Professional Documents

Culture Documents

7b1-33 Camioneta JMC

7b1-33 Camioneta JMC

Uploaded by

Rusonegro0 ratings0% found this document useful (0 votes)

3 views1 page1) The document provides assembly instructions for mounting a reverse shaft and gear assembly onto a mid-plate.

2) It lists 9 steps to complete the assembly, which includes mounting the shaft, gears, and other components and securing them with nuts tightened to the specified torque.

3) Special attention is given to lubricating parts, matching gear positions, and ensuring the thrust washer is oriented correctly.

Original Description:

JMC Chino

Original Title

7b1-33 Camioneta JMC

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1) The document provides assembly instructions for mounting a reverse shaft and gear assembly onto a mid-plate.

2) It lists 9 steps to complete the assembly, which includes mounting the shaft, gears, and other components and securing them with nuts tightened to the specified torque.

3) Special attention is given to lubricating parts, matching gear positions, and ensuring the thrust washer is oriented correctly.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views1 page7b1-33 Camioneta JMC

7b1-33 Camioneta JMC

Uploaded by

Rusonegro1) The document provides assembly instructions for mounting a reverse shaft and gear assembly onto a mid-plate.

2) It lists 9 steps to complete the assembly, which includes mounting the shaft, gears, and other components and securing them with nuts tightened to the specified torque.

3) Special attention is given to lubricating parts, matching gear positions, and ensuring the thrust washer is oriented correctly.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 1

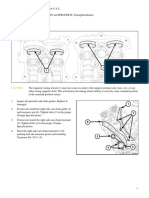

MSG 5E7B1-33

Important work

1.mid-plate

2.reverse shaft

1)Mount reverse shaft on mid-plate

2)Tight nuts with regulated torque.

Torque of shaft sleeve nut. mm

2

3)Place main shaft ①,gear assembly②and

countershaft gear assembly on fixing

equipment ③

Fixing equipment: 5-8840-2001-0

4)Claps fixing equipment (include major

and countershaft) with the pliers.

5)Match 3rd speed gear—4th speed gear at

3rd speed gear.

Match 1st speed gear—2nd speed gear at 1st speed gear.

6)Mount mid-plate to the ball bearing

between major shaft and countershaft gear

6.Reverse shaft bushing gear

8.Reverse gear lock nut of

countershaft.

1)Add oil to shaft bushing and reverse gear.

2)Mount reverse gear to shaft bushing.

3)Mount new mid-shaft reverse gear nuts.

Discard the used nuts

4)Tight the nuts to regulated torque.

Torque of lock nuts kg·m

11±1.0

9.Thrust washer

1)Add engine oil on both sides.

2)Install thrust washer on the mainshaft.

Thrust groove of thrust washer should be

faced side of reverse gear.

You might also like

- Important Work: 9.end Bearing of Mid-Shaft 10.5th Speed Gear of Mid-ShaftDocument1 pageImportant Work: 9.end Bearing of Mid-Shaft 10.5th Speed Gear of Mid-ShaftRusonegroNo ratings yet

- 7b1-12 Camioneta JMCDocument1 page7b1-12 Camioneta JMCRusonegroNo ratings yet

- VOLVO EC210 NLC EC210NLC EXCAVATOR Service Repair Manual PDFDocument16 pagesVOLVO EC210 NLC EC210NLC EXCAVATOR Service Repair Manual PDFfjjsjekdmme67% (3)

- Manual XQ29-1.8 Power Tong - MotDocument27 pagesManual XQ29-1.8 Power Tong - MotPedro GilNo ratings yet

- Levas Luv DmaxDocument5 pagesLevas Luv DmaxSamuel da SilvaNo ratings yet

- Calibracion de InyectoresDocument1 pageCalibracion de InyectoresJose FavaNo ratings yet

- Shop Manual Pc2000 8 Sen01607 00pd 381Document1 pageShop Manual Pc2000 8 Sen01607 00pd 3810005No ratings yet

- Cat3512camshaft TimingDocument4 pagesCat3512camshaft TimingEfrain FlorezNo ratings yet

- Spect Torque Cat 320DDocument8 pagesSpect Torque Cat 320Dlilik100% (2)

- XQ89 3YC英文说明书Document25 pagesXQ89 3YC英文说明书ADM MTC100% (1)

- Engine Installation: 1. Component ViewsDocument54 pagesEngine Installation: 1. Component ViewsEnriquealfonso Benavides CerdaNo ratings yet

- Location of ComponentsDocument103 pagesLocation of ComponentsAstrit Strati100% (1)

- Chery - SQR477F 1.5L 16V Sohc L4Document4 pagesChery - SQR477F 1.5L 16V Sohc L4ferran_alfonso0% (2)

- Nissan Almera n16 2001 Electronic Repair Manual 140Document1 pageNissan Almera n16 2001 Electronic Repair Manual 140netifig352No ratings yet

- Group 11 Front AxleDocument27 pagesGroup 11 Front AxleHậu MinhNo ratings yet

- Spect Torque Cat 320DDocument5 pagesSpect Torque Cat 320DlilikNo ratings yet

- MotorDocument9 pagesMotorjaimes.najithNo ratings yet

- SEN00322-04 50 Disassembly and AssemblyDocument10 pagesSEN00322-04 50 Disassembly and AssemblyЕгорNo ratings yet

- Point SheaveDocument2 pagesPoint SheaveGilney FreitasNo ratings yet

- Cigueñal CRD 2.8 SoportesDocument1 pageCigueñal CRD 2.8 Soportesgume pesaNo ratings yet

- Bifurcated Fan OM ManualDocument10 pagesBifurcated Fan OM ManualYana AzaharNo ratings yet

- Bomba Aceite Oil Cooler Carcasa FiltrosDocument15 pagesBomba Aceite Oil Cooler Carcasa FiltrosFredy QuistialNo ratings yet

- Axial Fan Series O&M ManualDocument11 pagesAxial Fan Series O&M ManualSebastian PrzybylowiczNo ratings yet

- DF Ghs Ergh SergDocument3 pagesDF Ghs Ergh SergThylaneNo ratings yet

- Fiesta 14 16v Fxja Engine Timing Belt GuideDocument1 pageFiesta 14 16v Fxja Engine Timing Belt GuideIdam Syahputra SamosirNo ratings yet

- SR4B 6AA Allign Single Bearing PDFDocument3 pagesSR4B 6AA Allign Single Bearing PDFMuhammad Usman ZamirNo ratings yet

- Reassembly of Basic EngineDocument19 pagesReassembly of Basic EnginePepe AlNo ratings yet

- Toyota 5FG33 45 5FD33 45 5FGE35 5FDE35 Forklift Service Repair Manual PDF - p135Document1 pageToyota 5FG33 45 5FD33 45 5FGE35 5FDE35 Forklift Service Repair Manual PDF - p135sơn forkliftNo ratings yet

- Power Train: Alternator RemovalDocument6 pagesPower Train: Alternator Removalchaos en venaNo ratings yet

- Final Drive AssemblyDocument118 pagesFinal Drive AssemblyKARTHICKRAJ KANDASAMYNo ratings yet

- ErhethrthdDocument2 pagesErhethrthdThylaneNo ratings yet

- 2 Piece Threaded Steel Ball Valves With Spring Return Installation, Operation, & Maintenance Guide 76-500/89-500 SeriesDocument3 pages2 Piece Threaded Steel Ball Valves With Spring Return Installation, Operation, & Maintenance Guide 76-500/89-500 SeriesRicardo OrdoñezNo ratings yet

- Cuidados Instalacion Bobina Motor EcotecDocument2 pagesCuidados Instalacion Bobina Motor Ecotecflash_24014910No ratings yet

- This Document Has Been Printed From SPI2. NOT FOR RESALE: Pump To ManifoldDocument1 pageThis Document Has Been Printed From SPI2. NOT FOR RESALE: Pump To Manifoldmoh asalanyNo ratings yet

- Alineacion CatDocument4 pagesAlineacion CatAndrea Zalamea100% (1)

- Suzuki APV Service ManualDocument7 pagesSuzuki APV Service ManualdhgdfgNo ratings yet

- Install Piston & Conrod 320 GCDocument3 pagesInstall Piston & Conrod 320 GCJebrodNo ratings yet

- Group 12 Rear AxleDocument23 pagesGroup 12 Rear AxleHậu MinhNo ratings yet

- Timing ChainDocument8 pagesTiming ChainAri Jeep Ppm100% (1)

- Dodge 3.6 TimingDocument8 pagesDodge 3.6 TimingBerg Auto Repairs100% (3)

- VW 20l CBDB Common Rail Engines Timing Belt Guide 1Document2 pagesVW 20l CBDB Common Rail Engines Timing Belt Guide 1Alberto DiazNo ratings yet

- Sincronizacion de Motor Suzuki j24bDocument15 pagesSincronizacion de Motor Suzuki j24bAndrés Sanín100% (3)

- Inplant Training ReportDocument56 pagesInplant Training Reportsankey11286No ratings yet

- Torque Bolt Main Bearing Engine GS1141 CATDocument3 pagesTorque Bolt Main Bearing Engine GS1141 CATM WahyudiNo ratings yet

- Assembling C32Document24 pagesAssembling C32Muhammad Ramadhan100% (2)

- Weichai Engine PrintDocument52 pagesWeichai Engine PrintKo ZayNo ratings yet

- Track Gearbox, Assembly: Service InformationDocument10 pagesTrack Gearbox, Assembly: Service InformationaungaungoomanualNo ratings yet

- 杰克科技股份有限公司 Jack Sewing Machine Co.,LtdDocument10 pages杰克科技股份有限公司 Jack Sewing Machine Co.,LtdSewing worldNo ratings yet

- Timing Belt Guide - Citron Saxo s0 s1 14 Liter Vts With Engine Code KFX KFW Tu3jpDocument6 pagesTiming Belt Guide - Citron Saxo s0 s1 14 Liter Vts With Engine Code KFX KFW Tu3jpSanteri SaariNo ratings yet

- Installation Procedure: NoticeDocument3 pagesInstallation Procedure: NoticeGlaidsonNo ratings yet

- Adjust InjectorDocument4 pagesAdjust InjectorAwanNo ratings yet

- Section 6-2Document80 pagesSection 6-2Raidul WafiNo ratings yet

- 142 PDFDocument38 pages142 PDFsoklongsrengNo ratings yet

- Group 10 TransmissionDocument54 pagesGroup 10 TransmissionDado OgameNo ratings yet

- 142 PDFDocument38 pages142 PDFsoklongsrengNo ratings yet

- ENGINE C15 (Torque de Bielas)Document4 pagesENGINE C15 (Torque de Bielas)Maquinaria Pesada ServisNo ratings yet

- Timing Chain: Service and Repair InstallationDocument3 pagesTiming Chain: Service and Repair InstallationDiego496No ratings yet

- Timing Chain: Service and Repair InstallationDocument3 pagesTiming Chain: Service and Repair InstallationDiego496No ratings yet

- Electrical (Generator and Electrical Plant): Modern Power Station PracticeFrom EverandElectrical (Generator and Electrical Plant): Modern Power Station PracticeRating: 4 out of 5 stars4/5 (9)

- Mechanical (Turbines and Auxiliary Equipment): Second Revised and Enlarged EditionFrom EverandMechanical (Turbines and Auxiliary Equipment): Second Revised and Enlarged EditionA. SherryRating: 4 out of 5 stars4/5 (5)

- 13-14.. Service Manual LoboDocument16 pages13-14.. Service Manual LoboRusonegroNo ratings yet

- 17-19Document58 pages17-19RusonegroNo ratings yet

- 12.. Lobo Service ManualDocument50 pages12.. Lobo Service ManualRusonegroNo ratings yet

- 8-11... Lobo Service ManualDocument41 pages8-11... Lobo Service ManualRusonegro100% (1)

- 7c-9 Embrague Camioneta JMCDocument1 page7c-9 Embrague Camioneta JMCRusonegroNo ratings yet

- 8-121&122 Embrague Camioneta JMCDocument2 pages8-121&122 Embrague Camioneta JMCRusonegroNo ratings yet

- MSG 5E7B1-4 Camioneta JMCDocument1 pageMSG 5E7B1-4 Camioneta JMCRusonegroNo ratings yet

- Type and Structure of Relay: Notes:1M Single Contact 2M Double Contact 1B Single ContactDocument21 pagesType and Structure of Relay: Notes:1M Single Contact 2M Double Contact 1B Single ContactRusonegroNo ratings yet

- 8-101 8-117 Embrague Camioneta JMCDocument18 pages8-101 8-117 Embrague Camioneta JMCRusonegroNo ratings yet

- 7b1-32 Camioneta JMCDocument1 page7b1-32 Camioneta JMCRusonegroNo ratings yet

- Major Gear and Counter Shaft Gears: TH RD TH RD RD ST STDocument1 pageMajor Gear and Counter Shaft Gears: TH RD TH RD RD ST STRusonegroNo ratings yet