Professional Documents

Culture Documents

ASDO Structural Tie Bars Design Cap

Uploaded by

Ajiboye MubarakOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASDO Structural Tie Bars Design Cap

Uploaded by

Ajiboye MubarakCopyright:

Available Formats

ASDO TIE BAR DESIGN CAPACITIES PRODUCT DATA

ASDO tie bars can be supplied in two grades of carbon steel and stainless steel.

All components are designed to exceed the capacity of the bar.

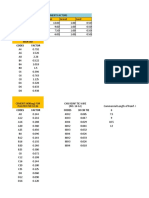

Table 1 - ASDO grade Table 2 - Standard stock bar lengths

ASDO350-S ASDO540-S ASDOE600-S Nominal thread size ASDO350-S ASDO540-S ASDOE600-S

Nominal thread size M100 - M130 M12 M16-42 M45-85 M90 - M100 M105 - M160* M12 - M42 M48 - M56 M16-M42 m - 12 6

fy [N/mm²] 355 355 540 540 520 630 600 460 M45-M100 m - 16 6

fua [N/mm²] 510 510 700 700 700 710 800 650 M105-M160 m 16 12 -

Minimum elongation for all grades 17%; Minimum charpy for all grades 27J @ -20 °C; ASDO350-S M140-M160 differ from above, refer to table 3 for design resistance For longer system lengths bars are connected using couplers or turnbuckles.

*ASDO540-S bars M105-M160 are quench and tempered and should not be galvanised M12 available in 6m lengths only.

Table 3 - Carbon steel

Nominal thread size M12 M16 M20 M24 M27 M30 M36 M42 M45 M48 M52 M56 M60 M64 M68 M72 M76 M80 M85 M90 M95 M100 M105 M110 M115 M120 M130 M140 M150 M160

Dimensional data

Nominal shaft size mm 12 16 20 24 27 30 36 42 45 48 52 56 60 64 68 72 76 80 85 90 95 100 105 110 115 120 130 140 150 160

Shaft area, Ag mm2 113 201 314 452 573 707 1,018 1,385 1,590 1,810 2,124 2,463 2,827 3,217 3,632 4,072 4,536 5,027 5,675 6,362 7,088 7,854 8,659 9,503 10,387 11,310 13,273 15,394 17,671 20,106

Thread pitch mm 1.75 2 2.5 3 3 3.5 4 4.5 4.5 5 5 5.5 5.5 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6

Thread stress area, As mm2 84 157 245 353 459 561 817 1,121 1,306 1,473 1,758 2,030 2,362 2,676 3,055 3,460 3,889 4,344 4,948 5,591 6,273 6,995 7,755 8,556 9,395 10,274 12,149 14,181 16,370 18,716

Weight per metre (bar) kg/m 0.9 1.6 2.5 3.6 4.5 5.5 8.0 10.9 12.5 14.2 16.7 19.3 22.2 25.3 28.5 32.0 35.6 39.5 44.5 49.9 55.6 61.7 68.0 74.6 81.5 88.8 104.2 120.8 138.7 157.8

Yield kN - - - - - - - - - - - - - - - - - - - - - 2,483 2,753 3,037 3,335 3,647 4,313 4,183 4,829 5,334

capacities

ASDO350-S

Ultimate kN - - - - - - - - - - - - - - - - - - - - - 3,567 3,955 4,363 4,791 5,240 6,196 6,665 7,694 8,422

Load

Yield kN 30 85 132 190 248 303 441 605 705 795 949 1,096 1,275 1,445 1,650 1,868 2,100 2,346 2,672 2,907 3,262 3,637 4,886 5,390 5,919 6,472 7,654 8,934 10,313 11,791

ASDO540-S

Ultimate kN 43 110 171 247 322 392 572 785 914 1,031 1,230 1,421 1,653 1,873 2,139 2,422 2,723 3,041 3,463 3,914 4,391 4,896 5,506 6,074 6,670 7,294 8,626 10,068 11,623 13,289

resistance1

ASDO350-S Ft,Rd kN - - - - - - - - - - - - - - - - - - - - - 2,535 2,795 3,067 3,352 3,650 4,284 4,128 4,739 5,209

Design

ASDO540-S Ft,Rd kN 31 79 123 178 232 283 412 565 658 742 886 1,023 1,190 1,349 1,540 1,744 1,960 2,189 2,494 2,818 3,162 3,525 3,965 4,374 4,803 5,252 6,210 7,249 8,368 9,568

Table 4 - Stainless steel Corrosion protection

Nominal thread size M12 M16 M20 M24 M27 M30 M36 M42 M48 M56 M60+ ASDO systems can be supplied self colour or galvanised as stand-

Dimensional data

Nominal shaft size mm 10.8 15 18 22 25 28 34 39 45 52 ard. Sizes up to M42 are supplied with forks, pins, turnbuckles,

Shaft area, Ag mm2 92 177 254 380 491 616 908 1,195 1,590 2,124 couplers and thread-cover sleeves hot dip galvanized as standard.

Thread pitch mm 1.75 2 2.5 3 3 3.5 4 4.5 5 5.5 Note ASDO540-S bars M105-M160 are quench and tempered steel

Thread stress area, As mm2 84 157 245 353 459 561 817 1,121 1,473 2,030

and therefore should not be galvanised.

Weight per metre (bar) kg/m 0.7 1.4 2.0 3.0 3.9 4.9 7.3 9.6 12.7 17.0 Larger

diameters

Bar threads can be formed after galvanising or are re-machined to

capacities

Yield kN 51 94 147 212 276 336 490 673 678 934

available

Load

at request size following galvanizing; repairs to the zinc coating are made in

Ultimate kN 67 125 196 282 368 448 653 897 958 1,320 accordance with DIN EN ISO 1461. Spanner flats on the tie-rods are

ASDOE600-S

pressed following hot galvanizing to prevent brittle fracture. Note,

resistance1

Design

Ft,Rd kN 47 87 136 195 255 311 453 621 656 900 due to the nature of the galvanising process the visual finish of gal-

vanised product is variable. If a high level of aesthetic finish is re-

quired systems should be subsequently painted after a suitable

Notes for tables 3 & 4: primer has been applied. ASDO tie bars cannot be supplied with Self colour Galvanised Stainless

1. Design tensile resistance Ft,Rd = min {fy x Ag / γM0; 0.9 x fua x As / γM2} as per EN1993-1-8 with partial factors γM0 = 1.0 & γM2 = 1.25 for carbon steel and γM0 = 1.1 & γM2 = 1.25 for stainless steel according EN1993-1-4 ‘top-coat’ finishes, this should be applied by the customer. Please

2. For the full design resistance to be utilised connection plates must be fabricated from S355J2 to EN10025 (or equivalent) and to minimum dimensions given in table 5

3. All threads are cut threads and are not suitable for dynamic loads. Rolled threads with higher fatigue resistance can be made on request - please contact our technical department

advise us before placing an order if bars are intended to be painted.

4. For full design capacity threads must be engaged at least 1.2 x thread diameter, see installation guide page 17

8 5. Stainless steel bar grades M12-M42 are austenitic 1.4401/4, M48+ are duplex 1.4462. Please contact our technical department for more detail. 9

You might also like

- The Facility Manager's HandbookDocument362 pagesThe Facility Manager's HandbookLuân Châu100% (14)

- Complete Fastener Solutions Hexagon BoltsDocument2 pagesComplete Fastener Solutions Hexagon Boltscoolkaisy100% (2)

- Operational Readiness Guide - 2017Document36 pagesOperational Readiness Guide - 2017albertocm18100% (2)

- SAP MM ReportsDocument59 pagesSAP MM Reportssaprajpal95% (21)

- Grammar Pages 109-112 2 PDFDocument4 pagesGrammar Pages 109-112 2 PDFSteve SernaNo ratings yet

- A319/A320/A321 Technical Training Manual Mechanics / Electrics & Avionics Course 33 LightsDocument224 pagesA319/A320/A321 Technical Training Manual Mechanics / Electrics & Avionics Course 33 LightsAhmedHamdyElsaidy100% (3)

- Asdo Tie Bar Design Capacities: Product DataDocument2 pagesAsdo Tie Bar Design Capacities: Product DatasivakumarNo ratings yet

- Tie Rod BrochureDocument20 pagesTie Rod Brochuremech_abhiNo ratings yet

- Industry Guidelines: Metal Backing Flanges For Use With Polyethylene (Pe) Pipe Flange AdaptorsDocument17 pagesIndustry Guidelines: Metal Backing Flanges For Use With Polyethylene (Pe) Pipe Flange AdaptorsAnthonyNo ratings yet

- Technical Data Sheet For Mgs and MGSRDocument3 pagesTechnical Data Sheet For Mgs and MGSRFILID MADNo ratings yet

- Metric DIN 609 SpecDocument4 pagesMetric DIN 609 SpecCAT MINING SHOVELNo ratings yet

- TORQUEDocument1 pageTORQUEputel_ajaNo ratings yet

- PapuciCupruTipL ConfSTAS KLAUKE GERKONELECTRO PDFDocument2 pagesPapuciCupruTipL ConfSTAS KLAUKE GERKONELECTRO PDFDitzsu tzsuDiNo ratings yet

- High Tensile Bolts TechnicalDocument6 pagesHigh Tensile Bolts Technicalventhan_kalaiNo ratings yet

- Bolt & Screw DetailsDocument6 pagesBolt & Screw Detailsjee01No ratings yet

- Hex Key Chart Provides Sizes and Dimensions for Allen KeysDocument1 pageHex Key Chart Provides Sizes and Dimensions for Allen KeysRoss EdwardNo ratings yet

- Dextra: System DescriptionDocument10 pagesDextra: System DescriptionHiba SolimanNo ratings yet

- Quantity EstimateDocument64 pagesQuantity Estimatefrancis sebastian lagamayoNo ratings yet

- NutsDocument8 pagesNutsGerry Dan ChanliongcoNo ratings yet

- Metric Thread Size Spanner Size A/F DIN (MM) Spanner Size A/F ISO (MM)Document3 pagesMetric Thread Size Spanner Size A/F DIN (MM) Spanner Size A/F ISO (MM)kianoush Volvo construction equipmentNo ratings yet

- Threads - Galvanized Bolts and Nuts Need Special Thread GagesDocument3 pagesThreads - Galvanized Bolts and Nuts Need Special Thread GagesBiaizidi Abbou SamirNo ratings yet

- Holding Down Bolts BS 7419 (Square Square) : Grade 4.6 & 8.8Document2 pagesHolding Down Bolts BS 7419 (Square Square) : Grade 4.6 & 8.8Thilan SenarathneNo ratings yet

- Hex Key ChartDocument1 pageHex Key Charter lopNo ratings yet

- Backing Rings Data PDFDocument1 pageBacking Rings Data PDFAbhijeet SahuNo ratings yet

- Screws Nuts Washer SizesDocument5 pagesScrews Nuts Washer SizesNanang RisdiantoNo ratings yet

- Hex. Bolt Size - Gi/Ms/Ss (Ansi B16.5 Class 150) : Size NB Face Fto Face BFV NRVDocument7 pagesHex. Bolt Size - Gi/Ms/Ss (Ansi B16.5 Class 150) : Size NB Face Fto Face BFV NRVBalaji PNo ratings yet

- Din 933Document2 pagesDin 933Sugumar0% (1)

- DIN 6796 - Conical Spring WasherDocument1 pageDIN 6796 - Conical Spring WasherRoby MastreNo ratings yet

- Metric Hex Bolt DimensionsDocument7 pagesMetric Hex Bolt DimensionsVishal MistryNo ratings yet

- Metric DIN 985 Nylon Insert Lock Nut Dimensions & SpecsDocument4 pagesMetric DIN 985 Nylon Insert Lock Nut Dimensions & Specsvikram jainNo ratings yet

- Standard Torque Values - Metric SystemDocument1 pageStandard Torque Values - Metric Systemnate anantathatNo ratings yet

- Table of Bolt SizesDocument5 pagesTable of Bolt Sizesnagaraj108No ratings yet

- Heavy Hex Bolts Screws ASTM A307 Gr.ADocument1 pageHeavy Hex Bolts Screws ASTM A307 Gr.AENGR 414No ratings yet

- Metric DIN 939 Double End Studs (1.25xD) : Visit Our For Product AvailabilityDocument4 pagesMetric DIN 939 Double End Studs (1.25xD) : Visit Our For Product Availabilitysudarshan pugaliaNo ratings yet

- SD II PDF - OCRDocument18 pagesSD II PDF - OCRSuraj KumarNo ratings yet

- Hex Key ChartDocument1 pageHex Key ChartMassimoNo ratings yet

- Metric DIN 439 Spec PDFDocument4 pagesMetric DIN 439 Spec PDFHasib SejdinovicNo ratings yet

- Price List No. 164 Price List No. 164Document12 pagesPrice List No. 164 Price List No. 164mshNo ratings yet

- Rawlbolt: Shield Anchor Loose BoltDocument2 pagesRawlbolt: Shield Anchor Loose BoltBappy IslamNo ratings yet

- Catalog Series RTC Aventics en 6912350Document150 pagesCatalog Series RTC Aventics en 6912350Omar Jasid LaraNo ratings yet

- RITZ Screw Specification PDFDocument12 pagesRITZ Screw Specification PDFThawatchai DanwangkhawNo ratings yet

- Metal Backing Flange GuidelinesDocument19 pagesMetal Backing Flange GuidelinesDang Hieu NguyenNo ratings yet

- 4flange Adaptor CouplingDocument1 page4flange Adaptor CouplingJoh SongthamNo ratings yet

- Wrench ClearancesDocument2 pagesWrench ClearancesRowan JoguilonNo ratings yet

- Hex Bolts - Minimum Tensile StressDocument4 pagesHex Bolts - Minimum Tensile StressWaqar FaziNo ratings yet

- Bolt Pro PDFDocument4 pagesBolt Pro PDFWaqar FaziNo ratings yet

- Nut Bolt HeightDocument8 pagesNut Bolt HeightMian M KhurramNo ratings yet

- Iso 965 2 1998Document8 pagesIso 965 2 1998Gerald CelisNo ratings yet

- Amphenol 97 Series Clamp and BushingDocument8 pagesAmphenol 97 Series Clamp and BushingtongsabaiNo ratings yet

- Mac AlloyDocument16 pagesMac AlloyAnonymous u7YkrCwCNo ratings yet

- Flat Plate: Sks - Ispat LTD - Ducting and Support MaterialsDocument5 pagesFlat Plate: Sks - Ispat LTD - Ducting and Support MaterialsJKKNo ratings yet

- Giddings & Lewis Zappendix ADocument9 pagesGiddings & Lewis Zappendix AAngel AdautaNo ratings yet

- MV Cable Current Carrying Capacity NA2XSEYBY SucacoDocument1 pageMV Cable Current Carrying Capacity NA2XSEYBY SucacoharisNo ratings yet

- Macalloy Brochure Tension Structures December - 2017 - V1Document16 pagesMacalloy Brochure Tension Structures December - 2017 - V1Isabel Christina Gonzalez MoralesNo ratings yet

- Thread Tolerances For Screws and NutsDocument2 pagesThread Tolerances For Screws and NutsBill WhiteNo ratings yet

- Thread Dimensions for Machine ScrewsDocument2 pagesThread Dimensions for Machine ScrewsarvindspakNo ratings yet

- SCRM BrochureDocument6 pagesSCRM BrochureRizwan TonoyNo ratings yet

- ASDO Marine Structures Tie Bar DesignCapDocument2 pagesASDO Marine Structures Tie Bar DesignCapFelipe Strafite CusterNo ratings yet

- Quantity EstimateDocument59 pagesQuantity EstimateJohn Christopher JusayanNo ratings yet

- Pricelist 202210 Complete Rev7 20230505Document40 pagesPricelist 202210 Complete Rev7 20230505zainal muttaqinNo ratings yet

- Standard Torque Values - Metric SystemDocument1 pageStandard Torque Values - Metric SystemproteccionesNo ratings yet

- Moment Strangere InoxDocument1 pageMoment Strangere Inoxtracam500100% (1)

- 30M 3 Legged Tower SpecificationDocument4 pages30M 3 Legged Tower SpecificationAjiboye MubarakNo ratings yet

- Good PracticesDocument43 pagesGood PracticesAndrei DiaconuNo ratings yet

- Good PracticesDocument43 pagesGood PracticesAndrei DiaconuNo ratings yet

- Exercises SolutionsDocument79 pagesExercises SolutionsAyushBaglaNo ratings yet

- Understanding CPP An Accelerated IntroductionDocument63 pagesUnderstanding CPP An Accelerated IntroductionMuhammad KashifNo ratings yet

- ELE 312 Measurements and InstrumentationDocument36 pagesELE 312 Measurements and InstrumentationAjiboye MubarakNo ratings yet

- Soil Compaction and StabilityDocument3 pagesSoil Compaction and Stabilitythedevilsdue9420No ratings yet

- Hanger Bars For Concrete Lifting AnchorsDocument5 pagesHanger Bars For Concrete Lifting AnchorsAjiboye MubarakNo ratings yet

- Ridwan Analysis AssignmentDocument8 pagesRidwan Analysis AssignmentAjiboye MubarakNo ratings yet

- Ground Mast 3Document21 pagesGround Mast 3Ajiboye MubarakNo ratings yet

- Lec17 Bearing CapacityDocument57 pagesLec17 Bearing CapacityMuhammad EhtshamNo ratings yet

- Mee 235: Engineering Technology: H.A. Ajimotokan (PHD)Document233 pagesMee 235: Engineering Technology: H.A. Ajimotokan (PHD)Ajiboye Mubarak100% (1)

- Timber Bridge DesignDocument30 pagesTimber Bridge DesignJohn Adams100% (2)

- BS5950 Load CasesDocument46 pagesBS5950 Load CasesthespecifierNo ratings yet

- D-2 UTEP Currey Final ReportDocument23 pagesD-2 UTEP Currey Final ReporthmcNo ratings yet

- Dreamers Chords by Jungkook (정국) tabs at Ultimate Guitar ArchiveDocument4 pagesDreamers Chords by Jungkook (정국) tabs at Ultimate Guitar ArchiveLauraNo ratings yet

- Enzyme KineticsDocument13 pagesEnzyme KineticsMohib100% (1)

- 12 Orpic Safety Rules Managers May 17 RevDocument36 pages12 Orpic Safety Rules Managers May 17 RevGordon Longforgan100% (3)

- 5e3 Like ApproachDocument1 page5e3 Like Approachdisse_detiNo ratings yet

- Rguhs Dissertation PharmacyDocument6 pagesRguhs Dissertation PharmacyWhatAreTheBestPaperWritingServicesSingapore100% (1)

- Far Eastern University Institute of Tourism and Hotel Management Tourism Management Program 1 Semester A.Y. 2019 - 2020Document46 pagesFar Eastern University Institute of Tourism and Hotel Management Tourism Management Program 1 Semester A.Y. 2019 - 2020Mico BolorNo ratings yet

- Service Manual for Daewoo Mini Component Sound SystemsDocument46 pagesService Manual for Daewoo Mini Component Sound SystemsDaifred GutiérrezNo ratings yet

- Transportation Chapter 3Document17 pagesTransportation Chapter 3Tuan NguyenNo ratings yet

- Sample Id: Sample Id: 6284347 Icmr Specimen Referral Form Icmr Specimen Referral Form For For Covid-19 (Sars-Cov2) Covid-19 (Sars-Cov2)Document2 pagesSample Id: Sample Id: 6284347 Icmr Specimen Referral Form Icmr Specimen Referral Form For For Covid-19 (Sars-Cov2) Covid-19 (Sars-Cov2)Praveen KumarNo ratings yet

- 2020-Effect of Biopolymers On Permeability of Sand-Bentonite MixturesDocument10 pages2020-Effect of Biopolymers On Permeability of Sand-Bentonite MixturesSaswati DattaNo ratings yet

- The 10 Most Inspiring Quotes of Charles F HaanelDocument21 pagesThe 10 Most Inspiring Quotes of Charles F HaanelKallisti Publishing Inc - "The Books You Need to Succeed"100% (2)

- A Critical Review: Constructive Analysis in English and Filipino 1 SEMESTER 2021-2022Document4 pagesA Critical Review: Constructive Analysis in English and Filipino 1 SEMESTER 2021-2022roseNo ratings yet

- Kaseya Performance and Best Practices Guide: Authors: Jacques Eagle Date: Thursday, April 29, 2010Document34 pagesKaseya Performance and Best Practices Guide: Authors: Jacques Eagle Date: Thursday, April 29, 2010markdavidboydNo ratings yet

- Grammar Notes-February2017 - by Aslinda RahmanDocument41 pagesGrammar Notes-February2017 - by Aslinda RahmanNadia Anuar100% (1)

- Al-Jahiz (781-869) : ZoologyDocument25 pagesAl-Jahiz (781-869) : ZoologyJA QuibzNo ratings yet

- Fundamentals of Accountancy Business Management 2: Learning PacketDocument33 pagesFundamentals of Accountancy Business Management 2: Learning PacketArjae Dantes50% (2)

- Assignement 4Document6 pagesAssignement 4sam khanNo ratings yet

- Steve Jobs MarketingDocument1 pageSteve Jobs MarketingAnurag DoshiNo ratings yet

- Laser Beam Machining (LBM)Document10 pagesLaser Beam Machining (LBM)RAMAKANT RANANo ratings yet

- Lesson Plan in ESPDocument4 pagesLesson Plan in ESPkaren daculaNo ratings yet

- Week 71Document25 pagesWeek 71Raphael SebucNo ratings yet

- Unit-3 22es14aDocument77 pagesUnit-3 22es14atejvimathNo ratings yet

- BOM RMCC Parking-Shed Rev2Document15 pagesBOM RMCC Parking-Shed Rev2Ephrem Marx AparicioNo ratings yet

- Samsung (UH5003-SEA) BN68-06750E-01ENG-0812Document2 pagesSamsung (UH5003-SEA) BN68-06750E-01ENG-0812asohas77No ratings yet