Professional Documents

Culture Documents

Dimensione Cartucce

Uploaded by

AntonioOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dimensione Cartucce

Uploaded by

AntonioCopyright:

Available Formats

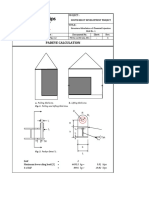

TAB.

VII

C.I.P. Cal. 4 Date 89-01-19

Revision 90-06-13

CARTRIDGE MAXIMALE

Dimens. Value Toler.

1)

d = 27.60 - 0.25

g = 30.45 - 0.45

1)

t = 3.25 - 0.40 Marking

h = 26.20 - 0.45

l = 82.40 - 2.50 4/82

l =101.00 - 2.50 4/101

CHAMBER MINIMALE

Dimens. Value Toler.

1)

D = 27.70 + 0.10

G = 30.50 + 0.10

1)

T = 3.30 + 0.10

H1) = 26.30 + 0.10 Marking Pressure transducer

1)

B = 23.35 + 0.70 Pmax PK PE M

α1

1)

= 10°30’ max bar

L1) = 82.60 + 2.00 4/82 1050 1200 1370 25/30

1)

L =101.20 + 2.00 4/101 1050 1200 1370 25/30

Headspace

Fe = 0.10 Proof Barrel

1)

Fe = 0.20 with bascule

1)

Fe = 0.35 automatic

Scale 1:2

Dimensions in « mm » Notes: 1) Check for safety reasons

Dimensions and tolerances for Proof Barrels:

See Appendix CR 4.

Reproduction forbidden as well as in the form of extracts without approval of C.I.P.

TAB. VII

C.I.P. Cal. 8 Date 89-01-19

Revision 90-06-13

CARTRIDGE MAXIMALE

Dimens. Value Toler.

1)

d = 23.50 - 0.25

g = 26.25 - 0.45

1)

t = 2.90 - 0.40 Marking

h = 23.15 - 0.45

l = 82.40 - 2.50 8/82

l =100.00 - 2.50 8/100

CHAMBER MINIMALE

Dimens. Value Toler.

1)

D = 23.65 + 0.10

G = 26.30 + 0.10

T1) = 2.95 + 0.10

1)

H = 23.20 + 0.10 Marking Pressure transducer

1)

B = 20.80 + 0.70 Pmax PK PE M

α11) = 10°30’ max bar

L1) = 82.60 + 2.00 8/82 1050 1200 1370 25/30

1)

L =100.50 + 2.00 8/100 1050 1200 1370 25/30

Headspace

Fe = 0.10 Proof Barrel

1)

Fe = 0.20 with bascule

Fe1) = 0.35 automatic

Scale 1:2

Dimensions in « mm » Notes : 1) Check for safety reasons

Dimensions and tolerances for Proof Barrels:

See Appendix CR 4.

Reproduction forbidden as well as in the form of extracts without approval of C.I.P.

TAB. VII

C.I.P. Cal. 10 Date 84-06-14

Revision 90-06-13

CARTRIDGE MAXIMALE

Dimens. Value Toler.

1)

d = 21.70 - 0.24

g = 23.65 - 0.64

1)

t = 1.90 - 0.40 Marking

h = 21.30 - 0.47

l = 76.00 - 2.50 10/76

l = 82.40 - 2.50 10/82

l = 88.70 - 2.50 10/89

CHAMBER MINIMALE

Dimens. Value Toler.

1)

D = 21.75 + 0.10

G = 23.75 + 0.10

T1) = 1.90 + 0.10

H1) = 21.40 + 0.10 Marking Pressure transducer

1)

B = 19.30 + 0.70 Pmax PK PE M

α1

1)

= 10°30’ max bar

1)

L = 76.20 + 2.00 10/76 1050 1200 1370 25/30

1)

L = 82.60 + 2.00 10/82 1050 1200 1370 25/30

L1) = 88.90 + 2.00 10/89 1050 1200 1370 25/30

Headspace

Fe = 0.10 Proof Barrel

1)

Fe = 0.20 with bascule

Fe1) = 0.35 automatic

Scale 1:2

Dimensions in « mm » Note : 1) Check for safety reasons

Dimensions and tolerances for Proof Barrels:

See Appendix CR 4.

Reproduction forbidden as well as in the form of extracts without approval of C.I.P.

TAB. VII

C.I.P. Cal. 12 Date 84-06-14

Revision 92-10-01

CARTRIDGE MAXIMALE

Dimens. Value Toler.

1)

d = 20.60 - 0.28

g = 22.45 - 0.48

1)

t = 1.85 - 0.30 Marking

h = 20.20 - 0.47

l = 50.00 - 2.50 12/50 SAPL

l = 60.00 - 2.50 12/60

l = 65.00 - 2.50 12/65

l = 67.50 - 2.50 12/67

l = 69.80 - 2.50 12/70

l = 72.80 - 2.50 12/73

l = 76.00 - 2.50 12/76

l = 88.70 - 2.50 12/89

CHAMBER MINIMALE

Dimens. Value Toler.

1)

D = 20.65 + 0.10

G = 22.55 + 0.10

T1) = 1.85 + 0.10

1)

H = 20.30 + 0.10 Marking Pressure transducer

1)

B = 18.20 + 0.70 Pmax PK PE M

α1

1)

= 10°30’ max bar

1)

L = 50.10 + 2.00 12/50 SAPL 150 173 195 25/30

1)

L = 60.10 + 2.00 12/60 740 850 960 25/30

L1) = 65.10 + 2.00 12/65 740 850 960 25/30

1)

L = 67.60 + 2.00 12/67 740 850 960 25/30

L1) = 69.90 + 2.00 12/70 740 850 960 25/30

1)

L = 73.00 + 2.00 10/73 1050 1200 1370 25/30

L1) = 76.20 + 2.00 10/76 1050 1200 1370 25/30

1)

L = 88.90 + 2.00 10/89 1050 1200 1370 25/30

Headspace

Fe = 0.10 Proof Barrel

1)

Fe = 0.20 with bascule

Fe1) = 0.35 automatic

Scale 1:1

Dimensions in « mm » Notes: 1) Check for safety reasons

Dimensions and tolerances for Proof Barrels :

See Appendix CR 4.

Reproduction forbidden as well as in the form of extracts without approval of C.I.P.

TAB. VII

C.I.P. Cal. 14 Date 84-06-14

Revision 90-06-13

CARTDRIGE MAXIMALE

Dimens. Value Toler.

1)

d = 19.65 - 0.25

g = 21.45 - 0.45

1)

t = 1.75 - 0.35 Marking

h = 19.30 - 0.50

l = 65.00 - 2.50 14/65

l = 67.50 - 2.50 14/67

l = 69.80 - 2.50 14/70

CHAMBER MINIMALE

Dimens. Value Toler.

D1) = 19.70 + 0.10

G = 21.55 + 0.10

1)

T = 1.75 + 0.10

1)

H = 19.35 + 0.10 Marking Pressure transducer

1)

B = 17.20 + 0.50 Pmax PK PE M

α11) = 10°30’ max bar

L1) = 65.10 + 2.00 14/65 740 850 960 25/30

L1) = 67.60 + 2.00 14/67 740 850 960 25/30

1)

L = 69.90 + 2.00 14/70 740 850 960 25/30

Headspace

Fe = 0.10 Proof Barrel

1)

Fe = 0.20 with bascule

Fe1) = 0.35 automatic

Scale 1:1

Dimensions in « mm » Notes : 1) Check for safety reasons

Dimensions and tolerances for Proof Barrels :

See Appendix CR 4.

Reproduction forbidden as well as in the form of extracts without approval of C.I.P.

TAB. VII

C.I.P. Cal. 16 Date 84-06-14

Revision 90-06-13

CARTRIDGE MAXIMALE

Dimens. Value Toler.

1)

d = 18.90 - 0.23

g = 20.65 - 0.33

1)

t = 1.65 - 0.35 Marking

h = 18.55 - 0.49

l = 65.00 - 2.50 16/65

l = 67.50 - 2.50 16/67

l = 69.80 - 2.50 16/70

CHAMBER MINIMALE

Dimens. Value Toler.

D1) = 18.95 + 0.10

G = 20.75 + 0.10

1)

T = 1.65 + 0.10

1)

H = 18.60 + 0.10 Marking Pressure transducer

1)

B = 16.80 + 0.50 Pmax PK PE M

α11) = 10°30’ max

L1) = 65.10 + 2.00 16/65 780 900 1020 25/30

L1) = 67.60 + 2.00 16/67 780 900 1020 25/30

1)

L = 69.90 + 2.00 16/70 780 900 1020 25/30

Headspace

Fe = 0.10 Proof Barrel

1)

Fe = 0.20 with bascule

Fe1) = 0.35 automatic

Scale 1 :1

Dimensions in « mm » Notes : 1) Check for safety reasons

Dimensions and tolerances for Proof Barrels :

See Appendix CR 4.

Reproduction forbidden as well as in the form of extracts without approval of C.I.P.

TAB. VII

C.I.P. Cal. 20 Date 84-06-14

Revision 90-06-13

CARTRIDGE MAXIMALE

Dimens. Value Toler.

1)

d = 17.70 - 0.22

g = 19.40 - 0.40

1)

t = 1.55 - 0.35 Marking

h = 17.35 - 0.49

l = 65.00 - 2.50 20/65

l = 67.50 - 2.50 20/67

l = 69.80 - 2.50 20/70

l = 76.00 - 2.50 20/76

CHAMBER MINIMALE

Dimens. Value Toler.

1)

D = 17.75 + 0.10

G = 19.50 + 0.10

T1) = 1.55 + 0.10

1)

H = 17.40 + 0.10 Marking Pressure transducer

1)

B = 15.70 + 0.50 Pmax PK PE M

α1

1)

= 10°30’ max bar

L1) = 65.10 + 2.00 20/65 830 950 1080 25/30

1)

L = 67.60 + 2.00 20/67 830 950 1080 25/30

L1) = 69.90 + 2.00 20/70 830 950 1080 25/30

1)

L = 76.20 + 2.00 20/76 1050 1200 1370 25/30

Headspace

Fe = 0.10 Proof Barrel

Fe1) = 0.20 with bascule

1)

Fe = 0.35 automatic

Scale 1:1

Dimensions in « mm » Notes : 1) Check for safety reasons

Dimensions and tolerances for Proof Barrels :

See Appendix CR 4.

Reproduction forbidden as well as in the form of extracts without approval of C.I.P.

TAB. VII

C.I.P. Cal. 24 Date 84-06-14

Revision 90-06-13

CARTRIDGE MAXIMALE

Dimens. Value Toler.

1)

d = 16.75 - 0.20

g = 18.45 - 0.40

1)

t = 1.55 - 0.35 Marking

h = 16.45 - 0.50

l = 63.50 - 2.50 24/63,5

l = 65.00 - 2.50 24/65

l = 69.80 - 2.50 24/70

CHAMBER MINIMALE

Dimens. Value Toler.

D1) = 16.80 + 0.10

G = 18.55 + 0.10

1)

T = 1.55 + 0.10

1)

H = 16.50 + 0.10 Marking Pressure transducer

1)

B = 14.70 + 0.50 Pmax PK PE M

α11) = 10°30’ max bar

L1) = 63.60 + 2.00 24/63,5 830 950 1080 17

L1) = 65.10 + 2.00 24/65 830 950 1080 17

1)

L = 69.90 + 2.00 24/70 830 950 1080 17

Headspace

Fe = 0.10 Proof Barrel

1)

Fe = 0.20 with bascule

Fe1) = 0.35 automatic

Scale 1:1

Dimensions in « mm » Notes : 1) Check for safety reasons

Dimensions and tolerances for Proof Barrels:

See Appendix CR 4.

Reproduction forbidden as well as in the form of extracts without approval of C.I.P.

TAB. VII

C.I.P. Cal. 28 Date 84-06-14

Revision 90-06-13

CARTRIDGE MAXIMALE

Dimens. Value Toler.

1)

d = 15.85 - 0.18

g = 17.40 - 0.38

1)

t = 1.55 - 0.35 Marking

h = 15.55 - 0.49

l = 63.50 - 2.50 28/63,5

l = 65.00 - 2.50 28/65

l = 69.80 - 2.50 28/70

CHAMBER MINIMALE

Dimens. Value Toler.

D1) = 15.90 + 0.10

G = 17.50 + 0.10

1)

T = 1.55 + 0.10

1)

H = 15.60 + 0.10 Marking Pressure transducer

1)

B = 13.80 + 0.50 Pmax PK PE M

α11) = 10°30’ max bar

L1) = 63.60 + 2.00 28/63,5 830 950 1080 17

L1) = 65.10 + 2.00 28/65 830 950 1080 17

1)

L = 69.90 + 2.00 28/70 830 950 1080 17

Headspace

Fe = 0.10 Proof Barrel

1)

Fe = 0.20 with bascule

1)

Fe = 0.35 automatic

Scale 1:1

Dimensions in « mm » Notes : 1) Check for safety reasons

Dimensions and tolerances for Proof Barrels:

See Appendix CR 4.

Reproduction forbidden as well as in the form of extracts without approval of C.I.P.

TAB. VII

C.I.P. Cal. 32 Date 84-06-14

Revision 99-04-20

CARTRIDGE MAXIMALE

Dimens. Value Toler.

d 1) = 14.55 - 0.15

g = 16.10 - 0.40

t 1) = 1.55 - 0.35 Marking

h = 14.25 - 0.35

l = 50.70 - 2.50 32/50,7

l = 60.00 - 2.50 32/60

l = 63.50 - 2.50 32/63.5

l = 65.00 - 2.50 32/65

l = 69.80 - 2.50 32/70

CHAMBER MINIMALE

Dimens. Value Toler.

D1) = 14.60 + 0.10

G = 16.20 + 0.10

T1) = 1.55 + 0.10

1)

H = 14.30 + 0.10 Marking Pressure transducer

1)

B = 12.70 + 0.50 Pmax PK PE M

α1

1)

= 10°30’ max bar

1)

L = 50.80 - 2.50 32/50,7 830 950 1080 17

L1) = 60.10 + 2.00 32/60 830 950 1080 17

1)

L = 63.60 + 2.00 32/63.5 830 950 1080 17

L1) = 65.10 + 2.00 32/65 830 950 1080 17

1)

L = 69.90 + 2.00 32/70 830 950 1080 17

Headspace

Fe = 0.10 Proof Barrel

1)

Fe = 0.20 with bascule

Fe1) = 0.35 automatic

Scale 1:1

Dimensions in « mm » Notes : 1) Check for safety reasons

Dimensions and tolerances for Proof Barrels:

See Appendix CR 4.

Reproduction forbidden as well as in the form of extracts without approval of C.I.P.

TAB. VII

C.I.P. Cal. 32 RUS Date 99-04-20

Revision

CATRIDGE MAXIMALE

Dimens. Value Toler.

d 1) = 13.60 - 0.20

g = 15.40 - 0.20

t 1) = 1.50 - 0.30 Marking

h = 13.25 - 0.35

l = 65.00 - 2.50 32/65 RUS

l = 69.80 - 2.50 32/70 RUS

CHAMBER MINIMALE

Dimens. Value Toler.

D1) = 13.60 + 0.10

G = 15.50 + 0.20

T1) = 1.50 + 0.10

1)

H = 13.30 + 0.10 Marking Pressure transducer

1)

B = 12.50 + 0.30 Pmax PK PE M

α1

1)

= 10°30’ max bar

L1) = 65.10 + 2.00 32/65 RUS 830 950 1080 17

L1) = 69.90 + 2.00 32/70 RUS 830 950 1080 17

Headspace

Fe = 0.10 Proof Barrel

1)

Fe = 0.20 with bascule

Fe1) = 0.35 automatic

Scale 1:1

Dimensions in « mm » Notes : 1) Check for safety reasons

Dimensions and tolerances for Proof Barrels:

See Appendix CR 4.

Reproduction forbidden as well as in the form of extracts without approval of C.I.P.

TAB. VII

C.I.P. Cal. 410 (36) Date 84-06-14

Revision 99-04-20

CARTRIDGE MAXIMALE

Dimens. Value Toler.

d 1) = 12.00 - 0.11

g = 13.60 - 0.40

t 1) = 1.55 - 0.35 Marking

h = 11.75 - 0.38

l = 50.70 - 2.50 410/50,7

l = 63.50 - 2.50 410/63.5

l = 65.00 - 2.50 410/65

l = 69.80 - 2.50 410/70

l = 72.80 - 2.50 410/73

l = 76.00 - 2.50 410/76

CHAMBER MINIMALE

Dimens. Value Toler.

D1) = 12.05 + 0.10

G = 13.70 + 0.10

T1) = 1.55 + 0.10

1)

H = 11.80 + 0.10 Marking Pressure transducer

1)

B = 10.20 + 0.50 Pmax PK PE M

α11) = 10°30’ max bar

L1) = 50.80 + 2.00 410/50,7 830 950 1080 12.5

L1) = 63.60 + 2.00 410/63,5 830 950 1080 17

1)

L = 65.10 + 2.00 410/65 830 950 1080 17

L1) = 69.90 + 2.00 410/70 830 950 1080 17

1)

L = 73.00 + 2.00 410/73 1050 1200 1370 17

L1) = 76.20 + 2.00 410/76 1050 1200 1370 17

Headspace

Fe = 0.10 Proof Barrel

Fe1) = 0.20 with bascule

1)

Fe = 0.35 automatic

Scale 1:1

Dimensions in « mm » Notes : 1) Check for safety reasons

Dimensions and tolerances for Proof Barrels:

See Appendix CR 4.

Reproduction forbidden as well as in the form of extracts without approval of C.I.P.

TAB. VII

C.I.P. Cal. 8 mm Date 89-01-19

Revision 94-03-01

CARTRIDGE MAXIMALE

Dimens. Value Toler.

d 1) = 9.80 - 0.10

g = 12.20 - 0.30

t 1) = 1.45 - 0.20 Marking

h = 9.00 - 0.20

l = 44.30 - 0.70 8 mm C.F.

CHAMBER MINIMALE

Dimens. Value Toler.

D1) = 9.85 + 0.10

G = 12.30 + 0.20

T1) = 1.45 + 0.10

H1) = 9.05 + 0.10 Marking Pressure transducer

1)

B = 7.90 + 0.50 Pmax PK PE M

α1

1)

= 10°30’ max bar

1)

L = 44.50 + 2.00 8 mm C.F. 830 950 1080 12.5

Headspace

Fe = 0.10 Proof Barrel

Fe1) = 0.20 with bascule

1)

Fe = 0.35 automatic

Scale 1:1

Dimensions in « mm » Notes : 1) Check for safety reasons

Dimensions and tolerances for Proof Barrels

See Appendix CR 4.

Reproduction forbidden as well as in the form of extracts without approval of C.I.P.

TAB. VII

C.I.P. Cal. 9 mm Date 89-01-19

Revision 90-06-13

CARTRIDGE MAXIMALE

Dimens. Value Toler.

d 1) = 9.85 - 0.10

g = 11.40 - 0.30

t 1) = 1.40 - 0.25 Marking

h = 9.65 - 0.35

l = 44.50 - 2.50 9 mm / 44,5

CHAMBER MINIMALE

Dimens. Value Toler.

1)

D = 9.90 + 0.10

G = 11.50 + 0.10

T1) = 1.45 + 0.10

1)

H = 9.70 + 0.10 Marking Pressure transducer

B1) = 8.50 + 0.50 Pmax PK PE M

α11) = 10°30’ max bar

L1) = 44.60 + 2.00 9 mm / 44,5 830 950 1080 12.5

Headspace

Fe = 0.10 Proof Barrel

1)

Fe = 0.20 with bascule

Fe1) = 0.35 automatic

Scale 1:1

Dimensions in « mm » Notes : 1) Check for safety reasons

Dimensions and tolerances for Proof Barrels:

See Appendix CR 4.

Reproduction forbidden as well as in the form of extracts without approval of C.I.P.

You might also like

- Gauge 12 (Cal. 12) DimensionsDocument1 pageGauge 12 (Cal. 12) DimensionsKuba GudzikowskiNo ratings yet

- ZAPATA EXTERIOR - MergedDocument33 pagesZAPATA EXTERIOR - MergedWilsonEignerNo ratings yet

- 5.calculo Muros y Losa PiscinaDocument4 pages5.calculo Muros y Losa PiscinaRAUL ALBERTO AGUIRRE PAUCARNo ratings yet

- 6 MM Centrale Falco enDocument1 page6 MM Centrale Falco endududadamikeNo ratings yet

- Memoria de Calculo Zapata Z1Document5 pagesMemoria de Calculo Zapata Z1Salvatore Yance RomeroNo ratings yet

- 001 AutoCAD 2D and 3D Practice Drawing CourseDocument11 pages001 AutoCAD 2D and 3D Practice Drawing CoursemathuNo ratings yet

- Padeye Calculation For Lifting AnalysisDocument3 pagesPadeye Calculation For Lifting Analysisberry habNo ratings yet

- Formato Zapata AisladaDocument169 pagesFormato Zapata AisladaJair SPNo ratings yet

- Systeme Isostatique: Consoles: Charge Concentrée À L'extrémitéDocument6 pagesSysteme Isostatique: Consoles: Charge Concentrée À L'extrémiténadaradji fontaineNo ratings yet

- Zapata Conectada 210670 Downloadable 1554396Document11 pagesZapata Conectada 210670 Downloadable 1554396Ajedrez UnpNo ratings yet

- Systeme Isostatique RDMDocument6 pagesSysteme Isostatique RDMDayane Mélèdje ADOUNo ratings yet

- Formu LaireRD MDocument6 pagesFormu LaireRD MMANo ratings yet

- Machine Design PDFDocument40 pagesMachine Design PDFYsyusushudyNo ratings yet

- Graficos Lab #7Document2 pagesGraficos Lab #7Anibal RuizNo ratings yet

- Poutre Axe 5-BisDocument10 pagesPoutre Axe 5-BisSami BojaadaNo ratings yet

- Disain Subgrade ReactionDocument8 pagesDisain Subgrade ReactionRaditiya PuteraNo ratings yet

- Systeme Isostatique: Consoles: Charge Concentrée À L'extrémitéDocument6 pagesSysteme Isostatique: Consoles: Charge Concentrée À L'extrémitéSidahmad KaouadjiNo ratings yet

- Zapata Conectada Zap - IntDocument4 pagesZapata Conectada Zap - IntHERBERT JESUS ZEVALLOS GUZMANNo ratings yet

- Flume AnalysisDocument11 pagesFlume AnalysisLarizza TesicoNo ratings yet

- Muro de Contención en VoladizoDocument4 pagesMuro de Contención en VoladizoERICK IXQUS AMAUTA GUEVARA NEYRANo ratings yet

- Ainaya Febi Amalia - M0318008 - P2Document25 pagesAinaya Febi Amalia - M0318008 - P2Alifiananda Rahmatul Dafa KesumaNo ratings yet

- Atap Baja WFDocument14 pagesAtap Baja WFNur ResikhaNo ratings yet

- Box Danasri 1.5x1.5mDocument84 pagesBox Danasri 1.5x1.5mSyahriar 'Thian' CoolNo ratings yet

- Semiconductor 2N4401SC: Technical DataDocument3 pagesSemiconductor 2N4401SC: Technical DataFernando GuerreroNo ratings yet

- Anexo Calculo de Almacenamiento, Distribución Y Bombeo para Edificio San NicolasDocument4 pagesAnexo Calculo de Almacenamiento, Distribución Y Bombeo para Edificio San NicolasDayana GomezNo ratings yet

- VIAK - Strap - Neighboring Foting Design 22.06Document14 pagesVIAK - Strap - Neighboring Foting Design 22.06mukim0201004No ratings yet

- SOLUTION (2.1) : Free Body: CDDocument14 pagesSOLUTION (2.1) : Free Body: CDKhalil SayeeNo ratings yet

- Zapata Medianera Conectada: Columna Interior Columna Medianera MaterialesDocument10 pagesZapata Medianera Conectada: Columna Interior Columna Medianera Materialesdavis rodriguezNo ratings yet

- CIP Standard ShotshellsDocument14 pagesCIP Standard ShotshellsKnut Inge OlsenNo ratings yet

- 10.7 Kips P: Weld Capacity of Eccentric Connection Based On AISC-ASD 9th EditionDocument4 pages10.7 Kips P: Weld Capacity of Eccentric Connection Based On AISC-ASD 9th EditionClaudia Alejandra Bustamante MontoyaNo ratings yet

- Footing Upon Pile DesignDocument5 pagesFooting Upon Pile DesignafvilavilanoriegaNo ratings yet

- Project Work Boost Conventer 2018Document5 pagesProject Work Boost Conventer 2018dedy SetyoNo ratings yet

- Design of Member : Strut (Layer 1)Document8 pagesDesign of Member : Strut (Layer 1)freddyNo ratings yet

- Retaining Wall (L-Type) 6.0mDocument22 pagesRetaining Wall (L-Type) 6.0mPrabha KaranNo ratings yet

- International Lateral LoadsDocument1 pageInternational Lateral LoadsCSEC Uganda Ltd.No ratings yet

- Full Download Plates and Shells Theory and Analysis 4th Ugural Solution Manual PDF Full ChapterDocument36 pagesFull Download Plates and Shells Theory and Analysis 4th Ugural Solution Manual PDF Full Chaptergadere.prick.k2x7q100% (22)

- Plates and Shells Theory and Analysis 4th Ugural Solution ManualDocument36 pagesPlates and Shells Theory and Analysis 4th Ugural Solution Manualpirl.broom.sx9ir100% (42)

- 1b. MÓNG ĐƠNDocument22 pages1b. MÓNG ĐƠNTrungNguyenNo ratings yet

- Tinh Toan Mong Don Dia ChatDocument7 pagesTinh Toan Mong Don Dia ChatNhật TrườngNo ratings yet

- Ec 8 Seismic AnalysisDocument1 pageEc 8 Seismic AnalysisCSEC Uganda Ltd.No ratings yet

- Tugas ThermDocument5 pagesTugas Thermaminah hasanahNo ratings yet

- Footing Upon Pile DesignDocument5 pagesFooting Upon Pile DesignCivilax.comNo ratings yet

- Design of Deck SlabDocument5 pagesDesign of Deck Slabjignesh shahNo ratings yet

- Unit 8 Assignment 2 DocumentDocument21 pagesUnit 8 Assignment 2 DocumentabinmaceNo ratings yet

- Steel Pipe: C S U A Max S MaxDocument4 pagesSteel Pipe: C S U A Max S Maxankkeshmundra1No ratings yet

- New Calculatio - 20240416 - 073251 - Iec61439Document1 pageNew Calculatio - 20240416 - 073251 - Iec61439Mateo Ibañez “mateocom”No ratings yet

- SOLUTION (2.1) : Free Body: CDDocument14 pagesSOLUTION (2.1) : Free Body: CDehab elsawyNo ratings yet

- DampingDocument7 pagesDampingTrangNo ratings yet

- Columnas Cortas Rectangulares A Flexo-Compresión Uniaxial: MomentosDocument1 pageColumnas Cortas Rectangulares A Flexo-Compresión Uniaxial: MomentosEduardo Elias OjedaNo ratings yet

- Diagrama de Interacción de La ColumnaDocument5 pagesDiagrama de Interacción de La ColumnaLEONARDO DIEGO TRUJILLO CARDENASNo ratings yet

- AbsorptionDocument7 pagesAbsorptionIrvan DwikiNo ratings yet

- ∆ P L D ρ V K ρ V: Find the pressure drop in this flow fieldDocument4 pages∆ P L D ρ V K ρ V: Find the pressure drop in this flow fieldbeyzanisandursunNo ratings yet

- Karakteristik Tanah Koefisien TanahDocument2 pagesKarakteristik Tanah Koefisien Tanahmoch.syafiuddinNo ratings yet

- S. No. Chainage Structure Number Type SizeDocument46 pagesS. No. Chainage Structure Number Type SizeHarish Kumar MahavarNo ratings yet

- ChE Day 2Document6 pagesChE Day 2JHuvieCLaireNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- WW1 Study GuideDocument3 pagesWW1 Study GuideJay KimNo ratings yet

- Join Indian Armed ForcesDocument10 pagesJoin Indian Armed ForcesNikunj RamaniNo ratings yet

- Harvey York 701-800Document594 pagesHarvey York 701-800Awanda MaulanaNo ratings yet

- Adeptus Titanicus Imperium Reference SheetDocument1 pageAdeptus Titanicus Imperium Reference SheetNando ArgilliNo ratings yet

- wh40k The Roboutian HeresyDocument413 pageswh40k The Roboutian Heresykartar567% (3)

- Laporan Praktikum Heat Pump IIDocument18 pagesLaporan Praktikum Heat Pump IIRISKY YOSUANo ratings yet

- Marie Andre CatilionDocument2 pagesMarie Andre CatilionCanadecafeaNo ratings yet

- GP80 BrochureDocument2 pagesGP80 BrochureUFUKKK100% (1)

- Episode 810, Story 2: GalvezDocument9 pagesEpisode 810, Story 2: GalvezChaz MenaNo ratings yet

- Plan Cofrare Planseu: MecanoflexDocument1 pagePlan Cofrare Planseu: Mecanoflexciocan mihaiNo ratings yet

- How To Adjust Reloading DiesDocument6 pagesHow To Adjust Reloading DieschososNo ratings yet

- Ambush Cards Single Sided Version 1Document10 pagesAmbush Cards Single Sided Version 1Ludo WhooNo ratings yet

- Notes On Zamboanga-From The Founding of La Caldera in 1595 To The Cholera of 1916Document83 pagesNotes On Zamboanga-From The Founding of La Caldera in 1595 To The Cholera of 1916arenriquezNo ratings yet

- Rise and Demise of The Territorial StateDocument22 pagesRise and Demise of The Territorial Statewarez4uallNo ratings yet

- Selection and Recruitment Process of Pak ArmyDocument13 pagesSelection and Recruitment Process of Pak ArmyMahmood NooriNo ratings yet

- Collective NounsDocument5 pagesCollective NounsLeneshNo ratings yet

- Floridablanca PampangaDocument7 pagesFloridablanca PampangaLisa MarshNo ratings yet

- Ship To Ship (STS) Transfer of Cargo: Latest Developments and Operational Risk AssessmentDocument24 pagesShip To Ship (STS) Transfer of Cargo: Latest Developments and Operational Risk Assessmentqualiman1100% (1)

- Chief Mate Stability 2005 2015 Past PapersDocument81 pagesChief Mate Stability 2005 2015 Past PapersVocacionado Npj50% (2)

- Morrowind SheetDocument2 pagesMorrowind SheetsmeezillaNo ratings yet

- The Persian ΚαρδακεσDocument16 pagesThe Persian ΚαρδακεσShahenda AnwerNo ratings yet

- Heavy Gear Blitz Beta RulesDocument136 pagesHeavy Gear Blitz Beta RulesJeff Hofer100% (2)

- How Bruce Randall Trained - Randall & RaderDocument18 pagesHow Bruce Randall Trained - Randall & RaderCALF100% (2)

- TOUS报价表 2店上新Document149 pagesTOUS报价表 2店上新Sebastian HuenumánNo ratings yet

- 27 Sniper Field Training ExercisesDocument4 pages27 Sniper Field Training ExercisesOLSNo ratings yet

- Faz Bindlestick's Guide To Firearms - GM BinderDocument14 pagesFaz Bindlestick's Guide To Firearms - GM Binder2ooneyNo ratings yet

- Curriculum Vitae: Personal DataDocument1 pageCurriculum Vitae: Personal DatarezaNo ratings yet

- Ballistic Vests UniversityDocument12 pagesBallistic Vests UniversityGeoSourcesNo ratings yet

- AH Submarine Master RulebookDocument77 pagesAH Submarine Master RulebookSebastian Navarro100% (1)

- Boeing AH-64 ApacheDocument9 pagesBoeing AH-64 ApacheIsac Andrei RobertNo ratings yet