pagesAsc 4 Designer S Reference Handbook 4189341075 UkJacques DuretNo ratings yet

- C11 ACERT 261bkWDocument5 pagesC11 ACERT 261bkWJulio huanriNo ratings yet

- Cummins Gearing RecommendationsDocument40 pagesCummins Gearing Recommendationskamikazeee100% (1)

- D - PMG Users Manual - Amg 0200-0450Document8 pagesD - PMG Users Manual - Amg 0200-0450donsallusNo ratings yet

- Coach & Bus EngineDocument2 pagesCoach & Bus EngineClegivaldoNo ratings yet

- Mtu 20VDocument2 pagesMtu 20VGLIEDRNo ratings yet

- Piston Cooling Jets - Remove and InstallDocument4 pagesPiston Cooling Jets - Remove and Installeshopmanual limaNo ratings yet

- Fuller Rtlo 18918bDocument2 pagesFuller Rtlo 18918bAnthony GarzaNo ratings yet

- Fuller 18-Speed Transmissions PDFDocument2 pagesFuller 18-Speed Transmissions PDFWILMAR ANDRES MONTOYA MAYANo ratings yet

- Graco Husky 1590 Diaphragm Pump ManualDocument36 pagesGraco Husky 1590 Diaphragm Pump ManualMROstop.comNo ratings yet

- Cylinder Liner Projection - Projeçao Camisa - c9Document1 pageCylinder Liner Projection - Projeçao Camisa - c9Victor NoschangNo ratings yet

- 2013-03 (P) - Revision A - Evinrude E-TEC 40-300 High Pressure Fuel Pump Kits PDFDocument1 page2013-03 (P) - Revision A - Evinrude E-TEC 40-300 High Pressure Fuel Pump Kits PDFElvin HernándezNo ratings yet

- Essential Tool List For Freightliner - MasterDocument4 pagesEssential Tool List For Freightliner - MasterAngel FraustoNo ratings yet

- Aeb09202 PDFDocument16 pagesAeb09202 PDFCesar G.No ratings yet

- EPA98 04 MBE 900 4000 Troubleshooting Manual (DDC-SVC-MAN-0027)Document4 pagesEPA98 04 MBE 900 4000 Troubleshooting Manual (DDC-SVC-MAN-0027)giovanni ampuero0% (1)

- Troubleshooting Ec-17 Antilock Systems With Optional Traction ControlDocument2 pagesTroubleshooting Ec-17 Antilock Systems With Optional Traction ControlrowanNo ratings yet

- Installation Manual MDKBHDocument34 pagesInstallation Manual MDKBHDaniel CastellanosNo ratings yet

- Visctronic 12 Volt 732/842/882 Fan Drives: StartDocument2 pagesVisctronic 12 Volt 732/842/882 Fan Drives: StartElmer Tintaya MamaniNo ratings yet

- Ecf9 Nh3 ManualDocument20 pagesEcf9 Nh3 Manualgonza100% (1)

- Diagrama C-15 PDFDocument2 pagesDiagrama C-15 PDFjose100% (1)

- VCT-20 VCT-100 VCT-200 VCT-250 VCT-2000 (Placa Nova) - Códigos de Erros (EN) (2014)Document2 pagesVCT-20 VCT-100 VCT-200 VCT-250 VCT-2000 (Placa Nova) - Códigos de Erros (EN) (2014)Thiago Azevedo0% (1)

- Air Brake System TroubleshootingDocument5 pagesAir Brake System Troubleshootingbhanuka2009No ratings yet

- Caterpillar C15 PDFDocument4 pagesCaterpillar C15 PDFAlfonso RectificadorNo ratings yet

- 4.XJ250 Convenio Tecnico de FlushbyDocument11 pages4.XJ250 Convenio Tecnico de FlushbyGabriel Alejandro JoaquinNo ratings yet

- Cummins Westport ISX12 G Brochure - 4971420 - 0313Document6 pagesCummins Westport ISX12 G Brochure - 4971420 - 0313noeing02No ratings yet

- Pump Goveror Class OneDocument38 pagesPump Goveror Class OneEolo RojasNo ratings yet

- At22 MaintenanceDocument37 pagesAt22 MaintenancefabuleukalengaNo ratings yet

- 10 Intermittentfault10Document94 pages10 Intermittentfault10libertyplusNo ratings yet

- Aeb 02138Document33 pagesAeb 02138Bosko KalicaninNo ratings yet

- Cummins: Fault Code: 369 PID: P1690 SPN: 1078 FMI: 2Document6 pagesCummins: Fault Code: 369 PID: P1690 SPN: 1078 FMI: 2Enrrique LaraNo ratings yet

- 600 Maintenance Operation Manual-A10141112Document63 pages600 Maintenance Operation Manual-A10141112Alexander DonatoNo ratings yet

- PV776 TSP130751 1Document4 pagesPV776 TSP130751 1Benjamin Miranda FloresNo ratings yet

- C9 Industrial Engine Electrical System: Top ViewDocument2 pagesC9 Industrial Engine Electrical System: Top ViewSergio Urquizo100% (1)

- QSX15 System DiagramDocument12 pagesQSX15 System Diagramnavid cheungNo ratings yet

- Mtu Series 2000 GensetDocument8 pagesMtu Series 2000 GensetAlex Robledo Olarte100% (2)

- Sauer Danfoss Orbital Motors PDFDocument5 pagesSauer Danfoss Orbital Motors PDFSoledad Navarro LazoNo ratings yet

- Mtu Series 60 MarineDocument5 pagesMtu Series 60 MarineMuhammad rizki0% (1)

- MTU PowerDriveUnit1Document7 pagesMTU PowerDriveUnit1facturacion.msdservicioNo ratings yet

- Three-Phase Induction Motors Empowering The Future: Catalog 03-2013Document180 pagesThree-Phase Induction Motors Empowering The Future: Catalog 03-2013hardik033No ratings yet

- Part Number Index Group Number Index Cover PageDocument2 pagesPart Number Index Group Number Index Cover Pagejesus_rs01No ratings yet

- Part Number Index Group Number Index Cover PageDocument2 pagesPart Number Index Group Number Index Cover Pagejesus_rs01No ratings yet

- Part Number Index Group Number Index Cover PageDocument2 pagesPart Number Index Group Number Index Cover Pagejesus_rs01No ratings yet

- Part Number Index Group Number Index Cover PageDocument2 pagesPart Number Index Group Number Index Cover Pagejesus_rs01No ratings yet

- Part Number Index Group Number Index Cover PageDocument2 pagesPart Number Index Group Number Index Cover Pagejesus_rs01No ratings yet

- Part Number Index Group Number Index Cover PageDocument2 pagesPart Number Index Group Number Index Cover Pagejesus_rs01No ratings yet

- Part Number Index Group Number Index Cover PageDocument2 pagesPart Number Index Group Number Index Cover Pagejesus_rs01No ratings yet

- Part Number Index Group Number Index Cover PageDocument2 pagesPart Number Index Group Number Index Cover Pagejesus_rs01No ratings yet

- Part Number Index Group Number Index Cover PageDocument2 pagesPart Number Index Group Number Index Cover Pagejesus_rs01No ratings yet

- Part Number Index Group Number Index Cover PageDocument2 pagesPart Number Index Group Number Index Cover Pagejesus_rs01No ratings yet

- Part Number Index Group Number Index Cover PageDocument2 pagesPart Number Index Group Number Index Cover Pagejesus_rs01No ratings yet

- Part Number Index Group Number Index Cover PageDocument2 pagesPart Number Index Group Number Index Cover Pagejesus_rs01No ratings yet

- Part Number Index Group Number Index Cover PageDocument2 pagesPart Number Index Group Number Index Cover Pagejesus_rs01No ratings yet

- Part Number Index Group Number Index Cover PageDocument2 pagesPart Number Index Group Number Index Cover Pagejesus_rs01No ratings yet

- Part Number Index Group Number Index Cover PageDocument2 pagesPart Number Index Group Number Index Cover Pagejesus_rs01No ratings yet

- Part Number Index Group Number Index Cover PageDocument2 pagesPart Number Index Group Number Index Cover Pagejesus_rs01No ratings yet

- Part Number Index Group Number Index Cover PageDocument2 pagesPart Number Index Group Number Index Cover Pagejesus_rs01No ratings yet

- Part Number Index Group Number Index Cover PageDocument2 pagesPart Number Index Group Number Index Cover Pagejesus_rs01No ratings yet

- Part Number Index Group Number Index Cover PageDocument2 pagesPart Number Index Group Number Index Cover Pagejesus_rs01No ratings yet

- Part Number Index Group Number Index Cover PageDocument2 pagesPart Number Index Group Number Index Cover Pagejesus_rs01No ratings yet

- Part Number Index Group Number Index Cover PageDocument2 pagesPart Number Index Group Number Index Cover Pagejesus_rs01No ratings yet

- Part Number Index Group Number Index Cover PageDocument2 pagesPart Number Index Group Number Index Cover Pagejesus_rs01No ratings yet

- Part Number Index Group Number Index Cover PageDocument2 pagesPart Number Index Group Number Index Cover Pagejesus_rs01No ratings yet

- Part Number Index Group Number Index Cover PageDocument2 pagesPart Number Index Group Number Index Cover Pagejesus_rs01No ratings yet

- Part Number Index Group Number Index Cover PageDocument2 pagesPart Number Index Group Number Index Cover Pagejesus_rs01No ratings yet

- Part Number Index Group Number Index Cover PageDocument2 pagesPart Number Index Group Number Index Cover Pagejesus_rs01No ratings yet

- Part Number Index Group Number Index Cover PageDocument2 pagesPart Number Index Group Number Index Cover Pagejesus_rs01No ratings yet

- Part Number Index Group Number Index Cover PageDocument2 pagesPart Number Index Group Number Index Cover Pagejesus_rs01No ratings yet

- Part Number Index Group Number Index Cover PageDocument2 pagesPart Number Index Group Number Index Cover Pagejesus_rs01No ratings yet

- Part Number Index Group Number Index Cover PageDocument2 pagesPart Number Index Group Number Index Cover Pagejesus_rs01No ratings yet

- Le LT LF Atlas CopcoDocument12 pagesLe LT LF Atlas CopcoAgustinus KNo ratings yet

- Airto Air Heat ExchangerDocument4 pagesAirto Air Heat Exchangerpauldurai kanagarajNo ratings yet

- C Series engine-121-SM-02-D PDFDocument49 pagesC Series engine-121-SM-02-D PDFRina SumardiNo ratings yet

- ASME PTC 22 (Gas Turbine Test Code)Document46 pagesASME PTC 22 (Gas Turbine Test Code)Nanang Hanani Wijaya100% (5)

- Marine Engine Maintenance Schedules LEXM6231-01Document39 pagesMarine Engine Maintenance Schedules LEXM6231-01gvillalva0% (1)

- CAT G3612 A4 Gas Engine Technical Data Sheet PDFDocument4 pagesCAT G3612 A4 Gas Engine Technical Data Sheet PDFEustacio MenesesNo ratings yet

- Sauer Compressors For ShippingDocument12 pagesSauer Compressors For ShippingBintang SinagaNo ratings yet

- Aftercooler - Test: Shutdown SIS Previous ScreenDocument7 pagesAftercooler - Test: Shutdown SIS Previous ScreenKeron Trotz100% (1)

- Inlet Ex SystemDocument5 pagesInlet Ex SystembejoythomasNo ratings yet

- Air Compressor MCQ'S: D.Mean Effective PressureDocument10 pagesAir Compressor MCQ'S: D.Mean Effective PressureAman SheikhNo ratings yet

- Lovol Perkins List1 PDFDocument142 pagesLovol Perkins List1 PDFEpure Gabriel100% (1)

- Cooling TowerDocument5 pagesCooling TowerfaisalnadimNo ratings yet

- Atlas Copco-Basic Product TrainingDocument42 pagesAtlas Copco-Basic Product TrainingArstNo ratings yet

- MBE 4000 Aplica e InstalacionDocument224 pagesMBE 4000 Aplica e InstalacionOmar Alberto Vicenteño SanchezNo ratings yet

- Engine Performance Data at 1800 RPM: X3.3 1 Cummins India Limited S3.8Document4 pagesEngine Performance Data at 1800 RPM: X3.3 1 Cummins India Limited S3.8Rasheed SiddiquiNo ratings yet

- IPD - Lista de Peças Do Motor - 1 PDFDocument3 pagesIPD - Lista de Peças Do Motor - 1 PDFxxxxxxxxxxxxxxxxxxx100% (1)

- Cummins 75 Kva - Ficha TecnicaDocument4 pagesCummins 75 Kva - Ficha TecnicaEduardo CortezNo ratings yet

- QSK Series MCRS Cooling SystemsDocument29 pagesQSK Series MCRS Cooling SystemsagvassNo ratings yet

- Maintenance Intervals: Operation and Maintenance Manual ExcerptDocument65 pagesMaintenance Intervals: Operation and Maintenance Manual ExcerptmedescalanteNo ratings yet

- Gas TurbineDocument22 pagesGas TurbineRizuanul Arefin EmonNo ratings yet

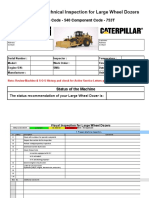

- Wheel Dozers TA2 ChecklistDocument22 pagesWheel Dozers TA2 ChecklistVictor Rodrigo Cortes YañezNo ratings yet

- ATS Catalogue Commercial Vehicle PartsCAT Ilovepdf CompressedDocument153 pagesATS Catalogue Commercial Vehicle PartsCAT Ilovepdf CompressedOleksandr U.50% (2)

- Makalah Tugas Bahasa Inggris Teknik Kimia UnilaDocument12 pagesMakalah Tugas Bahasa Inggris Teknik Kimia UnilaRhiki Sekti UtamiNo ratings yet

- Turbonetics 2014 Catalog MEDDocument53 pagesTurbonetics 2014 Catalog MEDGiuliano Gj100% (2)

- Chapter5 2Document55 pagesChapter5 2Digonto ChowdhuryNo ratings yet

- ISL8.9 330 P7-1: Engine Performance CurveDocument2 pagesISL8.9 330 P7-1: Engine Performance CurveFelipe AlmeidaNo ratings yet

- VRF DVM S Troubleshooting GL en 2016 Ver1 14Document190 pagesVRF DVM S Troubleshooting GL en 2016 Ver1 14El Manú ManúNo ratings yet

- Plant Air Centrifugal Compressors: Turbo-Air Series Featuring Oil-Free AirDocument20 pagesPlant Air Centrifugal Compressors: Turbo-Air Series Featuring Oil-Free AirSharad KokateNo ratings yet

- Heat Cummins PDFDocument3 pagesHeat Cummins PDFkamy_8524100% (1)

- Guascor SFGLD 480 Lean Burn Gas Engine: DimensionsDocument2 pagesGuascor SFGLD 480 Lean Burn Gas Engine: DimensionsEdu Lopez GarciaNo ratings yet