Professional Documents

Culture Documents

Package 4 Pavement Design

Uploaded by

Sumit JainOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Package 4 Pavement Design

Uploaded by

Sumit JainCopyright:

Available Formats

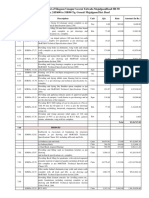

Flexible Pavement Design - Base Data

Name of work Improvement Improvement of Roads in the Osmanabad

District in Maharashtra State for Two laning road / Two

Laning road with paved shoulders under MRIP Package AU-

L1 on Hybrid Annuity Mode.

Carriageway width Two lane

Classification of road MDR

Design life 15

Initial traffic (A) (in both 1161

direction) (CVD)

Traffic growth rate 5

Year of traffic census 2019

Terrain Plain

Current year 2021

Construction period 2

CBR Values of subgrade used for Yes

calculcation of 80th Percentile 10.1,10,10.2,10.2,10.3

CBR Calcuation

80th Percentile CBR 10.3

Whether subgrade to be replace No

with borrow material

CBR of select sub grade (borrow NA

material)

Whether stage construction No

involved

If yes, life of bituminous layers 5 Years

Grade of Bitumen for wearing VG40

course and binder course

Initial Traffic after completion of =1161x(1+5%)^(2+2)x1

construction

Both Side Traffic 1411 CVD

TNHD_Pave_V 5.0 1/6 Released in - Aug.2019

Flexible Pavement Design - Base Data

Whether Axle Load Survey Yes

conducted?

If yes, VDF value from Axle Load 3.6

Survey

Vehicle Damage Factor used for 3.6

design traffic

Lane Distribution Factor 0.5

Design Traffic =365 * ( (1+r)^n - 1) * A * D * F )/ r

For 15 Years =365x((1+0.05)^15-1)x1411x0.5x3.6/0.05/1000000

20.00 MSa

For 5 Years =365x((1+0.05)^5-1)x1411x0.5x3.6/0.05/1000000/0.60

8.54 MSa

% volume of air voids (Va) to be 3.5

adopted in DBM

% volume of bitumen (Vb) to be 11.5

adopted in DBM

Type of Binder Course Adopted DBM

Stage construction can be

adopted

Rate of DBM used for cost

analysis

Note:

Stage construction can be adopted

TNHD_Pave_V 5.0 2/6 Released in - Aug.2019

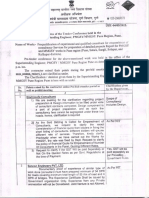

Percentile

80th and 90th percentile CBR values

Entered CBR Values

10.1,10,10.2,10.2,10.3

120

100

90 0 1.1259E+13 0

80

90 1.1259E+13 1.1259E+13 90

Percentile ---->

80 0 5.6295E+12 0

60

80 5.6295E+12 5.6295E+12 80

40

y =20-3333.3x3 + 101000x2 - 1E+06x + 3E+06

0

0 5E+12 1E+13 1.5E+13

CBR ---->

Equation of the CBR graph is y = -3333.3x3 + 101000x2 - 1E+06x + 3E+06

a b c d

-3333.3 +101000 -1E+06 + 3E+06

-4.75744E+42

-5.94681E+41

CBR values for 90 80

10.30 10.30

TNHD_Pave_V 5.0 3/6 Released in - Aug.2019

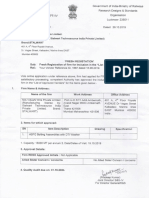

Design of flexible pavement - strain check

Improvement Improvement of Roads in the Osmanabad District in Maharashtra State for Two laning road /

Two Laning road with paved shoulders under MRIP Package AU-L1 on Hybrid Annuity Mode.

Design CBR = 10.3

Poisons ratio for cemented layers 0.25

Poisons ratio for all the other layers 0.35

Assumed Layer thickness for 1.Granular Base and Granular Subbase

BC = 40 110 Thickness of BC & DBM

DBM = 70

WMM = 250 450 Thickness of GSB + WMM

GSB = 200

560

MSA 20.00 Bitumen layer IITPAVE to be run for 3 layer analysis

20.00 Granular layer

5 Yrs with Factor = 8.54 5 Yrs = 5.12

15 Yrs = 20.00

20 Yrs = 20.00

Resilient modulus (M)

2

M Subgrade = 10*CBR For CBR <= 5 MR Eff = 2*(1-m )pa/d

= 17.6*(CBR) 0.64

For CBR > 5 m 0.35 Poisson's ration

MR Eff = 17.6x10.3^0.64 p 0.56 contact pressure

= 78.29

M Granular = 0.2 x E subgrade x h^0.45 a 150.8 Radius of circular

= 244.727019 contact area

M Granular = 245 d surface deflection

from IITPave

DBM MR of Bituminous layers

For BM Table 9.2 of IRC 37-2018 (For DBM)

2300 VG10 Temp 20oC

500 2000 VG10 Temp 25oC

M Bitumen = 3000 700 2000 VG30 Temp 35oC

3000 VG40 Temp 35oC

TNHD_Pave_V 5.0 4/6 Released in - Aug. 2019

Allowable Strain Calculation

Horizontal Tensile Strain at the bottom of the bituminous layers

Calculation of Tensile strain

Nf = 1.6064 x C x 10^ - 4 x {1/εt}^3.89 x [1/MR]^0.854 for 80 % reliability

Nf = 0.5161 x C x 10^ - 4 x {1/εt}^3.89 x [1/MR]^0.854 for 90 % reliability

Where C = 10^M, M=(4.84x (Vb /(Va+Vb)-0.69))

Va = 3.5 Vb = 11.5

1/εt = 4435.56326 #VALUE!

εt = 225.45E-06 (90%) Allowable Tensile strain

εt

Horizontal Tensile Strain at the bottom of the cemented base

Not Applicable

N= RF x [ (113000/E0.804+191) / εt ]12 RF = 1 if >1500 CVD and 2 if <1500 CVD

N= N/A

1/εt = N/A

εt = N/A in microstrain

εt = 000.00E+00 Allowable Tensile strain

Vertical Compresive Strain at the bottom of the Granular sub base

Calculation of Vertical strain

N = 4.1656*10^-8*(1/εv)^4.5337 for 80 % reliability

N = 1.41*10^-8*(1/εv)^4.5337 for 90 % reliability

1/εv = (20000000/(4.1656*10^-8))^(1/4.5337)

1/εv = 1730.89891

εv = 577.73E-06 (90%) Allowable Vertical strain

Comparison of allowable strain with actual strain(from IITPAVE)

Values given below are micro strain

Allowable Actual

Tensile strain at the bottom of bituminous layers 225 micro Strain 349 micro Strain

0 micro Strain 0 micro Strain

Vertical compressive strain at the top of Sub grade 578 micro Strain 523 micro Strain

The section is unsafe in tension at bottom of bituminous layer

The section is safe under compressive strain check

TNHD_Pave_V 5.0 5/6 Released in - Aug. 2019

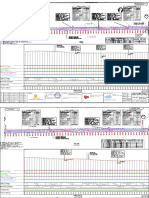

IITPAVE Result

No. of layers 3

E values (MPa) 2000.00 157.00 50.38

Mu values 0.350.350.35

thicknesses (mm) 105.00 450.00

single wheel load (N) 20000.00

tyre pressure (MPa) 0.56

Dual Wheel

Z R SigmaZ SigmaT SigmaR TaoRZ DispZ epZ epT epR

105.00 0.00-0.1705E+00 0.8875E+00 0.7097E+00-0.1848E-01 0.6282E+00-0.3648E-03 0.3494E-03 0.2294E-03

105.00L 0.00-0.1705E+00-0.1492E-01-0.2888E-01-0.1848E-01 0.6282E+00-0.9882E-03 0.3494E-03 0.2294E-03

105.00 155.00-0.1349E+00 0.6692E+00 0.1365E+00-0.7644E-01 0.6402E+00-0.2084E-03 0.3343E-03-0.2526E-04

105.00L 155.00-0.1349E+00-0.1439E-01-0.5621E-01-0.7644E-01 0.6402E+00-0.7017E-03 0.3343E-03-0.2526E-04

555.00 0.00-0.2319E-01 0.3372E-01 0.2879E-01-0.3974E-02 0.4193E+00-0.2870E-03 0.2023E-03 0.1599E-03

555.00L 0.00-0.2322E-01 0.2322E-02 0.7455E-03-0.3972E-02 0.4193E+00-0.4823E-03 0.2023E-03 0.1600E-03

555.00 155.00-0.2501E-01 0.3617E-01 0.3281E-01-0.5417E-02 0.4315E+00-0.3130E-03 0.2130E-03 0.1841E-03

555.00L 155.00-0.2500E-01 0.2457E-02 0.1390E-02-0.5406E-02 0.4315E+00-0.5230E-03 0.2128E-03 0.1842E-03

TNDB_Pave_V 5.0 6/6 Output from IITPave

You might also like

- Highways Department: Enable Macros To Use This ApplicationDocument17 pagesHighways Department: Enable Macros To Use This Applicationk.shanmuganathan100% (1)

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkFrom EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNo ratings yet

- Ottankadu - Punalvasal - SafeDocument6 pagesOttankadu - Punalvasal - SafeRenugopalNo ratings yet

- Poovalur - Neiveli - SafeDocument6 pagesPoovalur - Neiveli - SafeRenugopalNo ratings yet

- Flexible Pavement DesignDocument6 pagesFlexible Pavement DesignRenugopalNo ratings yet

- Highways Department: Enable Macros To Use This ApplicationDocument14 pagesHighways Department: Enable Macros To Use This Applicationveevimal100% (1)

- Highways Department: Enable Macros To Use This ApplicationDocument14 pagesHighways Department: Enable Macros To Use This ApplicationrahmangisNo ratings yet

- Flexible Pavement Design - Base DataDocument6 pagesFlexible Pavement Design - Base DataRenugopalNo ratings yet

- Kuruchi - Poovalur - SafeDocument6 pagesKuruchi - Poovalur - SafeRenugopalNo ratings yet

- Flexible Pavement Design - Base DataDocument6 pagesFlexible Pavement Design - Base DataveevimalNo ratings yet

- Unsafe Design TNHD - PaveDocument17 pagesUnsafe Design TNHD - Pavek.shanmuganathanNo ratings yet

- Flexible Pavement Design - Base Data: Upgradation of Udhayathur - Ilaiyanainarkulam RoadDocument6 pagesFlexible Pavement Design - Base Data: Upgradation of Udhayathur - Ilaiyanainarkulam RoadsheikNo ratings yet

- Thanjavur Vallam 4.6 SafeDocument6 pagesThanjavur Vallam 4.6 SafeRenugopalNo ratings yet

- Flexible Pavement Design AnalysisDocument6 pagesFlexible Pavement Design AnalysisRenugopalNo ratings yet

- Design Pmgsy WideningDocument5 pagesDesign Pmgsy WideningDaljeet SidhuNo ratings yet

- Flexible Pavement Design AnalysisDocument5 pagesFlexible Pavement Design AnalysisDaljeet SidhuNo ratings yet

- Flexible Pavement-Design ReportDocument4 pagesFlexible Pavement-Design ReportPraveen KumarNo ratings yet

- Kasiana Lang 18ftDocument5 pagesKasiana Lang 18ftDaljeet SidhuNo ratings yet

- FLEX_PAVE_DESIGNDocument6 pagesFLEX_PAVE_DESIGNYazer ArafathNo ratings yet

- I B Udaiyr 4,2 - 4,9slDocument6 pagesI B Udaiyr 4,2 - 4,9slveevimalNo ratings yet

- Flex_Pave_StrainDocument6 pagesFlex_Pave_StrainRenugopalNo ratings yet

- Flexible Pavement Design - Base Data: Improvements of Bhuvanagiri - Melamanagudi Road at KM 2/0-3/0Document6 pagesFlexible Pavement Design - Base Data: Improvements of Bhuvanagiri - Melamanagudi Road at KM 2/0-3/0veevimalNo ratings yet

- Flexible Pavement Design - Base DataDocument5 pagesFlexible Pavement Design - Base DataDr. Daljeet Singh SidhuNo ratings yet

- 1152 CE F244 Comprehensive Exam Question PaperDocument4 pages1152 CE F244 Comprehensive Exam Question PaperMUDIT SHARMANo ratings yet

- Flexible PavementDocument21 pagesFlexible PavementBijay Kumar PattnaikNo ratings yet

- Pavement Design IRC 37 2012Document1 pagePavement Design IRC 37 2012ashoknrNo ratings yet

- 1.0. Scope of ContractDocument23 pages1.0. Scope of Contractkajale.shrikantNo ratings yet

- RoadDocument11 pagesRoadShafiek IsmailNo ratings yet

- Stochastic in Highway EngineerDocument38 pagesStochastic in Highway EngineerDonlot DonlotanNo ratings yet

- Flexible Pavement Design for Batinah Expressway Service RoadsDocument4 pagesFlexible Pavement Design for Batinah Expressway Service RoadsRonald Yucra HuillcaNo ratings yet

- NTPC Coal Project Price ScheduleDocument3 pagesNTPC Coal Project Price ScheduleAnonymous R0s0Nd6yNo ratings yet

- Design Consideration: (For Flexible Pavement)Document8 pagesDesign Consideration: (For Flexible Pavement)Ashis MingalaNo ratings yet

- Ksksksks KSKSKSK Ksksks KSKSK Ksks KSK KS: Wheels For Railway Rolling StockDocument10 pagesKsksksks KSKSKSK Ksksks KSKSK Ksks KSK KS: Wheels For Railway Rolling StockNurdiansyahNo ratings yet

- Flexible Pavement Design Calculation Spreadsheet According To AASHTODocument45 pagesFlexible Pavement Design Calculation Spreadsheet According To AASHTOMohammed AL-sharafi100% (2)

- Rigid Pavement Design (1) 1Document4 pagesRigid Pavement Design (1) 1tai tahuNo ratings yet

- Link Budget CdmaDocument12 pagesLink Budget CdmaRayne SalsabilaNo ratings yet

- Pavement Design Report r2Document7 pagesPavement Design Report r2nzhazmiNo ratings yet

- Pavement Layer DesignDocument3 pagesPavement Layer DesignmarieojikenNo ratings yet

- Standard Design CBR 5 to 6 Strength EstimateDocument1 pageStandard Design CBR 5 to 6 Strength EstimateAmit KumarNo ratings yet

- Asphalt Killers Chat PresentationDocument72 pagesAsphalt Killers Chat PresentationLeonardo BittencourtNo ratings yet

- 001 R0 RNT Design of Closed PortionDocument37 pages001 R0 RNT Design of Closed PortionrohanZorbaNo ratings yet

- Datas 22-23Document76 pagesDatas 22-23gkkmailzNo ratings yet

- IRC-58-2015-for Pakhdeva Kokha MargDocument9 pagesIRC-58-2015-for Pakhdeva Kokha MargRam Samujh SharmaNo ratings yet

- Flexible Pavement Design PMGSY As Per IRC 72Document2 pagesFlexible Pavement Design PMGSY As Per IRC 72Mayuri ShahNo ratings yet

- Compliance Report On DPR S-KDocument9 pagesCompliance Report On DPR S-KGurram Lakshmi NavakanthNo ratings yet

- 932010123628PM1Vol II Des Traffic Feild Data PDFDocument109 pages932010123628PM1Vol II Des Traffic Feild Data PDFMohammed Zuber InamdarNo ratings yet

- Deformations Calculation and Control IIDocument7 pagesDeformations Calculation and Control IIMário RosaNo ratings yet

- Perkerasan KakuDocument5 pagesPerkerasan KakuTeknik SipilNo ratings yet

- Pavement Design Excel SheetDocument23 pagesPavement Design Excel Sheetharishreddy198571% (17)

- Simplified Procedure For Estimating Liquefaction Induced SettlementsDocument10 pagesSimplified Procedure For Estimating Liquefaction Induced SettlementsSamiul IslamNo ratings yet

- Track Monitoring: An Over View On Indian RailwayDocument135 pagesTrack Monitoring: An Over View On Indian RailwaySAROJ KUMAR BISWAL100% (1)

- Pavement Design WMM Stablized Iit Pave1 TTDocument16 pagesPavement Design WMM Stablized Iit Pave1 TTmineNo ratings yet

- M-N 12-16 Estimate 20.07.2022Document92 pagesM-N 12-16 Estimate 20.07.2022Happy HourNo ratings yet

- Model GP Building EstimateDocument153 pagesModel GP Building Estimate8790922772No ratings yet

- Timken TDO Bearing SpecsDocument5 pagesTimken TDO Bearing Specsjose.villanuevaNo ratings yet

- AASHTO flexible pavement design equationDocument22 pagesAASHTO flexible pavement design equationDiyoke Henry100% (1)

- Instructions To Students:: EEPB353 / EPPB3014 - Power System I Semester 1 - 2021/22 Computer Assignment - Power FlowDocument6 pagesInstructions To Students:: EEPB353 / EPPB3014 - Power System I Semester 1 - 2021/22 Computer Assignment - Power FlowVishal Vishal SathiaseelanNo ratings yet

- Pavement Design For NR-1Document50 pagesPavement Design For NR-1Phearüm PotNo ratings yet

- All Geotechnical ParametersDocument12 pagesAll Geotechnical ParametersBinha VargheseNo ratings yet

- AUX 10 Cost Estimate - 14-16Document3 pagesAUX 10 Cost Estimate - 14-16Sumit JainNo ratings yet

- M Tech-I Sem Exam Dec 2021: MTHE-0105Document1 pageM Tech-I Sem Exam Dec 2021: MTHE-0105Sumit JainNo ratings yet

- Nut Bolt QutatotionDocument1 pageNut Bolt QutatotionSumit JainNo ratings yet

- Eprocurement System Government of Maharashtra: Bids ListDocument4 pagesEprocurement System Government of Maharashtra: Bids ListSumit JainNo ratings yet

- Tech Prebid 1365019Document3 pagesTech Prebid 1365019Sumit JainNo ratings yet

- 18H020B PLAN & PROFILE (3+000 To 12+000)Document12 pages18H020B PLAN & PROFILE (3+000 To 12+000)Sumit JainNo ratings yet

- Project Title:-: Independent EngineerDocument1 pageProject Title:-: Independent EngineerSumit JainNo ratings yet

- Approval for Piers P2-P6 Design of Kapileshwar FootbridgeDocument1 pageApproval for Piers P2-P6 Design of Kapileshwar FootbridgeSumit JainNo ratings yet

- RDSO Approval LetterDocument1 pageRDSO Approval LetterSumit JainNo ratings yet

- Swami Vivekanand University Highway Engineering SyllabusDocument36 pagesSwami Vivekanand University Highway Engineering SyllabusSumit JainNo ratings yet

- Pack-2 Reivesd ChangesDocument1 pagePack-2 Reivesd ChangesSumit JainNo ratings yet

- STN (Iiitt, QQRQ (") Ii1Rrtg7Fi'"Jlc6T, - , RLGD R) Qfrs (, "F Irft - Fts-Y??Qoq IDocument4 pagesSTN (Iiitt, QQRQ (") Ii1Rrtg7Fi'"Jlc6T, - , RLGD R) Qfrs (, "F Irft - Fts-Y??Qoq ISumit JainNo ratings yet

- Profile: To Pathardi To Navgaon RajuriDocument6 pagesProfile: To Pathardi To Navgaon RajuriSumit JainNo ratings yet

- PACKAGE - 2 14 TO 21 & 32 TO 44 KM LAYOUT 16082021 New UpdateDocument24 pagesPACKAGE - 2 14 TO 21 & 32 TO 44 KM LAYOUT 16082021 New UpdateSumit JainNo ratings yet

- Package 4 Pavement DesignDocument6 pagesPackage 4 Pavement DesignSumit JainNo ratings yet

- Acculead Acculead: Osd-Beed-Latur Au-1 Stateways Private Limited. Osd-Beed-Latur Au-1 Stateways Private LimitedDocument2 pagesAcculead Acculead: Osd-Beed-Latur Au-1 Stateways Private Limited. Osd-Beed-Latur Au-1 Stateways Private LimitedSumit JainNo ratings yet

- Omega: ConsultantDocument7 pagesOmega: ConsultantSumit JainNo ratings yet

- To Pathardi To Navgaon Rajuri: Project TitleDocument23 pagesTo Pathardi To Navgaon Rajuri: Project TitleSumit JainNo ratings yet

- Parli To Bardapur Pacakage - 3-17-21Document4 pagesParli To Bardapur Pacakage - 3-17-21Sumit JainNo ratings yet

- Omega: Consultant ServicesDocument7 pagesOmega: Consultant ServicesSumit JainNo ratings yet

- Package-3 17-18Document2 pagesPackage-3 17-18Sumit JainNo ratings yet

- SR. DRG - No Drawing Title REV-0 REV-1 NO. Date DateDocument2 pagesSR. DRG - No Drawing Title REV-0 REV-1 NO. Date DateSumit JainNo ratings yet

- Omega: ServicesDocument7 pagesOmega: ServicesSumit JainNo ratings yet

- Omega Laboratory Test ReportDocument7 pagesOmega Laboratory Test ReportSumit JainNo ratings yet

- Hydrological Analysis: Bed Slope/Longitudinal Slope/ StreamDocument6 pagesHydrological Analysis: Bed Slope/Longitudinal Slope/ StreamSumit JainNo ratings yet

- Earth Work Filling-NSK 165 Recap Sheet Work Chainage Sr. No. Lead Chart Drw. SideDocument1 pageEarth Work Filling-NSK 165 Recap Sheet Work Chainage Sr. No. Lead Chart Drw. SideSumit JainNo ratings yet

- Omega: ServicesDocument7 pagesOmega: ServicesSumit JainNo ratings yet

- SR - No. Description Rate UnitDocument52 pagesSR - No. Description Rate UnitSumit JainNo ratings yet

- Hydrological Analysis: Bed Slope/Longitudinal Slope/ StreamDocument5 pagesHydrological Analysis: Bed Slope/Longitudinal Slope/ StreamSumit JainNo ratings yet

- VIN and parts list for ZH5CR0005H1000001 motorcycleDocument41 pagesVIN and parts list for ZH5CR0005H1000001 motorcycleMassi's ShedNo ratings yet

- Island Venture: Offshore Construction / Intervention VesselDocument2 pagesIsland Venture: Offshore Construction / Intervention VesselTra TopoNo ratings yet

- BMW DME Synchronization GuideDocument1 pageBMW DME Synchronization Guideonukvedat7219No ratings yet

- The Titanic Critical ReviewDocument2 pagesThe Titanic Critical Reviewmariette tayabanNo ratings yet

- Ustsites DLDocument2,112 pagesUstsites DLsdfNo ratings yet

- Reach Truck rd5700 Spec GBDocument6 pagesReach Truck rd5700 Spec GBWhina Mantu drmjNo ratings yet

- Sena Corridor – The route to economic growthDocument2 pagesSena Corridor – The route to economic growthFrank ChirwaNo ratings yet

- Traffic Actions For The Design of Roadway Bridges: A Comparison of International CodesDocument15 pagesTraffic Actions For The Design of Roadway Bridges: A Comparison of International CodesKrishna KadiyamNo ratings yet

- TSM 26 SdcuDocument3 pagesTSM 26 SdcuWaleed HassanNo ratings yet

- If The Ledge of 3 MTR Is Maintained On Galhar Side, The Ledge Available On Dul Side Is ZeroDocument75 pagesIf The Ledge of 3 MTR Is Maintained On Galhar Side, The Ledge Available On Dul Side Is ZeroAaron WilsonNo ratings yet

- Pour Card FormatsDocument11 pagesPour Card FormatsPraful N KNo ratings yet

- Dokumen Keselamatan Pengawakan Minimum No:: Minimum Safe Manning DocumentDocument2 pagesDokumen Keselamatan Pengawakan Minimum No:: Minimum Safe Manning DocumentAlfilia KhoirunnisaNo ratings yet

- Pidato Singkat Bahasa InggrisDocument2 pagesPidato Singkat Bahasa InggrisMoh Lizamudin TauhidNo ratings yet

- Digital Electronics ProjectDocument14 pagesDigital Electronics ProjectSana KhanNo ratings yet

- OJT AppDocument3 pagesOJT AppSaaddudin PaunteNo ratings yet

- K-06 A07 BIG UTAMA SMK Exam InsightsDocument13 pagesK-06 A07 BIG UTAMA SMK Exam InsightsAlfina RahmawatiNo ratings yet

- XC60 Owners Manual MY11 en-GB Tp18267Document430 pagesXC60 Owners Manual MY11 en-GB Tp18267nagyzoltan077No ratings yet

- Build Sheet ServletDocument7 pagesBuild Sheet ServletVictor PopescuNo ratings yet

- Conditional Sentence (Exercise)Document2 pagesConditional Sentence (Exercise)annisa alyaNo ratings yet

- Geography Presentation #1 (Friday) Trans Mountain Oil Pipeline SystemDocument1 pageGeography Presentation #1 (Friday) Trans Mountain Oil Pipeline Systemfaraz909No ratings yet

- Business Class M2 Workshop Manual-3-2Document145 pagesBusiness Class M2 Workshop Manual-3-2Dinator CortésNo ratings yet

- Airport Engineering (Runway Design) : BITS PilaniDocument117 pagesAirport Engineering (Runway Design) : BITS PilaniGaurav PanwarNo ratings yet

- Cayman Registry Master's Handbook 2020Document46 pagesCayman Registry Master's Handbook 2020Richard Kershaw100% (1)

- Air Algerie Confirmation SAID ZIANI L9TV38Document2 pagesAir Algerie Confirmation SAID ZIANI L9TV38ziani1976No ratings yet

- GTO CGK: Lawenga / Sarlin MrsDocument2 pagesGTO CGK: Lawenga / Sarlin MrsMohammad ArchandraNo ratings yet

- Massas Nova Ford CustomDocument69 pagesMassas Nova Ford CustomPedroCosta87No ratings yet

- iVoomi Service Center Locations ListDocument34 pagesiVoomi Service Center Locations ListDaniel AbrahamNo ratings yet

- Automated TransmissionsDocument33 pagesAutomated TransmissionsHERNAN CORTEZ FARFANNo ratings yet

- Single Stage Belt Drive CompressorsDocument4 pagesSingle Stage Belt Drive Compressorsvictor AnanthNo ratings yet

- Leonardo 125Document88 pagesLeonardo 125Miroslaw Gabalix GabalisNo ratings yet