Professional Documents

Culture Documents

Piping Sample Report

Uploaded by

gst ajahCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Piping Sample Report

Uploaded by

gst ajahCopyright:

Available Formats

Diversified Technology Services

2045 Preisker Lane Suite A – Santa Maria, California 93454 – 805-928-6392

VISUAL INSPECTION REPORT

(API-570 – Process Piping)

Client: DTS Client Location: Somewhere USA

Circuit Number: GL-P-03-03 Date Built: 1981

Circuit/Process

Name: Gas Gathering sub-header & header at well room #3.

P&ID No.: 558-F-101 Service: Gas Gathering

Inspector Name: API Visual Insp. API 570 # 18 Date: 11/25/03

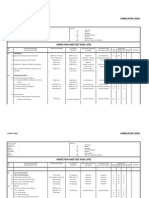

* Inspection Interval Statistics *

Date of last Inspection: Unknown Date of Next Inspection: 11/25/08

* Piping Statistics *

X Carbon Steel Stainless Steel Other

Insulated X Non-Insulated Partial Insulated

Condition

Item Area of Interest Comments

Good Fair Poor N/A

1 Insulation X

X

2 Insulation Jacketing X

X

3 Coating System X

X See narrative.

4 Supports X

X See narrative.

5 Spring Can Supports X

X

6 Orifice Nipples X

X

7 Vibration X

X

8 Alignment X

X

9 Dummy Legs X

X

10 Deck Penetrations X

X

11 Flanges X

X See narrative.

12 Flange Bolts X

X See narrative.

13 Welds and Seams X

X

14 Pipe Surface X

X See narrative.

15 Valve Packing X

X

16 Steam Tracing X

X

17 Expansion Joints X

X

File Name: 13 - Piping Sample Report Page: 1 of 5

Date: 04/06/2004

Diversified Technology Services

2045 Preisker Lane Suite A – Santa Maria, California 93454 – 805-928-6392

VISUAL INSPECTION REPORT

(API-570 – Process Piping)

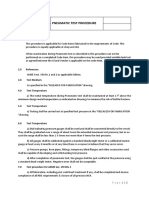

Condition

Item Area of Interest Comments

Good Fair Poor N/A

18 Other X

X

19 Other X

X

Condition

Item Area of Interest Comments

Yes No N/A

20 Safety Valve X

21 Clamps X

22 Mixed Metals X

23 Screwed Fittings X

24 Distortion (sagging) X

25 Leaks X

26 C.U.I. X

27 Bulges X

28 Corrosion X See narrative.

29 Other X

File Name: 13 - Piping Sample Report Page: 2 of 5

Date: 04/06/2004

Diversified Technology Services

2045 Preisker Lane Suite A – Santa Maria, California 93454 – 805-928-6392

VISUAL INSPECTION REPORT

(API-570 – Process Piping)

* Narrative description of findings *

Date: 11/25/03 Circuit No.: GL-P-03-03

An On-Stream inspection was performed in accordance with the guidelines of API-570. Due to the amount, severity

and location of the coating failure and associated external corrosion, complete removal of degraded coating or

corrosion and scale during inspection was not possible at this time. Random areas were selected for inspection in an

attempt to reflect the overall condition of this piping circuit.

Coating:

Throughout this circuit the coating on the header is mostly intact with few small corrosion blisters throughout and

significant corrosion at the point of contact with the supports. Most of the coating on the sub-headers has failed

and there is heavy corrosion and scale throughout the sub-headers. The damaged coating is not affecting the

operational conditions of the piping at this time. All areas of blistered or damaged coating, rust and scale should be

thoroughly cleaned to an industry standard acceptable to engineering and new coating applied to arrest the present

corrosion and prevent further corrosion.

Deck Penetrations:

There is heavy corrosion and scale on the piping through the deck penetrations.

Piping Surface:

At the areas of coating failure there is general wall loss due to corrosion of approximately 0.010” to 0.020”

throughout.

Valves:

The valves appear to be in fair condition.

Supports:

The piping does not have single points of contact between the piping and the support beams. Single points of

contact help prevent moisture from sitting against the piping surface and promoting corrosion. At this time

moderate to heavy corrosion and scale was noted at the contact points between the piping and supports.

U-Bolts:

Throughout the circuit, the U-bolts were found to be near failure due to corrosion.

Flanges and Bolts:

There is heavy corrosion and scale throughout this circuit.

Ultrasonic Thickness Evaluation:

Ultrasonic Thickness (UT) measurements were taken on this circuit. The results of this survey indicate that all areas

of U.T. evaluations were above the required thickness minimums for piping specification class ‘B’ (Refer to

ultrasonic inspection data report for results of survey).

Consideration should be given to scheduling the removal of any existing external corrosion for the purpose of

measurements, evaluation and / or repairs at such a time that any through-wall corrosion would not result in a

disruption of platform operations.

File Name: 13 - Piping Sample Report Page: 3 of 5

Date: 04/06/2004

Diversified Technology Services

2045 Preisker Lane Suite A – Santa Maria, California 93454 – 805-928-6392

VISUAL INSPECTION REPORT

(API-570 – Process Piping)

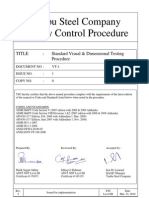

*Recommended Items for Repair*

Item Recommendations

Consideration should be given to removing corrosion from supports and installing single points of

1

contact to eliminate the possibility of future corrosion between the piping and supports.

2 Replace corroded, broken or missing U-bolts.

Consideration should be given to scheduling the removal of any existing external corrosion for the

3 purpose of measurements and / or repairs at such a time that any through-wall corrosion would not

result in a disruption of platform operations.

The damaged coating should be thoroughly cleaned to an industry standard acceptable to engineering

4

and new coating applied to arrest the present corrosion and prevent further corrosion.

*Completed Repairs*

Item Description of Repairs Completed

Report Sign-Off

11-25-2003

Api Visual Inspector Date

File Name: 13 - Piping Sample Report Page: 4 of 5

Date: 04/06/2004

Complete coating failure on Heavy corrosion and scale Heavy corrosion on U-Bolts

sub-header along bottom of headers and supports

Date: 04/06/2004

File Name: 13 - Piping Sample Report

Circuit No.GL-P-03-03

Coating failure with heavy

Heavy corrosion on sub- Complete coating failure

corrosion and scale on

headers above decking to and heavy corrosion on sub-

header to 6” valves on south

valves headers

wall

* Narrative Photo Attachment Page *

(API-570 – Process Piping)

VISUAL INSPECTION REPORT

Date: 11/25/03

2045 Preisker Lane Suite A – Santa Maria, California 93454 – 805-928-6392

Page: 5 of 5

Diversified Technology Services

You might also like

- 005-MS For Aboveground Cable Laying PDFDocument10 pages005-MS For Aboveground Cable Laying PDFKöksal PatanNo ratings yet

- B31.3 Process Piping Course - 18 In-Service PipingDocument18 pagesB31.3 Process Piping Course - 18 In-Service PipingglazetmNo ratings yet

- Moors Sovereign Dollarium 500 Gold Backed Dollarium PicautoDocument2 pagesMoors Sovereign Dollarium 500 Gold Backed Dollarium Picautoakil kemnebi easley elNo ratings yet

- General Piping InspectionDocument13 pagesGeneral Piping InspectionKingston Rivington100% (1)

- Piping Inspect & Testing ProcedureDocument11 pagesPiping Inspect & Testing ProcedureErlanggaBonaparteNo ratings yet

- Itp VesselDocument4 pagesItp VesselHakim BaihaqiNo ratings yet

- ACME Chemicals: High Pressure Steam (HS) PipingDocument40 pagesACME Chemicals: High Pressure Steam (HS) PipingRamu NallathambiNo ratings yet

- ITP - PipingDocument7 pagesITP - PipingRiaz Rasool100% (2)

- Inspection and Test Plan For Storage TankDocument7 pagesInspection and Test Plan For Storage TankAhmed100% (5)

- 020 - Tank Settlement Inspection ReportDocument1 page020 - Tank Settlement Inspection ReportDelil OzanNo ratings yet

- ITP For Piping WorksDocument3 pagesITP For Piping WorksOrlando1949100% (3)

- Electric ITP'sDocument23 pagesElectric ITP'sUtku Can Kılıç100% (3)

- Sample ItpDocument4 pagesSample ItpWijayanto BekasiNo ratings yet

- 3LPE Repair ProcedureDocument3 pages3LPE Repair Procedurelhanx2No ratings yet

- Storage Tank Inspection Check ListDocument2 pagesStorage Tank Inspection Check Listparthasarathy281267% (6)

- 24.tank Oil Chalk TestDocument3 pages24.tank Oil Chalk TestShubham ShuklaNo ratings yet

- Piping External Visual Inspection ProcedureDocument3 pagesPiping External Visual Inspection Procedurecamasa2011100% (1)

- Process Piping Inspection Procedure Rev.2 PDFDocument34 pagesProcess Piping Inspection Procedure Rev.2 PDFLevi Porter100% (6)

- 5 - Tank Itp - Inspection & Test Plan For TanksDocument10 pages5 - Tank Itp - Inspection & Test Plan For TanksAhmed Hassan100% (2)

- Livro Vertex MACIOCIADocument62 pagesLivro Vertex MACIOCIAxandinhag100% (5)

- API-570-Inspection Checklist PDFDocument2 pagesAPI-570-Inspection Checklist PDFFred Moore100% (16)

- Piping Inspection SystemDocument30 pagesPiping Inspection SystemAshfaq KhanNo ratings yet

- Sample Itp For VesselDocument10 pagesSample Itp For VesselWijayanto BekasiNo ratings yet

- Itp For Aboveground Piping Metallic (Fabrication, Erection, Installation and Pressure Testing)Document24 pagesItp For Aboveground Piping Metallic (Fabrication, Erection, Installation and Pressure Testing)Rakhesh Rajeevan100% (3)

- Base Line SurveyDocument10 pagesBase Line Surveycisar0007No ratings yet

- Procedure For Inspection of PipingDocument2 pagesProcedure For Inspection of PipingMuhAli_100% (2)

- PADI Rescue Diver - Blank Knowledge ReviewDocument13 pagesPADI Rescue Diver - Blank Knowledge ReviewAj Quek67% (3)

- Vaccum Test MethodDocument4 pagesVaccum Test MethodMahmud AlamNo ratings yet

- Pressure Testing of Pressure VesselDocument3 pagesPressure Testing of Pressure VesselAriq FauzanNo ratings yet

- ITP For Storage TankDocument6 pagesITP For Storage TankAhmed Ben HmidaNo ratings yet

- 974-0753 Onan RDJC RDJF Diesel Engine Service Manual (09-1984)Document64 pages974-0753 Onan RDJC RDJF Diesel Engine Service Manual (09-1984)Leo BurnsNo ratings yet

- Piping InspectionDocument6 pagesPiping InspectionFs100% (1)

- Torque ReportDocument1 pageTorque Reportjarofidz100% (1)

- Zombieworld PlaytestDocument30 pagesZombieworld PlaytestWellameGranaNo ratings yet

- Inspection and Test Plan For Pressure VesselDocument2 pagesInspection and Test Plan For Pressure Vesselalokbdas50% (2)

- 23 Piping InspectorDocument79 pages23 Piping InspectorBukty Siahaan100% (3)

- Cisco 1 Reviewer For Final ExamDocument9 pagesCisco 1 Reviewer For Final ExamAlNo ratings yet

- Pipehangers Support PDFDocument2 pagesPipehangers Support PDFKuppuraj ParamsivamNo ratings yet

- Flexible PipeDocument7 pagesFlexible Pipenaren57No ratings yet

- Pneumatic Test ProcedureDocument2 pagesPneumatic Test Proceduredyke_engg67% (3)

- A Pi 510 External Inspection Checklist SampleDocument3 pagesA Pi 510 External Inspection Checklist SampleMetallurgist007100% (3)

- Inspection and Test Plan: Offshore Pipeline RecertificationDocument3 pagesInspection and Test Plan: Offshore Pipeline RecertificationArisNo ratings yet

- Technical Specification For Vacuum SystemsDocument284 pagesTechnical Specification For Vacuum SystemsUday SuleNo ratings yet

- Polynesian MigrationsDocument2 pagesPolynesian Migrationskinneyjeffrey100% (1)

- 000-GC-P-009 R.3 Piping Installation PDFDocument35 pages000-GC-P-009 R.3 Piping Installation PDFJessica Torres100% (1)

- API 598 Testing Procedure-20130720-032647Document2 pagesAPI 598 Testing Procedure-20130720-032647JOMAGUES100% (1)

- DOW VISUAL INSPECTION Check CHECKLIST PDFDocument2 pagesDOW VISUAL INSPECTION Check CHECKLIST PDFDanny Boysie100% (1)

- Field Itp For Piping Work Samur Project Rev-5 (23 April 2013)Document28 pagesField Itp For Piping Work Samur Project Rev-5 (23 April 2013)Echik KiciNo ratings yet

- API 510 PV Inspection ChecklistDocument9 pagesAPI 510 PV Inspection ChecklistSreekumar SNo ratings yet

- F.sq-wI.008 Procedure For Inspection of Existing Storage TankDocument17 pagesF.sq-wI.008 Procedure For Inspection of Existing Storage TankIksan Adityo MulyoNo ratings yet

- Underground Piping Pressure Test RecordDocument1 pageUnderground Piping Pressure Test RecordPaulSwinbankNo ratings yet

- Integrity of Pipeline SystemsDocument2 pagesIntegrity of Pipeline Systemssl1828No ratings yet

- Roundness Check Accetance of Storage Tank - TierDocument1 pageRoundness Check Accetance of Storage Tank - Tierarkaprava ghoshNo ratings yet

- Inspection and Test Plan: On-Shore Pipeline CertificationDocument2 pagesInspection and Test Plan: On-Shore Pipeline CertificationKayra Riri Chirul100% (1)

- Visual Inspection Report PDFDocument2 pagesVisual Inspection Report PDFKalanithi GK50% (2)

- Api 650 RTDocument3 pagesApi 650 RTAdi QCNo ratings yet

- API Tank Inspection FormDocument4 pagesAPI Tank Inspection FormNavya Puttagunta50% (2)

- Visual Inspection of Tanks & Pressure VesselsDocument29 pagesVisual Inspection of Tanks & Pressure VesselsShahul Hameed Razik100% (5)

- PIPELINE Punch ListDocument2 pagesPIPELINE Punch ListTanveer Rajput EngrNo ratings yet

- Inspection & Test Plan For Nozzle Replacement On VS ShellDocument1 pageInspection & Test Plan For Nozzle Replacement On VS ShellQC Taner 453100% (2)

- Corrosion Control InspectionDocument6 pagesCorrosion Control InspectionAutumn SimonNo ratings yet

- Page 1 of 3 AUDITOR NOTE: 9001 F45.25.1 February 07Document3 pagesPage 1 of 3 AUDITOR NOTE: 9001 F45.25.1 February 07nubeNo ratings yet

- RCFA-2023-CPF2-COR-002-8'' CD Leak Near EDS-A (12-02-23)Document3 pagesRCFA-2023-CPF2-COR-002-8'' CD Leak Near EDS-A (12-02-23)Vignesh PanchabakesanNo ratings yet

- Section 21 11 00Document10 pagesSection 21 11 00Ismail MohammadNo ratings yet

- Th0800Coll Corrosive TechnologiesDocument35 pagesTh0800Coll Corrosive TechnologiesJoe BlagNo ratings yet

- Pipe ManualDocument60 pagesPipe ManualfernandojffNo ratings yet

- 32 31 00safDocument13 pages32 31 00safbrian walter abarintosNo ratings yet

- Notes For Mac and Linux Users SpeciallyDocument1 pageNotes For Mac and Linux Users SpeciallyS Surya DharmaNo ratings yet

- Eonfoamer W102: Material Safety Data SheetDocument5 pagesEonfoamer W102: Material Safety Data SheetS Surya DharmaNo ratings yet

- ACEC - 1350 2500 Air Foam Unit - TDSDocument1 pageACEC - 1350 2500 Air Foam Unit - TDSS Surya DharmaNo ratings yet

- Eonantifoam W220: Material Safety Data SheetDocument5 pagesEonantifoam W220: Material Safety Data SheetS Surya DharmaNo ratings yet

- Foam Service Report: PT. Umega Maju BersamaDocument2 pagesFoam Service Report: PT. Umega Maju BersamaS Surya DharmaNo ratings yet

- Well Sheet Data Manual: No Date No. Well Pu. Id Keterangan Csg. Pressure Tbg. Pressure Csg. Temp. Tbg. TempDocument3 pagesWell Sheet Data Manual: No Date No. Well Pu. Id Keterangan Csg. Pressure Tbg. Pressure Csg. Temp. Tbg. TempS Surya DharmaNo ratings yet

- Microsoft Visual Studio 2008 SP1-KB2251487 - 20131209 - 035429990-Msi0Document987 pagesMicrosoft Visual Studio 2008 SP1-KB2251487 - 20131209 - 035429990-Msi0S Surya DharmaNo ratings yet

- Exercises On Algebra MI1036Document12 pagesExercises On Algebra MI1036Sâm Mai HuyềnNo ratings yet

- Numerology 666 Meaning: What Angel Number 666 REALLY Means!Document2 pagesNumerology 666 Meaning: What Angel Number 666 REALLY Means!LlNo ratings yet

- Installiation of Automatic Fire Sprinkler System and Design CalculationDocument8 pagesInstalliation of Automatic Fire Sprinkler System and Design CalculationSat AungNo ratings yet

- Wednesday 12 June 2019: ChemistryDocument32 pagesWednesday 12 June 2019: ChemistryMohammad KhanNo ratings yet

- Biomedical Uses and Applications of Inorganic Chemistry. An OverviewDocument4 pagesBiomedical Uses and Applications of Inorganic Chemistry. An OverviewHiram CruzNo ratings yet

- Ecs C42iix Rev C Vit m2400 1Document36 pagesEcs C42iix Rev C Vit m2400 1Victor Pic100% (1)

- JBL Constant Beamwidth Technology - CBT Series Passive Controlled-Coverage ColumnsDocument12 pagesJBL Constant Beamwidth Technology - CBT Series Passive Controlled-Coverage ColumnsTom HampleNo ratings yet

- Cramers Rule 3 by 3 Notes PDFDocument4 pagesCramers Rule 3 by 3 Notes PDFIsabella LagboNo ratings yet

- Example Lab ReportDocument12 pagesExample Lab ReportHung Dang QuangNo ratings yet

- Hydrogen Codes and Standards Workshop: Naser ChowdhuryDocument24 pagesHydrogen Codes and Standards Workshop: Naser ChowdhuryDiana DhominicNo ratings yet

- Criaturas Do Reino DistanteDocument53 pagesCriaturas Do Reino DistanteDaniel Marinho100% (1)

- Embryo AssignmentDocument2 pagesEmbryo AssignmentA.j. MasagcaNo ratings yet

- Georgia Habitats Lesson PlansDocument5 pagesGeorgia Habitats Lesson PlansBecky BrownNo ratings yet

- Loving Vincent: by Dorota KobielaDocument45 pagesLoving Vincent: by Dorota KobielaFairut CharrisNo ratings yet

- Língua Inglesa: Reported SpeechDocument3 pagesLíngua Inglesa: Reported SpeechPatrick AlmeidaNo ratings yet

- Stationery Stock CardDocument100 pagesStationery Stock CardHuny BunyNo ratings yet

- Random Processes: Saravanan Vijayakumaran Sarva@ee - Iitb.ac - inDocument10 pagesRandom Processes: Saravanan Vijayakumaran Sarva@ee - Iitb.ac - inSonu kumarNo ratings yet

- Queueing TheoryDocument6 pagesQueueing TheoryElmer BabaloNo ratings yet

- I Give You Glory LyricsDocument5 pagesI Give You Glory LyricsJhy Sandro MarkusNo ratings yet

- Assignment 3 - NTFP&SLE (HNM AgFE IITKGP) - RERUN 2 (3) .NewDocument13 pagesAssignment 3 - NTFP&SLE (HNM AgFE IITKGP) - RERUN 2 (3) .NewDebasish Datta Research Scholar, Dept. of Biochem. Engg., IIT (BHU)No ratings yet

- cs229.... Machine Language. Andrew NGDocument17 pagescs229.... Machine Language. Andrew NGkrishnaNo ratings yet

- Alfa Laval Energy Balance Casestory enDocument2 pagesAlfa Laval Energy Balance Casestory enHélder FernandoNo ratings yet

- NUTRACEUTICALDocument8 pagesNUTRACEUTICALShubham GuptaNo ratings yet