Professional Documents

Culture Documents

CPK 16.02.2022

Uploaded by

SRI VYJAYANTHI QA0 ratings0% found this document useful (0 votes)

11 views1 pageOriginal Title

CPK 16.02.2022.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views1 pageCPK 16.02.2022

Uploaded by

SRI VYJAYANTHI QACopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

5.

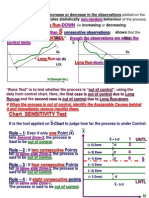

1 Process capability is carried out for the critical analytical parameters to be

calculated as follows.

CpK= USL-X or X-LSL

3* SD is 3 sigma

USL= Average + 3Sigma

LSL= Average -3sigma

Where USL= Upper specification Limit.

LSL= Lower specification Limit.

X= mean

SD= standard Deviation

This calculation helps to understand how close the process is producing out

comes compared to what the specification is.

Interpretation:

Cpk< 1.0 i.e. Not capable

Cpk 1.00 to 1.33 i.e. product is barely manufactured

Cpk 1.34 to 3.00 i.e. process is good

Cpk > 3.00 i.e. process is excellent

Note: Minimum 10 batches are required to calculate the process capability.

You might also like

- Lean Six Sigma Black Belt Mock ExamDocument26 pagesLean Six Sigma Black Belt Mock ExamAnonymous G5vlroDv100% (1)

- Capability ProcessDocument45 pagesCapability ProcessNurhayati SitorusNo ratings yet

- SPC Training 20230929Document38 pagesSPC Training 20230929rav.virendraNo ratings yet

- Chapter Six Process Capability Analysis: Daniel AbDocument24 pagesChapter Six Process Capability Analysis: Daniel AbComputer Maintainance Hardware and softwareNo ratings yet

- PTT LTTDocument1 pagePTT LTTbuddy122No ratings yet

- Process CapabilityDocument19 pagesProcess CapabilityRohit AroraNo ratings yet

- Process CapabilityDocument19 pagesProcess CapabilityFritz Jay TorreNo ratings yet

- JPM TQM Course Mat-5 T-3 Imba 2013Document14 pagesJPM TQM Course Mat-5 T-3 Imba 2013Vishnu PrasadNo ratings yet

- 01 Process CapabilityDocument33 pages01 Process CapabilitySrinivasagam Venkataramanan100% (1)

- Lecture 8-Process Capability PDFDocument29 pagesLecture 8-Process Capability PDFWoon How100% (1)

- 6.4 Process CapabilityDocument13 pages6.4 Process CapabilitychuszNo ratings yet

- CPKDocument1 pageCPKelisboa10No ratings yet

- Capability InfoDocument14 pagesCapability Infoantipstore004No ratings yet

- Statistical Process Control: by H.S.PundleDocument31 pagesStatistical Process Control: by H.S.PundlePALLAVI BHISENo ratings yet

- Advanced Process CapabilityDocument11 pagesAdvanced Process Capabilitycheqjieja100% (1)

- Process Capability - ToolDocument26 pagesProcess Capability - ToolFouzan SoniwalaNo ratings yet

- Processcapability Training PresentationDocument75 pagesProcesscapability Training PresentationVictoriaNo ratings yet

- Chapter 5a Process CapabilityDocument17 pagesChapter 5a Process CapabilityAnanthanarayananNo ratings yet

- Process Capability Index (CPK)Document5 pagesProcess Capability Index (CPK)lovlinNo ratings yet

- Reliability Software-RCMDocument1 pageReliability Software-RCMSandeep KumarNo ratings yet

- Process CapabilityDocument5 pagesProcess CapabilityLibyaFlowerNo ratings yet

- Process CapabilityDocument10 pagesProcess CapabilityskptcaeNo ratings yet

- What Should Be The CPK Limit in Asean Harmonization Guideline?Document48 pagesWhat Should Be The CPK Limit in Asean Harmonization Guideline?Praphon TangwongsathitchokNo ratings yet

- Process Capab SixsigmaDocument3 pagesProcess Capab SixsigmaHemantNo ratings yet

- ProcesscapabilityindicesDocument6 pagesProcesscapabilityindiceskripingNo ratings yet

- Process Capability: Process Capability Is Also Defined As The Capability of A Process To MeetDocument13 pagesProcess Capability: Process Capability Is Also Defined As The Capability of A Process To MeetNazia SyedNo ratings yet

- (1997) Process Capability Analysis For Non-Normal Relay Test DataDocument8 pages(1997) Process Capability Analysis For Non-Normal Relay Test DataNELSONHUGONo ratings yet

- SPCDocument12 pagesSPCalpanakaurNo ratings yet

- Basics of CapabilityDocument18 pagesBasics of Capabilitymancheung6429No ratings yet

- Chapter # 07 (Six Sigma)Document50 pagesChapter # 07 (Six Sigma)Hassan TariqNo ratings yet

- Process Capability Indices PDFDocument6 pagesProcess Capability Indices PDFasamadhNo ratings yet

- 4 Aa Process CapabilityDocument30 pages4 Aa Process CapabilityAniket Jain100% (2)

- Process Capability and Statistical Quality ControlDocument38 pagesProcess Capability and Statistical Quality ControlSuraj KumarNo ratings yet

- Metodologi Six Sigma Pertemuan 1Document13 pagesMetodologi Six Sigma Pertemuan 1Rafi YanuarNo ratings yet

- ASQ Process Capbility Overview Mar 10Document66 pagesASQ Process Capbility Overview Mar 10MuthuswamyNo ratings yet

- QMCS 16 - 2 Process CapabilityDocument27 pagesQMCS 16 - 2 Process CapabilityalegabipachecoNo ratings yet

- Capability Indices: P P P PKDocument5 pagesCapability Indices: P P P PKNeshika Pillay-NaidooNo ratings yet

- Six Sigma Vs TaguchiDocument14 pagesSix Sigma Vs TaguchiemykosmNo ratings yet

- Natural Tolerance Limits: Ch. 7 Process Capability Analysis (PCA)Document7 pagesNatural Tolerance Limits: Ch. 7 Process Capability Analysis (PCA)Ardian ArdianNo ratings yet

- CPK GuidelinesDocument2 pagesCPK GuidelinesNavnath Tamhane100% (1)

- Muhammad-Asif Process CapabilityDocument29 pagesMuhammad-Asif Process CapabilityJehan B KothariNo ratings yet

- CP, CPKDocument18 pagesCP, CPKsunjjoy gupta100% (1)

- Process and Measurement System Capability AnalysisDocument18 pagesProcess and Measurement System Capability AnalysisUtkarsh MittalNo ratings yet

- Quantitative Capability AssessmentDocument21 pagesQuantitative Capability Assessmentbeto206123No ratings yet

- The Quality Improvement Model: Is Process Capable?Document19 pagesThe Quality Improvement Model: Is Process Capable?shafie_buangNo ratings yet

- Process Capability IndicesDocument6 pagesProcess Capability IndicesVsm Krishna Sai EturiNo ratings yet

- 5 - Process CapabilityDocument50 pages5 - Process CapabilityWilliam BautistaNo ratings yet

- CPK Guide 0211 TECH1Document11 pagesCPK Guide 0211 TECH1Mark LacroNo ratings yet

- Process Capability To Prevent Failures: K.P.S.VermaDocument18 pagesProcess Capability To Prevent Failures: K.P.S.VermaeuserodriguezNo ratings yet

- USL LSL Min, 3 3Document1 pageUSL LSL Min, 3 3shaktimanNo ratings yet

- Process CapabilityDocument4 pagesProcess CapabilityLeonardo SanchezNo ratings yet

- Process Capability and Six SigmaDocument32 pagesProcess Capability and Six SigmaDr EngineerNo ratings yet

- CP and CPK SolutionDocument5 pagesCP and CPK SolutionlawtonNo ratings yet

- 1.8V 0.18 M CMOS Novel Successive Approximation ADC With Variable Sampling RateDocument5 pages1.8V 0.18 M CMOS Novel Successive Approximation ADC With Variable Sampling RateMiguel BrunoNo ratings yet

- Process Capability1Document29 pagesProcess Capability1Ashish KumawatNo ratings yet

- Chapter 6 - Process Capability AnalysisDocument21 pagesChapter 6 - Process Capability AnalysisKaya Eralp AsanNo ratings yet

- Projects With Microcontrollers And PICCFrom EverandProjects With Microcontrollers And PICCRating: 5 out of 5 stars5/5 (1)

- M7 Addendum Step 2Document89 pagesM7 Addendum Step 2SRI VYJAYANTHI QANo ratings yet

- Different Mesh Sizes and Mesh To Micron Conversion - Pharmaceutical Guidelines PDFDocument1 pageDifferent Mesh Sizes and Mesh To Micron Conversion - Pharmaceutical Guidelines PDFSRI VYJAYANTHI QANo ratings yet

- WHO Annex 3 GMP-Water 7feb06Document20 pagesWHO Annex 3 GMP-Water 7feb06SRI VYJAYANTHI QANo ratings yet

- Chapter 3 HACCP Workbook TemplateDocument18 pagesChapter 3 HACCP Workbook TemplateSRI VYJAYANTHI QANo ratings yet

- SVLL - Mesh Sizes Details PDFDocument3 pagesSVLL - Mesh Sizes Details PDFSRI VYJAYANTHI QANo ratings yet

- Glass Breakage SOP-SatyaDocument5 pagesGlass Breakage SOP-SatyaSRI VYJAYANTHI QANo ratings yet

- Case StudyDocument18 pagesCase StudySRI VYJAYANTHI QANo ratings yet

- Sri Vyjayanthi Labs Pvt. LTD.: Standard Operating Procedure Department: Title: Procedure For Zoning Area 1.0 PurposeDocument3 pagesSri Vyjayanthi Labs Pvt. LTD.: Standard Operating Procedure Department: Title: Procedure For Zoning Area 1.0 PurposeSRI VYJAYANTHI QANo ratings yet

- Do's Dont's 1.: Sri Vyjayanthi Labs Pvt. LTDDocument2 pagesDo's Dont's 1.: Sri Vyjayanthi Labs Pvt. LTDSRI VYJAYANTHI QANo ratings yet

- Glass Policy, Metal and Hygiene policy-VMRDocument3 pagesGlass Policy, Metal and Hygiene policy-VMRSRI VYJAYANTHI QANo ratings yet

- Break Down of Equipments and Machines - SopDocument3 pagesBreak Down of Equipments and Machines - SopSRI VYJAYANTHI QANo ratings yet

- Color Code SopDocument2 pagesColor Code SopSRI VYJAYANTHI QANo ratings yet

- (Inc. Barcharts) Senses Laminated Reference Guide (Z Lib - Org)Document2 pages(Inc. Barcharts) Senses Laminated Reference Guide (Z Lib - Org)Camilo Ignacio Arriagada Jara100% (1)

- Food Safety SOPWIENPFINALNon Cookingfacilitiesrevised 813Document51 pagesFood Safety SOPWIENPFINALNon Cookingfacilitiesrevised 813SRI VYJAYANTHI QANo ratings yet

- Glass Policy & Hard Plastic PolicyDocument2 pagesGlass Policy & Hard Plastic PolicySRI VYJAYANTHI QANo ratings yet

- Food Safety by Implementation of Haccp in Dairy and Food IndustryDocument17 pagesFood Safety by Implementation of Haccp in Dairy and Food IndustrySRI VYJAYANTHI QANo ratings yet

- Food Defence 16-03-2016NPBDocument11 pagesFood Defence 16-03-2016NPBSRI VYJAYANTHI QANo ratings yet

- Unique Insulation Technology: A Zotefoams PLC BrandDocument8 pagesUnique Insulation Technology: A Zotefoams PLC BrandSRI VYJAYANTHI QANo ratings yet

- T Fit Clean Tech PDFDocument2 pagesT Fit Clean Tech PDFSRI VYJAYANTHI QANo ratings yet

- Customer Information Sheet-KPS Engineers-17.07.2020Document2 pagesCustomer Information Sheet-KPS Engineers-17.07.2020SRI VYJAYANTHI QANo ratings yet

- Mistakes in The Document PDFDocument14 pagesMistakes in The Document PDFSRI VYJAYANTHI QANo ratings yet