Professional Documents

Culture Documents

Compressive Strength Characteristics of

Uploaded by

nagham tariqOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Compressive Strength Characteristics of

Uploaded by

nagham tariqCopyright:

Available Formats

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Impact Factor (2012): 3.358

Compressive Strength Characteristics of Concrete-

Filled Plastic Tubes Short Columns

Gathimba Naftary K.1*, Oyawa Walter O.2, Mang'uriu Geoffrey N.3

1

Department of Civil Engineering,

Jomo Kenyatta University of Agriculture and Technology,

P.O. box 62000-00200 Nairobi, Kenya

2

Department of Civil Engineering,

Jomo Kenyatta University of Agriculture and Technology

P.O. box 62000-00200 Nairobi, Kenya

3

School of Civil Engineering and Geospatial Engineering,

Jomo Kenyatta University of Agriculture and Technology,

P.O. box 62000-00200 Nairobi, Kenya

Abstract: This paper presents the results of an experimental programme which investigated the effect, on compressive strength, of

using unplasticized polyvinyl (UPVC) tubes in confining short concrete columns. Plastic tubes having varying diameters and heights

were used to confine concrete of different strengths. The resulting composite columns were subjected to concentric axial compressive

loads until failure. The principal failure mode was a typical shear failure. The results indicated that compressive strength of the column

specimens increase with increased concrete strength while the same decreased with increased column height, albeit by a small margin

since all the columns considered were short columns. A comparison of the ultimate load carrying capacity and column compressive

strength was then made between unconfined and the resulting composite column. Strength increased between 1.18 to 3.65 times the

unconfined strength. The study shows greater potentiality of plastics as concrete confinement construction materials of the near future.

Keywords: Short columns, confine, UPVC, Composite, compressive strength

1. Introduction evidenced by the severely deteriorated infrastructure and the

inability to guarantee safety against natural hazards such as

In many countries, including here in Kenya, there have been earthquakes. In consequence, governments are now investing

various cases of collapse of buildings either under heavily in collaboration with the private industry to develop

construction or when in use. Also, the rapid deterioration of unique high performance construction materials and systems,

infrastructure, especially those constructed in severe with special interest being directed towards advanced

environments such as bridge piles, as depicted in figure 1 composite materials and systems [3]. An example of

below, has increased the demand for rehabilitating and advancement into these types of new composite system is the

retrofitting existing concrete columns in building and bridge concrete-filled tube (CFT) column systems. For a number of

substructures. It is necessary to strengthen the deteriorated years, these column systems have been employing steel or

and damaged concrete columns to increase their carrying fiber-reinforced polymer tubes as the confinement material.

capacity (axial load and bending moment) and ductility for However the use of these materials is becoming prohibiting

improved seismic performance [1]. due to a number of factors such as the corrosion problem of

steel when used in aggressive environment such as undersea

piling, and also the prohibitive costs of manufacturing fiber-

reinforced polymer (FRP) material.

An alternative to the advanced composite materials tubing is

the commercially available UPVC plastic pipes. The tubes

are corrosive resistance and are rather inexpensive as

compared to the steel and FRPs. Although plastics have been

in use in construction for a while, rarely are they considered

for use in structural components or in load bearing elements

to contribute to structural strength but rather are used for

aesthetics. Though having low strength, they are highly

(a) (b) (c) elastic undergoing large displacement under load. Thus this

Figure 1 Degradation of conventional marine piles (a) research focused on investigating the behaviour of concrete-

Corroded steel piles b) Degraded concrete pile (c) filled plastic tubular columns subjected to compressive loads

Deteriorated timber piles, [2].

2. Review of Past Researches

Experience gained over the year in countries such as Japan,

Europe and the USA reveal that existing construction

technology has not delivered the reliability needed, as is It is well known that confinement improves the strength and

ductility of concrete [4, 5]. External confinement of concrete

Volume 3 Issue 9, September 2014

www.ijsr.net

Paper ID: SEP14554 2168

Licensed Under Creative Commons Attribution CC BY

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Impact Factor (2012): 3.358

columns has lately been widely employed in order to concrete columns during construction can be enhanced by

enhance the strength, ductility and energy absorption providing external confinement by employing UPVC tubes

capacity of the columns in construction. There has been a [14]. The tubes in composite construction will be used as

number of confinement mechanisms in use notably use of formwork during construction and thereafter as an integral

steel tubes and fiber reinforced polymers (FRPs). While the part of the column.

use of these technologies have been successful, problems

such as corrosion of steel when used in aggressive Plastics have exceptional properties, which make these

environment and the high cost incurred in producing FRPs materials attractive for different structural applications.

have necessitated the need for an alternative, cheaper means Some of these properties include high resistance to severe

of confining concrete columns. environmental attacks, electromagnetic transparency and

high strength to weight ratios. Due to these properties, there

Composite columns, made up of reinforced or unreinforced is great demand for structures such as piling, poles, highway

concrete confined with steel tubes, have been used in overhead signs and bridge substructures to be made of

building construction with great efficiency for many years. materials that are more durable in comparison to traditional

Many authors have dealt with theoretical and experimental materials and systems [15]. Use of plastics in construction

investigations on the behavior as well as the ultimate has been witnessed in Kenya's Nairobi-Thika superhighway

compressive strength of concrete-filled steel tube (CFST) where recycled plastic have been used to manufacture posts

columns. However, CFSTs are not only faced with the for road signs. PVC is a polymer used vastly in the

problem of corrosion of steel tubes but there is reduced construction industry. PVC tubes are characterized by

confinement effectiveness at low levels of loading if the tube having light weight which makes them easy to handle. They

is also loaded in the axial direction due to the fact that are impermeable to fluids and durable (their life cycle in

Poisson's ratio of concrete at low levels of loading, 0.15 to civil engineering construction goes beyond 50 years [15].

0.2 is smaller than the 0.3 value of steel [6]. Mirmiran and Very few authors have dealt with the ultimate strength of

Shahawy, 1997 observed that the differential radial plastic columns with concrete core [14, 16, 17].

expansion of steel tube and concrete, at low levels of

loading, results in partial separation between the two 3. Experimentation

materials leading to a premature buckling of the tube. Thus

effective confinement will only be achieved at higher 3.1 Material properties

loading when concrete begins to crack as it expands faster a) Aggregates

than the steel tube and becomes well confined [7]. Ordinary river sand and crushed rocks were used as fine

(FA) and coarse aggregates (CA) respectively in the

An alternative to CFSTs is FRP composites which have been manufacture of concrete. Aggregates were washed with

used as precast piles, girders, and pier columns [8]. As clean water to making sure that they are free from organic

opposed to steel CFTs, Poisson's ratio of FRP tubes can be impurities such as clay, organic content, silt and other

controlled through selected design of the laminate structure inferior materials. In order to ascertain the aggregates

to provide more confinement effect [9]. The confining suitability and also to enable design concrete mixes some of

pressure provided by steel tubes is limited to a constant value essential physical properties were determined following the

once the tube yields, whereas FRP tubes provide a standard laid down laboratory procedures and results

continuously increasing confining pressure, which adds to summarized in table 1 below.

both the ultimate confined strength and ductility [10].

Advances in the field of advanced composite materials have Particle size distribution of river sand, a very significant

resulted in the development of FRP sheets to confine attribute associated with fine aggregates, was also

existing concrete columns, resulting in enhanced determined from the sieve analysis using British standard

compressive strength and ductility and improving the test sieves having sizes; 5.00mm, 2.36mm, 1.18mm, 600

durability over conventional methods. Existing studies on microns, 300microns, 150microns and the results presented

the seismic behavior of FRP confined concrete columns have in a graphical manner, as shown in figure 2 below, which is

shown that FRP confinement can substantially improve the generally referred to as the grading curve. The grading curve

inelastic deformability of concrete columns [11]. In recent of the sand was within the Zone 2 envelope thus suitable for

years, the compressive behavior of FRP-confined concrete use in concrete production without need for blending it. Also

has been studied extensively. Few authors have tested to- the fineness modulus (FM) of fine aggregates, which is the

collapse concrete columns wrapped using carbon and glass weighted average of a sieve on which the material is

fiber sheets [12, 13]. Saafi et al., [12] proved that the retained, the sieves being counted from the finest, was

increase in axial stress over the confined specimen ranged determined from sieve analysis and found to be 2.53. The

from 51 to 131 percent for the concrete-filled glass tubes and higher the FM, the coarser the fine aggregates. FM is

57 to 177 percent for the concrete-filled carbon tubes. variable for measuring slight variations in the aggregates

from the same source (i.e. a day to day check). Typical

However, with the high cost of advanced composite values of FM are in the range 2.0 – 4.0 [18].

materials, the use of these materials in composite columns in

light construction is not recommended. Another alternative

to the advanced composite materials tubing would be the

commercially available plastic uPVC sewer pipes. The

strength, ductility and energy absorption capacity of new

Volume 3 Issue 9, September 2014

www.ijsr.net

Paper ID: SEP14554 2169

Licensed Under Creative Commons Attribution CC BY

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Impact Factor (2012): 3.358

Table 1: Summary of some physical properties of aggregates Table 2: Summary of concrete mix proportions

FA CA Aggregate Compressive

Class Water*/cement Water* Cement Sand (kg/m3) strength at 28

Specific gravity on oven Dry Basis 2.59 2.46

of mix ratio (kg/m3) (kg/m3 (kg/m3)

Specific gravity on saturated 2.61 2.51 5/10 10/20 days fck, (MPa)

surface dry (SSD) Basis C20 0.84 221.5 265 625 420 840 20.7

Apparent Specific Gravity 2.65 2.60

Water absorption (%) 0.87 2.08 C25 0.75 213.5 285 615 415 825 27.2

C30 0.70 210.0 310 605 410 810 30.7

*Includes free water for cement hydration and water for

absorption of aggregates to make them SSD.

Agroflow irrigation systems Limited, plastic pipes

manufacturing companies based in Nairobi, Kenya.

3.2 Specimen Instrumentation and Testing

A total of 144 short columns (i.e. 48 column sets replicated

three times, for statistics) were cast i.e. 72 unconfined and 72

UPVC-confined concrete columns. UPVC tubes with three

different outer diameters: 55mm, 83mm and 110mm were

used to confine concrete. The thicknesses of the tubes were

2.5mm, 3.0mm and 2.5mm respectively. The three

Figure 2: Particle size distribution for river sand (fine predesigned concrete mixes namely C20, C25, and C30 were

aggregate) used to fill the UPVC tubes. For each class of concrete and

b) Cement for each diameter and height selected, three unconfined and

Cement is widely used as the binder material in the concrete three UPVC-confined columns having the same length were

matrix in many applications. The cement commonly used in cast. To obtain unconfined conditions for a concrete column

Kenya is categorized as 32.5or 42.5 also referred to as power of a similar diameter as a confined column, empty UPVC

plus. Cement Class 42.5 (Ordinary Portland cement) for this tube was split on one side along the length and tied with

particular research. binding wires which was then used as a mould for casting of

columns. The outer plastic casing was then removed after 24

c) Concrete hrs, after concrete had hardened, leaving an unconfined

Three series of concrete grade C20, C25 and C30 were column specimen. Typical nomenclatures for the specimen

designed for use in this research work. The method of are used to designate them. For instance, C/C25/110/3

concrete mixing design applied here was in accordance to represent a confined (C) concrete column cast with concrete

the Department of Environment of British Research grade C25, having a diameter of 110mm and a slenderness

Establishment (BRE), United Kingdom (1988) and the ratio of 3. Freshly cast specimens were allowed to stand for

determination of various parameters necessary for the design 24 hrs until concrete was fully hardened. They were then

of the mixes was based on the design tables and figures marked for ease of identification then cured by covering

drawn from the BRE manual. The mixing of concrete was them with sisal sacks which were wetted daily with water

done according to the BS, ASTM and JIS procedures given until the testing date. The specimens were cured for 28 days

in laboratory guidelines. The BRE mix design procedure prior to testing.

from the DOE, UK was adopted for this research. A

summary of the calculated mix proportions and the The experimental work was conducted utilizing compression

concrete's compressive strength, fck, at 28 days is as given in machines at Structures and Materials laboratory of Civil

table 2 below. Engineering department of Jomo Kenyatta University of

Agriculture and Technology. The specimens were allowed to

c) Plastic tubes. dry prior to testing. All specimens were tested up to failure

Unplasticized polyvinyl chloride (UPVC) tubes were used to under monotonic loads. The specimens were subjected to

confine plain concrete stub columns. UPVC pipes concentric axial compressive load applied at the specimens’

conforming to Kenyan standards KS ISO 3633 and KS center by means of a hydraulic jack through uniform steel

2079-1-2007 were procured from Masterpipe Kenya (LTD) end plates to achieve a constant stress distribution at the

and concrete cross section. The load was applied to the entire

column section. Ata El-kareim [1] in his study on behaviour

of long concrete columns confined by means of plastic tubes

noted that when the load was applied to the entire section,

the contribution by the concrete core and tube to the total

axial force was constant along the height of the column, and

was not affected by the bond strength. Furthermore, Gardner

& Jacobson [19] in their study on structural behaviour of

Volume 3 Issue 9, September 2014

www.ijsr.net

Paper ID: SEP14554 2170

Licensed Under Creative Commons Attribution CC BY

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Impact Factor (2012): 3.358

concrete filled steel tube observed that the bond strength had was discovered. This led to the conclusion that no bond is

no influence on the structural behaviour of the column. developed between concrete and UPVC tube.

The columns were tested using an incremental loading 4.2 Effect of varying diameter and height on load and

procedure. Load cell of 500 kN capacity was used to monitor compressive strength of specimens

the applied load values. Due to the extensiveness and the Table 3 shows compressive load and strength test results for

magnitude of sample specimens being handled in this confined specimens who are presented graphically in Figures

research work, only compressive strength data is presented 4, 5 and 6. As expected, the load carrying capacity and the

in this paper. The applied load was kept constant at each compressive strength increase with increase in the grade of

load stage to allow for measurements and observations. The concrete, as is evidenced by the results in group I through

load cell was connected to TDS 303 data logger where the III. The graphically tabulated results show that as the

results were recorded for further analysis. diameter increases so does the load capacity, but a decrease

in compressive strength. This decrease in compressive

4. Results and Discussions strength with increased diameter is due to the increased area

with little increase in axial load carrying capacity of the

4.1 Observed behaviour columns. The anticipated increase in compressive stress with

All specimens behaved more or less in the same manner increase in pipe diameter could only be experienced when

during the loading process. Sounds were heard during the the variation or in other terms the deviation in column

early or middle stages of loading, which may be attributed to diameters is great to warrant column to support much

the micro cracking of the concrete. Bursting of the plastic greater loads as with the increased surface area and thus

tube was also witnessed toward the end of the loading increased compressive stress. However, the load capacity

process, for those specimens who were tested until total and the compressive strength both decrease with increase in

collapse (Figure 3(d)). It was also observed that the failure height to diameter ratio (slenderness ratio, l). In this

of the plastic tube was preceded by flow of resin which research, however the variation is small since all the columns

manifested itself by white patches at highly stressed sections considered are short with a maximum l=4. It was observed

(Figure 3(c)). that the load capacity values were in the range 54.7KN-

195.3KN, while the values of compressive stress were in the

range of 17 MPa-29.3 MPa. The stiffness of column

specimens' increase with decrease in slenderness ratio.

4.3 Confinement effectiveness

Table 4 and figure 7 reports finding on how confinement is

affected by varying concrete strength, tube thickness and

slenderness ratio. For an axially loaded concrete element,

transversal strains are induced resulting into radial concrete

expansion (Poisson's effect). Under low loading conditions,

the transverse strains are proportional to longitudinal strain,

and associated by the Poisson's coefficient which for

(a) (b) (c) (d) concrete usually varies between 0.15 to 0.25. After reaching

Figure 3: Typical specimens' failure modes a certain critical stress (typically between 60% and 80% of

the concrete strength), micro-cracking formation occurs in

Two failure modes were observed. The principal failure concrete, transversal strains increases quickly leading to

mode was a typical shear failure of the plastic tube (Figure large transversal strains for relatively small longitudinal

3(a)). A typical characteristic of shear failure is that the core strain. These micro-cracks evolve to macro-cracks that

concrete is damaged by shear stress in one direction due to eventually lead to concrete rapture with cracks parallel to the

weak confinement effect of the tube. The shear crack loading. This rupture of concrete can be delayed by

direction can be judged by the appearance of the specimen. confining the concrete appropriately. The confinement

mechanism of concrete is related to the use of materials that

The same type of mode of failure was also observed by provides tensile strength to restrict this increase in

Gupta [14] and Wang & Yang [20] in their experimental transversal strain. The effect of confinement of concrete at

program. This type of shear failure is affected by D/t ratio, high levels of loading leads to a triaxial compression stress

and in order to avoid this type of shear failure, the ratio state in concrete, which provide a superior behaviour in both

should be reduced, i.e., the wall thickness of the pipe should strength and ductility than concrete which is uniaxially

be increased. The second type of failure mode observed was compressed. Concrete columns can be confined by: Lateral

bulging which lead to column specimen crushing under reinforcement in the form of steel ties or spirals; Encasing

compression. This bulging was observed to occur either near concrete in steel tubes; External fiber composite wraps;

the bottom, top or mid-height of the specimen (Figure 3(b & Encasing concrete in fiber composite tubes; or Encasing

c)). This is a typical failure mode of short columns under concrete in plastic tubes (a new technology). All these means

pure concentric axial compressive load. At the end of the of confinement produce a so-called ‘passive’ state of

loading process, the encased concrete is totally crushed and confinement, in which the confining effect is a function of

almost pulverized. It was also observed that no concrete was the lateral expansion of the concrete core.

attached to the remainder of the tube, and a smooth interface

Volume 3 Issue 9, September 2014

www.ijsr.net

Paper ID: SEP14554 2171

Licensed Under Creative Commons Attribution CC BY

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Impact Factor (2012): 3.358

Table 3: Specimen details and compressive load and strength test results for confined specimens only

Column specimens dimensions

(mm) Average Average

Sample. Column Series Slenderness

Outer Tube load strength

No Designation Height, (h/D) ratio

diameter, thickness, (kN) (N/mm2)

h

D t

C/C20/110/2 220 2 167.3 17.6

110 2.5

C/C20/110/3 330 3 161.8 17.0

C/C20/83/2 166 2 131.1 24.2

GROUP C/C20/83/3 83 249 3.0 3 121.9 22.5

I C/C20/83/4 332 4 119.7 22.1

C/C20/55/2 110 2 60.1 25.3

C/C20/55/3 55 165 2.5 3 58.8 24.7

C/C20/55/4 220 4 54.7 23.0

C/C25/110/2 220 2 181.3 19.1

110 2.5

C/C25/110/3 330 3 171.8 18.1

C/C25/83/2 166 2 140.6 26.0

GROUP C/C25/83/3 83 249 3.0 3 133.2 24.6

II C/C25/83/4 332 4 130.2 24.1

C/C25/55/2 110 2 67.5 28.4

C/C25/55/3 55 165 2.5 3 64.0 26.9

C/C25/55/4 220 4 55.1 23.2

C/C30/110/2 220 2 195.3 20.5

110 2.5

C/C30/110/3 330 3 180.2 19.0

C/C30/83/2 166 2 144.8 26.8

GROUP C/C30/83/3 83 249 3.0 3 135.5 25.0

III C/C30/83/4 332 4 132.5 24.5

C/C30/55/2 110 2 69.6 29.3

C/C30/55/3 55 165 2.5 3 66.0 27.8

C/C30/55/4 220 4 62.6 26.3

Figures 4, 5, 6: Variation of Load capacity, Pult, and compressive strength, fcc, with change in concrete strength, diameter and

heights for UPVC-concrete confined columns

Volume 3 Issue 9, September 2014

www.ijsr.net

Paper ID: SEP14554 2172

Licensed Under Creative Commons Attribution CC BY

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Impact Factor (2012): 3.358

Table 4: Summary of experimental results in terms of Column load capacity, column strength and confinement effectiveness

Column Load capacity (kN) Column strength, Mpa

Column's - Tube Concrete Confinement

Dia/slenderne thickness, t, strength, Confined Unconfined, Unconfined f effectiveness

ss ratio (mm) f 'cu, (MPa) Confined f 'cc (f 'cc/f 'co)

Pcc Pco 'co

20 167.3 77.4 17.6 8.9 1.97

C-110/2 2.5 25 181.3 138.2 19.1 16.0 1.20

30 195.3 150.3 20.5 17.4 1.18

20 161.8 63.7 17.0 7.4 2.32

C-110/3 2.5 25 171.8 125.2 18.1 14.5 1.25

30 180.2 126.4 19.0 14.6 1.30

20 131.1 37.2 24.2 8.0 3.04

C-83/2 3.0 25 140.6 66.6 26.0 14.3 1.82

30 144.8 68.4 26.8 14.7 1.82

20 121.9 32.1 22.5 6.9 3.27

C-83/3 3.0 25 133.2 55.9 24.6 12.0 2.05

30 135.5 62.8 25.0 13.5 1.86

20 119.7 28.2 22.1 6.1 3.65

C-83/4 3.0 25 130.2 50.0 24.1 10.7 2.24

30 132.5 59.4 24.5 12.8 1.92

20 60.1 19.5 25.3 9.9 2.55

C-55/2 25 67.5 39.3 28.4 20.0 1.42

2.5

30 69.6 41.0 29.3 20.9 1.40

20 58.8 17.9 24.7 9.1 2.71

C-55/3 2.5 25 64.0 30.7 26.9 15.7 1.72

30 66.0 36.1 27.8 18.4 1.51

20 54.7 15.3 23.0 7.8 2.96

C-55/4 2.5 25 55.1 23.9 23.2 12.2 1.91

30 62.6 28.3 26.3 14.4 1.83

7, it is clear that plastic pipes are effective in confining

concrete, as evidenced by the increased compressive stress.

The enhancement in strength due to confinement of circular

columns is substantial. Depending on the level of

confinement, strength is increased anywhere from 1.18 to

3.65 times the unconfined strength. Figure 9 shows a general

trend where confinement effectiveness curve goes down with

increase in the grade of concrete. This is typical for all

column specimens tested regardless of their diameter, height

or tube thickness. This is due to the fact that the higher the

grade of concrete, the more brittle it is. It is postulated that

lower strength concrete is less stiff (as indicated by its low

elastic modulus which is usually related to the compressive

strength of concrete), and is therefore able to 'flow' thus

interacting with concrete tube more effectively, with

consequent increase in composite action. Another

observation from figure 9 is that the confinement

Figures 7: The relationship between confinement effectiveness increase with increase in slenderness ratio. This

effectiveness and concrete strength is depicted by the upward shift of the curves when the

slenderness ratio is increased with diameter kept constant.

The measure of how well a certain material confines This can be explained in the context that as slenderness ratio

concrete is referred to as confinement effectiveness which is increases, the load carrying capacity and consequently the

defined as f 'cc/f 'co , where f 'cc= compressive strength of column compressive stress reduces. However the reduction

confined concrete; f 'co =compressive strength of unconfined in compressive load and stress is more pronounced in

concrete. From the results as presented in table 4 and figure unconfined columns than in confined columns and therefore

Volume 3 Issue 9, September 2014

www.ijsr.net

Paper ID: SEP14554 2173

Licensed Under Creative Commons Attribution CC BY

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Impact Factor (2012): 3.358

the ratio of the stresses will he higher for longer columns due Analysis for Fiber-Reinforced Polymer Composites in

to the greater difference in stress than for short columns. A Civil Infrastructure,” Journal of composites for

notable observation is how the confinement effect for the construction, 7(3), 238-247, 2003.

83mm-diameter columns set was higher than the other [9] Shahawy, M., and Mirmiran, A. "Hybrid FRP-Concrete

column. This is attributed to the fact that the tube thickness Beam-Columns", Proc. of ICCEI5 Fifth International

was higher (3.0mm) as compared to the other columns Conference on Composites Engineering, Las Vegas,

(2.5mm). July 5-11, 1998, pp. 619-620.

[10] Michel Sabri Samaan, (1997). “An analytical and

5. Conclusion and Recommendations experimental investigation of concrete-filled fiber

reinforced plastics (FRP) tubes” PhD thesis, University

This paper reports the results of an experimental programme of Central Florida, Orlando, Florida.

which investigated the effect, on compressive strength, of [11] Ozbakkaloglu, T., and Saatcioglu, M. 2007. Seismic

using unplasticized polyvinyl (UPVC) tubes in confining Performance of Square High-Strength Concrete

short concrete columns. It was found out that plastic pipes Columns in FRP Stay-in-place Formwork. Journal of

are effective in confining concrete, as evidenced by the Structural Engineering-ASCE, 133(1), 44-56.

increased compressive stress. The enhancement in strength [12] Saafi, M., Toutanji, H., and Li, Z. 1999, Behavior of

due to confinement of circular columns is substantial and concrete columns confined with fiber reinforced

depending on the level of confinement, strength is increased polymer tubes, ACI Mat. Journal, 96(4):500–509.

anywhere from 1.18 to 3.65 times the unconfined strength [13] Toutanji, H.A. 1999, Stress–strain characteristics of

values. It was evident that confinement effectiveness is concrete columns externally confined with advanced

dependent on the strength of concrete where the former fiber composite sheets, ACI Mat. Jour., 96(3): 397–404.

reduces with the increase of the concrete strength due to the [14] Gupta, (2013):“Confinement of concrete columns with

brittle behaviour of high strength concrete. Low strength Unplasticized Poly-vinyl chloride tubes.” International

concrete tends to be more ductile suggesting the potential of Journal of Advanced Structural Engineering, Aug 2013.

an earthquake resistant composite column system. The tube Available online at:

thickness also affects the confinement effect of the plastic http://www.advancedstructeng.com/content/5/1/19

tubes and this research recommends that further research [15] M. Marzouck & K. Sennah, (2002). Concrete-filled

should be conducted with varying tube thicknesses to PVC tubes as compression members: Composite

establish the actual contribution it makes in column Materials in Concrete Construction. Proceedings of the

confinements. international congress “challenges of concrete

construction” 31-38

References [16] Daniali, S., (1992) "Investigation of the behavior of

reinforced plastic columns with concrete core." Proc.,

[1] Ata El-kareim Shoeib Soliman, (2011). “Behavior of ASCE 1992 Material Congress, 666-676

long confined concrete column.” Ain Shams [17] Carl E. Kurt, (1978). “Concrete filled structural plastic

Engineering Journal, 2, 141-148. columns.” Journal of the Structural Division, 104(1)

[2] Iskander, M. G., and Stachula, A. (1999) "FRP January 1978, 55-63

Composite Polymer Piling: An Alternative to Timer [18] Neville Adam M., (2011). “Properties of concrete”-- 5th

Pilling for Water-Front Applications." Geotechnical edition, ISBN 978-0-273-75580-7.

News, 4(Dec):27-29. [19] Gardner NJ, Jacobson ER. Structural behavior of

[3] Oyawa W. O., Sugiura K. & Watanabe E. (1998). concrete filled steel tube. ACI J, 1976:404–13.

“Elasto-plastic behaviour of axially loaded filled [20] Wang J, Yang Q (2010) Experimental study on

circular steel stub columns.” J. Struct. Engrg., JSCE, Mechanical Properties of concrete confined with plastic

44(A), 147-158. Pipe. Title no. 107-M17. ACI Mater J: 107,132–137

[4] Ahmad, S.H. and S. P. Shah, 1982. “Complete Triaxial

Stress-Strain Curves for Concrete, Journal of Structural

Division,” Proceedings of the American Society of Civil

Engineering, ASCE,108(ST4):728-742.

[5] Mander, J.B., M.J. N. Priestley and R. Park. 1988.

“Theoretical Stress-Strain Model for Confined

Concrete,” Journal of Structural Engineering, ASCE,

114:1804-1823.

[6] Wei, S., Mau, S. T., and Mantrala, S. K. "Performance

of New Sandwich Tube under Axial Loading:

Experiment", Journal of Structural Engineering, Vol.

121, No. 12, Dec. 1995, pp. 1806-1821.

[7] Ivan M. (1997), “Composite columns in composite

construction design for buildings,” ASCE, Mc Graw-

Hill, New York, 4.1-4.5.1

[8] V. M. Karbhari, J. W. Chin, D. Hunston. B.

Benmokrane, T. Juska, R. Morgan, J. J. Lesko, U.

Sorathia and D. Reynaud, (2003) “Durability Gap

Volume 3 Issue 9, September 2014

www.ijsr.net

Paper ID: SEP14554 2174

Licensed Under Creative Commons Attribution CC BY

You might also like

- A Review of Concrete Structure in Terms of Deterioration and Strengthening With Analysis of Recent TechnologyDocument4 pagesA Review of Concrete Structure in Terms of Deterioration and Strengthening With Analysis of Recent Technologyriri tenriNo ratings yet

- Structures: SciencedirectDocument17 pagesStructures: Sciencedirectaboodalshouha1998No ratings yet

- A Review On Failure Modes and Cracking Behaviors of Polypropylene Fibers Reinforced ConcreteDocument27 pagesA Review On Failure Modes and Cracking Behaviors of Polypropylene Fibers Reinforced ConcreteMohamed ArbiliNo ratings yet

- 2010 Experimental Studyon Mechanical Propertiesof Concrete Confinedwith Plastic PipeDocument7 pages2010 Experimental Studyon Mechanical Propertiesof Concrete Confinedwith Plastic PipefrankNo ratings yet

- 1 s2.0 S0950061822038296 MainDocument12 pages1 s2.0 S0950061822038296 MainMuhammad FiqriNo ratings yet

- Retrofitting of Concrete Structure With Fiber Reinforced PolymerDocument9 pagesRetrofitting of Concrete Structure With Fiber Reinforced PolymerramyaNo ratings yet

- CONICET Digital Nro. ADocument13 pagesCONICET Digital Nro. AespanruyaNo ratings yet

- TAREA No 04Document15 pagesTAREA No 04Bautista TañinNo ratings yet

- Construction and Building Materials Volume 106 Issue 2016 (Doi 10.1016 - J.conbuildmat.2015.12.165) Emon, Md. Abul Bashar Manzur, Tanvir Yazdani, Nur - Improving Performance of Light Weight ConcretDocument9 pagesConstruction and Building Materials Volume 106 Issue 2016 (Doi 10.1016 - J.conbuildmat.2015.12.165) Emon, Md. Abul Bashar Manzur, Tanvir Yazdani, Nur - Improving Performance of Light Weight ConcretSem_KalitNo ratings yet

- Materials Today: Proceedings: Juby Mariam Boban, Anjana Susan JohnDocument6 pagesMaterials Today: Proceedings: Juby Mariam Boban, Anjana Susan JohnJUBY MBNo ratings yet

- Structural Retrofitting - FRPDocument10 pagesStructural Retrofitting - FRPMarvin ZapataNo ratings yet

- Aq04605306316 PDFDocument11 pagesAq04605306316 PDFDinesh Kumar JNo ratings yet

- Review Paper On Effective Methods For The Retrofitting of Reinforced Concrete StructuresDocument6 pagesReview Paper On Effective Methods For The Retrofitting of Reinforced Concrete StructuresIJRASETPublicationsNo ratings yet

- Kadhim 2023 IOP Conf. Ser. Earth Environ. Sci. 1232 012034Document9 pagesKadhim 2023 IOP Conf. Ser. Earth Environ. Sci. 1232 012034engraslam39No ratings yet

- A State of The Art Review On Reinforced Concrete Beams With Openings Retrofitted With FRPDocument15 pagesA State of The Art Review On Reinforced Concrete Beams With Openings Retrofitted With FRPenghrc.2208No ratings yet

- Materials and Design: Libo Yan, Nawawi ChouwDocument11 pagesMaterials and Design: Libo Yan, Nawawi ChouwVaish NaoNo ratings yet

- Retrofitting of Reinforced Concrete Slabs Using FRP: July 2021Document6 pagesRetrofitting of Reinforced Concrete Slabs Using FRP: July 2021AminNo ratings yet

- Experimental Study of Maintenance and Treatment of R.C.C. Building by Fiber Reinforced PlasticDocument4 pagesExperimental Study of Maintenance and Treatment of R.C.C. Building by Fiber Reinforced PlasticEditor IJTSRDNo ratings yet

- FinalpaperDocument18 pagesFinalpaperrene inerNo ratings yet

- Development and Experimental Study of Bond Between FRP Rebar and ConcreteDocument6 pagesDevelopment and Experimental Study of Bond Between FRP Rebar and ConcreteApplied Science and Engineering Journal for Advanced ResearchNo ratings yet

- Assessment of Prestressed Concrete Aplications in NigeriaDocument5 pagesAssessment of Prestressed Concrete Aplications in NigeriaonyejekweNo ratings yet

- Increase in Strength of Concrete by Using Bottle CapsDocument6 pagesIncrease in Strength of Concrete by Using Bottle Capsaffan aliNo ratings yet

- Materials 14 02184 PDFDocument17 pagesMaterials 14 02184 PDFPatrickNo ratings yet

- Strengthening On RC SlabsDocument16 pagesStrengthening On RC SlabsHarshNo ratings yet

- 1 s2.0 S1110016823000790 MainDocument11 pages1 s2.0 S1110016823000790 MainI MixNo ratings yet

- Strength Properties of Various Types of Fiber-Reinforced Concrete For Production of Driven PilesDocument20 pagesStrength Properties of Various Types of Fiber-Reinforced Concrete For Production of Driven Pilessbaia amineNo ratings yet

- To Investigate How Well Industrial Waste Polymer Fibre Performs Physically and Mechanically When Utilised in Concrete MixturesDocument6 pagesTo Investigate How Well Industrial Waste Polymer Fibre Performs Physically and Mechanically When Utilised in Concrete MixturesIJRASETPublicationsNo ratings yet

- Structures: T. Tafsirojjaman, Sabrina Fawzia, David P. ThambiratnamDocument11 pagesStructures: T. Tafsirojjaman, Sabrina Fawzia, David P. ThambiratnamBayuAgungGilangWibowoNo ratings yet

- A Review of The Repair of Reinforced Concrete Beams: January 2006Document11 pagesA Review of The Repair of Reinforced Concrete Beams: January 2006death darkNo ratings yet

- Ijciet 08 09 109Document10 pagesIjciet 08 09 109Snehal AbhyankarNo ratings yet

- Journal of Rehabilitation in Civil EnginDocument11 pagesJournal of Rehabilitation in Civil EnginKasmiNo ratings yet

- Strengthening of Reinforced Concrete Work Data 6Document58 pagesStrengthening of Reinforced Concrete Work Data 6M ChoudharyNo ratings yet

- 1 s2.0 S0950061818329015 MainDocument15 pages1 s2.0 S0950061818329015 MainKowTeckshengNo ratings yet

- Fibre Reinforced Polymer Concrete Structures - Opportunities and ConcernsDocument11 pagesFibre Reinforced Polymer Concrete Structures - Opportunities and ConcernsNurHaziqahNo ratings yet

- Composite Structures: SciencedirectDocument15 pagesComposite Structures: SciencedirectAliNo ratings yet

- Oalibj 2022040716105497Document12 pagesOalibj 2022040716105497anunciano GuterresNo ratings yet

- Structural Strengtheningrepair of Reinforced Concrete RC Beams by Different Fiberreinforced Cementitious Materials A STDocument15 pagesStructural Strengtheningrepair of Reinforced Concrete RC Beams by Different Fiberreinforced Cementitious Materials A STEng.Hesham AL-HelaleeNo ratings yet

- Axial Behavior of Reinforced Concrete Column With Ultra-High Performance Concrete Stay-In-Place FormworkDocument14 pagesAxial Behavior of Reinforced Concrete Column With Ultra-High Performance Concrete Stay-In-Place Formworknagham tariqNo ratings yet

- PROJECT Sewage TreatmentDocument16 pagesPROJECT Sewage TreatmentKaushiki KambojNo ratings yet

- 1 s2.0 S2214785320407217 MainDocument4 pages1 s2.0 S2214785320407217 MainSamuel NkereuwemNo ratings yet

- Ede Agbede - Use of Coconut Husk Fiber For Improved Compressive PDFDocument8 pagesEde Agbede - Use of Coconut Husk Fiber For Improved Compressive PDFgreece loloNo ratings yet

- Icrdet Ce 1001Document6 pagesIcrdet Ce 1001Saurabh Agrawal100% (1)

- Finite Element Modeling of Reinforced Concrete Beam Patch Repaired and Strengthened With Fiber-Reinforced PolymersDocument9 pagesFinite Element Modeling of Reinforced Concrete Beam Patch Repaired and Strengthened With Fiber-Reinforced PolymersbroodyNo ratings yet

- TimeeDocument13 pagesTimeeyra.viluan14No ratings yet

- Influence of Heat-Cool Cyclic Exposure On The Performance of Fiber-Reinforced High-Strength ConcreteDocument24 pagesInfluence of Heat-Cool Cyclic Exposure On The Performance of Fiber-Reinforced High-Strength ConcreteShaker QaidiNo ratings yet

- Design, Construction, and Field-Testing of An RC Box Culvert Bridge Reinforced With GFRP BarsDocument19 pagesDesign, Construction, and Field-Testing of An RC Box Culvert Bridge Reinforced With GFRP BarsartsidartsyNo ratings yet

- Strengthening of R.C.C. Beam-Using Different Glass Fiber: Sandeep G. Sawant, A. B. Sawant, M. B. KumthekarDocument8 pagesStrengthening of R.C.C. Beam-Using Different Glass Fiber: Sandeep G. Sawant, A. B. Sawant, M. B. KumthekarAjmal MuhammedNo ratings yet

- Use of Steel Fibre in m20 ConcreteDocument44 pagesUse of Steel Fibre in m20 ConcretenemsharuNo ratings yet

- Ahmed Mohamed SalehDocument12 pagesAhmed Mohamed SalehramyaNo ratings yet

- FIBRE REINFORCED CONCRETE - DocumentationDocument23 pagesFIBRE REINFORCED CONCRETE - DocumentationSandeep ChowdaryNo ratings yet

- Fmats 09 1048228Document18 pagesFmats 09 1048228rtripulariasNo ratings yet

- Reinforcement Corrosion in Concrete Structures and Service Life Predictions - A ReviewDocument5 pagesReinforcement Corrosion in Concrete Structures and Service Life Predictions - A ReviewAdnan BuljubasicNo ratings yet

- Anti Blast Properties of 6063 T5 Aluminum Alloy Circular Tub - 2021 - Thin WalleDocument19 pagesAnti Blast Properties of 6063 T5 Aluminum Alloy Circular Tub - 2021 - Thin WalleRodrigoNo ratings yet

- Energy Absorption and Exural Toughness Evaluation of Fibre Reinforced Polymer Modified ConcreteDocument10 pagesEnergy Absorption and Exural Toughness Evaluation of Fibre Reinforced Polymer Modified ConcreteLê Chí HiệpNo ratings yet

- Compressive Behaviour of RC Column With Fibre Reinforced Concrete Confined by CFRP StripsDocument12 pagesCompressive Behaviour of RC Column With Fibre Reinforced Concrete Confined by CFRP Stripsmalek malekNo ratings yet

- Ajeassp 2011 93 101231123Document10 pagesAjeassp 2011 93 101231123Paul MoraNo ratings yet

- Materials: Effect Steel Fibre Content On The Load-Carrying Capacity of Fibre-Reinforced Concrete Expansion AnchorDocument14 pagesMaterials: Effect Steel Fibre Content On The Load-Carrying Capacity of Fibre-Reinforced Concrete Expansion AnchorInes Cajo MozoNo ratings yet

- Conexiones y Aplicaciones Estructurales de Compuestos Poliméricos Reforzados Con Fibra para Infraestructura Civil en Entornos AgresivosDocument15 pagesConexiones y Aplicaciones Estructurales de Compuestos Poliméricos Reforzados Con Fibra para Infraestructura Civil en Entornos Agresivosjose mauricio muñoz bolivarNo ratings yet

- Retrofitting of Reinforced Concrete Columns Using Ferrocement JacketingDocument7 pagesRetrofitting of Reinforced Concrete Columns Using Ferrocement Jacketingsurajitkundu2002No ratings yet

- Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition): Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)From EverandComposite Steel and Concrete Structures: Fundamental Behaviour (Second Edition): Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)Rating: 4 out of 5 stars4/5 (10)

- Prestressed Concrete-Ch-2-2020Document32 pagesPrestressed Concrete-Ch-2-2020nagham tariqNo ratings yet

- Behaviour of Eccentric Concrete Columns ReinforcedDocument14 pagesBehaviour of Eccentric Concrete Columns Reinforcednagham tariqNo ratings yet

- Out 2Document142 pagesOut 2nagham tariqNo ratings yet

- Prediction of Shear Capacity and Mechanical Properties of Recycled Reinforced High Strength Concrete Beams Without StirrupsDocument37 pagesPrediction of Shear Capacity and Mechanical Properties of Recycled Reinforced High Strength Concrete Beams Without Stirrupsnagham tariqNo ratings yet

- Serviceability Limit State ofDocument9 pagesServiceability Limit State ofnagham tariqNo ratings yet

- Ijciet 08 05 112Document12 pagesIjciet 08 05 112nagham tariqNo ratings yet

- Astm A1046-2019Document10 pagesAstm A1046-2019nagham tariq100% (1)

- Flexural Behavior of ECC Hollow Beams Incorporating Different Synthetic FibersDocument13 pagesFlexural Behavior of ECC Hollow Beams Incorporating Different Synthetic Fibersnagham tariqNo ratings yet

- Behaviour of Self-Consolidating Concrete Two Way Slabs Under Uniform LoadingDocument12 pagesBehaviour of Self-Consolidating Concrete Two Way Slabs Under Uniform Loadingnagham tariqNo ratings yet

- Flexural Behaviour of Hollow Reinforced Concrete T-BeamsDocument12 pagesFlexural Behaviour of Hollow Reinforced Concrete T-Beamsnagham tariqNo ratings yet

- Composite Structures: SciencedirectDocument12 pagesComposite Structures: Sciencedirectnagham tariqNo ratings yet

- Axial Behavior of Reinforced Concrete Column With Ultra-High Performance Concrete Stay-In-Place FormworkDocument14 pagesAxial Behavior of Reinforced Concrete Column With Ultra-High Performance Concrete Stay-In-Place Formworknagham tariqNo ratings yet

- Journal of Building EngineeringDocument14 pagesJournal of Building Engineeringnagham tariqNo ratings yet

- Journal of Thi-Qar University Vol.13 No.4 Dec 2018: WWW - Jutq.utq - Edu.iqDocument21 pagesJournal of Thi-Qar University Vol.13 No.4 Dec 2018: WWW - Jutq.utq - Edu.iqnagham tariqNo ratings yet

- Engineering Structures: Alessio Cascardi, Francesco Micelli, Maria Antonietta AielloDocument12 pagesEngineering Structures: Alessio Cascardi, Francesco Micelli, Maria Antonietta Aiellonagham tariqNo ratings yet

- Program SimpozionDocument119 pagesProgram Simpozionmh_aditzNo ratings yet

- Swaps: Options, Futures, and Other Derivatives, 9th Edition, 1Document34 pagesSwaps: Options, Futures, and Other Derivatives, 9th Edition, 1胡丹阳No ratings yet

- Oktoberfest ReportDocument28 pagesOktoberfest ReportUvin RanaweeraNo ratings yet

- Magazine of The U.S. Navy February 1990Document52 pagesMagazine of The U.S. Navy February 1990Fred NoeyesNo ratings yet

- Marcoeconomics 11e Arnold HW Chapter 10 Attempt 4Document5 pagesMarcoeconomics 11e Arnold HW Chapter 10 Attempt 4PatNo ratings yet

- Agricultural FinanceDocument8 pagesAgricultural FinanceYayah Koroma100% (1)

- 2023 WARN Notice ListingsDocument15 pages2023 WARN Notice ListingsMasonNo ratings yet

- Barrios V MartinezDocument13 pagesBarrios V MartinezMp CasNo ratings yet

- Larranaga V CADocument15 pagesLarranaga V CAKhay AnnNo ratings yet

- Dhilp ProjectDocument53 pagesDhilp ProjectSowmiya karunanithiNo ratings yet

- 1991 Indianapolis 500 - WikipediaDocument48 pages1991 Indianapolis 500 - WikipediabNo ratings yet

- Contrasting MO and VB TheoryDocument4 pagesContrasting MO and VB TheoryPhillimonNo ratings yet

- IIM Indore US Pathway BrochureDocument20 pagesIIM Indore US Pathway Brochurecinofi7972No ratings yet

- Three Levels of SustainabilityDocument330 pagesThree Levels of SustainabilityChristian Prez100% (5)

- The Teaching ProfessionDocument119 pagesThe Teaching ProfessionhelmaparisanNo ratings yet

- Zenith Aircraft Stol CH 701: Wing Spar Wing Spar Main Gear StiffenerDocument16 pagesZenith Aircraft Stol CH 701: Wing Spar Wing Spar Main Gear StiffenerSteven100% (1)

- Mat Lab Interview QuestionsDocument2 pagesMat Lab Interview QuestionsSiddu Shiva KadiwalNo ratings yet

- An Investigation Into The Use of GAMA Water Tunnel For Visualization of Vortex Breakdown On The Delta WingDocument7 pagesAn Investigation Into The Use of GAMA Water Tunnel For Visualization of Vortex Breakdown On The Delta WingEdy BudimanNo ratings yet

- PEOPLE Vs Rodolfo DiazDocument9 pagesPEOPLE Vs Rodolfo DiazRaymondNo ratings yet

- Pathorchur Coleus Aromaticus A Review of The MedicDocument9 pagesPathorchur Coleus Aromaticus A Review of The MedicDung NguyenNo ratings yet

- Mouth Breathing: Adverse Effects On Facial Growth, Health, Academics, and BehaviorDocument8 pagesMouth Breathing: Adverse Effects On Facial Growth, Health, Academics, and BehaviorlogoioanninaNo ratings yet

- Judicial & Bar CouncilDocument3 pagesJudicial & Bar Councilmitch galaxNo ratings yet

- Companion Study Guide: 15 LessonsDocument124 pagesCompanion Study Guide: 15 LessonsLuisk MaldonadoNo ratings yet

- Robbery and Hold-Up CountermeasuresDocument10 pagesRobbery and Hold-Up CountermeasuresMildred B. Austria100% (2)

- Casals Song of The BirdsDocument4 pagesCasals Song of The BirdsHiroka MatsumotoNo ratings yet

- Architecture Firms: CCBA DesignsDocument1 pageArchitecture Firms: CCBA DesignspallaviNo ratings yet

- Las - 9-12Document11 pagesLas - 9-12maria teresa aparreNo ratings yet

- Umali V EstanislaoDocument2 pagesUmali V EstanislaoVian O.No ratings yet

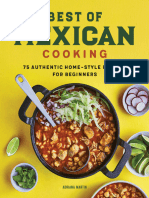

- Best of Mexican CookingDocument154 pagesBest of Mexican CookingJuanNo ratings yet

- Detailed Lesson Plan in TLEDocument7 pagesDetailed Lesson Plan in TLEma kathrine cecille macapagalNo ratings yet