Professional Documents

Culture Documents

Technical Data Sheet For Mgs and MGSR

Uploaded by

FILID MADOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Data Sheet For Mgs and MGSR

Uploaded by

FILID MADCopyright:

Available Formats

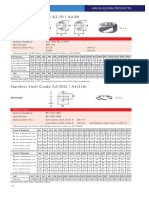

Technical Data Sheet for MGS and MGSr

MGS Threaded Rod, zinc plated, steel quality 4.6

or 8.8 and MGSr Threaded Rod, stainless steel

A4-70/316 for Mungo chemical fixing products

1 DESCRIPTION

Mungo post-installed anchoring applications MGS and MGSr are designed for a reliable performance in a wide

range of chemical anchoring applications. Threaded Rods MGS and MGSr can be used with all Mungo chemical

fixing products. Threaded Rods are suitable for individual use with different setting depths in steel grades 4.6

or 8.8 (MIT-S) and A4-70 (MGSr) and A4-50 for MGSr size M30.

For separate design with MGS or MGSr and corresponding Mungo chemical application, please see the relevant

ETA or Mungo Design software.

MGS: Reliable Mungo quality to fulfil the basic needs in steel quality 4.6 or high-strength steel quality 8.8 for

post-installed chemical anchoring applications.

MGSr: Increased performances including high-strength and stainless steel combination. Reliable usability for

the most demand areas with chemical applications.

2 DESIGNATION OF ANCHOR PARTS AND DIMENSIONS

Futures:

Anchor Rod Basic Pitch Stress Major Diameter Pitch Diameter Minor Diameter

dimensions Diameter Diameter

[mm] [mm] [mm2] [mm] [mm] [mm] [mm] [mm] [mm]

M D p As dmax dmin d2max d2min d3max d3min

M5 5 0.80 14.18 4.98 4.83 4.46 4.36 4.10 3.87

M6 6 1.00 20.12 5.97 5.79 5.32 5.21 4.88 4.60

M8 8 1.25 36.61 7.97 7.76 7.16 7.04 6.59 6.27

M10 10 1.50 57.99 9.97 9.73 8.99 8.86 8.31 7.94

M12 12 1.75 84.27 11.97 11.70 10.83 10.68 10.03 9.60

M16 16 2.00 156.67 15.96 15.68 14.66 14.50 13.74 13.27

M20 20 2.50 244.79 19.96 19.62 18.33 18.16 17.17 16.62

M24 24 3.00 352.50 23.95 23.58 22.00 21.80 20.60 19.96

M30 30 3.50 560.59 29.95 29.52 27.67 27.46 26.03 25.31

3 PRODUCT INFORMATION

MGS Threaded Rod, steel quality 4.6 or 8.8,

Article code Article code Article code Dimensions Length

MGSr Threaded Rod, stainless steel A4-70/316

MGS 4.6 MGS 8.8 MGSr A4-70 [mm]

zinc plated zinc plated stainless steel L

7460510* 7880510* 7040510* M5 x 1000 1000

7460610* 7880610* 7040610* M6 x 1000 1000

7460810 7880810 7040810 M8 x 1000 1000

7461010 7881010 7041010 M10 x 1000 1000

7461210 7881210 7041210 M12 x 1000 1000

7461610 7881610 7041610 M16 x 1000 1000

― 7882010 7042010 M20 x 1000 1000

― 7882410 7042410 M24 x 1000 1000

― 7883010 7043010** M30 x 1000 1000

*Not part of the approval

**Stainless steel A4-50 (Tensile strength 500 N/mm2)

4 VALUES FOR STEEL TENSION RESISTANCE AND STEEL SHEAR RESISTANCE

4.1 Recommended values for steel tension resistance and steel shear resistance:

Nrec,s.= NRk,s /ɣMs,N/ɣF ; Vrec,s = VRk,s /ɣMs,V/ɣF ; Mrec,s = MRk,s /ɣMs,V/ɣF

Threaded Rod size M5 M6 M8 M10 M12 M16 M20 M24 M30

Recommended tension resistance

MGS, steel proprerty class 4.6 Nrec,s [kN] 2.03 2.87 5.23 8.29 12.04 22.43 35.00 50.43 80.14

MGS, steel proprerty class 8.8 Nrec,s [kN] 5.40 7.66 13.94 22.10 32.11 59.81 93.33 134.48 213.71

MGS, stainless steel A4, property class 70 Nrec,s [kN] 3.79 5.37 9.79 15.51 22.54 41.98 65.51 94.39 70.05

Recommended shear resistance

MGS, steel proprerty class 4.6 Vrec,s [kN] 1.21 1.72 3.13 4.96 7.21 13.43 20.96 30.20 47.99

MGS, steel proprerty class 8.8 Vrec,s [kN] 3.24 4.59 8.37 13.26 19.27 35.89 56.00 80.69 128.23

MGS, stainless steel A4, property class 70 Vrec,s [kN] 2.27 3.22 5.87 9.29 13.51 25.16 39.26 56.57 42.09

Recommended bending moment resistance

MGS, steel proprerty class 4.6 Mrec,s [Nm] 1.5 2.6 6.4 12.8 22.4 57.0 111.0 192.1 384.8

MGS, steel proprerty class 8.8 Mrec,s [Nm] 4.1 7.0 17.1 34.2 59.9 152.2 296.7 513.2 1028.1

MGS, stainless steel A4, property class 70 Mrec,s [Nm] 2.9 4.9 12.0 24.0 42.0 106.7 208.0 359.8 337.5

The partial safety factors of the resistances ɣMs (EOTA, TR 029) as well as a partial safety factor of the load ɣF = 1.4 are considered.

4.2 Design values for steel tension resistance and steel shear resistance:

NRd,s.= NRk,s /ɣMs,N ; VRd,s = VRk,s /ɣMs,V ; MRd,s = MRk,s /ɣMs,V

Threaded Rod size M5 M6 M8 M10 M12 M16 M20 M24 M30

Design tension resistance

MGS, steel proprerty class 4.6 NRd,s [kN] 2.84 4.02 7.32 11.60 16.86 31.40 49.00 70.60 112.20

MGS, steel proprerty class 8.8 NRd,s [kN] 7.56 10.72 19.52 30.93 44.96 83.73 130.67 188.27 299.20

MGS, stainless steel A4, property class 70 NRd,s [kN] 5.31 7.52 13.70 21.71 31.56 58.77 91.71 132.14 98.08

Design shear resistance

MGS, steel proprerty class 4.6 VRd,s [kN] 1.70 2.41 4.38 6.95 10.10 18.80 29.34 42.28 67.19

MGS, steel proprerty class 8.8 VRd,s [kN] 4.54 6.43 11.71 18.56 26.98 50.24 78.40 112.96 179.52

MGS, stainless steel A4, property class 70 VRd,s [kN] 3.18 4.51 8.21 13.01 18.91 35.22 54.97 79.20 58.93

Design bending moment resistance

MGS, steel proprerty class 4.6 MRd,s [Nm] 2.2 3.7 9.0 17.9 31.4 79.8 155.5 268.9 538.7

MGS, steel proprerty class 8.8 MRd,s [Nm] 5.8 9.8 24.0 47.8 83.8 213.1 415.4 718.4 1439.4

MGS, stainless steel A4, property class 70 MRd,s [Nm] 4.1 6.8 16.8 33.5 58.8 149.4 291.3 503.7 472.5

The partial safety factors of the resistances ɣMs (EOTA, TR 029) is considered.

4.3 Characteristic values for steel tension resistance and steel shear resistance:

Threaded Rod size M5 M6 M8 M10 M12 M16 M20 M24 M30

Characteristic tension resistance

MGS, steel proprerty class 4.6 NRk,s [kN] 5.67 8.04 14.64 23.20 33.72 62.80 98.00 141.20 224.40

MGS, steel proprerty class 8.8 NRk,s [kN] 11.34 16.08 29.28 46.40 67.44 125.60 196.00 282.40 448.80

MGS, stainless steel A4, property class 70 NRk,s [kN] 9.93 14.07 25.62 40.60 59.01 109.90 171.50 247.10 280.50

Characteristic shear resistance

MGS, steel proprerty class 4.6 VRk,s [kN] 2.84 4.02 7.32 11.60 16.86 31.40 49.00 70.60 112.20

MGS, steel proprerty class 8.8 VRk,s [kN] 5.67 8.04 14.64 23.20 33.72 62.80 98.00 141.20 224.40

MGS, stainless steel A4, property class 70 VRk,s [kN] 4.96 7.04 12.81 20.30 29.51 54.95 85.75 123.55 140.25

Characteristic bending moment resistance

MGS, steel proprerty class 4.6 MRk,s [Nm] 3.6 6.1 15.0 29.9 52.4 133.2 259.6 449.0 899.6

MGS, steel proprerty class 8.8 MRk,s [Nm] 7.2 12.2 30.0 59.8 104.8 266.4 519.3 898.0 1799.2

MGS, stainless steel A4, property class 70 MRk,s [Nm] 6.3 10.7 26.2 52.3 91.7 233.1 454.4 785.8 1124.5

Partial safety factors for ɣMs are determined as a function of the type of loading following EOTA, TR 029, Design of Bonded Anchors;

- MGS steel property class 4.6; ɣMs,N = 2.0 and ɣMs,V = 1.67

- MGS steel property class 8.8; ɣMs,N = 1.5 and ɣMs,V = 1.25

- MGSr stainless steel A4-70; ɣMs,N = 1.87 and ɣMs,V = 1.56 (MGSr M30 A4-50; ɣMs,N = 2.86 and ɣMs,V = 2.38)

Partial safety factors are in absence of national regulation.

5 ATTENTION

The data input must be checked by the user under the responsibility of an engineer experienced in anchorage. This is to

ensure there are no errors and all data is complete and accurate and complies with all rules and regulations for the actual

conditions and application. The data contained in the technical data sheet is based on principles, formulas and safety

regulations according to the existing guidelines for anchorages.

You might also like

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Torque SettingsDocument3 pagesTorque Settingsgamedbk002No ratings yet

- Torque Chart NormetDocument1 pageTorque Chart NormetvmrvdnvNo ratings yet

- ASDO Structural Tie Bars Design CapDocument1 pageASDO Structural Tie Bars Design CapAjiboye MubarakNo ratings yet

- Asdo Tie Bar Design Capacities: Product DataDocument2 pagesAsdo Tie Bar Design Capacities: Product DatasivakumarNo ratings yet

- Milindshore Kottarappappi PDFDocument1 pageMilindshore Kottarappappi PDFshaan1001gbNo ratings yet

- BS 3692 Gr. 8.8 bolt and nut dimensions and properties tableDocument1 pageBS 3692 Gr. 8.8 bolt and nut dimensions and properties tableAsif Raza0% (1)

- Metric DIN 985 Nylon Insert Lock Nut Dimensions & SpecsDocument4 pagesMetric DIN 985 Nylon Insert Lock Nut Dimensions & Specsvikram jainNo ratings yet

- SAMPAG ANCHOR CHANELS CatalogueNo.8 PDFDocument40 pagesSAMPAG ANCHOR CHANELS CatalogueNo.8 PDFKemo TufoNo ratings yet

- Group 2 Tightening Torque: 1. Major ComponentsDocument3 pagesGroup 2 Tightening Torque: 1. Major ComponentsDenNo ratings yet

- Metric DIN 439 Spec PDFDocument4 pagesMetric DIN 439 Spec PDFHasib SejdinovicNo ratings yet

- Complete Fastener Solutions Hexagon BoltsDocument2 pagesComplete Fastener Solutions Hexagon Boltscoolkaisy100% (2)

- Metric DIN 433 Flat Washer Dimensions and SpecificationsDocument4 pagesMetric DIN 433 Flat Washer Dimensions and SpecificationsChris StefanouNo ratings yet

- Group 2 Tightening TorqueDocument3 pagesGroup 2 Tightening TorquerolandseNo ratings yet

- DIN 439hexagon Thin-Lock NutsDocument1 pageDIN 439hexagon Thin-Lock NutsGrimmo1979No ratings yet

- 01-Grade 8.8 Bolt & NutDocument1 page01-Grade 8.8 Bolt & NutbingminNo ratings yet

- HTD Dim CM Spring WashDocument1 pageHTD Dim CM Spring WashRockiBalaNo ratings yet

- Group 2 Tightening Torque: 1. Major ComponentsDocument3 pagesGroup 2 Tightening Torque: 1. Major ComponentsFábio Costa100% (1)

- Stainless Steel Grade A2-70 / A4-80: Nut & WasherDocument1 pageStainless Steel Grade A2-70 / A4-80: Nut & WasherMichael GabrielNo ratings yet

- Thread Tolerances For Screws and NutsDocument2 pagesThread Tolerances For Screws and NutsBill WhiteNo ratings yet

- GROUP 2 TIGHTENING TORQUE SPECSDocument3 pagesGROUP 2 TIGHTENING TORQUE SPECSlevinton jose tobias genesNo ratings yet

- Technical Data Sheet for Metric Thread BoltsDocument10 pagesTechnical Data Sheet for Metric Thread BoltsRobenNo ratings yet

- HTD HXB cl10.9 Tight TorqDocument1 pageHTD HXB cl10.9 Tight Torqaegean227No ratings yet

- Din 931Document1 pageDin 931Showkath Ali100% (2)

- Hex Nut WeightDocument1 pageHex Nut Weightmx100sanookNo ratings yet

- SOCKET HEAD CAP SCREW TIGHTENING TORQUE GUIDEDocument1 pageSOCKET HEAD CAP SCREW TIGHTENING TORQUE GUIDEChandru Vel100% (1)

- High Tensile Bolts TechnicalDocument6 pagesHigh Tensile Bolts Technicalventhan_kalaiNo ratings yet

- Metric DIN 939 Double End Studs (1.25xD) : Visit Our For Product AvailabilityDocument4 pagesMetric DIN 939 Double End Studs (1.25xD) : Visit Our For Product Availabilitysudarshan pugaliaNo ratings yet

- Metric Bolt Torque Table NM - CNCexpoDocument1 pageMetric Bolt Torque Table NM - CNCexponate anantathat100% (1)

- Metric Bolt Torque Table NmDocument1 pageMetric Bolt Torque Table NmninatenaNo ratings yet

- DIN 7980 Spring Lock Washer - Fasteners ChinaDocument2 pagesDIN 7980 Spring Lock Washer - Fasteners ChinaHala Ibrahim El-BassyouniNo ratings yet

- Metric DIN 609 SpecDocument4 pagesMetric DIN 609 SpecCAT MINING SHOVELNo ratings yet

- Metric DIN 6797 Tooth Lock Washers: Visit Our For Product AvailabilityDocument5 pagesMetric DIN 6797 Tooth Lock Washers: Visit Our For Product AvailabilityShrikant DeshmukhNo ratings yet

- Group 2 Tightening Torque: Major Components 1Document3 pagesGroup 2 Tightening Torque: Major Components 1АлексейNo ratings yet

- P.F. High Strength Structural Fasteners Dimensions & SpecificationsDocument4 pagesP.F. High Strength Structural Fasteners Dimensions & SpecificationspajipitarNo ratings yet

- RITZ Screw Specification PDFDocument12 pagesRITZ Screw Specification PDFThawatchai DanwangkhawNo ratings yet

- 934 2Document2 pages934 2simpatico131No ratings yet

- Table of Bolt SizesDocument5 pagesTable of Bolt Sizesnagaraj108No ratings yet

- Metric hex nuts style 2 dimensions and propertiesDocument1 pageMetric hex nuts style 2 dimensions and propertiesRatendra kumarNo ratings yet

- Metric Bolt Torque Table NM - CNCexpoDocument1 pageMetric Bolt Torque Table NM - CNCexpoNepoleon KaruppiahNo ratings yet

- HSA Stud AnchorDocument11 pagesHSA Stud AnchorWin ThanNo ratings yet

- Hex NutsDocument10 pagesHex Nutsjaskaran singhNo ratings yet

- Diâmetro Ds D K R S T W B Nominal Máx. Min. Máx. Min. Máx. Min. Min. Máx. Min. Min. Min. RefDocument1 pageDiâmetro Ds D K R S T W B Nominal Máx. Min. Máx. Min. Máx. Min. Min. Máx. Min. Min. Min. RefrudneoNo ratings yet

- Thread Dimensions for Machine ScrewsDocument2 pagesThread Dimensions for Machine ScrewsarvindspakNo ratings yet

- Table of Bolt SizesDocument8 pagesTable of Bolt SizesAbdul Aziz Julkarnain ZulkifliNo ratings yet

- R210LC-7 8-2Document3 pagesR210LC-7 8-2Krystian PalaciosNo ratings yet

- Bapp Preload Assem Bsen14399hr 3 HrassDocument4 pagesBapp Preload Assem Bsen14399hr 3 HrasspolpositionNo ratings yet

- BAPP-Preload-Assem-BS EN 14399HR-3-HRASS PDFDocument4 pagesBAPP-Preload-Assem-BS EN 14399HR-3-HRASS PDFrjtcostaNo ratings yet

- TORQUEDocument1 pageTORQUEputel_ajaNo ratings yet

- 8-2 Group 2 Tightening Torque PDFDocument3 pages8-2 Group 2 Tightening Torque PDFrodinei cesar gomes gomes100% (1)

- FCU&FANSDocument50 pagesFCU&FANSmohamad.damerly.zaidg.kaigNo ratings yet

- Proof Load, Yield & Tensile Strength Chart MetricDocument1 pageProof Load, Yield & Tensile Strength Chart MetricAnonymous YWS7ndsiNo ratings yet

- Minimum Thread Engagement Chart - MetricDocument1 pageMinimum Thread Engagement Chart - MetricMustafa Al-YamaniNo ratings yet

- BS7419 (SQSQ) StandardDocument2 pagesBS7419 (SQSQ) StandardGurdeep SinghNo ratings yet

- Group 2 Tightening Torque: 1. Major ComponentsDocument3 pagesGroup 2 Tightening Torque: 1. Major Componentslevinton jose tobias genesNo ratings yet

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityFrom EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNo ratings yet

- Finance NotesDocument90 pagesFinance NotesRavi GuptaNo ratings yet

- Dab CatalogueDocument382 pagesDab CatalogueFILID MADNo ratings yet

- SketchupDocument39 pagesSketchupFILID MADNo ratings yet

- Excel Formulas Cheat SheetDocument7 pagesExcel Formulas Cheat SheetZhori Duberry0% (1)

- Peter Bregman - 18 Minutes - Find Your Focus, Master Distraction, and Get The Right Things Done - Business Plus (2011)Document249 pagesPeter Bregman - 18 Minutes - Find Your Focus, Master Distraction, and Get The Right Things Done - Business Plus (2011)FILID MAD100% (1)

- Sketchup Modeling and Rendering: Phnom Penh Engineer CenterDocument33 pagesSketchup Modeling and Rendering: Phnom Penh Engineer CentermensambathNo ratings yet

- 02 - AutoCAD LessonDocument236 pages02 - AutoCAD LessonJohn ChivNo ratings yet

- 978 1 63057 111 5 2 PDFDocument54 pages978 1 63057 111 5 2 PDFRichzad PrimaNo ratings yet

- Green Town Architectures & Printing Center - 1 - Skecth UpDocument39 pagesGreen Town Architectures & Printing Center - 1 - Skecth UpFILID MADNo ratings yet

- Mebs6000 1011 03 Cold and Hot Water DesignDocument82 pagesMebs6000 1011 03 Cold and Hot Water DesignSocratis SocratousNo ratings yet

- Keyboard Shortcuts Guide for RevitDocument9 pagesKeyboard Shortcuts Guide for RevitMohit KohliNo ratings yet

- Revit Mep 1Document30 pagesRevit Mep 1Ali Alosh100% (1)

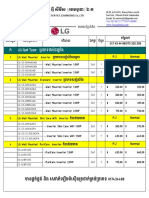

- ក LG Spit Type ប្រចេទជារ់ជញ្ជំង: #132 st.N.W21, Borey New world Sen Sok, Phnom Penh CambodiaDocument2 pagesក LG Spit Type ប្រចេទជារ់ជញ្ជំង: #132 st.N.W21, Borey New world Sen Sok, Phnom Penh CambodiaFILID MADNo ratings yet

- (Impreso) Revit 2018 Architecture - Certification Exam Study GuideDocument50 pages(Impreso) Revit 2018 Architecture - Certification Exam Study GuiderobertoNo ratings yet

- 3D Modeling Commands GuideDocument35 pages3D Modeling Commands GuideFILID MADNo ratings yet

- Pressure DropDocument81 pagesPressure Drophamzashafiq1100% (1)

- Khmer Auto CAD 2010 Thong KhinDocument67 pagesKhmer Auto CAD 2010 Thong KhinCheng Por EngNo ratings yet

- MODEL 5406A: Instruction ManualDocument24 pagesMODEL 5406A: Instruction ManualFILID MADNo ratings yet

- YORK Wall Mount InverterDocument4 pagesYORK Wall Mount InverterFILID MADNo ratings yet

- MODEL8031: Warning Phase Rotation TesterDocument2 pagesMODEL8031: Warning Phase Rotation TesterFILID MADNo ratings yet

- Hydraulic Hose Sizing NomographDocument3 pagesHydraulic Hose Sizing NomographFILID MADNo ratings yet

- Convert Amps to kVA Using VoltageDocument2 pagesConvert Amps to kVA Using VoltageFILID MADNo ratings yet

- How To Size Water Supply PipesDocument1 pageHow To Size Water Supply PipesFILID MADNo ratings yet

- FCU Air Flow TestDocument4 pagesFCU Air Flow TestFILID MADNo ratings yet

- SUBMERSIBLE PUMP SelectionDocument6 pagesSUBMERSIBLE PUMP SelectionSyed Muztuza AliNo ratings yet

- Energy + Nutrients RECYCLING When Possible: Industrial Wastewater Sewage: Human Domestic WastewaterDocument12 pagesEnergy + Nutrients RECYCLING When Possible: Industrial Wastewater Sewage: Human Domestic WastewaterFILID MADNo ratings yet

- How To Calculate Three Phase AmperageDocument2 pagesHow To Calculate Three Phase AmperageFILID MADNo ratings yet

- CalculationDocument5 pagesCalculationalok_rajpoot786100% (2)

- How Much Water Pressure Is Required For Fire Sprinkler SystemsDocument23 pagesHow Much Water Pressure Is Required For Fire Sprinkler SystemsFILID MADNo ratings yet

- AC Convert Formula: How To Convert Horsepower (Metric) To KilowattDocument2 pagesAC Convert Formula: How To Convert Horsepower (Metric) To KilowattFILID MADNo ratings yet

- 09 - Bolt PDFDocument2 pages09 - Bolt PDFShivam Shakti DubeyNo ratings yet

- B1 Pendent SprinklerDocument2 pagesB1 Pendent SprinklerDave BrownNo ratings yet

- CIVL 222 AXIAL MEMBERSDocument27 pagesCIVL 222 AXIAL MEMBERSskhan247100% (1)

- Pop Rivets ToolsDocument68 pagesPop Rivets ToolsrasheedgotzNo ratings yet

- Plateloadtests Asif Mir2021Document18 pagesPlateloadtests Asif Mir2021gouseyaNo ratings yet

- 2D CAD Data ListDocument809 pages2D CAD Data ListDesign IPGENo ratings yet

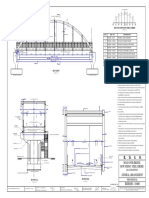

- Key elevation of bow string girderDocument1 pageKey elevation of bow string girdergoutammand100% (2)

- Structural Engineering Projects NameDocument12 pagesStructural Engineering Projects Namerssiit8137No ratings yet

- COMPANY FIELD LENGTH LISTDocument698 pagesCOMPANY FIELD LENGTH LISTroyalbrahmanNo ratings yet

- UU CD TestsDocument24 pagesUU CD TestsDenver James RabaraNo ratings yet

- Insurance - Plan Shell Peterhead Project For CCRSDocument68 pagesInsurance - Plan Shell Peterhead Project For CCRSjasper richards100% (1)

- Mini SquingDocument8 pagesMini SquingAhmed Al-JewariNo ratings yet

- Types of Steel PDFDocument8 pagesTypes of Steel PDFIyappan MuruganNo ratings yet

- Chapter 9d FractureDocument67 pagesChapter 9d Fractureprathik sNo ratings yet

- Plasterboard Installation Manual - Montaj RigipsDocument52 pagesPlasterboard Installation Manual - Montaj Rigipssarmis2No ratings yet

- Perfect Polymers - Product-Introduction - SUNPAL Multiwall Cell) Polycarbonate Standing-Seam Architectural SystemDocument28 pagesPerfect Polymers - Product-Introduction - SUNPAL Multiwall Cell) Polycarbonate Standing-Seam Architectural SystemGirish DhawanNo ratings yet

- Four-Storey Apartment Project Cost AnalysisDocument109 pagesFour-Storey Apartment Project Cost AnalysisKiesha SantosNo ratings yet

- Awtz14lbc Aotz14lbc 9315236036 OperationDocument28 pagesAwtz14lbc Aotz14lbc 9315236036 OperationjovanangelssNo ratings yet

- 29psheet Design Master HVACDocument3 pages29psheet Design Master HVACRhadityo Shakti Budiman100% (2)

- 2012 FWP Steps BrochureDocument12 pages2012 FWP Steps BrochureFort Wayne PoolsNo ratings yet

- Georgia Construction MonitorDocument67 pagesGeorgia Construction Monitorluke elbertNo ratings yet

- CYPECAD - User's ManualDocument141 pagesCYPECAD - User's ManualMajid AbujalilNo ratings yet

- Cutler Hammer 1MCB1000R BrochureDocument42 pagesCutler Hammer 1MCB1000R BrochureHoku's NickNo ratings yet

- Metric DIN 444 SpecDocument6 pagesMetric DIN 444 SpecJagadesh PNo ratings yet

- MS Underground HDPE PN10, Corrugated & uPVC Pipe Installation Works Rev01Document20 pagesMS Underground HDPE PN10, Corrugated & uPVC Pipe Installation Works Rev01mieadidassNo ratings yet

- Deterioration of Monuments and Their PreservationDocument11 pagesDeterioration of Monuments and Their PreservationPranav PadmavasanNo ratings yet

- Fasten BoltDocument1 pageFasten BoltSara BookerNo ratings yet

- Pl100 Pl200 Pl300 Pl400 SparepartDocument9 pagesPl100 Pl200 Pl300 Pl400 Sparepartphantomboyz_aip100% (1)

- BOT 02 2526.slimhole - BroDocument4 pagesBOT 02 2526.slimhole - Brorake1981No ratings yet

- Bearing Terminology: Principles of Bearing Selection and ApplicationDocument12 pagesBearing Terminology: Principles of Bearing Selection and ApplicationparthasfriendsNo ratings yet