Professional Documents

Culture Documents

EGN UIX10204 - Airodek Prop & Panel Falsework

Uploaded by

AmerCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EGN UIX10204 - Airodek Prop & Panel Falsework

Uploaded by

AmerCopyright:

Available Formats

Equipment Guidance Note UIX10204

Airodek Prop and Panel

1.0 Introduction

This guidance note is for the erection, use and

dismantling of the Airodek Prop & Panel support

system for concrete slabs – ‘Airodek’.

This document shall not be used as a working

method statement. It is the customer’s

responsibility to assimilate this information into a

method statement specific to the site conditions.

2.0 References

This document must be read in conjunction with

the RMD Kwikform (RMDK) drawings, when

provided.

Please refer to the RMDK Airodek brochure,

Technical Data Sheets and the attendant RMDK

Risk Assessment. Reference should also be

made to the Project Work Method Statement

and construction drawings provided by the

contractor for specific details and sequences.

3.0 Health & Safety

This document is for general guidance only and

does not relieve the customer of responsibility

for the safe erection, use and dismantling of the equipment.

Work with Airodek should only be undertaken and supervised by appropriately trained

personnel familiar with safe use of the equipment. Where needed, Airodek product

demonstration can be provided by RMDK but it remains the customer’s responsibility to

determine competence of erectors & supervisors.

Provide safe access and a safe working platform at all times. Safe systems of work shall

reflect industry best practice and comply with applicable local legislation.

4.0 Design Parameters

The Airodek Prop & Panel System is designed to support reinforced concrete slabs up to

500mm thick using 1800x900mm panels, 700mm thick concrete using 1800x600 panels

and 900mm thick using 1800x300mm panels plus the live loads associated with placing

the concrete. Where appropriate RMDK will provide scheme drawings, which clearly

indicate the design parameters used. If any of this information is believed to be incorrect,

the relevant RMDK office must be contacted prior to erection.

Issue J Further info: +44 (0) 1922 743743 Sheet 1 of 7

The information contained within these data sheets remain the property of RMD Kwikform and is not to be altered or reproduced without permission.

13/03/14 RMD Kwikform reserves the right to change any specification without giving prior notice

It is the customers responsibility to incorporate this generic information into a document specific to the site conditions

Equipment Guidance Note UIX10204

Airodek Prop and Panel

4.1. Stability

During erection equipment is stabilised by fitting Airodek Spacing Gates and Spacing Gate

Legs to the props at the noted centres, the maximum spacing is 5.4m in each direction

Stability during all subsequent stages of construction is provided at the top of the system

by the soffit infill plywood being cut in tight around the column heads and/or walls.

It is the customer’s responsibility to ensure that the permanent works and the interface

with the soffit, as constructed on site, can safely resist all notional and actual horizontal

loads.

5.0 Component Identification

The system comprises aluminium-framed panels supported by crowns and props.

Figure 1. Airodek HD Crown Rapidshor Sleeve Clip

Airodek

Spacing Gate

Airodek

Panel Spacing Gate and Legs Telescopic Strut

Airodek

Prop

5.1. Telescopic Strut

A Telescopic Strut is used for temporary support of Figure 2. Figure 3.

panel ends during erection and dismantling. The claw

at the top of the strut engages in the rectangular cut

out in the end of the panel frame. During the raising

and lowering operations engage the claw as figure 2.

Engage the locking tab shown in figure 3 when the

Telescopic Strut supports the panel temporarily at

high level to prevent accidental dislodging of the strut.

Issue J Further info: +44 (0) 1922 743743 Sheet 2 of 7

The information contained within these data sheets remain the property of RMD Kwikform and is not to be altered or reproduced without permission.

13/03/14 RMD Kwikform reserves the right to change any specification without giving prior notice

It is the customers responsibility to incorporate this generic information into a document specific to the site conditions

Equipment Guidance Note UIX10204

Airodek Prop and Panel

6.0 Foundations

Airodek Prop and Panel equipment is usually founded on a previously cast and cured

concrete slab. Foundations need to be relatively flat and of a suitably compacted material

that will adequately withstand the indicated leg loads without undue settlement. In multi

storey construction backpropping may be necessary to enable load sharing between 2 or

more floor slabs. Where the falsework is founded directly on the ground use appropriate

sole boards to spread the load from the standards.

7.0 Assembl y

7.1. Preparation

Adjust all of the props to the approximate length required. This will be the floor to ceiling

height minus 170mm. Check that there is a minimum of five threads available on the prop

outer to allow the collar to be wound down during striking. Ensure that the Stepped Prop

Pins are engaged correctly and are not in their notched stuck positions. Add an Airodek

HD Crown to the top of each prop and connect using a Rapidshor Sleeve Clip.

If an RMDK drawing has been supplied, the position of the prop grid will be clearly set out.

It is important that the falsework system is in the correct location relative to the structure.

Set out the first line of props adjacent to a wall and the position of the first prop on the line.

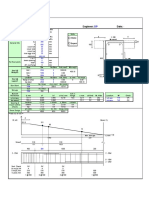

7.2. Erection Sequence (Figure 4)

1. Lay the first pair of Airodek Props horizontal on the slab with their bases in their

approximate final position. This will normally be adjacent to a wall. Join the props with a

900mm Spacing Gate. Ensure the gate is orientated the correct way up and the correct

way round so that the Spacing Gate Legs will be able to be fitted to the same side as

the panels will be erected. Set the upper rail of the gate in line with the paint band on

the props (The top of the rail will be 935mm off the bottom of the props). Tighten the

connection by engaging the integral sliding clamps with the prop bodies and driving

them lightly down the inclined Spacing Gate members with a hammer.

2. Raise the assembled pair of props and attach a pair of Spacing Gate Legs to the

Spacing Gate. Fit both legs to the side of the gate remote from the wall securing with

the integral latch. Adjust the position of this first assembly to suit the setting out of the

prop grid. The assembly should now be stable. (If the equipment is not founded on a

cured concrete slab use four spacing gates to make a stable initial assembly of four

props and work away from this assembly. Use 1800mm spacing gates to brace the first

row of props to the second row every other bay with the progress of erection)

3. Lift an Airodek Panel and hang the top end on the crown prongs.

4. Rotate the lower end of the panel part way up by hand and engage the claw of the

Airodek Telescopic Strut in the rectangular cut out in the end of the panel frame.

Complete the raising of the panel using the Telescopic Strut and support it at soffit

level. Ensure that the locking tab of the claw is engaged as figure 3. Check that the

telescopic Strut is set to the correct length to support the panel without the base sliding

and that the clamping screw that sets the strut to length is adequately tightened.

Issue J Further info: +44 (0) 1922 743743 Sheet 3 of 7

The information contained within these data sheets remain the property of RMD Kwikform and is not to be altered or reproduced without permission.

13/03/14 RMD Kwikform reserves the right to change any specification without giving prior notice

It is the customers responsibility to incorporate this generic information into a document specific to the site conditions

Equipment Guidance Note UIX10204

Airodek Prop and Panel

1 2 3

4 5 6

7 8 9

Figure 4.

Airodek Prop and Panel

Erection sequence

10

Issue J Further info: +44 (0) 1922 743743 Sheet 4 of 7

The information contained within these data sheets remain the property of RMD Kwikform and is not to be altered or reproduced without permission.

13/03/14 RMD Kwikform reserves the right to change any specification without giving prior notice

It is the customers responsibility to incorporate this generic information into a document specific to the site conditions

Equipment Guidance Note UIX10204

Airodek Prop and Panel

5. Place an Airodek Prop under the free corner of the first panel. Ensure the panel frame

engages snugly with the seating in the Airodek Crown. Install an 1800mm Spacing

Gate.

6. Install an Airodek Prop 900mm away from the first pair of props and stabilise with a

900mm Spacing Gate or manually restrain. Engage a second panel on the crowns.

7. Raise the panel as before and support with a second Telescopic Strut.

8. Place an Airodek Prop under the adjacent corners of the erected panels. Remove the

Telescopic Strut from first panel. Install a further Airodek Prop 900mm away from the

first three props and stabilise with an assembly of 900mm Spacing Gate and Spacing

Gate Legs or manually restrain. Engage a third panel on the crowns.

9. Raise the panel and support it with a Telescopic Strut. Place an Airodek Prop under the

adjacent corners of the erected panels etc. As erection of the first row of panels

progresses check the position and squareness of the prop grid and adjust.

10. Once seven panels have been erected and a second 1800mm Spacing Gate is in-situ

then all except the first and last 900mm Spacing Gates and Legs installed may be

removed for use to assist with further erection of the first row of equipment.

Continue this sequence to complete the soffit, positioning spacing gates as indicated in

7.3. Check the level of the soffit as each row of panels is erected to minimise gaps

between panels. Carry out minor adjustments by rotation of the Airodek Prop Collars.

Place Infills to column heads and perimeter walls in accordance with 7.4 before allowing

full access to the soffit or loading it with any materials.

7.3. Spacing Gates

Install pairs of spacing Figure 5.

gates at 5.4m centres in

each direction as the

soffit is erected to

ensure stability of the

equipment. This

corresponds to every

third bay in the 1800mm

pitch direction and every

sixth bay in the 900mm

pitch direction (Figure 5).

Issue J Further info: +44 (0) 1922 743743 Sheet 5 of 7

The information contained within these data sheets remain the property of RMD Kwikform and is not to be altered or reproduced without permission.

13/03/14 RMD Kwikform reserves the right to change any specification without giving prior notice

It is the customers responsibility to incorporate this generic information into a document specific to the site conditions

Equipment Guidance Note UIX10204

Airodek Prop and Panel

7.4. Infill Formwork

MATERIALS, PLANT & REINFORCEMENT SHALL NOT BE LOADED ONTO THE

SOFFIT PRIOR TO SECURING THE INFILLS

Controlled personnel access is permitted on the soffit before the infills are placed for the

carpenters to secure the infill plywood. Appropriate safety measures shall be taken to

ensure that these operatives work at a safe distance from unguarded edges and/or wear

appropriate fall arrest equipment.

Add infills around the columns and the

perimeter of the soffit as shown on the RMDK

drawing supplied. Infills should be constructed

using the Airodek 1800mm and 900mm Infill

Beams and 17-19mm thick plywood.

Add infills to any ancillary soffit support shown

constructed using alternative equipment as

indicated on the RMDK scheme drawing.

7.5. Access Accessories

Install Airodek Handrail Sockets and Rapidshor Standards to any open edges as required.

Fix Rapidshor Ledgers as handrails and install toeboards. Provide barriers and warning

notices to prevent access to incomplete sections of the soffit. Ensure that safe access and

egress routes are provided to all working areas, and that such routes, including ladders

and stairways, are clear.

7.6. Wind Precautions

Airodek panels are lightweight. Controlling the accidental movement of large area,

lightweight materials on a windy day on site will always be an issue and Airodek panels

are no exception. Between uses in windy conditions, panels should not be left loose on the

slab or leaning against columns or cores but should be stacked in Airodek panel stillages

which more effectively contain the panels and can be readily handled using a pallet truck

thus easing the transport of materials between levels.

Erected panels are vulnerable to uplift in high winds. Connect panels down to Airodek

Crowns and together through the edge sections using the details shown on the RMDK

drawing.

If the falsework is to be left unloaded during conditions exceeding the Maximum Working

Wind Speed of 18m/s, strap the soffit down to the supporting slab every other panel

around the perimeter and on a 3.6m grid in both directions internally.

7.7. Checks and Loading

Ensure that bins or stillages loaded out onto the Airodek soffit are not stacked and that the

weight of materials in each container does not exceed 1000kg spread evenly over the four

Issue J Further info: +44 (0) 1922 743743 Sheet 6 of 7

The information contained within these data sheets remain the property of RMD Kwikform and is not to be altered or reproduced without permission.

13/03/14 RMD Kwikform reserves the right to change any specification without giving prior notice

It is the customers responsibility to incorporate this generic information into a document specific to the site conditions

Equipment Guidance Note UIX10204

Airodek Prop and Panel

feet of the unit. Timber bites supporting bundled reinforcement should be placed such that

each bite attracts a maximum weight of 250kg.

Prior to placement of concrete, check the Airodek system to ensure that all connections

are sound and all necessary components are correctly installed. Check the props are

vertical and their foundations are firm. Check that the Stepped Pins are not positioned

within their striking notches. Consult the drawings for any specific requirements for

placement of concrete and any restrictions to loading. Issue Permit to Load.

Place the concrete ensuring that heaping is avoided throughout.

8.0 Striking and Dismantling

After a suitable curing period strike the Airodek Stepped Pins by driving them into their

striking notches with a hammer. This will result in a lowering of the soffit by 4mm. Wind

down the prop collars by four turns each (25mm).

WARNING! If the above procedure is not carried out prior to lowering the panels then the

panel edges will be damaged during the subsequent stages of striking.

• Begin the stripping operation at a soffit infill section. Remove the soffit infill area(s)

adjacent to the stripping face.

• Position two Airodek Telescopic Struts on the front edge of adjacent panels. Ensure the

locking tab on the claw is not engaged and is passed through the rectangular cut out in

the end of the panel (figure 2).

• Remove the three Airodek Props beneath the ends of the panels now supported by the

Telescopic Struts.

• Lower the first panel to its hanging position supported by the crown prongs. Repeat for

the second panel removing the Telescopic Struts in the process.

• Lower the remaining panels in the first line alternating installation of the Telescopic

Struts, removal of the Airodek Props and lowering of the panels.

• Remove the first row of panels from the crown prongs, clean and stack carefully in the

Airodek Pallets or Stillages provided.

• Repeat this procedure for subsequent rows of panels and props removing the spacing

gates and legs as stripping progresses.

Ensure that at all stages the props and panels are stable during the stripping procedure. It

is recommended that stripping progresses back towards the location where erection of the

panels was first started.

Clean and stack the dismantled components neatly in the appropriate containers or

stillages. Oil the ply surface if appropriate.

IT IS THE CUSTOMER’S RESPONSIBILITY TO ENSURE THAT ALL EQUIPMENT IS

CLEAN AND THAT STACKED EQUIPMENT IS SAFE TO HANDLE AND TRANSPORT.

Issue J Further info: +44 (0) 1922 743743 Sheet 7 of 7

The information contained within these data sheets remain the property of RMD Kwikform and is not to be altered or reproduced without permission.

13/03/14 RMD Kwikform reserves the right to change any specification without giving prior notice

It is the customers responsibility to incorporate this generic information into a document specific to the site conditions

You might also like

- EGN UIX10205 - Airodek DeckingDocument9 pagesEGN UIX10205 - Airodek DeckingAmerNo ratings yet

- EGN UIX10401 - Rapidclimb Climbing FormworkDocument11 pagesEGN UIX10401 - Rapidclimb Climbing FormworkAbdalhameed A YonesNo ratings yet

- Alshor Plus FalseworkDocument11 pagesAlshor Plus FalseworkezzularabNo ratings yet

- 39CQ Iom 06302014Document20 pages39CQ Iom 06302014Non Etabas GadnatamNo ratings yet

- SafetyLink FastFit Ladder HandbookDocument67 pagesSafetyLink FastFit Ladder HandbookNirooban VigneswaranNo ratings yet

- P20 2020 Quick Start Guide-V1.1 EN202107151146Document28 pagesP20 2020 Quick Start Guide-V1.1 EN202107151146Adilson Dos SantosNo ratings yet

- 1MRK504017-UEN en Installation and Commissioning Manual RET 521 2.3Document67 pages1MRK504017-UEN en Installation and Commissioning Manual RET 521 2.3haichau199No ratings yet

- 112020094-SICOM3024P (V3.1) Industrial Ethernet Switch Hardware Installation Manual - V2.8Document28 pages112020094-SICOM3024P (V3.1) Industrial Ethernet Switch Hardware Installation Manual - V2.8Dung VuNo ratings yet

- RE - 5 - Protection, Monitoring and Control: Installation ManualDocument20 pagesRE - 5 - Protection, Monitoring and Control: Installation ManualBata ZivanovicNo ratings yet

- MS For Scaffold and Cladding WorkDocument16 pagesMS For Scaffold and Cladding WorkSujan AugustinNo ratings yet

- AN5006-20 Small-Sized Integrated Access Device Quick Installation Guide (Version D)Document26 pagesAN5006-20 Small-Sized Integrated Access Device Quick Installation Guide (Version D)JeffersonFelixNo ratings yet

- DTTN-DT2-PC-MET-EL-0004 A Method Statement For Inverter and Transformer Installation and CommissioningDocument13 pagesDTTN-DT2-PC-MET-EL-0004 A Method Statement For Inverter and Transformer Installation and CommissioningTariq Ali SialNo ratings yet

- Instructions ENDocument21 pagesInstructions ENOsuntogun QozeemNo ratings yet

- 20-1701 Slips DCSDocument7 pages20-1701 Slips DCSRahul M.RNo ratings yet

- V 1 - G Eh&S Eh&S P: Scaffolding 25-010540Document19 pagesV 1 - G Eh&S Eh&S P: Scaffolding 25-010540Bhavanishankar ShettyNo ratings yet

- Project: Brooklyn School of Inquiry (K) Site: 50 Avenue P, Brooklyn, Ny 11204 CONTRACT NO: C000014965Document8 pagesProject: Brooklyn School of Inquiry (K) Site: 50 Avenue P, Brooklyn, Ny 11204 CONTRACT NO: C000014965Rahul PillaiNo ratings yet

- Nokia 5 Schematics (Phonelumi - Com)Document92 pagesNokia 5 Schematics (Phonelumi - Com)Karan MataleNo ratings yet

- EASiPacer OCSS IN 1046225ADocument20 pagesEASiPacer OCSS IN 1046225Aangelbendito34No ratings yet

- INCO-MS-PIP-0009-SAFE WORK Method Statement For Piping Support FabricationDocument8 pagesINCO-MS-PIP-0009-SAFE WORK Method Statement For Piping Support FabricationHichem BklNo ratings yet

- User Guide: SZ16-ZN/EN-A03Document36 pagesUser Guide: SZ16-ZN/EN-A03Cohen SimulationNo ratings yet

- GEA DryCoolers InstalationDocument28 pagesGEA DryCoolers InstalationArif BinorikaNo ratings yet

- Solar PV Methodology - BRIDocument20 pagesSolar PV Methodology - BRI2020dlb121685No ratings yet

- Installation Guide: MO-L Series MonitorsDocument21 pagesInstallation Guide: MO-L Series MonitorsphyothuyazinNo ratings yet

- PPPPP PDFDocument98 pagesPPPPP PDFValeria CalleNo ratings yet

- TP-270H User Manual de Instalacion Duplicadores by SolidParkingDocument43 pagesTP-270H User Manual de Instalacion Duplicadores by SolidParkingAtzopNo ratings yet

- T Series Spreading System: 使用说明 User GuideDocument19 pagesT Series Spreading System: 使用说明 User GuideLuis Anibal Contreras DuranNo ratings yet

- Central Station Air Handling Units 39 GDocument27 pagesCentral Station Air Handling Units 39 Gthanh_79No ratings yet

- WMS Infineon Project Tower (HT HV Cabling Work) - Rev-1Document6 pagesWMS Infineon Project Tower (HT HV Cabling Work) - Rev-1tanaNo ratings yet

- Your Ultimate Guide To Choosing The Best Drone PCBDocument9 pagesYour Ultimate Guide To Choosing The Best Drone PCBjackNo ratings yet

- #3 .Bạt VJC A320 Installation Instr V.04.01-1Document18 pages#3 .Bạt VJC A320 Installation Instr V.04.01-1Hiếu Đồng MinhNo ratings yet

- Hikvision ITS Traffic Flow Detection TCD203-A Installation Guide201809Document23 pagesHikvision ITS Traffic Flow Detection TCD203-A Installation Guide201809Luis Fernando López MuñozNo ratings yet

- METHOD STATEMENT of Table Formwork PDFDocument18 pagesMETHOD STATEMENT of Table Formwork PDFMade GileeNo ratings yet

- 7XT71xx Manual A5 en de HW DDDocument84 pages7XT71xx Manual A5 en de HW DDAlberto José Bermúdez AriasNo ratings yet

- EGN UIX10202 - Rapidsor Falsework PDFDocument5 pagesEGN UIX10202 - Rapidsor Falsework PDFSayed Diab AlsayedNo ratings yet

- BlueMAX Cirrus Perspective Install Quick Ref Guide R2Document9 pagesBlueMAX Cirrus Perspective Install Quick Ref Guide R2herik meloNo ratings yet

- Operation & Instruction Manual Om 1270 50 FTDocument830 pagesOperation & Instruction Manual Om 1270 50 FTAriel Avalos100% (1)

- Millennium 3: User'S ManualDocument26 pagesMillennium 3: User'S Manualartur silvaNo ratings yet

- CT Trench PDFDocument17 pagesCT Trench PDFradinalNo ratings yet

- MOS AG Drainage SystemDocument22 pagesMOS AG Drainage SystemAdrianaChivuNo ratings yet

- Spare Parts List: Asphalt and Concrete Cutter T400001Document22 pagesSpare Parts List: Asphalt and Concrete Cutter T400001Tadas PNo ratings yet

- 7SG11 Argus 8 Technical Manual Chapter 6 InstallationDocument6 pages7SG11 Argus 8 Technical Manual Chapter 6 InstallationbitshitassNo ratings yet

- Aps Advance RVC Audi A3 8v EnglischDocument12 pagesAps Advance RVC Audi A3 8v Englischpamiki28No ratings yet

- ID Fan ManualDocument25 pagesID Fan Manualkamatamogh80% (5)

- Rittal 3245500 Anleitung 3 4847Document20 pagesRittal 3245500 Anleitung 3 4847esicafgNo ratings yet

- DIS 3.6 Lifting Ops.Document18 pagesDIS 3.6 Lifting Ops.Ashraf Ismail HassenNo ratings yet

- XYLEM - Type XA ModulesDocument62 pagesXYLEM - Type XA Modulessindalisindi100% (2)

- Perform With Precision: Box Culvert TravelerDocument14 pagesPerform With Precision: Box Culvert Traveler魏雨辰No ratings yet

- ECP External Casing Packer - Operating Procedure 181113Document15 pagesECP External Casing Packer - Operating Procedure 181113Игорь КачалинNo ratings yet

- Tooling Standards Manual: MouldsDocument36 pagesTooling Standards Manual: Mouldsandre boniniNo ratings yet

- ClickFit EVO Universal Roof HookDocument27 pagesClickFit EVO Universal Roof HookBORBEL ADRIANNo ratings yet

- Assmbly Distribution ST PDFDocument20 pagesAssmbly Distribution ST PDFadiamiruNo ratings yet

- DOMINO Kasutusjuhend ENGDocument68 pagesDOMINO Kasutusjuhend ENGOvidiu HolocNo ratings yet

- Technical Specifications (MES SPEC - NO.17T6017-SP)Document80 pagesTechnical Specifications (MES SPEC - NO.17T6017-SP)uun jayasaputraNo ratings yet

- Switchboard & PanelboardDocument8 pagesSwitchboard & PanelboardWalidNo ratings yet

- Pro Wedge XL Manual PDFDocument36 pagesPro Wedge XL Manual PDFGiordano ArgentaNo ratings yet

- 72 Operation ManualDocument136 pages72 Operation ManualChristopher M ChenNo ratings yet

- 2.manual TC 110 KV 70788001 - 05Document17 pages2.manual TC 110 KV 70788001 - 05Pop GabrielNo ratings yet

- Man FX60 A FX130 9828093385 Ed 00 (EN)Document18 pagesMan FX60 A FX130 9828093385 Ed 00 (EN)Jarvis MillareNo ratings yet

- TJ Full Cage Kit Install: Parts ListDocument7 pagesTJ Full Cage Kit Install: Parts ListMark BarberaNo ratings yet

- Small Unmanned Fixed-wing Aircraft Design: A Practical ApproachFrom EverandSmall Unmanned Fixed-wing Aircraft Design: A Practical ApproachNo ratings yet

- D - Internet - Myiemorgmy - Intranet - Assets - Doc - Alldoc - Document - 11756 - List of Ebooks IEM Library PDFDocument54 pagesD - Internet - Myiemorgmy - Intranet - Assets - Doc - Alldoc - Document - 11756 - List of Ebooks IEM Library PDFAsyraf ZaidiNo ratings yet

- Bahria University (Karachi Campus) : Midterm Assessment Assignment Spring 2020Document4 pagesBahria University (Karachi Campus) : Midterm Assessment Assignment Spring 2020osaidahmedNo ratings yet

- HSE-Method Statement ScaffoldingDocument32 pagesHSE-Method Statement ScaffoldingihsanNo ratings yet

- Pattern MaterialsDocument16 pagesPattern MaterialsMani Kandan100% (1)

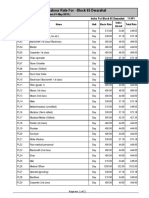

- Block 65 Dwarahat - ResourceRate - LabourDocument2 pagesBlock 65 Dwarahat - ResourceRate - LabourManojNo ratings yet

- MCC - Remaining Works To CompleteDocument1 pageMCC - Remaining Works To CompleteRhannie GarciaNo ratings yet

- Ma022016 Dupa 01Document171 pagesMa022016 Dupa 01Irene Ionie Rarangol - TengcoNo ratings yet

- Rencana Penugasan PersonilDocument1 pageRencana Penugasan PersonilKONSULTAN RELOKASI RTGNo ratings yet

- Concrete Beam Design (CSA A23.1-94)Document2 pagesConcrete Beam Design (CSA A23.1-94)marijean catuiraNo ratings yet

- TDS Conbextra GP2 India6Document4 pagesTDS Conbextra GP2 India6SK MadhavanNo ratings yet

- Sample BOQDocument2 pagesSample BOQJose Wilberto CarreteroNo ratings yet

- Chapter-5 Tank DesignDocument36 pagesChapter-5 Tank Designkassahun kebede100% (1)

- Design of One-Way SlabDocument4 pagesDesign of One-Way SlabAnton_Young_1962No ratings yet

- Oilite CatalogueDocument26 pagesOilite CatalogueghanNo ratings yet

- Design Principle of Rockbolting: Harshil Bhatt Manisha Meena Manik BadhwarDocument6 pagesDesign Principle of Rockbolting: Harshil Bhatt Manisha Meena Manik BadhwarMuhammad Saqib JanNo ratings yet

- Clamp Design 7F9BEDocument3 pagesClamp Design 7F9BECivil StructureNo ratings yet

- NMB Rwhp4a Pip Bod 40000 - 01 SFSB Commented Code BDocument38 pagesNMB Rwhp4a Pip Bod 40000 - 01 SFSB Commented Code BChanNo ratings yet

- Harmor" The Linking: Mi TureDocument5 pagesHarmor" The Linking: Mi TureRawan ShalaldehNo ratings yet

- XPS and Foam BoardDocument6 pagesXPS and Foam BoarddantranzNo ratings yet

- Okazaki2 PDFDocument85 pagesOkazaki2 PDFMouy PhonThornNo ratings yet

- Checklist For Inspection of Bridges by Bridge Line UnitsDocument3 pagesChecklist For Inspection of Bridges by Bridge Line UnitsSSE Bridge SSBNo ratings yet

- Summary Sheet For Boq ScheduleDocument29 pagesSummary Sheet For Boq ScheduleHesham HassanNo ratings yet

- XV703G XV703G XV703G XV703G Mod: Mod: Mod: ModDocument2 pagesXV703G XV703G XV703G XV703G Mod: Mod: Mod: ModСергей ГрибановNo ratings yet

- Development of Modular Insulated Sandwich Wall Panel Using Nylon-Fiber-Reinforced Styrocrete As Core LayerDocument2 pagesDevelopment of Modular Insulated Sandwich Wall Panel Using Nylon-Fiber-Reinforced Styrocrete As Core LayerChristine Joyce BunyiNo ratings yet

- Inspection & Test Plan Revision: 0 Project: Owner: Location: Contract/PO No.: Engineer(s) : QA/QC Phase: Structural SteelDocument2 pagesInspection & Test Plan Revision: 0 Project: Owner: Location: Contract/PO No.: Engineer(s) : QA/QC Phase: Structural SteelmetroroadNo ratings yet

- 1 - Interior Blank BQ - Built in Furniture 7th Jan 2022Document8 pages1 - Interior Blank BQ - Built in Furniture 7th Jan 2022Aleki Desu100% (1)

- Effects of Low Temperatures On Flexural Strength of Macro-Synthetic Fiber Reinforced Concrete: Experimental and Numerical InvestigationDocument14 pagesEffects of Low Temperatures On Flexural Strength of Macro-Synthetic Fiber Reinforced Concrete: Experimental and Numerical InvestigationMaría DiazNo ratings yet

- Theory Building Analysis EtabsDocument9 pagesTheory Building Analysis Etabssaumya shresthaNo ratings yet

- Fema306 PDFDocument270 pagesFema306 PDFSuhas MangaloreNo ratings yet

- Design Basis Report PDFDocument3 pagesDesign Basis Report PDFakash_solanki_7No ratings yet