Professional Documents

Culture Documents

Blow Room, Part 1

Uploaded by

GM Sofiqul islam Sumon0 ratings0% found this document useful (0 votes)

12 views3 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views3 pagesBlow Room, Part 1

Uploaded by

GM Sofiqul islam SumonCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

1. What is Blow room?

Blow room is the 1st step of cotton yarn

manufacturing process. It consists of several

machines or operations. Functions of blow room

are---opening, cleaning, mixing & blending and

making suitable package (lap or chute).

Here the material is passed through different

machines by the help of airflow. That is why

scientists had given the name of total operation as

Blow room.

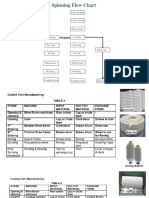

2. Show a list of machines in the Blow room.

A) Bale opener

B) Metal separator

C) Pre-cleaner

D) Multimixer

E) Fine-cleaner

F) Foreign particle separator

G) Chute feed system

3. Describe the functions of Blow room.

A) Opening: At the beginning, bale is taken to

start production. In the bale, cotton is highly

compressed. At the initial stage, by bale opener

(which uses powerful blade), some intermadiate

mass of cotton (flock) is produced. Finally by

applying airflow and beating, flocks are converted

into small mass named tuft. A tuft has a weight of

0.1 mg.

B) Cleaning: When opening occurs at blow room,

continuously dirts are coming out from inside. The

impurities are leaf, bark, seed, sand, plastic, paper,

thread etc. When a small amount of dirt is come out

from cotton, instantly these are to be taken away.

Air suction is the technology to remove the dirts

from cotton.

C) Mixing & blending:

Initially cotton bales are blended on the floor by

making a special plan to fulfill the buyer

requirement as well as to decrease the price. In the

middle of blow room these blended cotton are

mixed perfectly by a special machine named

multimix.

D) Even flow of cotton:

To make an even yarn it is essential to control the

flow of cotton evenly as maximum as possible. That

is why some optical sensors are used here to

control the flow of cotton.

E) Suitable output for carding:

At last modern Blow room produces chute instead

of lap where production is high, time is needed low

and even/regular mass/unit length.

You might also like

- Sustainable Innovations in Recycled TextilesFrom EverandSustainable Innovations in Recycled TextilesNo ratings yet

- Blow Room-3-1Document11 pagesBlow Room-3-1Tarif HasanNo ratings yet

- Blowroom Process in CottonDocument6 pagesBlowroom Process in Cottonrolandsalifu124No ratings yet

- Blow RoomDocument2 pagesBlow RoomRobotrix100% (1)

- YMT-I Class LectureDocument69 pagesYMT-I Class LectureMasud RanaNo ratings yet

- Lect2 - Blow Room 1Document18 pagesLect2 - Blow Room 1Mina Samy abd el zaherNo ratings yet

- Inspection of Waste Extracted by Different Machines of Spinning Department.Document3 pagesInspection of Waste Extracted by Different Machines of Spinning Department.Ammar Naeem BhattiNo ratings yet

- A Tour Report On Industrial Aqsa Khan 6249Document11 pagesA Tour Report On Industrial Aqsa Khan 6249Talha shabirNo ratings yet

- Spining ProcessDocument61 pagesSpining ProcessNiveditaKumariNo ratings yet

- Blow RoomDocument27 pagesBlow Roomapi-377494789% (19)

- Module 2 (Fibre - Fabric) : Indirect System Direct System Universal SystemDocument21 pagesModule 2 (Fibre - Fabric) : Indirect System Direct System Universal SystemKAWSER RAFINo ratings yet

- Bag FiltersDocument4 pagesBag FiltersDoaa Badarneh100% (1)

- Title:: Dust Removal in Spinning Section Department Third Year Textile Engineering Peer Group - 8Document13 pagesTitle:: Dust Removal in Spinning Section Department Third Year Textile Engineering Peer Group - 8gizachew adaneNo ratings yet

- Index:: Name of Industry: Harshanil Agro Industries PVT LTDDocument15 pagesIndex:: Name of Industry: Harshanil Agro Industries PVT LTDSoumyadip RoyNo ratings yet

- New Microsoft PowerPoint PresentationDocument10 pagesNew Microsoft PowerPoint PresentationfekadeNo ratings yet

- Ym-Assignment 1 (Roll#56)Document21 pagesYm-Assignment 1 (Roll#56)Huma AjmalNo ratings yet

- Prof YmDocument80 pagesProf YmGourav Katyal100% (1)

- 1224fabric Dust CollectorsDocument2 pages1224fabric Dust Collectorsrmm99rmm99No ratings yet

- Stenter Exhaust Heat Recovery For Combustion Air PreheatingDocument76 pagesStenter Exhaust Heat Recovery For Combustion Air Preheatingmohitishar100% (2)

- Blow RoomDocument4 pagesBlow RoomSuman Debnath IfNo ratings yet

- Assignment of Yern Formation: SUBJECT: Object of Blow Room and CardingDocument4 pagesAssignment of Yern Formation: SUBJECT: Object of Blow Room and CardingSuman Debnath IfNo ratings yet

- Ginning Paper 1Document8 pagesGinning Paper 1fekadeNo ratings yet

- Blowroom TheoryDocument5 pagesBlowroom TheoryRahul raman sahuNo ratings yet

- Basic Operations in The BlowroomDocument7 pagesBasic Operations in The BlowroomVikrant KanugondaNo ratings yet

- Cotton Spinning PDFDocument63 pagesCotton Spinning PDFMoody's100% (1)

- Fabric Manufacturing ProcessDocument13 pagesFabric Manufacturing ProcessChristian AsareNo ratings yet

- Yarn Manufacturing I Blow RoomDocument39 pagesYarn Manufacturing I Blow RoomLolla Ravi71% (7)

- Study On Air Jet Weaving MechanismDocument8 pagesStudy On Air Jet Weaving MechanismNaimul Hasan0% (1)

- Cotton GinningDocument9 pagesCotton GinningsaqureshNo ratings yet

- Introduction To BlowroomDocument21 pagesIntroduction To Blowroomsujal jha100% (1)

- Bale Opener: Belts and Rope DrivesDocument27 pagesBale Opener: Belts and Rope Drivesgizex2013No ratings yet

- Lect3 - Blow Room 2Document12 pagesLect3 - Blow Room 2Mina Samy abd el zaherNo ratings yet

- Raymond UCO DenimDocument25 pagesRaymond UCO DenimChaitanya Gajbhiye100% (1)

- Yarn-1, Report On Mill VisitDocument11 pagesYarn-1, Report On Mill VisitBoier Sesh Pata100% (2)

- Textile Internship at VardhmanDocument60 pagesTextile Internship at VardhmanNeetek SahayNo ratings yet

- Internship Report On Reliance Weaving MillsDocument49 pagesInternship Report On Reliance Weaving MillsAnthony Black75% (4)

- Fabric Dust Collector SystemsDocument50 pagesFabric Dust Collector Systemsbreyes25100% (3)

- Textile Spinning To Finishing Process: Business English ProgramDocument41 pagesTextile Spinning To Finishing Process: Business English ProgramM.TauqeerNo ratings yet

- 7.0 Fabric Filter & ScrubberDocument78 pages7.0 Fabric Filter & ScrubberohoreyNo ratings yet

- Sami Ullah AssignmentDocument7 pagesSami Ullah AssignmentUmår F ÃfriDiNo ratings yet

- Sami Ullah AssignmentDocument7 pagesSami Ullah AssignmentUmår F ÃfriDiNo ratings yet

- Sami AssignmentDocument7 pagesSami AssignmentUmår F ÃfriDiNo ratings yet

- Sami Ullah AssignmentDocument7 pagesSami Ullah AssignmentUmår F ÃfriDiNo ratings yet

- Sami Ullah AssignmentDocument7 pagesSami Ullah AssignmentUmår F ÃfriDiNo ratings yet

- Bag Filters Types, Working Principles & Daily Maintenance - INFINITY FOR CEMENT EQUIPMENT PDFDocument14 pagesBag Filters Types, Working Principles & Daily Maintenance - INFINITY FOR CEMENT EQUIPMENT PDFRICARDOALEXBORGES100% (2)

- Qasir Spinning ReportDocument60 pagesQasir Spinning ReportRana AtiqueNo ratings yet

- Chap 9Document12 pagesChap 9LLNo ratings yet

- Mixing:: Basic Tasks of Blow RoomDocument9 pagesMixing:: Basic Tasks of Blow RoommohitNo ratings yet

- Object of BlendingDocument5 pagesObject of Blendingnazmul wasickNo ratings yet

- Technical TextilesDocument40 pagesTechnical TextilesAmrutha RP0% (1)

- Design and Development of Pneumatic Cotton Picker: Durgesh Gupta, Jayesh Teli, Paras Badhe, Suraj BanhattiDocument3 pagesDesign and Development of Pneumatic Cotton Picker: Durgesh Gupta, Jayesh Teli, Paras Badhe, Suraj Banhattidurgesh3guptaNo ratings yet

- Stenter Exhaust Heat Recovery For Combustion Air PreheatingDocument17 pagesStenter Exhaust Heat Recovery For Combustion Air PreheatingMansoor Khanali100% (1)

- Blowroom: Basic OperationsDocument13 pagesBlowroom: Basic OperationsNeelakandan D100% (1)

- Ama 44 (1) 2013Document10 pagesAma 44 (1) 2013Associate Professor Dr. Said Elshahat AbdallahNo ratings yet

- Study of Comber MachineDocument6 pagesStudy of Comber MachineNaimul Hasan0% (1)

- Knit Fabric Dyeing Yarn CalculDocument14 pagesKnit Fabric Dyeing Yarn CalculMahabbat HossainNo ratings yet

- ElseDocument19 pagesElsepenihaniNo ratings yet

- Timo RissanenDocument10 pagesTimo RissanenAndreea-Livia IvanoviciNo ratings yet

- E-News Letter by Vahyu TechnologiesDocument3 pagesE-News Letter by Vahyu TechnologieskshahulhameedNo ratings yet