Professional Documents

Culture Documents

29 05 2022 655386446

29 05 2022 655386446

Uploaded by

K KARTHIK0 ratings0% found this document useful (0 votes)

4 views38 pagesfhgfh

Original Title

29_05_2022_655386446

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentfhgfh

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views38 pages29 05 2022 655386446

29 05 2022 655386446

Uploaded by

K KARTHIKfhgfh

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 38

~7~eVvuevuweec

National Ru

Format for information to QM fe

rastructure Development Agency

Ministry of Rural Development, Govern

nent of India

Format QB Version 2021.0- Part I

nspection of Ongoing/Completed Bridge Wark

PART J- Work Information (Zo be filled:up by PLL

ERAL:

L Work: (check any one bax) Completed |

UL. Date of inspection: 25-04-2022

MON of quali xe [ex

l. Name of quality monitor (QM) ‘i

quality (QM): S+ Rejerdn Pruad ST soar If coved Eas

WW. Sute: [clan gana Distt maabi Bragat] Block: [ Qhoels pat |

4 5

V. Name of bridge &

Location

VL. Packagenumber: [TS O24) BHWIRLBOF

VII. Sanctioned length of the bridge. 4a

Deviation in length of the bridge (If any): m

VIL. Reasons for deviation (ifany):

IX, Estimated cost (as cleared by GOD: Rs. 307-44 Lakh

X. Technical sanction cost: Rs 01-44 Lakh

XI. Awarded cost: Rs. 20¢-1% Lakh

XII Expenditure: (if work is ongoing) a. Expenditure done: [ Rs, Lakh

b.Bills pending: = [Rs. Lakh

Total expenditure =(atb) Rs. Lakh

XIII, Completion cost: (if work is completed) Rs. Takh

Scanned with CamScanner

XIV. Date of award of work: (date/ month’ year) Sa Wwe

XV. Date of start of work:(tate/ month’ year) _|

XVI Stiputated date of completion:(date/ month/year) |___ ‘] L—] |__|

XVIL Actual date of completion: (date! month? 26 II Ot }[202%

vear)(in case of completed work):

2, PHYSICAL PROGRESS: (Ong:

ng/Completed)

Construction programme and Physical progress (Strike off whichever not applicable):

Ktemofwork | Units | Quantity [Quantity | Completed Fill in start and completion dates [Delay in|

s perDPR| executed | percentage ; Ten omielon months

ogress | Sta “ompletion

often ‘status Date Date

a Q) ) 4) ©) ) 2 ie 1 (9)

5 Due aalower | acloqlet

) Layout ley oT | $250 “Asha ostoile talosl

Due aortas | eof ute

') Foundation me | 595-4 Actual [eclohe| el oak

D trifay | gotezke

ii) Substructure r® | cao] Dee —_as fe

Due eter] eotecky

+) Superstructure wm | ue. le Achat

2 f Due atlostarf zoloslre

)Proteetion works | mm? | tq.gy al

Due. etlostu-] of nha

i) Approaches mht] 3-t0-.| al

ii) Mandatory boards/ . Due en hes aefetes

Signage etc. Ne) s ‘Actual

~ PARTICULARS OF THE BRIDGE:

3.1 Type ofthe bridge (according to HFL) [_ Submersible omaubmeniblel

(according to Material) RCC Steel

[Composite Pre-Stress

3.2 Type of foundation [ Open Raft

Pile Well

3.3. Length of bridge Th G5

34 Number of spans and spans length 4

P “1Venks af & ym

Scanned with CamScanner

aaa

38

3.6

37

38

39

3.10

3.12

3.13,

3.14

3.15

3.16

3.17

3.18

Width of the bridge

Footpaths provided

Ifprovided, width of footpath

Formation Level (F.L.)

Highest Flood Level (IIFL)/Ordinary Flood Level (OF

Bed level (Lowest)

Catchment area

Linear waterway at HEL

Design discharge

Design velocity

Foundation levels (a) Piers

(b) Abutments

(©) Retums

Foundation Strata

Safe Bearing Capacity (SBC)

River protection works provided or not

if provided

Type of Substructure

@) Piers —

©) Abutments —

(nl

Yes No

46450 m

1) [tol S00 _m m

7141. 650

120 ken?

6 m

5 62-2 Qocumec’

pi ae) [po [ea

pa PES [Ps

GGat|

P7

m| [Ps m| | P9 m

far FOF

[Ri PE] [Re

5 Sard

Is

tons/m?

Yes No

7 Big toate pron

pate aca

Solid circular

Hollow circular

Wall type pier

Any other type:

Gravity type

Spill through |

Counter fort type

Box type

Any other type:

Scanned with CamScanner

© Returns -

3.19 Type of bear

3.20. Test report of bearings available or not

3.21, Type of superstructure

3.22. Type of expansion joints

3.23. Type of wearing coat

3.24. Type of drainage spouts

ecine [tantra

|__Vied returns Cantilever type

Any other type:

Hlastomeric Pot PTFE

Rocker & Roller]

Any other type

iL Yes No

| RCC

Solid slab T Beam slab_|

Voided slab Box girder

Any other type:

Steel

Plate girder _ | Truss frame _|

Arch bridges Cable stayed

Suspension [ Bailey bridges

: Buried Copper plate

[| Bituminous Strip seal

Modular Finger type

Any other type: Mastic pad

Vee Bituminous

V | As per IRC SP As per Design

042

Scanned with CamScanner

a

>

D 3.25. Design loading

>

,

»

3.26

327

3.28

3.29

4,

L. Location of Field Laboratory

IIL, Reason for delay in establishment of field laboratory (if so):

IRC class “18” loading

Single lane IRC Class "AA" loading or|

double lane IRC class “A” loading which

ever produces severe stresses.

Whether approaches are in cutting or in filling

‘Type of pitching in approaches

Whether bench marks and alignment are established

near the bridge site (give locations and RLs)

Type of Railings

QUALITY CONTROL:

Inne IRC class “OR™ loading oF

double lane IRC class “A” loading which

ever produces severe stresses,

‘Any other type: |

WL Filling |

Lcuting

i Partly cutting and filling

[Boulder pitching] [ Concrete block |

x Yes { No

Location: RL: m

Location: RL: ™

Location: RL: m

{A Rec as per Pipe railings

standard pitching

Steel Collapsible

pitching

: ak ete Fuse

Geo-tagged photograph of laboratory uploaded on: (date/ month/ year): I

IV. Details of contractor, executing the work:

24-ol-2our,

Name of contractor | _ PAN number

E-mail ID.

Crimvada eck Fle pri

ial dell ik AACCSe zioy

[Mobile number |

i

~ Seanned with CamScanner

‘ i aH a

V- Details of contractor's engincer available at ste: (Responsible for maintaining quality control register part

SE TW. tractor’s | Duration of posting at site

0 erica" T identity number | Mobile wumber LP on 7a

1} achok 1315.44 2.9%| Shov1754.on}

|_| |. £0 |

VL B.oihvas | FSE5e6UY

VI. Details of head of PIU supervising the work:

SI. 2 ; a

7 Head of PIU . i Duration of posting at site

©.) Executive Engincer) | Employee number | Mobile number — To

M_ Maule tall, wousar | a gu3sazeq

VI. Details of assistant engineer supervising the work and maintaining quality control register Part

‘Name of assistant - Duration of posting at site

si engineer Employee number | Mobile number | To

Abhi 16 3534 Sosnarag

VII. Details of the junior engineer supervising the work:

Sl. nk a a a,

no.| Name ofiunior | ersptoyeenumber | Mobile number | Duration of posting at ste

engineer

From To

IX. List of equipment available in field lab:

abhadwnd Proida

Available equipment that are in working condition

@

Available equipment that are not in working

condition (2)

X. List of equipment not available in field lab:

Scanned with CamScanner

XI. Reasons put forth by PIU for non-availability of equipment in field lab:

NIL. Details of calibrations of equipment done:

XII. Equipment, documents and drawings ready to be made available to QM before or during the inspection

Sew ae

te Aube let

3 ctn

te Redo ned

§. DETAILS OF MIX DESIGNG):

[si Tipe Average | Details of Institute/ Details of Mix

No. Daa Mix laboratory where mix | Design approving

Design design was done | PMGSY Authority

Strength

i. | Cement Concrete M20 26 Noy” | Civil Teck [abe] 20 N[ mm

ii, | Cement Concrete M25 log N [ow CIC Tech lal 965 N [may

‘Cement Concrete M30

iv. | Cement Concrete M35

v. | Cement Concrete M40

vi. | Wet Mix Macadam (WMM)

vii. | Dense Bituminous Macadam

viii. | Semi Dense Bituminous Concrete |

ix. | Bituminous Concrete

Scanned with CamScanner

©

6. ONS DY NOM, SOM or SENIOR DEPARTMENTAL ©

Fs) AND AC’ “<

©

Date fi ‘of work at the time | “Retiontaken by PIU |

aaa of of inspection with date «

La ©

©

= ©

©

©

c

~ ~— —_

e

€

a

~~ — i

Signature of the Head’ of PIU.

Executive Engi

Seal of PIU

Name and Designation of the HRWA OMATUN. Matatahoadse.

Mobile Number of the Head of PIU..

E-mail of the Head of PIU..

Address of the PIU...

Date:

eer (FRY

FRUBS324 6

‘Scanned with CamScanner

National Rural Infrastructure Development Agency

Ministry of Rural Development, Government of India

Format QB Version 2021.0- Part I

Report of National Quality Monitor (NQMy/State Quality Monitor (SQM)

(To be filled-up by QM)

1, GENERAL DETAILS:

1. Date of inspection:

2S. 04. 272

1 ey Moat now Jf coal =

Name of Quality Motor (QM) [Ss RAevone PRR | RRIeUbAA PAanAD ]

(checkv relevant box and fill code) cFeom |[ coe] FS

IIL. State: | Yatengons _ | District: Block:

naar}

TV. Name of Bridge & Location:

‘V.. Package number:

VIL. Physical status of work: 4

(check anyone box)

Ongoing Completed

VII. Present status of work: (check boxes as applicable)

Layout \{(Foundation Substructure

Superstructure

Protection work

Approaches

Finishing stage

VIII. Photographic or video-graphic records (optional) of all hidden items like reinforeements of foundations! sub

structures/ super structures etc. are kept by PIU, till Defect liability period is over for bridge for any Future

reference or not: (Check V any one box) lies | [

No

Scanned with CamScanner

2, QUALITY ARRANGEM

(Geo-tagged photograph of the

“OBSERVATIONS (In case of ongoing works only):

laboratory showing the avaitabte eq)

ment's to be uploaded)

oe

1. Whether field taboratory established:(check ¥ any one hax) Aves Partly No] we

MH. Whether location of field laboratory i 7

v a eld laboratory is same as 7

indicated by PIU in format pattl:(eheekV any ome hs) xe[Yex N «

«

II. Whether necessary equipments indicated in patel are actually [CF Vex Party | [ [ro

available: (cheek ¥ any one box) «

TW. Whether equipments have been used: (check ¥ any one box) Ula Partly No] @

Ve all necessary equipment is not available, whether you have ©

Verified them with the list of deficient equipment's provided —|res | [—] ro é

by PIU in format Part-| (check any one box)

‘VI. Calibration of equipment done or not: (check any one box) [Yes No &

e

VIF. Whether contractor's engineer as per Part-l of this format, is Ares | No

available at site: (check any one box) e

«

VIII. If contractor's engineer as per Part- ofthis repor is not available, [Tye] [ Panty |{—[No Lat

whether you are satisfied with alternative arrangement made to «

maintain QCR-I: (check any one box)

a 4

IX. Whether lab technician and other staff is available for testing in the Tes No ‘

laboratory: (check any one box)

(

Guiding note: IF the field laboratory is not established, overall item grading shall be Uc Fanyone or more ‘

sub-items are graded partly or no, overall itgm grading shal be Si

Item Grading-2: Ts aa U ‘

(Check / any one box) hectine i 1

If this item is graded SRUU, write clear reasons and suggestions for improvement, indicating important

deficient equipments:

S

3. ATTENTION TO QUALITY (in case of ongoing works only):

I. Maintenance of Quality Control Test Registers:

4

(@) Based on executed quantities, whether all mandatory px ae 7

tests conducted: (chech any one box)

(b) Whether Quality control test register maintained as We ray wo

per provisions: (check / any one box)

(©) Whether QC register part II maintained and test results < = =

monitored as per provisions: (check v any one box)

0

Scanned with CamScanner

I. (a): Adequacy of quality control tests, as per quality control test register:

ltem of Work | Quantity | Quantity | Name ofthe | Number of | Numbaror [Testing]

‘asper | executed test tests required tests adequate

DPR Casper execured | getually | (Yes/No)

quantity) conducted

mo | @ @ “ () © a)

Foundation Carmmnpreremnas

work S A300 [SSL | at * & 7

Substructure.

work me S _ io _ —

Superstructure

work

Approach Slab

and fixed

items (Railing,

kerb, Crash

barrier ete.)

‘Approach

work

() testing foun

adequate, the reason for less testing: (Check v one or more box)

: Negligence

. Lack of equipment in lab

. Lack of knowledge

. Angee plense epecipe [

(©) Verification of test results: (C: conforming, N: non-conforming)

‘Quality control tests to be conducted by QM and the results to be matched with test results previously

recorded in Quality control test register, at the same component of the structure.

Tem of | Nameof | Results ofthe | Testresultsas per [Results of the test| Whether the test

Work Test test Quality Control test | conducted | results recorded in

conducted by | register at the same |previously by QM] Quality control

QM at the location. at defined test register and

component of |(Mention the Page no.| location. as conducted by

the structure. of Register) (CN) QMare in

(cm) conformity?

Cube tert (Yes No)

a) @ @) @) 6) ©

Rape |Compenree

LeaMhic Stren sty

ee ly aaaus [Ou ay = c

en ‘ arg, 00 |o 294 Fy = Sa

pr] " c2a-sd |e 2q0y ae | — q

=

Feo Ley

pare (650. To} =

ey gap CIE G

° “ WW

Scanned with CamScanner —

(@ Whether non-conformities recorded in QCR-I by AE have been rectified and

recorded in Quality control test register again as conformities, after conducting

necessary tests:

(Cheek Zany one box) No

[ves |}

(©) Imorder to assess the quality of concrete in case of doubt, if any Non Destructive

Test (NDT) such as Rebound Hanuner test, Ultra Sonic Pulse Velocity (UPY) etc.

has been conducted: (Check any one box) re | No

‘Guiding note: If the QC registers are not maintained or verification of test results are not conforming,

overall item grading shall be U. Ifanyone or more sub-items are graded partly or no, overall item grading

shall be SRI.

Item Grading-3:

a

(Check any one box) Ss SRI U

If this item is graded SRUU, write clear reasons and suggestions for improvement, are to be recorded:

vA

S

Scanned with CamScanner

~ ere ewvue

4. FOUNDATION; ———— 0 Sma He Fa we

wap taal +

A) Ongoing (Work In progress) cp

progress as on date uf inepeetion-in Ya

putments and Ret

1, Foundation Pi

Abutments: [AL Me AL Yo

Vers r_ mm %)] Py _%) _%) Ps _%)

m7] PO) So Pe

Ret mM) «(ee

Grade of | Quality of material Ts adequate as per quality | “Testing | Grade

Item of | concrete control register of (si)

work Cement | Coarse Fine Steel_| concrete

aggregate | aggregate cubes

by

NQM

‘if any)

a 2 @) @ () © | m | ®

Location’ | Grade | Form work | Reinforcement | Workabitity | Compaction | Curing | Grade

Itemof | of | quality and | checked by Of | arrangement | arrangements | (Sy)

work | conerete | arrangements | competent} Concrete

authority

a) @ QB) 4 (5) 6) @. (8)

II. Whether Cement and Steel tests (other than those provided by supplier), got conducted by

independent laboratories:

(CheekV/any one box) Yes No

f bored

III, Whether flushing of bore before and after placement of reinforcement done in case of

uneased cast-insitu piles.

(CheckVany one box) Yes No

a

Scanned with CamScanner

IV. Whether nt least GOOMM extra length af pill casted beyond ent off fevel, to he dismantled for

nitance effect

(Cheek Zam ane boo) |

Ve Whether bottom plugging: | M nt

Jom pluggling in case of well foundation earried out hy v ly

(heekJany rie bor) No

B) Completed work

Location | Grade] Compressive | Testing of ‘Surface ize and | Quality Grade

Memof | of | strength of ) concrete | acceptability | shape as | assessment | (S/t)

work [concrete] Conerete | cubes by and per | by personal |

cubes as per | NQM(if | workmanship | design judgment

Quatity any)

Control Test

Register

a) Q) a (7)

are Q) 4) © © @

oe Po | mas 2q.us7 | 22-us7 [urceeptese | 6-u. [SrSfeetny| S

Pa ‘ 29 24-0 y oe 9

2 es » 29.04 16-50 4 one. Ld &,

Foo lm, e|

P35. map | (6-s> Isso u Ove u Ss

I. Whether Cement and Steel tests other than provided by supplier, got conducted by independent

laboratories:

(Check/any one box) Kes No

Il. In order to assess the quality of concrete in case of doubt, if any, Non Destructive Test (NDT)

such as Rebound hammer test, Ultra Sonie Pulse Velocity (UPV) ete. has been conducted:

(CheckVany one box) res No

Guiding note: If quality of either material or workmanship is U, the overall tem shall be graded as

Item Grading-4: As Tu

(check J any one box)

(this item is graded as U, clear reasons and suggestions for improvement are to be recorded)

+

S

Scanned with CamScanner

$. SUBSTRUCTURE

no ——

A) Ongoing (Work in progress)

(Location? | Gmde of Quality of material is adequate as Grade

Hem of | concrete eonteal re (SIU)

‘work ‘Cement Contse Steel | concrete

oggregate | nggrepate cubes

by

NOM

_ | Gtany)

© 2 Q a 5) G) 0) (8)

Location | Grade Form work | Reinforcement | Workability [ Compaction ‘Curing Grade

Item of of quality and | checked by or arrangement | arrangements } (57.

work | concrete | arrangements | competent | Concrete

authority

o) @) 3) 4 (S) 9) o] 8)

Whether granular/ sandy filling behind the abutments and returns done properly:

(Check¥any one box) Yes No

Whether marking with paint is done on bridge components with date of casting for concrete:

(CheckVany one box) ves }[ [no

Whether Cement and Steel tests other than provided by supplier, got conducted by

independent laboratories:

(CheckVany one box) Yes | No

Scanned with CamScanner

B) Completed work

Location

Festina] Swtice | Sine

n/ tem Quality “| Weep] Ridien [Gr

rere oF Concrete Yemnrete | ity ant | Shape [ty perma] Adeqine

cubesa ceubes hy | workmay a i me eee

an | ns per jalan om |

per Ona {NOM aE | akin Pein airs |

Control | any) bss |

vest and | |

fees: return) | |

Qo |e Se {

@ © |@ | o

I. Whether Cement and Steel tests other than provided by supplier, got conducted by

independent laboratories:

(Checkv any one box) Yes No

In order to assess the quality of concrete in case of doubt, if any Non Destructive Test (NDT)

such as Rebound hammer test, Ultra Sonic Pulse Velocity (UPV) ete. has been conducted:

(Check/any one box) Yes No

Guiding note:

Item Grading-5:

(check J any one box)

(if this item is graded as U, cle

nNe— Smu aw tem vs te ot

——_

s u |

exe ee:

quality of ether material or workmanship is U, the overall item shall be graded as“U"

‘ar reasons and suggestions for improvement are to be recorded).

aan mannan aeees

Scanned with CamScanner

6. SUPERSTRUCTURE

(RCC Superstructure

A) Ongoing (Work in progress)

Quallty of moteriat

Els a 3

i a 3

3] a, Ale Veegs dae 2i|3

Eletl el] bls delisel ai] 2 | ia }4

gieé|elele Pepe) ob) & | ca | 3

= Ele ByeH a’) és aie

O) Q) QG | @ |e) (8) @ [a9 Tay tT oz [03

Whether Cement

independent laboratories:

(Checky any one box)

nd Steel tests other than provided by supplier, got conducted by

Yes

No

Guiding note: If quality of either material ot workmanship is U, the overall item shall be graded as “U™.

Item Grading-6 A:

(check / any one box)

s

[u

(fthis item is graded as U, clear reasons and suggestions for improvement are to be recorded).

_—

She te

erential’

Tow re & Ge,

Scanned with CamScanner

B) Completed work '

2 ‘ # 3 1

Bled stds esa] elal lelelal,|3la

Peel Haale ela; lal alelal i

pled earl b) a2 ele al eyala

PRAHA Tear PELL Ey a

OTe 2 ae] KO EN CY ES WL

I. Whether Cement and Steel tests other than provided by supplier, got conducted by

independent laboratories:

(Check any one box) Yes No

|. In order to assess the quality of concrete in case of doubt, Non Destructive Test (NDT) such

as Rebound hammer test, Ultra Sonic Pulse Velocity (UPV) ete. has been conducted if any:

(Check¥ any one box) Yes No

Item Grading-6 B: s] Llu

(check J any one box)

(If this item is graded as U, clear reasons and suggestions for improvement are to be recorded).

He— Sma du tom me rot

senee tid

Scanned with CamScanner

(i) Steet Suporstructure, gy

A) Ongoing (Work in progress)

Quality of Material

. 8 |_ Workmanship as

§ 3 a fe » |e 2 25

Si; (ele 4 g.\2 | 2. (23.5

é/ 2/4) lee] Be 23 |22-| 23, | #242

sla] f|a| ee] fola3 22 ies) be [epee

2/8) 2) 2)s2) 42 86 |s22| 252 |g27°

3 ei\3le |a> se leer) Ba- | as

3 Sls|2 | & ev |e a ge

Fle le 16 Be \é 2 bE

q@ | @ |e) | @ | © @) | @ @) (9) (10) (uy)

I. Presence of water spray or moisture in the vicinity of bridge such as waterfall or marshy wet Iand?

(Check/any one box)

Yes ‘No

IL, Presence of industrial units nearby, which emit corrosive fumes or discharge chemical effluents?

(Check/any one box)

Yes No

IIL. Presence of salinity in the atmosphere? __(CheckVany one box) ‘Yes No

Guiding note: If quality of either material or workmanship is U, the overall tem shall be graded as “U".

Item Grading-6A: : U

(check ¥ any one box)

(Uf this item is graded as U, clear reasons and suggestions for improvement are to be recorded).

Ne Smee thee TR no Pv UN

i pon Pr I TO

1»

Scanned with CamScanner

B) Completed Work

Welding

i -¢ af Corrosto ~|

_|4% (Yes! No)

g/e Wes, type of

els corsion and specific ‘Any change in

Ss] i resence of | trecence of load

i g vite Buckling | _¢lassifiation

a ec le | Fracture (Yes/No)

= Es |gsl] 8] cen (Yes! No)

: PEE EE

£ £5 /o8)%S

O1O)O TOT So [ola ©) © 0)

_|

L. Presence of water spray or moisture in the vicinity of bridge such as waterfall or marshy wet land?

(Check any one box) [ [ves No

Il. Presence of industrial units nearby, which emit corrosive fumes or discharge chemical effluents?

(Check/any one box) Yes I No

sh

IIL. Presence of salinity in the atmosphere? __(CheekVany one box) Yes No

Ttem Grading-6B: S| U

(check Y any one box)

Yn ppt fu

(f this item is graded as U, elear reasons and suggestions for improvement are to be recorded).

pra —— Sa SRew PE 0 Pprwtsen

ren

Scanned with CamScanner

(iii) Bailey Bridge Suporstructure

no ——

A) Ongoing (Work in progress)

r Gaal a ats 3 Warton

2/7) .5/, |e [eels [42

3 2] 22 . = a 2205

E Ss] 23 | ¢8s/8.> gas Be £242

3 & gs ge eae2\|28 Bas bse

3 S| 2S | 823 |we3/ESe | 22 £232

; Z| 82 | S6e |gee Bie | eee gho~

3 z2 | 2 a |£e5/2 ne

A 24° (8 é3

2 |@ oe

a a) ® @ Co @ @

A. Any bolt andi or rakers and tie plates are missing or loose?%(CheckVany one box) | Yes. ‘No

Tl. Any sway braces and/ or transom clamps are missing or loose? Yes No

(Check/any one box)

TIL. Presence of any cracking in the Bailey bridge? (Check¥any one box) Yes No

IV. Presence of any bends in bridge members? (Check/any one box) Yes No

Guiding note: If any of panel PIN is missing or loose, the overall item shall be graded as “U™

Item Grading-6A: CTs] U

(check / any one box)

Uf this item is graded as U, clear reasons and suggestions for improvement are to be recorded).

wa — Sma drew no prestige

Ona Tar -

™ perme fy

Scanned with CamScanner

B) Completed Work

Welding Material

*€ 2 2 Presence of Corrosion Lee

3 3 3 (Yes! No) Bz

Ss e & IFYes, type of corrosion and ae8

5 43] 3s specific Incation pat

= ol 33 238

5 gE

& a2] €2 | ¢. 3| Efe

3 ¢ | 3° | £8 a3) 2E3

3 ple |t Be) a2

é é ao O| 282

oO, ® ® @ ) © | @® @®

I. Any bolt and/ or rakers and tie plates are missing or toose?(CheckVany one box)| | Yes, No

II. Any sway braces and/ or transom clamps are missing or loose? Yes No

(Check any one box)

III. Presence of any cracking in the Bailey bridge? (Check/any one box) Yes No

TV. Presence of any bends in bridge members? (Check/any one box) Yes No

Guiding note: [fany of panel PIN is missing or loose, the overall item shall be graded as “U"

Item Grading-6B: s { U

(check J any one box)

(if this item is graded as U, clear reasons and suggestions for improvement are to be recorded).

Ne— ame drew fh ne Py etsten Hy

peu fir nb Tee?

Scanned with CamScanner

ny

7. LOAD TEST =————~ a _

1. Results of Load Test attached of not (check Zany ane box) CJ ves | 7 [xe] {

Iryes, comments required and copy’ of test results shall he enclosed

Guiding none! Toad 168 Fe not dane or wal salfsfietary, Avera ten

Ts] Cie]

U this itenr is graded U. write clear reasons and suggestions for improvement

ial be U.

rr Smee Ihe ever fh wy ‘2

Sree oy.

—

8. BEARINGS ot

A) Types of Bearing (Tick Vappropriate)

Roller and Rocker Bearing

Elastomerie Bearing

Pot cum PTFE Bearing

Spherical Bearing

Cylindrical Bearing

‘Any other type

pn

B) Condition of Bearings

(@) Metallic Bearings

i. General Condition- any rusting / ceasing of plates/ cleanliness or not s u

ii, Functioning ~any excessive movement tilting/ jumping off guides | s uU

reasing/ oil bath required to be redone or not [ s U

iv. Cracks in supporting member- Abutment cap, Pier cap, Pedestal, if any s U

¥. Effectiveness of anchor bolts, whether in position and tight or not s U

vi, Report any other defect or observation found

2

Scanned with CamScanner

() Elastomerie Hearings

i. Report conn of pads Oslin, Cee Fates

Bulging, Spliting, Displacement ifany

ii, Report — Bearings are elean anu fee or not

Report any other dofect or observation found

(©) Any type other than ‘a’ and ‘b’ above

Report - Any other defect or observat

found

1. Whether test results of bearings are available or not:

(CheckVany one box) im Yes

Guiding note: IF anyone of the sub-items are graded as U, overall item grading shail be U.

Item Grading-8:

(check J any one box)

Ss

[uv

(this item is graded as U, clear reasons and suggestions for improvement are to be recorded).

——— NB Smee daewoo prretiten 1

pn fer PS Tee

u

Scanned with CamScanner

9. EXPANSION JOINT

A) Types of

xpanston joint (tek appropriate)

ied Expansion joint

Joint - ~

Modular Strip 7 Box Seal joint ——j———

Finger Joint

Reinforced Coupled Elastomeric Joint

B) Condition of Expansion joints

i. Is there any crack in the wearing coat Yes No

fi, Whether existing gap is improper Yes No

iii, Any hardening / cracking observed in bitumen filler Yoo No

iv. Any splitting/ oxidation/ creep/ bulging observed in neoprene

Yes [xo

sealing material

¥. Corrosion/ damage to welds is visible Yes No

L

vi. Presence of debris in the joint ]¥es LTre

vi Report - any other defect or observation found [rs Ne

rer

o

Item Grading-9:

(check ¥ any one box)

ing note: IF any response of questions in sub item 9 B is "Yes", the overall tem shail be graded as

S u |

(Uf this item is graded as U, clear reasons and suggestions for improvement are to be recorded).

— Smue drew vs ne prenn

m pon for cde ten:

Scanned with CamScanner

10. APPROACHES

WA

10.1 Embankment

Cocation | Suitability of soil | Compaction Side stapes Grade

(s/ SRIU)

© ® @ | (Gy

10.2 Sub Base (G.S.B.)

Location) Conforms] Material | Dry JYeComp.] Whether [Thickness | Measured [Prescribed

(RD) to Suitable | density | action |compaction jas per DPR| ‘Thickness Thickness

Grading | from kN/m? is adequate (in (in mm) provided.

(YN) | plasticity (YN) mm) (YIN)

angle

@ @ ym) o) | Oy © @ @) 9)

10.3 Base Course (Non Bituminous (WMM) and Bituminous Macadam (BM))

Location | Grading of | Plasticity | Volume of | Compaction | Design ‘Thickness |Thickness

Aggregates} of Filler fill based on | thickness | ofeach | adequate

RD) | Gu) | material | material | volumetric las per DPR} layer of | (S/U)

(S/U) | percent of _|analysis/ sandl WBM/

coarse | replacement | (mm) | WMM

Ageregate | method (mm)

(SU)

a) 6)

@) Q 4 © (ay )

*

Scanned with CamScanner

Grading of | Laying

Surface

Coarse | Temper {eontent % as eantent of layer unevenness

Aggregate | ature ot | per Qcwed | git | Ot sill)

wruy the mis JAs measured) Sti

as per by

OCR} NoM/soM

@ @ “ “0 6 a ay

10.5 Protection Work:

1. Whether sanctioned DPR has the provision of protection works: yes | [___[no |

(check/any one box)

Tl. Type of protection work: (check V boxes as applicable)

[ Retaining wall_} Breast wall Parapet wall |

Any other type of Protection work

a

b.

TH. Quality of Materials:

[Location /] Structure Type | Type of Protection |General quality of] Size and [Quality assessment

RD |(Retaining Wall/| work (RCC/CC/_\material conforms| shape as | by personal

Breast Wall/ | Masonry/ wire | tospecifications |per design | judgement

Parapets) crate) (Yes/No) | (Yes/No)

@) @) GB) (4) G) (6)

n

Scanned with CamScanner

IV, Workmanship of Retaining structures

Location? | Workmansh

forkmanship ot Whether Tiave weep holes [ Adequacy of

RD J retaining structures | honeycembingfany | | been provided sweep holes

‘other defects are (Yes/No) (if provided)

observed (Y/N) (YesiNo)

wo @ @) «@ (3)

Incase, Stone masonry is used in retaining structure:

a) ‘Workmanship of stone masonry is acceptable: Pe] No

(check Many one box)

b) Bond stone has been provided in stone masonry: [ves | No

(check any one box)

Guiding note: If sub item 10.2, 10.3, 10.4 are graded as U, the overall item shall be U.

Item Grading-10:

(check V any one box)

s

SRL U

(Uf this item is graded SRUU, write clear reasons and suggestions for improvement).

—— NA

erect *

Sma dw eS

ls be,

8

nat

‘Scanned with CamScanner

1. BRIDGE FURNITURE AND MARKINGS:

11.4 Observations: Quali

of Bridge Furniture and Markings : (Ongoing / Completed works)

Ww Main Information Board

Fixed : (X prtekayyrte aba /ln, 4 fs 7

. : Mrenaat 2] Rakend boalam key i platires

» ackage No. vale

TEOURHMIRER OF

>

~ Date of Inspection: O5-O04- Ir)

> Chainage:, Fdays Prag

© poe mee He Bk. Feat Mire” better feb

.

w _

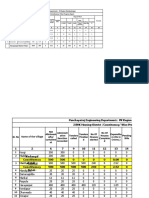

« a3 at Sh (se) 1s 4

» ig =

Shy 2 ste 30 20 23 14 1a is ered.

» =

au | 33 | 20 1s 13 1S

° L

2

> dew tt

> Po tp footy

>

> 16 is | ts

>

a haat 14 1s \6

) vl

) (F 14 is

’

) 4 :

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 11.angwadi Center (8.00 Lakhs) RIDF-XVI-Feb PR NRPTDocument5 pages11.angwadi Center (8.00 Lakhs) RIDF-XVI-Feb PR NRPTK KARTHIKNo ratings yet

- 11.angwadi Center (8.00 Lakhs) NEW MGNREGSDocument5 pages11.angwadi Center (8.00 Lakhs) NEW MGNREGSK KARTHIKNo ratings yet

- 3.PMGSY Ongoing VIII To IIIDocument2 pages3.PMGSY Ongoing VIII To IIIK KARTHIKNo ratings yet

- GP Buildings ABSTRACT, WW Region - Region As On 11.01.2022Document4 pagesGP Buildings ABSTRACT, WW Region - Region As On 11.01.2022K KARTHIKNo ratings yet

- SDF Divsion Report Sep 2020Document4 pagesSDF Divsion Report Sep 2020K KARTHIKNo ratings yet

- CDP New Sanction NRPT MLA1Document3 pagesCDP New Sanction NRPT MLA1K KARTHIKNo ratings yet

- DPR 19Document110 pagesDPR 19K KARTHIKNo ratings yet

- SCDD Govt SC Hostel Building Progress ReportDocument4 pagesSCDD Govt SC Hostel Building Progress ReportK KARTHIKNo ratings yet

- Cattle Shleter 20.00 Lakhs MgnregsDocument2 pagesCattle Shleter 20.00 Lakhs MgnregsK KARTHIKNo ratings yet

- Construction of (400) 2BHK HOUSES (G+1) of Narayanapet Mandal, in Narayanapet Muncipality of Narayanpet District, Telangana StateDocument89 pagesConstruction of (400) 2BHK HOUSES (G+1) of Narayanapet Mandal, in Narayanapet Muncipality of Narayanpet District, Telangana StateK KARTHIKNo ratings yet

- Narayana Pet 400 (g+1) Houses-UrbanDocument103 pagesNarayana Pet 400 (g+1) Houses-UrbanK KARTHIKNo ratings yet

- MRR Package 20 July 2019Document18 pagesMRR Package 20 July 2019K KARTHIKNo ratings yet

- Progress Report of Mgnregs Grants: For The Month of NOVEMBER - 2016Document25 pagesProgress Report of Mgnregs Grants: For The Month of NOVEMBER - 2016K KARTHIKNo ratings yet

- Abstract All grants-NRPT DIV 11.01.2022Document8 pagesAbstract All grants-NRPT DIV 11.01.2022K KARTHIKNo ratings yet

- STSDF (Tribal Welfare Department) GO NO.336Document2 pagesSTSDF (Tribal Welfare Department) GO NO.336K KARTHIKNo ratings yet

- BT Renewal ANNEXURE II & III of PR Division, Narayanpet Mandal 13.02.2022Document11 pagesBT Renewal ANNEXURE II & III of PR Division, Narayanpet Mandal 13.02.2022K KARTHIKNo ratings yet

- CDP NEW Kashi Reddy MLC (LAC-2) M'nagarDocument1 pageCDP NEW Kashi Reddy MLC (LAC-2) M'nagarK KARTHIKNo ratings yet

- CRR Progress ReportDocument7 pagesCRR Progress ReportK KARTHIKNo ratings yet

- MRR Govt 300 July Go Report.Document8 pagesMRR Govt 300 July Go Report.K KARTHIKNo ratings yet

- 9 Road Mileage Details 01.04.2021 Division Report - PIU MBNRDocument66 pages9 Road Mileage Details 01.04.2021 Division Report - PIU MBNRK KARTHIKNo ratings yet

- 29 05 2022 721719955Document40 pages29 05 2022 721719955K KARTHIKNo ratings yet

- BT Renewal Proposals AS ON 13.02.2022 PR DIV NRPTDocument15 pagesBT Renewal Proposals AS ON 13.02.2022 PR DIV NRPTK KARTHIKNo ratings yet

- DocScanner Jun 8, 2022 5-41 PMDocument1 pageDocScanner Jun 8, 2022 5-41 PMK KARTHIKNo ratings yet

- Design of Horizontal Curves With Superelevation Design DataDocument4 pagesDesign of Horizontal Curves With Superelevation Design DataK KARTHIKNo ratings yet

- Mana Vooru Mana Badi 13.06.2022Document31 pagesMana Vooru Mana Badi 13.06.2022K KARTHIKNo ratings yet

- Mana Vooru Mana Badi 13.06.2022Document24 pagesMana Vooru Mana Badi 13.06.2022K KARTHIKNo ratings yet

- 2BHK Abstract & Village Wise Progress Report PR Region Mahabubnagar 14.12.2021Document5 pages2BHK Abstract & Village Wise Progress Report PR Region Mahabubnagar 14.12.2021K KARTHIKNo ratings yet

- 29 05 2022 283524154Document45 pages29 05 2022 283524154K KARTHIKNo ratings yet

- 29 05 2022 12849797Document62 pages29 05 2022 12849797K KARTHIKNo ratings yet

- 29 05 2022 591393450Document41 pages29 05 2022 591393450K KARTHIKNo ratings yet