Professional Documents

Culture Documents

Macalloy S650 May 2020 V5

Uploaded by

bradenCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Macalloy S650 May 2020 V5

Uploaded by

bradenCopyright:

Available Formats

4

May 2020

Applications of Macalloy 650 Stainless

Bridge and building Mini Piles Holding down bolts

Soil Nails and Rock Bolts Strengthening and tunnel repairs

Macalloy S650 Stainless

Fully Threaded Bar Systems

Eugene Corniche Retaining Wall

This publication provides the technical details currently used by Macalloy in the manufacture of its components.

The company reserves the right to amend technical details as and where necessary in line with its policy of continuous development.

Macalloy, Caxton Way, Dinnington, Sheffield S25 3QE, U.K. Tel: +44 (0)1909 519200. Fax: +44 (0)1909 519201

Website: www.macalloy.com Email: sales@macalloy.com Email: technical@macalloy.com

is a Registered Trade Mark of McCalls Special Products Ltd.

EXPERIENCE INNOVATION QUALITY

2 3

Macalloy S650 Stainless specification

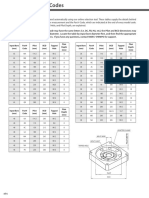

Macalloy S650 Stainless accessories

Macalloy has been the leader The Macalloy S650 Stainless has 500 63 & 75mm geotechnical

in the design, manufacture and been introduced to complement range. Table 3: Macalloy S650 Stainless Accessories

supply of threaded bar systems the existing carbon steel Macalloy

Couplers Nominal Diameter 16 20 24 29 33 36 40 50

since 1948.

Part Code 650MSC16 650MSC20 650MSC24 650MSC29 650MSC33 650MSC36 650MSC40 650MSC50

Length (L) mm 51 65 70 81 93 103 121 149

Macalloy S650 stainless bar can be end threaded only, rather than be supplied fully threaded. Outside (D) mm

Diameter

27.3 33 38.7 51.8 55 60 70 82

Table 1: Mechanical properties of Macalloy 650 Stainless Nuts Nominal Diameter 16 20 24 29 33 36 40 50

Bar diameters Minimum 0.2% proof stress Minimum ultimate tensile strength

mm N/mm2 N/mm2 Part Code 650MSN16 650MSN20 650MSN24 650MSN29 650MSN33 650MSN36 650MSN40 650MSN50

16 to 50 650 800 Full Nut Length (L) mm 22 30 32 37 40 46 50 70

Lock Nut Length (L) mm 10.4 14.4 15.4 17.4 19.4 22.4 24.4 34.4

Width A/F 31.75 38.1 44.5 55 63.5 70* 76.2* 101.6*

The System Quality Assurance *Round Nut

The Macalloy S650 Stainless is Macalloy is a quality assured Flat Plates Nominal Diameter 16 20 24 29 33 36 40 50

a high strength continuously company holding BBA

Part Code 650MSP16 650MSP20 650MSP24 650MSP29 650MSP33 650MSP36 650MSP40 650MSP50

threaded bar system. It is accreditation to BS EN ISO 9001.

available from stock in diameters The Macalloy S650 Stainless Dimensions - mm 100 x 100 x 8 125 x 125 x10 150 x 150 x 10 150 x 150 x 10 215 x 215 x 15 245 x 245 x 20 260 x 260 x 30 320 x 320 x 30

16 to 50mm. Fittings come as System is manufactured under a

standard across the range, factory control system in

standard lengths are 6 metres. accordance with this quality

regime.

For availability of 50mm please contact our Technical department.

Table 2: Range and Characteristic Loads of Macalloy 650 Stainless

Bar reference Major diameter Stress area Mass per metre Thread pitch Minimum 0.2% proof Minimum falling load Available within the Macalloy S650 Stainless Steel range are dished plate washers, pattress plates, lantern spacers and

mm mm mm2 Kg/m mm kN kN hemispherical seating. Full details available upon request.

16 17.7 176 1.60 5 114 140 Site Stressing Other Stainless Systems from

20 21.9 287 2.45 5 186 229 Hydraulic jacking equipment is Macalloy

24 25.4 380 3.48 6 247 304 available to apply load to the bars. A further stainless bar offered

Jacks are provided with gauges by Macalloy is the high strength

29 31.5 599 5.28 6 389 479

Macalloy S1030 system

33 35.5 761 7.18 6 494 608

load cell to register the force with a 0.1% proof stress of

36 40.2 978 8.50 6 635 782 exerted on the bars. In addition, 835N/mm2 and an ultimate

40 45.3 1199 10.50 8 779 959 load cells are available to give stress of 1030N/mm2. Details

50* 54.8 1860 15.86 8 1208 1487 an independent check on the of this system can be found in

* Not stocked accuracy of the pump gauge if our Macalloy Post Tensioning

Steel Quality Threads necessary. Systems brochure.

Macalloy S650 Stainless has a The coarse thread is rolled The threads are rolled on the bars

minimum characteristic yield Hand and air operated pumps are

directly onto the bar, the form is in the factory with stringent

stress after threading of controls on tolerance and form. available for the full range of

specially designed to give speed

650N/mm 2. It is available as jacks. Our site service team is

and ease of assembly. The thread Load is transferred from bar to

standard in grade 316 stainless also available to provide on-site

steel and 304 on request. gives the minimum anchorage fittings over the full circumference

stressing and training.

strengths shown in table 2. The of the bars allowing the use of

bond value of the coarse thread compact fittings. The continuous

when cast into concrete, or engineered thread provides lower

grouted into a preformed hole, coupler slip loss’s than other

provides in excess of 5N/mm2. geotechnical bars.

EXPERIENCE INNOVATION QUALITY INNOVATION QUALITY

EXPERIENCE

You might also like

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Experience Innovation Quality: Applications of Macalloy 650 StainlessDocument2 pagesExperience Innovation Quality: Applications of Macalloy 650 StainlessMaitrabarun KarjeeNo ratings yet

- Macalloy 650 Fully Threaded Bar SRGDocument4 pagesMacalloy 650 Fully Threaded Bar SRGselvan44No ratings yet

- Mac AlloyDocument16 pagesMac AlloyAnonymous u7YkrCwCNo ratings yet

- Anchor Channel Typical Product Catalogue 2019.4.9 PDFDocument43 pagesAnchor Channel Typical Product Catalogue 2019.4.9 PDFSultana KhanumNo ratings yet

- Macalloy PT BarsDocument12 pagesMacalloy PT Barsirshad khanNo ratings yet

- Carbon MFT25 to MFT50 onlyDocument12 pagesCarbon MFT25 to MFT50 onlyMaitrabarun KarjeeNo ratings yet

- SRG Global - Macalloy 1030 Stress BarDocument12 pagesSRG Global - Macalloy 1030 Stress BarbradenNo ratings yet

- Macalloy Brochure Tension Structures December - 2017 - V1Document16 pagesMacalloy Brochure Tension Structures December - 2017 - V1Isabel Christina Gonzalez MoralesNo ratings yet

- Post Tensioning System V3Document12 pagesPost Tensioning System V3akajsiNo ratings yet

- POST TENSIONING SYSTEM OVERVIEWDocument8 pagesPOST TENSIONING SYSTEM OVERVIEWjsbharadwajNo ratings yet

- Macalloy PDFDocument12 pagesMacalloy PDFmperelmuterNo ratings yet

- Macalloy 650Document4 pagesMacalloy 650Juan Garcia ArevalilloNo ratings yet

- 2016 A4 Post Tensioning 1030 Brochure FINALDocument12 pages2016 A4 Post Tensioning 1030 Brochure FINALJames MizziNo ratings yet

- Weicco India Hangers PDFDocument4 pagesWeicco India Hangers PDFAMEENNo ratings yet

- SECTIONAL PROPERTIES AND UNSYMMETRICAL BENDINGDocument4 pagesSECTIONAL PROPERTIES AND UNSYMMETRICAL BENDINGOmkarNo ratings yet

- Barras Macalloy 1030 PDFDocument12 pagesBarras Macalloy 1030 PDFchrono146No ratings yet

- New Macalloy Compression Struts BrochureDocument4 pagesNew Macalloy Compression Struts BrochureJoslyn Cachia BantickNo ratings yet

- Flexible Metal HosesDocument16 pagesFlexible Metal Hosesyoonchankim0911No ratings yet

- Macalloy Post Tensioning System GuideDocument12 pagesMacalloy Post Tensioning System GuidepandianNo ratings yet

- The Wear-Resistant SteelDocument16 pagesThe Wear-Resistant SteelredNo ratings yet

- Tie Rod BrochureDocument20 pagesTie Rod Brochuremech_abhiNo ratings yet

- SHIMS Permabloc BrochureDocument4 pagesSHIMS Permabloc BrochurehrstgaNo ratings yet

- Finite Element Analysis of Metal Matrix Composite MaterialsDocument10 pagesFinite Element Analysis of Metal Matrix Composite MaterialssnvijayanNo ratings yet

- Metalcom Manual de DisenoDocument66 pagesMetalcom Manual de DisenoJavier F. Via GiglioNo ratings yet

- Ts4040 Double Walled Brazed TubesDocument3 pagesTs4040 Double Walled Brazed TubesFCP PUNEKARNo ratings yet

- 40LCM30AA853Document1 page40LCM30AA853surya1392No ratings yet

- 2011 Heiber PV Int Review Diamond Wire Wafering Technology Meyer BurgerDocument9 pages2011 Heiber PV Int Review Diamond Wire Wafering Technology Meyer BurgerBeyza Nur AKBOLATNo ratings yet

- SP Col 200X400Document5 pagesSP Col 200X400mary joy mengulloNo ratings yet

- Macalloy 500Document4 pagesMacalloy 500Karen BarmakiNo ratings yet

- 螺丝扭力规格及标准Document4 pages螺丝扭力规格及标准smk729No ratings yet

- Pro Railing 2017Document90 pagesPro Railing 2017Peter DavidsonNo ratings yet

- Structural Use of Higher Grade Steels (S500Q & S690Q) : Koji OKI JFE Steel CorporationDocument20 pagesStructural Use of Higher Grade Steels (S500Q & S690Q) : Koji OKI JFE Steel CorporationNicholas Chin Yong LekNo ratings yet

- Schiavi Enc Met Page021Document1 pageSchiavi Enc Met Page021Adel AdelNo ratings yet

- PB Nozzles eDocument21 pagesPB Nozzles echipulinoNo ratings yet

- Section A: (Attached: BS 8110/1 CL 3.6 BS 8110/2 CL 4.2)Document21 pagesSection A: (Attached: BS 8110/1 CL 3.6 BS 8110/2 CL 4.2)Puneetkumar GargNo ratings yet

- HS FSW01 00000088aec - CDocument5 pagesHS FSW01 00000088aec - CMarcoNo ratings yet

- ASDO Structural Tie Bars Design CapDocument1 pageASDO Structural Tie Bars Design CapAjiboye MubarakNo ratings yet

- Asdo Tie Bar Design Capacities: Product DataDocument2 pagesAsdo Tie Bar Design Capacities: Product DatasivakumarNo ratings yet

- Elite Extrusion BrochureDocument13 pagesElite Extrusion BrochureSultana KhanumNo ratings yet

- Traveling BlockDocument2 pagesTraveling Blockrodon falathNo ratings yet

- General Information: 2.1. ConcreteDocument4 pagesGeneral Information: 2.1. ConcreteWilliam ProvidoNo ratings yet

- Design of Reinforced Concrete Elements: UsingDocument62 pagesDesign of Reinforced Concrete Elements: UsingISsa Qafa'itiNo ratings yet

- Motor Mounting CodesDocument4 pagesMotor Mounting CodesHARSHA PNo ratings yet

- CGTH系列Document15 pagesCGTH系列ʚʬ Thành Péo ʚʬNo ratings yet

- KOP en Technical Data SheetDocument6 pagesKOP en Technical Data SheetmcbluedNo ratings yet

- FRANK SeparadoresDocument4 pagesFRANK SeparadorespablopelaNo ratings yet

- FiltriDocument255 pagesFiltriLavinia CalinNo ratings yet

- CTOL load cells for tension and compression applicationsDocument2 pagesCTOL load cells for tension and compression applicationsSharbelNo ratings yet

- Macalloy 500Document4 pagesMacalloy 500jc100adNo ratings yet

- TDS-MY-MacTex MXC, Feb2020Document1 pageTDS-MY-MacTex MXC, Feb2020CHEONG WEI HAONo ratings yet

- Complete Fastener Solutions Hexagon BoltsDocument2 pagesComplete Fastener Solutions Hexagon Boltscoolkaisy100% (2)

- FT AC enDocument6 pagesFT AC enMOHAMEDNo ratings yet

- Advanced Structural DesignDocument22 pagesAdvanced Structural DesignSarvag NarsudeNo ratings yet

- Anchor BoltDocument18 pagesAnchor BoltDa WongNo ratings yet

- Inconel 82 PDFDocument1 pageInconel 82 PDFMiguel MorenoNo ratings yet

- fm82 1Document1 pagefm82 1harikrishnanNo ratings yet

- Kaajma Cover Block BrochureDocument12 pagesKaajma Cover Block BrochureSOURAV RANJAN KHANRANo ratings yet

- Busbar InsulatorsDocument3 pagesBusbar InsulatorsThomas WilliamNo ratings yet

- Macalloy Brochure Tension Structures December - 2017 - V1Document16 pagesMacalloy Brochure Tension Structures December - 2017 - V1Isabel Christina Gonzalez MoralesNo ratings yet

- SRG Global - Macalloy Sheet Piling Tie BarsDocument12 pagesSRG Global - Macalloy Sheet Piling Tie BarsbradenNo ratings yet

- As 1684-2-2010 Residential Timber Framed Construction Non Cyclonic AreasDocument10 pagesAs 1684-2-2010 Residential Timber Framed Construction Non Cyclonic AreasbradenNo ratings yet

- SRG Global - Macalloy 1030 Stress BarDocument12 pagesSRG Global - Macalloy 1030 Stress BarbradenNo ratings yet

- Coupleurs C1094S WWENDocument2 pagesCoupleurs C1094S WWENjohnNo ratings yet

- S13 Metric Parallel Bolt Coupler, Plain, Worldwide Design - EL16S13NDocument3 pagesS13 Metric Parallel Bolt Coupler, Plain, Worldwide Design - EL16S13NbradenNo ratings yet

- SRG Global - Macalloy Sheet Piling Tie BarsDocument12 pagesSRG Global - Macalloy Sheet Piling Tie BarsbradenNo ratings yet

- Macalloy Brochure Tension Structures December - 2017 - V1Document16 pagesMacalloy Brochure Tension Structures December - 2017 - V1Isabel Christina Gonzalez MoralesNo ratings yet

- SRG Global - Macalloy 1030 Stress BarDocument12 pagesSRG Global - Macalloy 1030 Stress BarbradenNo ratings yet

- Macalloy Bridge Applications BrochureDocument6 pagesMacalloy Bridge Applications BrochurebradenNo ratings yet

- VicRoads Section 631 - Protective Treatment of SteelworkDocument17 pagesVicRoads Section 631 - Protective Treatment of Steelworkbraden100% (1)

- RRSL320WSM2006Document5,500 pagesRRSL320WSM2006bradenNo ratings yet

- Product Index Bridges Other StructuresDocument26 pagesProduct Index Bridges Other StructuresbradenNo ratings yet

- 76 Going To The Hairdresser CanDocument13 pages76 Going To The Hairdresser CanOlga AmyNo ratings yet

- Geological Exploration Flowchart and SumDocument1 pageGeological Exploration Flowchart and SumKareemAmenNo ratings yet

- Install Notes VTK5 VC2010 Win64Document5 pagesInstall Notes VTK5 VC2010 Win640raeNo ratings yet

- Joanne Mitchell 2223rtkl0155 Email Orig - RedactedDocument29 pagesJoanne Mitchell 2223rtkl0155 Email Orig - RedactedmegankshannonNo ratings yet

- Report on Seminar Submitted by Akshata on MicrogridsDocument12 pagesReport on Seminar Submitted by Akshata on MicrogridsNitin Kakad73% (11)

- Eh TW5825Document2 pagesEh TW5825Lim Hendra Kurniawan Halim (Hendra)No ratings yet

- Start Here Middle School Public Forum PREVIEWDocument5 pagesStart Here Middle School Public Forum PREVIEWi am henryNo ratings yet

- Brochure For CTPT AnalyzerDocument6 pagesBrochure For CTPT AnalyzerBogdan IlieNo ratings yet

- Trust 2Document12 pagesTrust 2mochamad sirodjudinNo ratings yet

- 11 Mindfuck Tactics Used by Abusers and Cult LeadersDocument3 pages11 Mindfuck Tactics Used by Abusers and Cult LeadersIgnotum Umbra100% (1)

- EFDC - Explorer Users Manual (040416-Draft)Document74 pagesEFDC - Explorer Users Manual (040416-Draft)Jongjib ParkNo ratings yet

- A10v RexrothDocument3 pagesA10v RexrothHidroil Neuquen Srl100% (1)

- Introduction To Value Management & Value Engineering in Construction ProjectsDocument6 pagesIntroduction To Value Management & Value Engineering in Construction ProjectsNandhini SilambarasanNo ratings yet

- Qualcomm Snapdragon 732g Mobile Platform Product BriefDocument2 pagesQualcomm Snapdragon 732g Mobile Platform Product BriefGilqlobroNo ratings yet

- Major Report Wood LumberDocument45 pagesMajor Report Wood LumberTorreja JonjiNo ratings yet

- ROSS FRL LubricatorsDocument16 pagesROSS FRL LubricatorsDavid Antonio Vargas CastilloNo ratings yet

- Module 2 - Individual BehaviourDocument187 pagesModule 2 - Individual BehaviourBiswajeet DashNo ratings yet

- Untitled PresentationDocument14 pagesUntitled PresentationThe BeatableNo ratings yet

- Enumerators (x50) - Job Search MalawiDocument4 pagesEnumerators (x50) - Job Search MalawicliftonkacheremNo ratings yet

- Modul 8 SMM - 2Document12 pagesModul 8 SMM - 2Irvin Richard WinataNo ratings yet

- Legris Compression Fitting With PLDocument36 pagesLegris Compression Fitting With PLhannahveluz_iasNo ratings yet

- Boiler Tube FailuresDocument15 pagesBoiler Tube FailuresBIRANCHINo ratings yet

- State of Maine DMR Motion To InterveneDocument147 pagesState of Maine DMR Motion To InterveneNEWS CENTER MaineNo ratings yet

- Accident Investigation, Reporting and Analysis: Safety Engineering and Management For MEDocument38 pagesAccident Investigation, Reporting and Analysis: Safety Engineering and Management For MEAndre De VillaNo ratings yet

- Science Flow ChartDocument3 pagesScience Flow ChartEuodia HodeshNo ratings yet

- Mass and Energy Balancing Calculations For Plant ChapterDocument50 pagesMass and Energy Balancing Calculations For Plant ChapterRamesh SoniNo ratings yet

- 5239 PLC SplitterDocument3 pages5239 PLC SplittermksayshiNo ratings yet

- Cylinder Head: SpecificationsDocument5 pagesCylinder Head: SpecificationsFares100% (1)

- Microsoft pre-training skills assessment checklistDocument1 pageMicrosoft pre-training skills assessment checklistRichard DiotelesNo ratings yet

- Jack Welch's Leadership Transforms GEDocument2 pagesJack Welch's Leadership Transforms GEkimNo ratings yet