Professional Documents

Culture Documents

Sri Vyjayanthi Labs Pvt. LTD.: Standard Operating Procedure Department: Title: Procedure For Zoning Area 1.0 Purpose

Uploaded by

SRI VYJAYANTHI QAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sri Vyjayanthi Labs Pvt. LTD.: Standard Operating Procedure Department: Title: Procedure For Zoning Area 1.0 Purpose

Uploaded by

SRI VYJAYANTHI QACopyright:

Available Formats

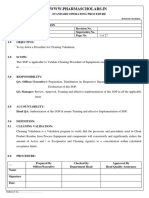

SRI VYJAYANTHI LABS PVT. LTD.

PLOT NO. 27/A, JNPC, PARAWADA (M) VISAKHAPATNAM – 531 019.

Doc No.: SVLL/PD/SOP/034-00

Standard Issue date : Effective date:

Operating

Procedure Review date :

Supersedes: Nil

Page 1 of 3

Department: Production

TITLE: PROCEDURE FOR ZONING AREA

1.0 Purpose:

To describe the procedure for zoning areas in Production block.

2.0 Scope:

This procedure is applicable for segregation of zoning areas in manufacturing Block-A at Sri

Vyjayanthi Labs Pvt. Ltd.

3.0 Definitions: Nil

4.0 Responsibility:

Production in-charge and operators shall responsible and follow the SOP.

The department head shall responsible for reviewing the SOP.

Quality Assurance shall responsible for compliance with the SOP.

5.0 Procedure:

5.1 The zoning areas in production block-A has identified the same to avoid cross

contamination.

5.2 The degree of hygiene control in the facility depends on the type of the operation and the

analysis of the potential risk.

5.3 The more sensitive of the product, the more important it is to be given and separate the

facility into different hygiene areas.

Prepared by Reviewed by Approved by

Name V.MADHAVA RAO

Designation EXECUTIVE - PD MANAGER - PD MANAGER - QA

Sign & Date

SRI VYJAYANTHI LABS PVT. LTD.

PLOT NO. 27/A, JNPC, PARAWADA (M) VISAKHAPATNAM – 531 019.

Doc No.: SVLL/PD/SOP/034-00 Page 2 of 3

TITLE: PROCEDURE FOR ZONING AREA

5.4 Each manufacturing operation requires an appropriate environmental cleanliness level in

order to minimize risks of contamination.

5.5 The facility is divided into areas with different allowable processing steps, different rules

or procedures for persons who are allowed to entry with different levels of cleanliness

5.6 The areas are classified as Low, Medium and High hygiene areas.

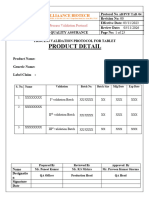

Types of Zones:

5.6.1 High hygiene area (Drying, Milling, Sifting, Blending and packing area)

5.6.2 Medium hygiene area (Crystallization and Buchner area)

5.6.3 Basic / Low Hygiene area (Corridor area)

5.7 High hygiene area:

High hygiene areas are those where dry material of the product is exposed to environment

and personnel and to pathogenic growth in this area operating practices relating to

personnel, product are to be controlled to minimize contamination.

5.8 Medium hygiene area:

Medium hygiene areas in which the material will be under washing treatment and in wet

condition.

5.9 Basic hygiene area /Low Hygiene area:

Low Hygiene areas are those where the material and men movement is present.

Prepared by Reviewed by Approved by

Name V.MADHAVA RAO

Designation EXECUTIVE - PD MANAGER - PD MANAGER - QA

Sign & Date

SRI VYJAYANTHI LABS PVT. LTD.

PLOT NO. 27/A, JNPC, PARAWADA (M) VISAKHAPATNAM – 531 019.

Doc No.: SVLL/PD/SOP/034-00 Page 3 of 3

TITLE: PROCEDURE FOR ZONING AREA

Hygienic Zoning

lcif

Ca

ica

Zo

tio

ne

of

n

6.0 Related Documents: Nil

7.0 Revision Record:

Date Revision Status Details of Revision Remarks

00 First issue --

Prepared by Reviewed by Approved by

Name V.MADHAVA RAO

Designation EXECUTIVE - PD MANAGER - PD MANAGER - QA

Sign & Date

You might also like

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- The Laboratory Quality Assurance System: A Manual of Quality Procedures and FormsFrom EverandThe Laboratory Quality Assurance System: A Manual of Quality Procedures and FormsNo ratings yet

- Color Code SopDocument2 pagesColor Code SopSRI VYJAYANTHI QANo ratings yet

- Medioint Lifescience PVT - LTD.: Standard Operating ProcedureDocument3 pagesMedioint Lifescience PVT - LTD.: Standard Operating ProcedureChoudhary DhirajNo ratings yet

- Break Down of Equipments and Machines - SopDocument3 pagesBreak Down of Equipments and Machines - SopSRI VYJAYANTHI QANo ratings yet

- Oasis: Laboratories Private Limited, DehradunDocument4 pagesOasis: Laboratories Private Limited, DehradunASHOK KUMAR LENKANo ratings yet

- Medioint Lifescience PVT - LTD.: Standard Operating ProcedureDocument3 pagesMedioint Lifescience PVT - LTD.: Standard Operating ProcedureChoudhary DhirajNo ratings yet

- Air Monitoring by Settle Plate BL-MC-03 01.09.2021Document3 pagesAir Monitoring by Settle Plate BL-MC-03 01.09.2021nishthaNo ratings yet

- Medioint Lifescience PVT - LTD.: Standard Operating ProcedureDocument3 pagesMedioint Lifescience PVT - LTD.: Standard Operating ProcedureChoudhary DhirajNo ratings yet

- Surface Testing SOP 08.09.21Document5 pagesSurface Testing SOP 08.09.21nishthaNo ratings yet

- AHU Protocol.Document12 pagesAHU Protocol.Jinna SmaNo ratings yet

- Performance Qualification Protocol Cum OF Weighing Balance: Document No. MG/PQ/BAL-00 Page 1 of 12 Effective DateDocument12 pagesPerformance Qualification Protocol Cum OF Weighing Balance: Document No. MG/PQ/BAL-00 Page 1 of 12 Effective DateMAXTAR BIO-GENICSNo ratings yet

- APQP Format NationalDocument53 pagesAPQP Format NationalqualityNo ratings yet

- Medioint Lifescience PVT - LTD.: Standard Operating ProcedureDocument3 pagesMedioint Lifescience PVT - LTD.: Standard Operating ProcedureChoudhary DhirajNo ratings yet

- 5-Safety Guidelines in QC DepartmentDocument6 pages5-Safety Guidelines in QC DepartmentJAGADISH PHARMACEUTICALSNo ratings yet

- Installation Qualification Protocol Cum OF Weighing Balance: Document No. MG/IQ/BAL-00 Page 1 of 12 Effective DateDocument12 pagesInstallation Qualification Protocol Cum OF Weighing Balance: Document No. MG/IQ/BAL-00 Page 1 of 12 Effective DateMAXTAR BIO-GENICSNo ratings yet

- 004 Handling of Deviation 2-1Document16 pages004 Handling of Deviation 2-1Sagar ChavanNo ratings yet

- Operation Qualification Protocol Cum OF Weighing Balance: Document No. MG/OQ/BAL-00 Page 1 of 11 Effective DateDocument11 pagesOperation Qualification Protocol Cum OF Weighing Balance: Document No. MG/OQ/BAL-00 Page 1 of 11 Effective DateMAXTAR BIO-GENICSNo ratings yet

- Validation Report of Sampling Rod-12!02!13Document13 pagesValidation Report of Sampling Rod-12!02!13P HeramsNo ratings yet

- OOT NWDocument2 pagesOOT NWSagar ChavanNo ratings yet

- Confidentialit SopDocument6 pagesConfidentialit SopVaibhav GadhaweNo ratings yet

- Process Validation Protocol of Desvel 50Mg Tablet: Medisure Laboratories Pakistan (PVT.) LTDDocument16 pagesProcess Validation Protocol of Desvel 50Mg Tablet: Medisure Laboratories Pakistan (PVT.) LTDsamia khanNo ratings yet

- SOP For Change OverDocument6 pagesSOP For Change OverJayesh Meharwal100% (3)

- 022 Operation Procedure For Gas Chromatography - 04Document6 pages022 Operation Procedure For Gas Chromatography - 04surendra varmaNo ratings yet

- PAS 220 ChecklistDocument25 pagesPAS 220 ChecklistRameshNo ratings yet

- NFPL D23 08Document2 pagesNFPL D23 08harun bdNo ratings yet

- SopDocument1 pageSopNaomi RosadoNo ratings yet

- 01 Cleaning of Vibratory Sifter CL-01Document3 pages01 Cleaning of Vibratory Sifter CL-01Ravi YadavNo ratings yet

- 18 Rabiprazole Capsule.Document15 pages18 Rabiprazole Capsule.negishivam679No ratings yet

- Sop For Destruction of Sample After Analysis.Document5 pagesSop For Destruction of Sample After Analysis.vasant ugaleNo ratings yet

- Standard Operating Procedure Somatec: Title: Sop For SopDocument2 pagesStandard Operating Procedure Somatec: Title: Sop For SopMajed Hossain MasumNo ratings yet

- Sop 003 For Analysis of Rinse SampleDocument3 pagesSop 003 For Analysis of Rinse Samplevasant ugale100% (1)

- AI-VO-PRC-004 R1 Procedure For Inspection DefermentDocument14 pagesAI-VO-PRC-004 R1 Procedure For Inspection Defermentkhairie rahimNo ratings yet

- Sop For Environmental Monitoring For PersonnelDocument4 pagesSop For Environmental Monitoring For PersonnelMusyoka UrbanusNo ratings yet

- 7T04 CS Kma PR ND 0005Document12 pages7T04 CS Kma PR ND 0005Hatem Ragab100% (1)

- SOP FOR STIFFNESS Tester (09.6.17)Document2 pagesSOP FOR STIFFNESS Tester (09.6.17)Q ANo ratings yet

- PVPRDocument47 pagesPVPRBRIJENDRA KUMAR SINGH100% (2)

- F03qa038-00 VMPDocument24 pagesF03qa038-00 VMPMeet Vermaa100% (1)

- Maintenance of DesiccatorDocument3 pagesMaintenance of Desiccatorsaadi387100% (2)

- MHL-VLP-XX Fumigation ValidationDocument10 pagesMHL-VLP-XX Fumigation ValidationMedicare Hygiene LimitedNo ratings yet

- MB-01-005-Procedure For Collection of Swab Samples From Equipments and FloorsDocument2 pagesMB-01-005-Procedure For Collection of Swab Samples From Equipments and FloorsmeghaNo ratings yet

- CV Protocol-Coated TabletsDocument22 pagesCV Protocol-Coated Tabletsqaheadjml007No ratings yet

- Different Mesh Sizes and Mesh To Micron ConversionDocument10 pagesDifferent Mesh Sizes and Mesh To Micron ConversionDevanandDongreNo ratings yet

- Prosedur Penetran TestingDocument11 pagesProsedur Penetran TestingIkhsan DalimuntheNo ratings yet

- Cleaning Validation Cleaning Validation Is A Validation Program To VerifyDocument27 pagesCleaning Validation Cleaning Validation Is A Validation Program To Verify董彬彬100% (2)

- 36 Leak Test Apparatus 036Document2 pages36 Leak Test Apparatus 036ASHOK KUMAR LENKANo ratings yet

- OQ Protocol Air ShowerDocument6 pagesOQ Protocol Air Showerziauddin bukhari0% (1)

- SOP of Line Clearance of Manufacturing AreaDocument3 pagesSOP of Line Clearance of Manufacturing Areashekhar khanal0% (1)

- PQ-Sample fIVEDocument13 pagesPQ-Sample fIVEcpkakopeNo ratings yet

- Sakuti Method - Statement - For - HRSG - Works CrsherDocument32 pagesSakuti Method - Statement - For - HRSG - Works CrsherMIL RABNo ratings yet

- Wnp-Qc-Sop-011 Procedure For Referenced & Working StandardsDocument6 pagesWnp-Qc-Sop-011 Procedure For Referenced & Working StandardsMuhammad ImranNo ratings yet

- QAD 002 Change Control ProcedureDocument14 pagesQAD 002 Change Control ProcedureShejil BalakrishnanNo ratings yet

- Tugas 5 (PQ Sterilization Autoclave UII Grup 1) PDFDocument9 pagesTugas 5 (PQ Sterilization Autoclave UII Grup 1) PDFsetyaNo ratings yet

- PPEPL-SOP-03 Procedure For Control of NCDocument7 pagesPPEPL-SOP-03 Procedure For Control of NCRaja RehaNo ratings yet

- Cleaning of Sampling BoothDocument4 pagesCleaning of Sampling Boothasit_m100% (3)

- Genetica Laboratory Pvt. LTD: Standard Operating ProcedureDocument2 pagesGenetica Laboratory Pvt. LTD: Standard Operating ProcedureRajendra ChaudharyNo ratings yet

- NFPL D23 09Document2 pagesNFPL D23 09harun bdNo ratings yet

- Microbiology Sop SDocument33 pagesMicrobiology Sop SAngel CvetanovNo ratings yet

- Latest Tablet ProtocolDocument23 pagesLatest Tablet Protocolnegishivam679No ratings yet

- Sucralfate Oral SuspensionDocument17 pagesSucralfate Oral SuspensionOm PandeyNo ratings yet

- M7 Addendum Step 2Document89 pagesM7 Addendum Step 2SRI VYJAYANTHI QANo ratings yet

- Different Mesh Sizes and Mesh To Micron Conversion - Pharmaceutical Guidelines PDFDocument1 pageDifferent Mesh Sizes and Mesh To Micron Conversion - Pharmaceutical Guidelines PDFSRI VYJAYANTHI QANo ratings yet

- WHO Annex 3 GMP-Water 7feb06Document20 pagesWHO Annex 3 GMP-Water 7feb06SRI VYJAYANTHI QANo ratings yet

- CPK 16.02.2022Document1 pageCPK 16.02.2022SRI VYJAYANTHI QANo ratings yet

- SVLL - Mesh Sizes Details PDFDocument3 pagesSVLL - Mesh Sizes Details PDFSRI VYJAYANTHI QANo ratings yet

- Glass Policy, Metal and Hygiene policy-VMRDocument3 pagesGlass Policy, Metal and Hygiene policy-VMRSRI VYJAYANTHI QANo ratings yet

- Case StudyDocument18 pagesCase StudySRI VYJAYANTHI QANo ratings yet

- Do's Dont's 1.: Sri Vyjayanthi Labs Pvt. LTDDocument2 pagesDo's Dont's 1.: Sri Vyjayanthi Labs Pvt. LTDSRI VYJAYANTHI QANo ratings yet

- Chapter 3 HACCP Workbook TemplateDocument18 pagesChapter 3 HACCP Workbook TemplateSRI VYJAYANTHI QANo ratings yet

- Glass Breakage SOP-SatyaDocument5 pagesGlass Breakage SOP-SatyaSRI VYJAYANTHI QANo ratings yet

- (Inc. Barcharts) Senses Laminated Reference Guide (Z Lib - Org)Document2 pages(Inc. Barcharts) Senses Laminated Reference Guide (Z Lib - Org)Camilo Ignacio Arriagada Jara100% (1)

- Food Safety SOPWIENPFINALNon Cookingfacilitiesrevised 813Document51 pagesFood Safety SOPWIENPFINALNon Cookingfacilitiesrevised 813SRI VYJAYANTHI QANo ratings yet

- Glass Policy & Hard Plastic PolicyDocument2 pagesGlass Policy & Hard Plastic PolicySRI VYJAYANTHI QANo ratings yet

- Food Safety by Implementation of Haccp in Dairy and Food IndustryDocument17 pagesFood Safety by Implementation of Haccp in Dairy and Food IndustrySRI VYJAYANTHI QANo ratings yet

- Food Defence 16-03-2016NPBDocument11 pagesFood Defence 16-03-2016NPBSRI VYJAYANTHI QANo ratings yet

- Unique Insulation Technology: A Zotefoams PLC BrandDocument8 pagesUnique Insulation Technology: A Zotefoams PLC BrandSRI VYJAYANTHI QANo ratings yet

- T Fit Clean Tech PDFDocument2 pagesT Fit Clean Tech PDFSRI VYJAYANTHI QANo ratings yet

- Customer Information Sheet-KPS Engineers-17.07.2020Document2 pagesCustomer Information Sheet-KPS Engineers-17.07.2020SRI VYJAYANTHI QANo ratings yet

- Mistakes in The Document PDFDocument14 pagesMistakes in The Document PDFSRI VYJAYANTHI QANo ratings yet

- Credit CreationDocument17 pagesCredit Creationaman100% (1)

- Cir V SLMC DigestDocument3 pagesCir V SLMC DigestYour Public ProfileNo ratings yet

- List of Industries PackingDocument6 pagesList of Industries PackingRavichandran SNo ratings yet

- 11th 12th Economics Q EM Sample PagesDocument27 pages11th 12th Economics Q EM Sample PagesKirthika RajaNo ratings yet

- Long Tom SluiceDocument6 pagesLong Tom SluiceJovanny HerreraNo ratings yet

- Example of A Project CharterDocument9 pagesExample of A Project CharterHenry Sithole100% (1)

- Chapter 6 - An Introduction To The Tourism Geography of EuroDocument12 pagesChapter 6 - An Introduction To The Tourism Geography of EuroAnonymous 1ClGHbiT0JNo ratings yet

- Laboratory Rules and SafetyDocument2 pagesLaboratory Rules and SafetySamantha Tachtenberg100% (1)

- Q3 Las WK 2 - Applied EconomicsDocument10 pagesQ3 Las WK 2 - Applied Economicsmichelle ann luzon100% (1)

- Antwerp Dimamond CaseDocument5 pagesAntwerp Dimamond Casechiranjeeb mitra100% (1)

- Ra 11057Document16 pagesRa 11057Rio Sanchez100% (9)

- Od124222428139339000 4Document2 pagesOd124222428139339000 4biren shahNo ratings yet

- 3M Knowledge Management-Group 1Document22 pages3M Knowledge Management-Group 1Siddharth Sourav PadheeNo ratings yet

- Diffrent Income Group Houses in IndiaDocument1 pageDiffrent Income Group Houses in IndiaAatma SahniNo ratings yet

- Contoh Presentasi PerusahaanDocument20 pagesContoh Presentasi PerusahaanTafrihan Puput SantosaNo ratings yet

- Wedding BlissDocument16 pagesWedding BlissThe Myanmar TimesNo ratings yet

- Economic Development Complete NotesDocument36 pagesEconomic Development Complete Notessajad ahmadNo ratings yet

- Institutional Investor - 07 JUL 2009Document72 pagesInstitutional Investor - 07 JUL 2009jumanleeNo ratings yet

- Sim CBM 122 Lesson 3Document9 pagesSim CBM 122 Lesson 3Andrew Sy ScottNo ratings yet

- Report On Brick - 1Document6 pagesReport On Brick - 1Meghashree100% (1)

- Rich Dad Poor Dad: Book SummaryDocument7 pagesRich Dad Poor Dad: Book SummarySnehal YagnikNo ratings yet

- Jose C. Guico For Petitioner. Wilfredo Cortez For Private RespondentsDocument5 pagesJose C. Guico For Petitioner. Wilfredo Cortez For Private Respondentsmichelle m. templadoNo ratings yet

- RECEIPTSDocument6 pagesRECEIPTSLyka DanniellaNo ratings yet

- MBBS MO OptionsDocument46 pagesMBBS MO Optionskrishna madkeNo ratings yet

- Political Economy of Media - A Short IntroductionDocument5 pagesPolitical Economy of Media - A Short Introductionmatthewhandy100% (1)

- SMR0275 Four Horsemen of The American Apocalypse ReportDocument44 pagesSMR0275 Four Horsemen of The American Apocalypse Reportmaat3x3No ratings yet

- Sustainability at Whole FoodsDocument13 pagesSustainability at Whole FoodsHannah Erickson100% (1)

- Dennis Redmond Adorno MicrologiesDocument14 pagesDennis Redmond Adorno MicrologiespatriceframbosaNo ratings yet

- Udai Pareek Scal For SES RuralDocument3 pagesUdai Pareek Scal For SES Ruralopyadav544100% (1)

- Compact Heat Exchangers Heat Exchanger Types and ClassificationsDocument39 pagesCompact Heat Exchangers Heat Exchanger Types and Classificationsasyer aryoNo ratings yet