Professional Documents

Culture Documents

29 05 2022 591393450

29 05 2022 591393450

Uploaded by

K KARTHIK0 ratings0% found this document useful (0 votes)

5 views41 pagesdfhfg

Original Title

29_05_2022_591393450

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentdfhfg

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views41 pages29 05 2022 591393450

29 05 2022 591393450

Uploaded by

K KARTHIKdfhfg

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 41

Nationa

Minis

try Of R

ormat for j

formation to QM for Inspection of Om

GENERAL;

Work: (check Wany one box)

ML Date of inspection:

I. Name of quality monitor (QM):

Vv.

Rural Infrastr

‘ucture Development Agency

ural Development, Government of India

Format QB Version 2021.0- Part I

going/Completed Bridge Work

PARTE Work tnformation (Lo be iled-uo by PIL)

FT hetregen [compieica |

204 ore

wow J[ coo] _]

SRATENPRA PRACAD. SoM || couch3zae)

State:

TE ANA AWA District: MATA BURNALAR Block: DEVARKA DRA

V. Name ofbridge& [EqneTaaTiON oF HEUH LEVEL BREDAR OW RIF]

Location RacWh Tt pALLY TO PE veKAD he (oo

VI. Package number. TS04DE pipe .

VII. Sanctioned length of the bridge.: S432"

Deviation in length of the bridge (If any). =m

ave SEDO

IX. Estimated cost (as cleared by GOD): Rs rB5b-26 (CO eae. ‘Jak

X. Technical sanction cost Re eSteee, La

XI. Awarded cost: Rs. L$%.> OL Lakh

XII. Expenditure: (if work is ongoing) a. Expenditure done: [ Rs, == Lakh

b. Bills pending: Rs = Lakh

Total expenditure = (arb) [Rs — Lakh

XIII, Completion cost: (if work is completed) Rs == Lakh

Scanned with CamScanner

=

e

XIV. Date of award of work. (date/ month/year) 1

XV. Date of start of work: date/ month/year) '

i

XVI Stipulated date of completion: (date/ month’ year) '

XVI Actual date of completion; (dave/ month/

year) in case of completed work) !

2. PHYSICAL PROGRESS: (Ongoing/Completed)

Construction programme and Physical progress (Strike off whichever not applicable) _—

—— | Belay in

Tem of work Units | Quantity | Quantity | Completed Fill in st and completion dates | meaie

lasperDPR| executed | percentage -— TS Lcompetion

wim | Pee =

= — @ | o

q . bey Fy

| @ TeToe | Le oli

i) Layout Gan | Aip-eo 226500) CAO! Actual _ nla se

Due

| 4 > olnla -

ii) Foundation -&] | 306) (GG poy | Actual 2: +—

Conn | 2955/1369) 188 p02 SF [2elql2al

iit) Substructure 8 F/ [Actual 11 4fosdae.

Sa conn | 3-66 | 212-624 JSAM Aen solos |

iv) Superstructure - - Actual —

) Sepentine Cow | 43.66) ie Zolub2 | reload

v) Protection Works ~|c- “Acie = =

en Noel = aelthe | sehihs |

vi) thes. KMS | 0358, Actual Zz ee

jo) Auaee $ ie Sofuh2 [a ekg |

vii) Mandatory boards! \ “Actual

Signage etc. Nos] S a - =

‘LARS OF THE BRIDGE:

5 pete ‘bridge (according to HFL) Submersible fon-submersible

(according to Material) rece swel__|

‘Composite Pre-Stress

3.2 Type of foundation [open ir

Pile Well

3.3. Length of bridge

3.4. Number of spans and spans length

Scanned wit

ith CamScanner

~- 7 r rw w er wweeeee ee

36

ay

38

39

3.10

3.

3.12

3.13

34

3.15

3.16

317

It

Provided, width of footpath,

Fi

‘ormation Level (Ft, Cee)

Hi

Bed level (Lowest)

Catchment area

Linear waterway at HEL

Design discharge

Design velocity

Foundation levels (a) Piers

(b) Abutments

(©) Returns

Foundation Strata

Safe Bearing Capacity (SBC)

River protection works provided or not

if provided

Type of Substructure

(@) Piers ~

(b) Abutments ~

a

=F APonsins

LA y¥es No

Rigid boulder apron Jefcxibie boulder apron}

Solid circular Hollow circular

Wall type pier

Any other type

Gravity type Spill through

Box type AEounter for ype

[ian VST SETEUEEEEEEEEEEE

Any other type:

—— woe

el

st Fi =

hes! Flood Level (HFLY/Ordinary Flood Level (OFL) Liceasem | Ca)

S4.3e m

6 tor Seumec

Scanned with CamScanner

©) Retums -

3.19 Type of bearings

3.20 Test report of bearings available or not

3.21 Type of superstructure

3.22 Type of expansion joints

3.23 Type of wearing coat

3.24 Type of drainage spouts

Box type Counter fort

Tied returns Cantilever typ

=

Any other type:

Elastomeric

Rocker & Roller

on _PosPTFE

Any other type

l Yes “! No

RCC

{Solid stab T Beam slab

Voided slab Box girder

Any other type:

Steel

Plate girder Truss frame

Arch bridges Cable stayed

[eiimeaion

Bailey bridge:

Buried [ Copper plate

Bituminous AA strip seal

Modular Finger type

Any other type:

wl Rec Bituminous

As erTRG! sP As per Design

Scanned with CamScanner

3.26 Wh

ell

ther approaches are in cutting or in

3.27

TYPe of pitching in approaches

3.28

filling

Whether bene

‘er bench marks and alignment are established

ni

rear the bridge site (give locations and RLs)

Type of Railings

4. QUALITY CONTROL:

eve

An

—_—

Single lane IRC Class

double lane IRC class

ever produces severe stresses —_———-— 1

| sine tone TRC class “70R™ loading or

‘CU Ydouble tane IRC class “A” loading which |

——

‘Av loading oF

loading which

evere stresses. __—

af prod

y other type

Sse

Filly

Partly cutting and filling

[Boul

Ider pitching] | ‘Concrete block |

No

Yes L

Location:

Tre joralem |

a

aeons

Location: ‘an

CVE TP RL: OFS M |

——tamere? oan) m |

Location: “Cann 3) RL: [0326 ) m

Location: RL: m

L2€c as per Pipe railings

standard _ pitching

Steel Collapsible

pitching

Any other type: ]

1. Location of Field Laboratory DEVARKADPR VI LLAKE

TI Geo-tagged photograph of laboratory uploaded on: (date/ month’ year):[ 24] 1r-] roxy

IIL, Reason for delay in establishment of field laboratory (if so):

1 delay in establishment of field laboratory (ifs): _lygaities

IV. Details of contractor, executing the work:

‘Name of contractor PAN number Mobile number E-mail ID.

VaMveauipne rep] A&rpeney) 45282078)

Scanned with CamScanner —

ble at site: (Responsible for maintaining quality control register part-1

| Duration of posting at site |

From | To |

= Sty Go ge | salolry I Protet

Wentity number | Mobile number

VL. Details of head of PIU supervising the work:

el meme

a meat ha Duration of post

(Executive Engineer) | Employee number | Mobile number |g

140439) 9 48632304 | afer bn

LL |

VII. Details of assistant engineer supervising the work and maintaining quality control register Part-II

| Duration of posting at site

Employee number | Mobile number |, | ‘To

si_| Name of assistant

a engineer

te] C Pomeareicinn | 1737193 | quan rues] 27behy | past

VIII. Details of the junior engineer supervising the work:

os jon of posting at site

no. Nene of fami Employee number | Mobile number Cente -

engineer To

\ Gy. Sedazs wails} 116 344 | GomAeuqys, propedt

sis sana

— KIS+ ertlerd —

je

1X. List of equipment available in field lab:

king condition | Available equipment that are not in working

‘Available equipment that a 80 condition (2)

— na( —

Al —

[ee

i in field lab:

x. List of equipment not available in fcld Ia Re

al

Scanned with CamScanner

5.

XL

XI

1 of equipment in field lab

Na ly |

aALL&

Equi

‘Quipment, documents and drawings ready to be made available to QM before or during the inspection

DPR, AnPEE HEM Copy) DESI® MIX 9T BMS

DETAILS OF MIX DESIGN(s):

si. = = —

‘Average | Details of Institute! Details of Mix

as sail Mix | laboratory where mix | Qesign approving

Design design was done PMGSY Authority

Strength

TOP TCH TE

ce Races pul

asonbed Hype na BAD —

ii, | Cement Conerete M25 Top recy TEAS

: CpRVACKS PT

rasscohd a

i | Cement Concrete M20

Top wore Testi!

iit | Cement Conerete M30

syesmbt cp pucks mud

iv. ‘Cement Conerete M35

|

v. | Cement Conerete M40 = =

vi._| Wet Mix Macadam (WMM) |

vii. | Dense Bituminous Macadam _— _

Vai. | Semi Dense Bituminous Concrete) = |

ix. | Bituminous Concrete

a =e

Scanned with CamScanner —

EARLIER iy

OFFICERS

of inspectin,

me

(NQM/soM

SPECTIONS BY NoM, 5

(Please tidus & CEs) Any

and Designatio

‘a -Dacnemieny

. QM or SENIOR DEPARTMENTAL

i ACTION TAKEN STATEMENT:

name and designation of the officer who had inspected the work)

le chronologicay

Stage

off tage of work at the time Major observations Action taken by PIU

eet | of ingpection | with date

SE) |

+ Q) @ 7 {)

|

z 7 Srapron tei

Prey conpentpplcompenave taarng |t- arprane faye}

Yrueaisve » Peygtepoe mat bescrrve AYO

Lays Mop Haittne.| tempol POPs FORT,

COMPLETED FOR fnaier n= me Preconenal’| Mate P

mn Cheer tone ot

ouimeniss preng P: Spel tent Yuli Miroeks Keberety

Two Focpamns

bala

Signature of the Head of PIU...

Ovi Ml Norenat ce

Name and Designation of the Head of PIU ...%4.C¥.1.1¥&....

ME SLI33S,

fit Perot,

: Stet

Address of the PIU... 2:2) Mah. PAA prdivlead. .eriCe [Stetect

Walebinegel ®

loylrer,

Mobile Number of the Head of PIU....

E-mail of the Head of PIU.

Date:..

Scanned with CamScanner

Format QB Version 2021.0- Part I

Report of)

L Re f National Quality Moy itor (NOMY/State Quality Monitor (SQM)

(To be filled-up by QM)

1. GENERAL DETAILS:

© Date of inspection

26. 0y..022

nom ][ Code] —

TL, Name of Quality Monitor (QM) baa prasao |

(check relevant box and ft code) |S RATEW OMA Pres AO Fsom |Lcoa], Sider:

TH. State: | Getengeme | District: Block:

gems Deverene ag

Mena besrager

Clo High ft Badge om ip Bes

TV. Name of Bridge & Location:

& Devereatadrae Shoo © Sfeoo

yy

V. Package number: TsOYy DEMBcao}

VIL. Physical status of work: wr cee Completed

(check anyone box)

VIL. Present status of work: (check boxes as applicable)

Layout Foundation N Substructure

Sunerstructure Protection work Apareati

Finishine stave

Photographic or video graphic records (optional) ofall hidden items like reinforcements of foundations/ sub

Structures/ super structures et. are kep by PIU, till Defect liability period is over fox bridge for any fue

reference or not: (Check / any one box) ria Cr]

s No

- Scanned with CamScanner

QUALITY ARRANGEMENTS-OBSERVATIONS (in case of ongoing works only):

(Geo-tagged photograph of the laboratory showing the avai

‘ble equipment’s to be uploaded)

aa an

-

1. Whether field laboratory estnblished:(check V any one box) Hees |[ | ly | No

TL. Whether location of field laboratory is same as Ave | [ [no

indicated by PIU in format part-I: (check ¥ any one box) =

TIL. Whether necessary equipment as indicated in part-1 are actually ‘es | {| Partly No

available: (check V any one box) -

IV. Whether equipment's have been used: (check ¥ any one box) M yes |{ _| Partly No

V. [all necessary equipment is not available, whether you have

verified them with the list of deficient equipment’s provided —|ves

by PIU in format Part-L: (check¥ any one box)

Fes No

VI. Calibration of equipment done or not: (check any one box) .

VIL. Whether contractor's engineer as per Part-I of this format, is Ayes No

available at site: (check/ any one box)

VIII. If contractor's engineer as per Part-I of this report is not available, [ Aye A Partly

whether you are satisfied with alternative arrangement made to -

maintain QCR-L (check / any one box)

A

TX. Whether lab technician and other stafT is available for testing in the Aves ‘No

laboratory: (check / any one box)

Guiding note: If the field laboratory te not established, overall Kem grading shall be U. Wanyone or more |

subsitems are graded partly or no, overall ip grading shall be SRI

Item Grading-2: = |

| Chek on oe bn Ts] [Tse] (fu

l

If this item is graded SRI/U, write clear reasons and suggestions for improvement, indicating important

deficient equipments: ft

S

3. ATTENTION TO QUALITY (in case of ongoing works only):

I. Maintenance of Quality Control Test Registers:

(a) Based on executed quantities, whether all mandatory

tests conducted: (check/ any one box) Fires [

Partly ] No

(b) Whether Quality control test register maintained as —

per trovidnd (techy ngonetany — CL¥ | [roa] [a

(c) Whether QC register part I maintained and test results

monitored as per provisions: (check v am

Scanned with CamScanner

» Quant

a8 per

DPR

y Tam = .

Y | Quantity [Name ofthe | Number of | Numberof | Testing

executed test tests required tests adequate

(apererecuted | actually | (YesNo)

conducted

6) _M__|

30 Z

Approach Slab | —

and fixed

items (Railing,

kerb, Crash

barrier etc.)

Approach

work

+ ta

+ [=] Negligence

k of knowledge

+ [&) Lack of equipment in lab

+ [] Any other, please specifi:

(b) If testing found inadequate, the reason for less testing: (Check ¥ one or more box)

(c) Verification of test results: (C: conforming, N: non-conforming)

Quality control tests to be conducted by QM and the results to be matched with test results previously

recorded in Quality control test register, at the same component of the structure.

Item of [Name of Results of the | Test results as per [Results of the test] Whether the test

Work Test test Quality Control test conducted | results recorded in

conducted by | register at the same previously by QM) Quality control

‘QM at the location. at defined test register and

component of | (Mention the Page no. location as conducted by

| the structure. of Register) (CN) QM are in

cN) conformity?

__ (Yes/No)

@ @ @ @ ®& ©

My meee tin | SSO |C 29% qa — Lah

Pi mice cor. [ce 2097 Gem Y

1 c. =

P»mMpo 4 Cimon [o 1383 quer i Bi

bap P39 [Om Me = nh

» PY me “ csc WSR Gab a ¥

rm 5 crow @ MHI qr-6 = }

Scanned with CamScanner

(Whether non-conformities recorded in QCR-II by AE have been rectified and

Tecorded in Quality control test register again as conformities, after conducting

necessary tests: ‘

(Cheek any one box) [ ve] [ —INo

y ctive

In order to assess the quality of concrete in case of doubt, if any Non Destruc

" Velocity (UPV) etc.

Test (NDT) such as Rebound Hammer test, Ultra Sonic Pulse Velocity (UPY) etc

has been conducted: (CheckJany one box) [Tey [ No

7)

[ “Guiding note: Trike |

s z2/s/8 /2 (gg eeize° | Fe |¢

eB; 2/3 64} 5 ae

-l3 6 =) 8 é 2 G

O1@TeatT@eare elo ® [eo (io) a)

=

— | Y

I. Presence of water spray or moisture in the vicinity of bridge such as waterfall or marshy wet land?

(Check/ any one box) a aa

II. Presence of industrial units nearby, which emit corrosive fumes or discharge chemical effluents?

(Cheek¥ any one box) Yo te

IIT. Presence of salinity in the atmosphere? (Check any one box) Yes No

of either material or workmanship is U, the overall item shall be graded as “U™

Guiding note: If qualit

Item Grading-6A: ; U

(cheek f any one box)

(Uf this item ts graded as U, clear reasons and suggestions for improvement are to be recorded).

a— Sma Srv FH no Prot say bw

——

Os roe Mm Ppr—

Scanned with CamScanner

ee.

B) Completed Work ak Ca

c _ ce.

on a

_ Welding | Material a. e

* Py sp | Presence of Corrosion | r |

= e 4 (Ves/ No} | @&

$/3ie If Yes, type of

S| & | Ba | S| comosion and specific | presence of Te ‘oad mo

2) §5 i 3 location revence Of | Presence Of | tassifcatio &

S| 8 E | S2}——_— | jassification

= 2 SP Buckling .

2 as Fracture Ne (Yes/No)

i S S222 ge las] g| aan | OM oe

ol el ae | Bal Bs

d Ele | Fe lEe aE | ¢

Ee (2° eek © @

@|@! 6 |o/| —o_ | \

L

IL Presence of water spray or moisture inthe vicinity of bridge such as waterfall or marshy wetland?

(CheckVany one box) Ye No

IL. Presence of industrial units nearby, which emit corrosive fumes or discharge chemical effluents?

(Check/any one box) Yes No

IIL. Presence of salinity in the atmosphere? (Cheek any one box) Yes No

Item Grading-6B: a U

(check J any one box)

(this item is graded as U, clear reasons and suggestions for improvement are to be recorded)

wee Sime Sree Bone pretes Py DEN

be FOS:

”

Scanned with CamScanner

NN

ee Progress)

. i

« |. Quality of Material 4 [rls |

= | $43 423 | aE |

fable la, je |fRe\a 24,5]

= acs gz Bs | a5) hee i, boa”

= | 2g¢| ef be 222|\28 biz | gags

8 | Ssa| g= | geo |esalebeleee | 22%=

ae ES Peo) se 237 gs

3 RUE Be | Bez |g8c| Bae | oem g

2/38] a3 )2% (2 |fee| ea? i

a . 5 |24°|3 é

O : 5

2 @) @ o | @o_ (an

|

|

ul

I. Any bolt and/ or rakers and tie plates are missing or loose?(Check¥ any one boo[ Yes No

TE. Any sway braces and/ or transom clamps are missing or loose? Yes No

(Check¥ any one box)

IIL. Presence of any cracking in the Bailey bridge” (Cheek/any one box) ‘Yes No

IV. Presence of any bends in bridge members? (Check/any one box) Yes No

[Gag woe Tay ‘oF panel PIN is missing or loose, the overall item shall be graded as“

Item Grading-6A: $ U

(check J any one box)

(this tem is graded as U, clear reasons and suggestions for improvement are to be recorded)

| ose N@e— Smu cher A no prevtiten >

| perme fe dhe Ta |

Scanned with CamScanner

B) Com

pleted Work.

ee —_—

- NA

. Welding Material s

= z =

= = s Presence of Corrosion E25 &

S e ¢ (Yes! No) Bee 3

= Z]3 & I'Yes, type of corrosion and | 2 EB 3s

2 a 3 2 2 2 specific location g = 3 z

E 3) 53) £3 e322 ss

3 2) 22| €2 ) gs | es s| £25 id

3 g| 3. Co 22 2 ieg2) 3&4 5

3 e) 8 8 a |) 38) 823 5

5 g Zé BE |aé: 2 3

3 g Ef & | 78 z

£ £ 2 2

MT @ & @ ® oO | o o

\ |

|

= fanny - _ -

|

Te Any bolt and or rakers and tie plates are missing oF Joose(CheckVany ane box) Yes No

M. pps are missing or loose? Yes No

(CheekVany 0

IIL, Presence of any cracking in the Bailey bridge ny one LOX) Yes: No.

IV. Presence of any bends im brid mibers? (Cheek/any ene box) Yes No

val PIN is missing hose, the wera item sal be grave

s uv]

Item Gradin

(ehieck J any one bos)

dUfuhis tem is grated as U, clear reason and suggestions for

NA Sma the Ts no Petite »

penn fe Or Mae

eae

improvement are to be recorded)

___——

|

|

J

Scanned with CamScanner

It

YES. comments

Sduited and copy of test results shall be enclosed

| Guiding noir

ding note: Tie;

tem Gr ie (est isnot done a

(Check von Cis} Ci)

any one

W this item is erate :

Staded U. write clear reasons and suggestions for improvement

ee

. BEARINGS ON”

A) Types of Beari

ig (Tick / appropriate)

Roller and Rocker Bearing

Elastomeric Bearing

Pot cum PTFE Bearing

‘Spherical Bearing

Cylindrical Bearing

‘Any other type

B) Condition of Bearings

(a) Metallic Bearings

i. General Condition- any rusting / ceasing of plates/ cleanliness or not s u

ji. Functioning —any excessive movement! tlting/ jumping off guides s u

jii, Greasing/ oil bath required to be redone or not $ U

iv. Cracks in supporting member- Abutment cap, Pier cap, Pedestal, ifany S U

x, Effectiveness of anchor bolts, whether in position an¢ tight or not s U

vi, Report any otdier defect or observation found

Scanned with CamScanner

(b) Elastomeric Bearings

i. Report condition of pds —

Oxidation, Creep, Flavtening,

Bulging, Spliting, Displacement ifany

ii, Report ~ Bearings are elean andl free or not |

iil. Report any other defeet or observation found

(© Any type other than ‘a’ and ‘b above

Report - Any other defect or observation found

1, Whether test results of bearings are available or not:

(CheckVany one box) Yes No |

Guiding nove: If anyone of the sub-tems are graded as U, overall em grading shall be U.

Item Grading-8: 3 U

(check Z any one box)

(ifthis item is graded as U, clear reasons and suggestions for improvement are to be recorded).

nee Shen PS nO Pres sieg

m pea fw dre tee

Scanned with CamScanner

Reinforced Elastomerie Joint

Modular Sirip 7 Box Seal joint

Finger Joint

Reinforced Coupled Elastomerie Jomt

B) Condition of Expansion joints

i. Is there any crack in the wearing coat Yes xe]

ii, Whether existing gap is improper Yes No

iii, Any hardening / cracking observed in bitumen filler Yes [xe ]

iv. Any splitting/ oxidation/ creep/ bulging observed in neoprene

Yes No

sealing material

v. Corrosion/ damage to welds is visible Yes No

Presence of debris in the joint Yes No

‘Yes No

vii. Report - any other defect or observation found

Guiding note: If any response of questions in sub item 9 B is “Yes, the overall tem shall be graded as

su"

Item Grading-9: [ U

(check J any one box)

(Uf this tem is graded as U, clear reasons and suggestions for improvement are to be recorded)

ra— Sma dre vs no powtores

m Dern fe des rem.

as

Scanned with CamScanner

10. APPROACHES

bankme

Suitability of soil |” Compaction

ee 8)

Side slopes

SGo txt

Leroreteny.

=

St Gitte > Tapahotet

Lebowetony 22 fedo ou

pene Seth pectony,

J

a

Scanned with CamScanner

E, Comments about difference In observations made by NQMV/SQMs In carter Inspections (the

NOM/SQAT shall study the enrller Inspection reports of NOMS/SQMs, if any and offer his clear

comments about the differences In obscevatlons, If any), (check relevant box and fll detaits)

Whether any difference found in previous observations of OMs | —F Yes (Pxo_]

ity

6. YoUr comment on difference in observation

F. Other observations, if any:

ii

CEO apo

Seen

”

Scanned with CamScanner

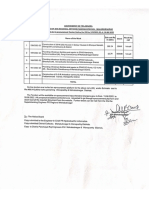

13. OVERALL GRADING OF BRIDGE WORK

Item Awardable | Awarded

No. Grade | Grade

1 General Details

2 | Quality Arrangements -_ Ysrvu S$

3 | Atention to Quality SSRI 3

4 | Foundation (Stage 1 si

‘5 | Sub-Structure (Stage Il) SU Sg

6 | Super-structure ( Stage 111) su =

7 Load Test su et

3 | Bering = a

(Grading to be same as for condition of Bearing)

‘A. Type of Bearing- Roller and Rocker Bearing, Elastomeric

Bearing, Pot cum PTFE Bearing, Spherical Bearing,

Cylindrical Bearing Any other Bearing)

* | B. Condition of bearing su —

9 | Expansion Joint on

(Grading to be same as for condition of Expansion joints) —_

Type of Expansion Joint- Buried Expansion joint, Filler

Joint with Copper Plate, Asphaltic Plug Joint,

Compression Seal Joint, Single Swip / Box Seal Joint, |

Reinforced Elastomeric Joint, Modular Strip / Box Seal

joint, Finger Joint, Reinforced Coupled Elastomerie Joint.

B. Condition of Expansion Joint s/U _

10 | Approaches

(To be U, ifany of the sub items (ii, (ii), (iv) are SRI or U) SISRIT =

(i) Embankment a

(i Sub Base (G.S.B) S/SRVU _

(iit) Base Course ; SaRTU _

(Non Bituminous (WBM) and Bituminous(BM))

(iv) Wearing Course ssRIU |

(w) Protection Work SISRIU _

a

Scanned with CamScanner

Tr] Bridge Famiture and Markings sunit 3

(to be U, if any of the sub items are U)

@ Main information Board SgRvU “s

(H Citizen Tafomation Hoard A

(ii) Guard slone on approaches S/SRVU _

(iv) Mandatory and Caution signage a

S/SRIU Ss

Overall Grading

Guiding notes for overall grading:

‘+ Ifall work items are “S”, the overall quality of work shall be “‘S””

+ Ifitems at sl, nos. 4, 5, 6, 7 and 8 are “S” and other items are either “SRI” or

the overall quality of work shall be “SRI”

u

* Ifany item at st. nos, 4, 5, 6, 7 and 8 are “U", the overall quality of work shall be

“ye

Signature of QM

Name of QM

Date

respective of the quality grading of other items.

u

Scanned with CamScanner

14, QUALITY GRADING OF ITEMS OF BRIDGE WORKS:

r

Item No. Trem for observation ‘Awardable | Awarded

L Grade Grade

Tem No. 1 General Details = - —

Trem No. 2 ‘Quality Controf Arrangements S7SRI70 <

Trem No. 3 ‘Aitention to Quality ‘S7SRI170 S

Trem No, 4 Foundation s7U __

Item No. 5 ‘Sub structure s/u es

Item No. 6 Super siructure s7U _

Item No. 7 Load Test suf

Kem No. 8B | Condition of Bearing s7U _

Tem No. 9 Expansion Joint s7U _

Tem No. 10 | Approaches (Stage Hand 1) S7SRI/U =

Item No. 11 Bridge furniture & marking ~~ §/SRI/U s .

‘Overall Grading S/SRU/U s

Signature of QM

Name of QM

Date

8

S: PAT ES Daa PNrEseo

Scanned with CamScanner

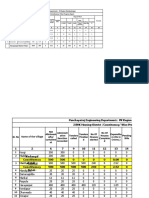

Quallty Control! Lab Equipments

Namo

of tho Worl

A SONSTRUCTION OF HIGH LEVEL BRIDGE ROAD FROM BASWAIPALLY 10

IEVARKADRA AT 5/200 TO 5/400 KM OF DEVARKADRA MANDAL MAHABUBNAGAR DISTRICT

Grant

MGSY «Ill, Batch «Il

Package No:TSO4DEIIIBLB01

Estimate Cost : R:256.26 Laks (2506.26)

‘Mandal: Devarakadra

Distriet : Manabubnagar

_ Lakhs

SINo List of Equipments No's

1 [is Stoves Set with Lid pan One set_

2 [Auto Levotting instrument with staff and Stand ‘Oneset =

3 [Compressive strength testing machine One set

4 [Rebound Hammer One set

5 [Aggregate Impact test Apparatus One set

6 |Flakinoss and Elongation Guage 2.Nos a

7. |Etectronic Weighing Machines 30 Kg, 10kg Each 11No

8 [Measurement tape, Rodometer, Spirit Level Glass Jar l= sets

9 |Slump test Device No

10. |Rapid moisture Meter 1No

11. [Cube Moulds of 150 mm x 150 mm 6 No

42 [Proctor Density Apparatus 2ngs

Scanned with CamScanner

'

' \

\ { \

was .

Ne nyo 330 Gradag

a _peF

do] waniny UO 787 €0T Jsezztz6t [e9SETL |e

do} yaajn> uD S8c EOL ZS9Z'6LET |69ZG'EETT |C

quawaseg JaWJojsues| UD 9T6°zOT LvdS'0002 |ZvTz'0Es = |T

SIEWSY WEL apne] apny8u07 ON'IS

seSeuqngeyew):3sid

eupexsenag:|epuey|

SyAPT 97'9SZ SY=3S09"3S3

TOSTSINIIGPOSL:ON a3ex2eq

-4oIea‘II-ASDWd ues,

yLYsIG seZeugnqeye!‘|epue| espeyesensgq U] eupeyesenag 0}

Ajjediemseg 4/y-GO1YW a8eI|I\ eapexesenag Jean adpiig JeAe] YBIH JO UO!}INIYsSUOD -:410M ay} JO BWEN,

isi Wal

Scanned with CamScanner

~y~weew

Rebound Hammer Test

Dain

Name of the road: Gon Gleweti oy High hemek Pridge 9%) 2}

Reswaipalty 0 peragaient at ¢]%D -lo C1400 Haye

Package No: 1S 04 Pi TT) PL od

Date of inspection: = Joy ror

Mbstwen! “RA. (38 dans) Wee = 71 (24 douys)

2g 3g 30 rw ra 30 |

D2) By | ge ng | 2 |p

32] re | 22 ad | rx | 2

Ng Voue = 2 vy rl

PS pet pesihiorM 95.50 ofan

* Cornp Sarenge™

pier mw days)

1S foer | ry

Dy} ar 24

re | 22 | 257

A Vg vole gp 27007) | wae

NE Pet Pewidion 2

Coynprucive Soret 2

ft,

Pash

Bomavintiy

Wyre] wa

Dag Vebe s ete) sot

PS per Perici — LW) wb

. Comp Sheugt

Pier p30 dens)

28 re

2g

26 Us 26 |

“" J] uU

Prvg. vole 2 268 nurs

i

BE per periion F e oo wJunmt

Cormprowpive Sega ©

pecpwabl. UF En

Scanned with CamScanner

Rebound Hammer Test

ge ont JR Ragenipa lay

Name of nee, Gmaruurion of High Janek Pret

WO Peamranrs ad (hao to Sluoe Ming

Package No: 16 04 DEM MLROA

Date of Inspection: 26 leu | y

Frbupmeed MLC dons)

Pier “Pel Casoyg

2) 2! zy at 1% 2 |

24 [re 26 we re re

a zy BY uw 30 | 1

Avg vane = 2498 1) wae Avgivaue = 24:3 30) me

atti Pee Oe eases ret eset her

L

. i

, a

ewasey pee forest Us Bay

Scanned with CamScanner

Cube Strength Test of Concrete (as per 18:816-1959 )

Nmeo Brides COMER VOT EW OF TIER of PIE BAIN PALLY

10 PHVARE RPAH AY Creo ve cluce Wags

Giadewr Conese: Kg Cop Cap UMP E

Sweorcube: gs ( TX OAE LOTS MEYS

Dateot testing '- 2 ¢ Loy)ror

yelght 0 ee ee ee

Caen | Steck | MAES |aegut Nt] ale Nin | Semarhs

1 2 3 4 5 6

sre Gose | 39 lass | jaa | Flt |

rete | eeu | ype | win | zewn | 2edous

ZC pier

ot Soey boo LESS | rorww DWrdoufs

Pe y ed

(SH) | e034 ane ariop | roe | tA

a A nee

AEPred pes Dw soy

DewosncdAs,

108

Scanned with CamScanner

rage NaS

pate wn which

Ntece

Date wt =

Dearne ee

x “

TestsiChec H COMM ruetion : 1

>} sustas Comte nt th Coane | | 4

Aramgate 1

4 | | tate i

. j Moisture Content in Pine |

} Argrepate: | \

bs | table . |

ching wf Form Work ’

5 (renpth of clamps and {

a ity of Form work, zs |

Mortar tightness [sae i

eight ofpanels | “

SBST.27 |" Workabitity of Concrete | -

; = “ Table

SBST-28 | “Checking of Conereting a [_

3 ate

31 _SBST-29 "| “Checking of Curing

1 Table t -

| _SBST-30 | “Check for Cement Content

Table

Cube Strength Test of . ;

‘SBST-31

Sensis Test! Pephut Yes

Test? [aqlsin | Ves 1

Test3 [oatetn) Vea

Test4 | Fels|aal_ yee

TestS | ovlulvel Yes

Test [eyluhr| Yes

Test? | o¢.ly|12! Yas,

Test8 | eoluhr| Yor

[test [i\yl | ¥-

[Test 10 | tylylaa | yey r

Test [telyln | Yea {

Test 12 | |Mpr| Yes

Test 13 [alah | Yoo

Testl4 [ojl4tn| ya

Test15 la >fuby| yes,

Test 16

Test 17 c Ii —

Test 18 f

Scanned with CamScanner

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 11.angwadi Center (8.00 Lakhs) RIDF-XVI-Feb PR NRPTDocument5 pages11.angwadi Center (8.00 Lakhs) RIDF-XVI-Feb PR NRPTK KARTHIKNo ratings yet

- 11.angwadi Center (8.00 Lakhs) NEW MGNREGSDocument5 pages11.angwadi Center (8.00 Lakhs) NEW MGNREGSK KARTHIKNo ratings yet

- 3.PMGSY Ongoing VIII To IIIDocument2 pages3.PMGSY Ongoing VIII To IIIK KARTHIKNo ratings yet

- GP Buildings ABSTRACT, WW Region - Region As On 11.01.2022Document4 pagesGP Buildings ABSTRACT, WW Region - Region As On 11.01.2022K KARTHIKNo ratings yet

- SDF Divsion Report Sep 2020Document4 pagesSDF Divsion Report Sep 2020K KARTHIKNo ratings yet

- CDP New Sanction NRPT MLA1Document3 pagesCDP New Sanction NRPT MLA1K KARTHIKNo ratings yet

- DPR 19Document110 pagesDPR 19K KARTHIKNo ratings yet

- SCDD Govt SC Hostel Building Progress ReportDocument4 pagesSCDD Govt SC Hostel Building Progress ReportK KARTHIKNo ratings yet

- Cattle Shleter 20.00 Lakhs MgnregsDocument2 pagesCattle Shleter 20.00 Lakhs MgnregsK KARTHIKNo ratings yet

- Construction of (400) 2BHK HOUSES (G+1) of Narayanapet Mandal, in Narayanapet Muncipality of Narayanpet District, Telangana StateDocument89 pagesConstruction of (400) 2BHK HOUSES (G+1) of Narayanapet Mandal, in Narayanapet Muncipality of Narayanpet District, Telangana StateK KARTHIKNo ratings yet

- Narayana Pet 400 (g+1) Houses-UrbanDocument103 pagesNarayana Pet 400 (g+1) Houses-UrbanK KARTHIKNo ratings yet

- MRR Package 20 July 2019Document18 pagesMRR Package 20 July 2019K KARTHIKNo ratings yet

- Progress Report of Mgnregs Grants: For The Month of NOVEMBER - 2016Document25 pagesProgress Report of Mgnregs Grants: For The Month of NOVEMBER - 2016K KARTHIKNo ratings yet

- Abstract All grants-NRPT DIV 11.01.2022Document8 pagesAbstract All grants-NRPT DIV 11.01.2022K KARTHIKNo ratings yet

- STSDF (Tribal Welfare Department) GO NO.336Document2 pagesSTSDF (Tribal Welfare Department) GO NO.336K KARTHIKNo ratings yet

- BT Renewal ANNEXURE II & III of PR Division, Narayanpet Mandal 13.02.2022Document11 pagesBT Renewal ANNEXURE II & III of PR Division, Narayanpet Mandal 13.02.2022K KARTHIKNo ratings yet

- CDP NEW Kashi Reddy MLC (LAC-2) M'nagarDocument1 pageCDP NEW Kashi Reddy MLC (LAC-2) M'nagarK KARTHIKNo ratings yet

- CRR Progress ReportDocument7 pagesCRR Progress ReportK KARTHIKNo ratings yet

- MRR Govt 300 July Go Report.Document8 pagesMRR Govt 300 July Go Report.K KARTHIKNo ratings yet

- 9 Road Mileage Details 01.04.2021 Division Report - PIU MBNRDocument66 pages9 Road Mileage Details 01.04.2021 Division Report - PIU MBNRK KARTHIKNo ratings yet

- 29 05 2022 721719955Document40 pages29 05 2022 721719955K KARTHIKNo ratings yet

- BT Renewal Proposals AS ON 13.02.2022 PR DIV NRPTDocument15 pagesBT Renewal Proposals AS ON 13.02.2022 PR DIV NRPTK KARTHIKNo ratings yet

- DocScanner Jun 8, 2022 5-41 PMDocument1 pageDocScanner Jun 8, 2022 5-41 PMK KARTHIKNo ratings yet

- Design of Horizontal Curves With Superelevation Design DataDocument4 pagesDesign of Horizontal Curves With Superelevation Design DataK KARTHIKNo ratings yet

- Mana Vooru Mana Badi 13.06.2022Document31 pagesMana Vooru Mana Badi 13.06.2022K KARTHIKNo ratings yet

- Mana Vooru Mana Badi 13.06.2022Document24 pagesMana Vooru Mana Badi 13.06.2022K KARTHIKNo ratings yet

- 2BHK Abstract & Village Wise Progress Report PR Region Mahabubnagar 14.12.2021Document5 pages2BHK Abstract & Village Wise Progress Report PR Region Mahabubnagar 14.12.2021K KARTHIKNo ratings yet

- 29 05 2022 283524154Document45 pages29 05 2022 283524154K KARTHIKNo ratings yet

- 29 05 2022 12849797Document62 pages29 05 2022 12849797K KARTHIKNo ratings yet

- 29 05 2022 655386446Document38 pages29 05 2022 655386446K KARTHIKNo ratings yet