Professional Documents

Culture Documents

PRC 2001 Current

Uploaded by

enrico susantoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PRC 2001 Current

Uploaded by

enrico susantoCopyright:

Available Formats

PRC-2001 Rev.

Process Specification for the Heat Treatment of Steel

Alloys

Engineering Directorate

Structural Engineering Division

December 2019

National Aeronautics and

Space Administration

Lyndon B. Johnson Space Center

Houston, Texas

Verify correct version before use.

Page 1 of 13

PRC-2001 Rev. I

Process Specification for the Heat Treatment of Steel

Alloys

Prepared by: Signature on File 12/20/2019

Daila Gonzalez Date

Materials and Processes Branch/ES4

Reviewed by: Signature on File 12/20/2019

John Figert Date

Materials and Processes Branch/ES4

Approved by: Signature on File 12/21/2019

Brian Mayeaux Date

Materials and Processes Branch/ES4

Verify correct version before use.

Page 2 of 13

PRC-2001 Rev. I

REVISIONS

VERSION CHANGES DATE

Baseline Original version 5/96

A Expanded sec. 3.0, furnace chart info., tensile requirements 5/27/98

B Changed Training Requirements, Updated to SAE AMS-H-6875A 7/21/99

C Modified Training Requirements, Labeling Tensile Bars & Stock 2/24/00

D Included Information on Post-Weld Stress Relief, Reduced 8/24/00

Labeling Tensile Bars & Stock Requirements

E Changed sec. 6.0 on aging requirements for A286. Updated 6/06/02

document due to reorganization from EM2 to ES4.

F Reviewed for accuracy and updated author. 10/04/06

G Clarified the Usage Statement 8/10/09

H Verify current condition of raw stock material; added statement 10/2011

on tool and die steels; added Table 1 and Table 2; subdivided

PROCESS VERIFICATION section; added ASTM E18 under

REFERENCES section; replaced JSC 8500 with JPR 8500.4

under REFERENCES section; updated and added definitions to

section 10.0; other grammatical changes.

I Deleted Structural Engineering Division logo; updated revision, 12/2019

date, and Approved by signature; added Figure 1 on heat tint to

Section 3.1 Process Sequence; deleted statement on 2hr delay

between welding and stress relieving as previously noted in

Section 3.1 Process Sequence; added AMS 2759/13 (Gaseous

Nitrocarburizing) to Table 2; reworded most of Section 10.0

Definitions; added MTR definition to Section 10.0 Definitions;

alphabetized definitions in Section 10.0 Definitions; minor

grammatical corrections.

Verify correct version before use.

Page 3 of 13

PRC-2001 Rev. I

1.0 SCOPE

This process specification establishes the engineering requirements for

the heat treatment of steel and stainless steel alloys.

2.0 APPLICABILITY

This specification shall be applicable whenever the heat treatment of steel

or stainless steel alloys is invoked per section 3.0, "Usage." Heat treatment

of steel and stainless steel alloys may be performed on raw stock material

(includes, but not limited to, plate, bar, forgings, and extrusions) or on parts

produced from raw material.

3.0 USAGE

The material to be heat treated shall be listed on the drawing, in the heat

treat condition in which the material is to be procured; the procurement

specification shall be listed alongside the material to be heat treated.

Availability of product forms and tempers may be obtained from a

manufacturing production controller or from an ES4 materials engineer.

This process specification shall be called out on the engineering

drawing by using an appropriate drawing note. The specific heat

treat process or combination of processes shall be noted along with

the final temper. For example:

For Class A (Carbon and Low Alloy Steels):

QUENCH AND TEMPER TO 160-180 KSI PER NASA/JSC PRC-2001.

For Class B (Martensitic Corrosion Resistant Steels (CRES)):

QUENCH AND TEMPER AT 450°F PER NASA/JSC PRC-2001.

For Class C (Austenitic CRES):

ANNEAL PER NASA/JSC PRC-2001.

For Class C (Austenitic CRES):

AGE HARDEN TO CONDITION H1025 NASA/JSC PRC-2001.

3.1 PROCESS SEQUENCE

Unless otherwise specified on the engineering drawing, all parts shall

be heat treated before final machining to remove scale and

decarburization, as well as to avoid dimensional changes. Scale and

decarburization, typically produced at temperatures above 1200°F, are

normally detrimental to the finished part and cannot be removed by

Verify correct version before use.

Page 4 of 13

PRC-2001 Rev. I

mechanical or chemical finishing techniques. After heat treating, a

minimum of 0.020" will be removed from all scaled or decarburized

rough machined surfaces during final machining.

In some cases, it may be necessary to heat treat after final machining. It

is recommended to restrict heat treat processes to those such as

tempering, which are performed at low temperatures. Heat tint, which

ranges in color from straw to light blue may be formed during these low

temperature heat treatments

(Figure 1).

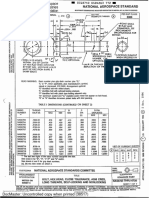

Figure 1: Heat Tint Color Post Tempering of Steel Samples at Various Temperatures in Circulating Air

It may be required to remove heat tint for cosmetic purposes. An

appropriate finishing procedure to remove the heat tint shall be called out

on the engineering drawing, if heat treating will result in a heat tinted

surface that will not be removed by final machining. For example:

HEAT TREAT AFTER FINAL MACHINING. REMOVE HEAT TINT BY

ELECTROPOLISHING PER NASA/JSC PRC-5009.

Class A and Class B steels often require a stress relieving heat

treatment after welding operations. Stress relieving after welding should

be performed as soon as possible after the welding operation. Post

stress relieving on Class C and Class D steels may not be necessary

for specific reasons. A qualified welding procedure for the specific

application needs to be reviewed before making the stress relieving

note. For example:

STRESS RELIEVE AT 1000°F FOR 2 HOURS IMMEDIATELY AFTER WELDING.

Verify correct version before use.

Page 5 of 13

PRC-2001 Rev. I

4.0 REFERENCES

All documents listed are assumed to be the current revision unless a

specific revision is listed.

Document Number Document Name

SAE AMS-H-6875 Society of Automotive Engineers,

Inc., Aerospace Material

Specification, Heat Treatment of Steel

Raw Materials

SAEAMS2759 Heat Treatment of Steel Parts

General Requirements

ASTM E18

American Society for Testing and

Materials Specification, Rockwell

Hardness and Rockwell Superficial

Hardness of Metallic Materials

ASTMA370 American Society for Testing and

Materials Specification, Standard Test

Methods and Definitions for

Mechanical Testing of Steel Products

MMPDS Handbook, Metallic Materials

Properties Development and

Standardization

Tl-2000-01 Training Instruction: Training for Heat

Treat Personnel

SAE ARP 1962 Training and Approval of Heat-

Treating Personnel

Verify correct version before use.

Page 6 of 13

PRC-2001 Rev. I

The following references were used in developing this process specification:

Document Number Document Name

SOP-007.1 Preparation and Revision of Process

Specifications

JPR 8500.4 Engineering Drawing System Requirements

5.0 MATERIALS REQUIREMENTS

Current heat treat condition shall be verified before performing any subsequent

heat treatment on raw stock material. Subsequent heat treatment shall be

performed per AMS-H-6875.

Material requirements for parts shall be as specified in AMS 2759.

6.0 PROCESS REQUIREMENTS

6.1 Raw Stock Steel and Stainless Steel Material

All heat treatment of raw steel and stainless steel alloys shall comply with

the requirements specified in section 3 of SAE AMS-H-6875 and the

corresponding drawing requirements.

Specific heat treating times and temperatures are provided in various

tables in SAE AMS-H-6875. Table 1 provides a list of these heat treating

tables.

Verify correct version before use.

Page 7 of 13

PRC-2001 Rev. I

Table 1: List of Tables with Heat Treating Times and Temperatures Per SAE

AMS-H-6875

Table Name

1A Heat-Treatment Procedure for Class A (Carbon and Low Alloy) Steel

1B Heat-Treatment Procedure for Class B (Martensitic Corrosion-Resistant)

Steel

1C Annealing Procedure for Class C (Austenitic Corrosion-Resistant) Steel

1D* Heat-Treatment Procedure for Class D (Precipitation-Hardening and

Maraginq) Steel

2A Heating and Holding Time for Annealing, Normalizing, Austenitizing, and

Stress Relieving Class A Steel and Class B Steel

2B Holding Time for Class C (Corrosion-Resistant) Steel

3 Required Tempering Conditions

"An exception to Table 1D must be noted when age hardening A286. The age hardening time and

temperature provided by Table 1D yields the minimum tensile strength that can be attained for A286,

without cold working the material. The tensile strength of A286 can be increased by the amount of

cold work input into the material. The age hardening time and temperature for A286 material that has

been cold worked is not listed in Table 1D. The corresponding material specification(s) shall be used

to age harden A286 material that has been cold worked.

Tools and equipment shall be as specified in SAE AMS-H-6875. Safety

precautions and warning notes shall be as specified in SAE AMS-H-6875.

6.2 Steel and Stainless-Steel Alloy Parts

All heat treatment of steel and stainless-steel alloy parts shall comply with the

requirements specified in section 3 of AMS 2759 and the corresponding drawing

requirements.

Specific heat treating times and temperatures are provided in various derivations

of AMS 2759. Table 2 provides a list of these AMS 2759 derivations.

Verify correct version before use.

Page 8 of 13

PRC-2001 Rev. I

Table 2: List of AMS 2759 Derivations

Steel and Stainless-Steel Heat Treat Procedures AMS 2759 Derivations

Carbon and Low-Alloy Below 220 ksi UTS AMS 2759/1

Low-Alloy 220 ksi UTS and Higher AMS 2759/2

PH and Maraging AMS 2759/3

Austenitic AMS 2759/4

Martensitic AMS 2759/5

Gas Nitriding AMS 2759/6

Gas and Vacuum Carburizing AMS 2759ll

Ion Nitriding AMS 2759/8

Hydrogen Embrittlement Relief (Baking) of Steel AMS 2759/9

Parts

Automated Gaseous Nitriding Potential AMS 2759/10

Stress Relief of Steel Parts AMS 2759/11

Gaseous Nitrocarburizing, Automatically Controlled AMS 2759/12

by Potentials

Gaseous Nitrocarburizing AMS 2759/13

*Heat Treatment of Parts in a Vacuum AMS 2769

*Not an AMS 2759 specification.

Tools and equipment shall be as specified in AMS 2759. Safety

precautions and warning notes shall be as specified in AMS 2759.

6.3 Tool and Die Steels

An ES4 materials engineer shall be consulted for process

requirements and specific heat treating times and temperatures for

heat treatment of tool and die steels.

7.0 PROCESS QUALIFICATION

Not required. However, work instructions shall be generated for

implementing this process specification. The work instructions shall

contain sufficient detail to ensure that the manufacturing process produces

consistent, repeatable products that comply with this specification.

8.0 PROCESS VERIFICATION

8.1 Verification of Heat Treat Cycles

Verification of furnace temperatures shall be accomplished by recording the

furnace temperatures on strip charts or other suitable hard copy recordings.

Furnace charts for heat treatment shall be maintained with the hardware's

Verify correct version before use.

Page 9 of 13

PRC-2001 Rev. I

work order router package (or equivalent documentation).

8.2 Heat Treat Verification by Hardness Test

Heat treat verification of steel and stainless steel is typically achieved by

measuring hardness per ASTM E18.

8.2.1 Notations Related to Hardness Tests

Hardness tests will be performed on the raw stock material or the semi-

finished part unless otherwise specified on the engineering drawing. Hardness

impressions will be machined away during subsequent machining for most

parts. When hardness impressions must be made on the finished part, a test

location shall be chosen by the designer and the materials engineer that will

not be detrimental to the function of the finished part. Notes must be included

on the engineering drawing, such as:

HARDNESS TEST SHALL BE PERFORMED ON FINISHED PART IN

SPECIFIED LOCATION

Hardness tests may be performed on sample parts instead of finished parts.

Sample parts shall be sketched and/or described on the engineering drawing.

They may have a simplified contour and may use nominal dimensioning.

Sample parts shall be made from the same lot of raw stock material and · shall

be processed before heat treatment in an identical manner as the finished

parts.

When the heat treating process includes quenching, the sample parts must be

of similar cross section as the finished parts, or shall be parted from the same

lot of raw stock material that will be used for finished parts post heat treatment.

If finished parts have to be processed in more than one batch and sample

parts are needed, each batch must have its own set of labeled sample parts.

When a hardness test is to be performed on a sample part, special instructions

shall be included on the engineering drawing, such as:

HARDNESS TEST SHALL BE PERFORMED ON SAMPLE PART.

SAMPLE PART SHALL CONSIST OF ONE 1" LENGTH OF THE SAME

RAW STOCK MATERIAL USED FOR FINISHED PARTS.

OR

HARDNESS TEST SHALL BE PERFORMED ON 2" PROLONGATION

OF RAW STOCK MATERIAL THAT IS PARTED AFTER HEAT

TREATMENT.

Verify correct version before use.

Page 10 of 13

PRC-2001 Rev. I

8.2.2 Hardness Test Results

Hardness test results shall meet the values that appear on the procurement

specifications or the drawing requirements.

8.3 Heat Treat Verification by Tensile Test

When tensile tests are required by the drawing for more critical parts, tensile

tests shall be performed according to ASTM A370 by either the JSC Structures

Test Laboratory, the Receiving Inspection and Test Facility (RITF), or an

accredited mechanical testing laboratory.

8.3.1 Notations Related to Tensile Tests

Sample parts for tensile coupons shall be machined according to ASTM A370,

using full-sized coupons whenever possible. Sample parts shall be machined

from the same lot of raw stock material and processed before heat treatment

in an identical manner as the finished parts. The number of coupons, grain

direction (when applicable), and any special acceptance criteria (i.e.: tensile

strength, % elongation, etc.) shall be noted on the engineering drawing when

tensile testing is required. For example:

TENSILE TESTING IS REQUIRED AND SHALL BE PERFORMED ON

SAMPLE PART(S). SAMPLE PARTS SHALL CONSIST OF THREE 6"

LENGTHS OF THE SAME RAW STOCK MATERIAL LOT USED FOR

FINISHED PARTS.

8.3.2 Labeling of Tensile Coupons

Tensile coupons shall be labeled individually. Label information shall always

include material lot certification #. If the tensile bars or tensile coupons are

made prior to heat treating, the tensile bars or tensile coupons shall be labeled

using austenitic stainless tags and austenitic stainless wire. If the tensile bars

or tensile coupons are made after heat treating, cotton string and paper tags

may be used instead of stainless tags and wire. Paper tags shall include

the material type, the material lot certification #, and the work order router

number.

8.3.3 Tensile Test Results

Tensile test results for Class A, Class 8, and Class C steels shall meet the

yield strength and elongation drawing requirements per MMPDS. Tensile

tests are not required to verify annealed condition of Class C steels.

8.4 Miscellaneous

Verify correct version before use.

Page 11 of 13

PRC-2001 Rev. I

Hardness testing and tensile testing are not required post weld stress

relieving operations, except for rare exceptions.

9.0 TRAINING AND CERTIFICATION OF PERSONNEL

All heat treatment of steel and stainless steel alloys used for flight

hardware shall be performed by qualified operators who have been

certified according to the requirements in Tl-2000-01, Training for Heat

Treat Personnel. For vendors, a training program consistent with the

recommended practices in SAE ARP 1962 shall be required.

10.0 DEFINITIONS

Age Harden Aging that causes hardening constituents to

strain and strengthen the lattice.

Annealing A treatment consisting of heating to and holding

at a suitable temperature, followed by slow rate

cooling, used primarily to soften metallic

materials.

Austenitizing Forming austenite by heating a ferrous

alloy into the transformation range (partial

austenitizing) or above the transformation

range (complete austenitizing).

Cryogenic Treatment carried out after quenching to

Treatment transform retained austenite into martensite,

involving cooling and holding at a Cryogenic

temperature.

Decarburization Loss of carbon from the surface of a carbon-

containing alloy by reaction with other elements

(usually oxygen) during heat treatment

Heat Tint A thin, tightly adhering oxide layer that forms when

steels are heat treated at low temperatures, or for

a short time, in air or in a mildly oxidizing

atmosphere; the color ranges from straw to light

blue.

Material Lot A single batch (bar, forging, extrusion, etc.) of

material that is produced by the mill vendor and is

Verify correct version before use.

Page 12 of 13

PRC-2001 Rev. I

documented by a MTR.

Material Test A report generated by a mill, and provided by a

Report (MTR) mill or a material vendor when procuring raw

stock. MTRs include mill lot elemental chemistry

data, as-received mechanical properties such as

hardness and/or tensile strength, as well as

demonstrable mechanical properties such as

tensile strength, yield strength, percent

elongation, and reduction of area

Normalizing A heat treating cycle for steels above the

ferrite/austenite transformation temperature

followed by cooling in air.

Quenching Rapid cooling from the austenitizing or solution

heat treating temperature.

Tempering Reheating hardened steel to decreases hardness

and to increase both ductility and toughness.

Scale A heavy, penetrating oxide layer that forms when

steels are heat treated at higher temperatures, or

at longer times, in air or other oxidizing

atmospheres.

Solid Solution A single, solid, homogeneous crystalline phase

containing two or more chemical species.

Stress Relieving Heating to a suitable temperature (50°F below

the tempering temperature), holding long enough

to reduce residual stresses, and then cooling

slowly enough to minimize the development of

residual stresses.

Verify correct version before use.

Page 13 of 13

You might also like

- Astm A 240-18Document12 pagesAstm A 240-18Giann' Andreh'xd100% (2)

- Aerospace Material Specification: Polytetrafluoroethylene Film General Purpose GradeDocument8 pagesAerospace Material Specification: Polytetrafluoroethylene Film General Purpose GradeMax SalogniNo ratings yet

- D706 21603-1 PDFDocument6 pagesD706 21603-1 PDFMaeon LaboratoriesNo ratings yet

- Astm B248-22Document13 pagesAstm B248-22Luis GuidekNo ratings yet

- Mar-M-247 1984Document22 pagesMar-M-247 1984sunsirNo ratings yet

- Iso 9809 1 2010 en PDFDocument11 pagesIso 9809 1 2010 en PDFgabrielNo ratings yet

- Sae Arp1331Document12 pagesSae Arp1331niky186No ratings yet

- SAE - AMS 4050hv004Document9 pagesSAE - AMS 4050hv004Nilesh PatilNo ratings yet

- SS 400Document2 pagesSS 400Jigar M. Upadhyay100% (1)

- Aerospace Material SpecificationDocument7 pagesAerospace Material SpecificationdaNo ratings yet

- SAE AMS4011E Aluminum, Foil and Light Gage Sheet 99.45al (1145-0) AnnealedDocument11 pagesSAE AMS4011E Aluminum, Foil and Light Gage Sheet 99.45al (1145-0) AnnealeddaNo ratings yet

- Sae Ams 5520G-2015Document7 pagesSae Ams 5520G-2015Mehdi MokhtariNo ratings yet

- Features and Benefits: Technical Data SheetDocument6 pagesFeatures and Benefits: Technical Data SheetTaufiq SatrioNo ratings yet

- Steel Wire, Carbon, For General UseDocument3 pagesSteel Wire, Carbon, For General Userobert gridleyNo ratings yet

- E 1751 - e 1751M - 15Document95 pagesE 1751 - e 1751M - 15Eric GozzerNo ratings yet

- Ams 2451 Rev. DDocument9 pagesAms 2451 Rev. DJorge Luis Gonzalez Gonzalez100% (1)

- 6061 Aluminum Plate - AMS 4027 - 6061-T651 PlateDocument3 pages6061 Aluminum Plate - AMS 4027 - 6061-T651 Platemini p shendeNo ratings yet

- Aerospace Material SpecificationDocument6 pagesAerospace Material SpecificationMohammad LavasaniNo ratings yet

- 17-7 Material PDFDocument5 pages17-7 Material PDFJothi ManiNo ratings yet

- Aerospace Material SpecificationDocument9 pagesAerospace Material Specificationjuan100% (1)

- AMS5397FDocument10 pagesAMS5397Fremaja1249No ratings yet

- Sae Ams 2759-3H-2019Document20 pagesSae Ams 2759-3H-2019Reza NooriNo ratings yet

- PREMIUM RELEASE CTG. FOR INDUSTRIAL APPLICATIONSDocument2 pagesPREMIUM RELEASE CTG. FOR INDUSTRIAL APPLICATIONSlucas amorimNo ratings yet

- Nas 6704Document7 pagesNas 6704Konelek AeroNo ratings yet

- Sae Ams 1320aDocument5 pagesSae Ams 1320achris nelsonNo ratings yet

- QQ-A-250 - 12F - Aluminum Alloy 7075, Plate and Sheet - StandardDocument7 pagesQQ-A-250 - 12F - Aluminum Alloy 7075, Plate and Sheet - StandardSüleymanNo ratings yet

- A554-15a Standard Specification For Welded Stainless Steel Mechanical TubingDocument5 pagesA554-15a Standard Specification For Welded Stainless Steel Mechanical TubingChuthaNo ratings yet

- BS EN 353-1-2014-LiteDocument52 pagesBS EN 353-1-2014-LiteAndré Bento SantosNo ratings yet

- Ams 4640Document5 pagesAms 4640Himanshu MishraNo ratings yet

- SAE AMS 5548p-2012Document6 pagesSAE AMS 5548p-2012Mehdi MokhtariNo ratings yet

- A 29 - A 29M - 16Document17 pagesA 29 - A 29M - 16Isabel Christina Gonzalez MoralesNo ratings yet

- Aluminum-And Magnesium-Alloy Products: Standard Terminology Relating ToDocument7 pagesAluminum-And Magnesium-Alloy Products: Standard Terminology Relating Toanurag yadavNo ratings yet

- 11 Iso 10110Document28 pages11 Iso 10110fmeylanNo ratings yet

- Ansi-B18 2 3 5m-1979 PDFDocument20 pagesAnsi-B18 2 3 5m-1979 PDFeGnEsToMcNo ratings yet

- NASA Technical Memorandum Details Titanium Welding ProceduresDocument236 pagesNASA Technical Memorandum Details Titanium Welding ProceduresMilan JavornikNo ratings yet

- E18 Rockwell Hardness PDFDocument22 pagesE18 Rockwell Hardness PDFAna Laura GonzálezNo ratings yet

- Development of Nickel Alloys for Aerospace ApplicationsDocument9 pagesDevelopment of Nickel Alloys for Aerospace ApplicationsAditya Budi FauziNo ratings yet

- Nasm 21044Document4 pagesNasm 21044karthiprojectsNo ratings yet

- Handbook of Quenchants and Quenching TechnologyDocument518 pagesHandbook of Quenchants and Quenching TechnologyDiego mena contrerasNo ratings yet

- 15638Document3 pages15638Bruno MauNo ratings yet

- Laminated Shim Stock SpecificationDocument11 pagesLaminated Shim Stock SpecificationAsker Ali TPNo ratings yet

- Sae Ams5837f 1999Document7 pagesSae Ams5837f 1999이연지No ratings yet

- Ansi b17 2 Woodruff Keys Flat Bottom Type 1Document3 pagesAnsi b17 2 Woodruff Keys Flat Bottom Type 1rbagriNo ratings yet

- Astm F 1941-00 PDFDocument11 pagesAstm F 1941-00 PDFJORGE ARTURO TORIBIO HUERTANo ratings yet

- Tlulilv: For Polytetrafluoroethylene Molded BasicDocument6 pagesTlulilv: For Polytetrafluoroethylene Molded BasicjenishjsNo ratings yet

- Sae Ams 5536N-2012Document6 pagesSae Ams 5536N-2012Mehdi Mokhtari100% (1)

- Astm f1537-07 - Standard Specification For Wrought Cobalt-28chromium-6molybdenum Alloys For Surgical ImplantsDocument4 pagesAstm f1537-07 - Standard Specification For Wrought Cobalt-28chromium-6molybdenum Alloys For Surgical ImplantsJohnBMurleyNo ratings yet

- Astm A131 2019 PDFDocument8 pagesAstm A131 2019 PDFazam RazzaqNo ratings yet

- Metallisches Strahlmittel Gerundetes Stahldrahtkorn Bezeichnung, Güteanforderungen, PrüfungenDocument5 pagesMetallisches Strahlmittel Gerundetes Stahldrahtkorn Bezeichnung, Güteanforderungen, PrüfungenWilmer Quezada MurilloNo ratings yet

- Heat Treatment Specification GuideDocument29 pagesHeat Treatment Specification Guidefordsho95No ratings yet

- All your fastener needs from a single source: Metric DIN 7991 hex socket cap screwsDocument5 pagesAll your fastener needs from a single source: Metric DIN 7991 hex socket cap screwsmohamadreza bagheriNo ratings yet

- En 573-3-2009Document36 pagesEn 573-3-2009akifNo ratings yet

- B 221 - 14-Aluminum ProfilesDocument15 pagesB 221 - 14-Aluminum ProfilesJose100% (1)

- Sae Ams03-3-2015Document8 pagesSae Ams03-3-2015raulNo ratings yet

- Aluminum and Aluminum-Alloy Sheet and Plate (Metric) : Standard Specification ForDocument26 pagesAluminum and Aluminum-Alloy Sheet and Plate (Metric) : Standard Specification ForPUENTES2407No ratings yet

- Ams 4985CDocument13 pagesAms 4985CBacksniper100% (1)

- D1153 - 12 Standard Specification For Methyl Isobutyl Ketone PDFDocument2 pagesD1153 - 12 Standard Specification For Methyl Isobutyl Ketone PDFJacques BlueqNo ratings yet

- Astm A304 - 12.16Document48 pagesAstm A304 - 12.16gkhn100% (1)

- Asme B18.2.6 2003Document11 pagesAsme B18.2.6 2003Jesse ChenNo ratings yet

- Mil PRF 8625 Amend02Document20 pagesMil PRF 8625 Amend02dan howsNo ratings yet

- PRC 2001 CurrentDocument13 pagesPRC 2001 CurrentAbhijeet PandeyNo ratings yet

- Process Specification For The Heat Treatment of Aluminum Alloys PDFDocument8 pagesProcess Specification For The Heat Treatment of Aluminum Alloys PDFashokksamy100% (1)

- Iso 23825 2020Document12 pagesIso 23825 2020enrico susantoNo ratings yet

- High-Carbon Steel Sheets For Power Train Parts - Formable High-Carbon Steel Sheets Suitable For One-Piece FormingDocument6 pagesHigh-Carbon Steel Sheets For Power Train Parts - Formable High-Carbon Steel Sheets Suitable For One-Piece Formingenrico susantoNo ratings yet

- Effect of Repeated Quenching Heat Treatment On Microstructure and Dry Sliding Wear Behaviour of Low Carbon PM SteelDocument2 pagesEffect of Repeated Quenching Heat Treatment On Microstructure and Dry Sliding Wear Behaviour of Low Carbon PM Steelenrico susantoNo ratings yet

- Cutting WheelDocument1 pageCutting Wheelenrico susantoNo ratings yet

- Improvement in Performance of Cold-Drawn SCM435 Alloy Steel Wires Through Optimization of Intercritical Annealing ParametersDocument16 pagesImprovement in Performance of Cold-Drawn SCM435 Alloy Steel Wires Through Optimization of Intercritical Annealing Parametersenrico susantoNo ratings yet

- The Spheroidizing Tendency and Spheroidization MecDocument8 pagesThe Spheroidizing Tendency and Spheroidization Mecenrico susantoNo ratings yet

- Optimization in Spheroidized Annealing of Two AISI 1022 Low Carbon Steels Used in Bolt IndustryDocument7 pagesOptimization in Spheroidized Annealing of Two AISI 1022 Low Carbon Steels Used in Bolt Industryenrico susantoNo ratings yet

- Proses Heat Treatment: Pt. Indoseiki Metal UtamaDocument1 pageProses Heat Treatment: Pt. Indoseiki Metal Utamaenrico susantoNo ratings yet

- Heat Treatment of Steel Parts: Rev Ecn No. Date Reviewed by Approved by StatusDocument15 pagesHeat Treatment of Steel Parts: Rev Ecn No. Date Reviewed by Approved by StatusAnonymous ZSne5ChQNo ratings yet

- Sales Offices and Product Data for Grade 430 Stainless SteelDocument2 pagesSales Offices and Product Data for Grade 430 Stainless Steeltranngocthuan200No ratings yet

- GIS 46-010 Specification For Pressure VesselsDocument97 pagesGIS 46-010 Specification For Pressure VesselsMayur Patel100% (4)

- 2-3 Introduction To Tyco's Unique Solutions and New ProductsDocument27 pages2-3 Introduction To Tyco's Unique Solutions and New ProductsMuhammedNo ratings yet

- 2.2.3.1 Buildex® Screw Fasteners: 2.2.3.1.1 Fastener Assembly and DesignationDocument11 pages2.2.3.1 Buildex® Screw Fasteners: 2.2.3.1.1 Fastener Assembly and DesignationJoseph BookerNo ratings yet

- 32 Samss 020Document18 pages32 Samss 020naruto256No ratings yet

- Catálogo General REX MCC PDFDocument208 pagesCatálogo General REX MCC PDFramiro velazquezNo ratings yet

- Autodesk Inventor Exercises - Learn by Practicing Design 100 Real-World 3D Models by Practicing (Sandeep Dogra) (Z-Library)Document136 pagesAutodesk Inventor Exercises - Learn by Practicing Design 100 Real-World 3D Models by Practicing (Sandeep Dogra) (Z-Library)DINESH TIWARINo ratings yet

- Why Is Stainless Steel Corrosion ResistantDocument4 pagesWhy Is Stainless Steel Corrosion ResistantMELVIN MAGBANUANo ratings yet

- Corrosion Monitoring Methods (Chevron)Document65 pagesCorrosion Monitoring Methods (Chevron)Sergey KichenkoNo ratings yet

- Duplex Stainless Steel 2304 Spec Sheet for Weight Savings & Corrosion ResistanceDocument2 pagesDuplex Stainless Steel 2304 Spec Sheet for Weight Savings & Corrosion ResistanceDeepak TdNo ratings yet

- AKM Selection - Guide en US - RevB PDFDocument76 pagesAKM Selection - Guide en US - RevB PDFAgou Rango100% (1)

- Foam Bladder Tanks: Technical Specifications and Ordering InformationDocument11 pagesFoam Bladder Tanks: Technical Specifications and Ordering InformationNovancyNo ratings yet

- Accutech - General Catalog DTD 030717Document4 pagesAccutech - General Catalog DTD 030717Em JoeNo ratings yet

- Product Data SheetsDocument44 pagesProduct Data Sheetssalem elhajNo ratings yet

- What Is The Difference 4130 Weld Inlay With SS316 or INC625: Wellhead Senior Engineer at Aker SolutionsDocument3 pagesWhat Is The Difference 4130 Weld Inlay With SS316 or INC625: Wellhead Senior Engineer at Aker Solutionsalokbdas100% (1)

- SSC Cat Spirax Sarco Vacuum BreakersDocument1 pageSSC Cat Spirax Sarco Vacuum BreakersEb RahimNo ratings yet

- Swagelok Ball ValveDocument8 pagesSwagelok Ball ValveSyahirul AlimNo ratings yet

- Instrument Manifold Valves - Series 5000Document16 pagesInstrument Manifold Valves - Series 5000Maria MantillaNo ratings yet

- Comparative Corrosion Testing Cui KraussDocument57 pagesComparative Corrosion Testing Cui KraussOctavio LópezNo ratings yet

- Barduc - Pur-Inox 382 Mhf-As enDocument1 pageBarduc - Pur-Inox 382 Mhf-As enhojo coNo ratings yet

- Relief Valves RH4 SeriesDocument6 pagesRelief Valves RH4 SerieslorenzoNo ratings yet

- (INCO 2980) Austenitic Chromium-Nickel Stainless Steels at Elevated Temperatures Mechanical and Physical PropertiesDocument20 pages(INCO 2980) Austenitic Chromium-Nickel Stainless Steels at Elevated Temperatures Mechanical and Physical PropertiesYuanqing WangNo ratings yet

- Method One Single Character MarkersDocument16 pagesMethod One Single Character MarkersdeepakNo ratings yet

- Asco Series Maglatch 3 Way Catalog PDFDocument2 pagesAsco Series Maglatch 3 Way Catalog PDFPrashant Kumar mishraNo ratings yet

- SISTEMA DI GESTIONE CERTIFICATO DA ICIMDocument1 pageSISTEMA DI GESTIONE CERTIFICATO DA ICIMRhyan EdwinNo ratings yet

- Carbon Monoxide and SyngasDocument82 pagesCarbon Monoxide and SyngasRobert00682No ratings yet

- WNT Catalogue 2016 - 01 Hss Drilling PDFDocument55 pagesWNT Catalogue 2016 - 01 Hss Drilling PDFoluja93No ratings yet