Professional Documents

Culture Documents

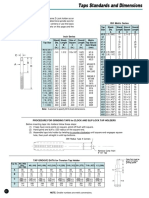

Thread Dimensions for Machine Screws

Uploaded by

arvindspakOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thread Dimensions for Machine Screws

Uploaded by

arvindspakCopyright:

Available Formats

Thread Dimensions

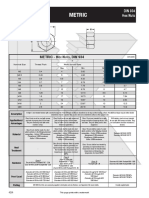

Machine Screws METRIC Mech. & Perform. Requirements

L

Basic

L

major

diameter

Basic

pitch

diameter

Minor

diameter

Axis of screw thread

DIN 13;

METRIC - External Threads for Machine Screws & Cap Screws, Class 6g ISO 898-1 &

965

Stress Tensile Strength for STEEL Screws

Nominal Major Diameter Pitch Diameter Minor Diameter

Area, N, min.

Size

Max Min Max Min Max Min mm2 Class 4.8 Class 8.8 Class 10.9

M1.6 1.581 1.496 1.354 1.291 1.151 1.075 - -

M2 1.981 1.886 1.721 1.654 1.490 1.407 - -

M2.5 2.480 2.380 2.188 2.117 1.928 1.840 - -

M3 2.980 2.874 2.655 2.580 2.367 2.273 5.03 2110 4020 5230

M4 3.978 3.838 3.523 3.433 3.119 3.002 8.78 3690 7020 9130

M5 4.976 4.826 4.456 4.361 3.995 3.869 14.2 5960 11,350 14,800

M6 5.974 5.794 5.324 5.212 4.747 4.596 20.1 8440 16,100 20,900

M8 7.972 7.760 7.160 7.042 6.438 6.272 36.6 15,400 29,200 38,100

M10 9.968 9.732 8.994 8.862 8.128 7.938 58 24,400 46,400 60,300

M12 11.966 11.701 10.829 10.679 9.819 9.602 84.3 35,400 67,400 87,700

M14 13.962 13.682 12.663 12.503 11.508 11.271 115 48,300 92,000 120,000

M16 15.962 15.682 14.663 14.503 13.508 13.271 157 65,900 125,000 163,000

M20 19.958 19.623 18.334 18.164 16.891 16.625 245 103,000 203,000 255,000

M24 23.952 23.577 22.003 21.803 20.271 19.955 353 148,000 293,000 367,000

M30 29.947 29.522 27.674 27.462 25.653 25.306 561 236,000 466,000 583,000

M36 35.940 35.465 33.342 33.118 31.033 30.655 817 343,000 678,000 850,000

M42 41.937 41.437 39.014 38.778 36.416 36.007

M48 47.929 47.399 44.681 44.431 41.795 41.352

M56 55.925 55.365 52.353 52.088 49.177 48.700

M64 63.920 63.320 60.023 59.743 56.559 56.048

3mm: ±0.2 4-6mm: ±0.24 8-10mm: ±0.29 12-16mm: ±0.35

Tolerance on Length

20-30mm: ±0.42 35-50mm: ±0.5 55-60mm: ±0.95

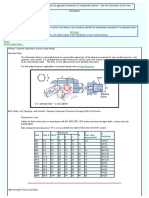

A metric machine screw is a straight shank fastener with a metric thread pitch designed to go through a hole or nut that is pre-tapped to

Description form a mating thread for the screw.

Machine screws form a fastening superior in strength to spaced thread screws. Metric screws are the type almost exclusively used in

Applications/ Advantages items manufactured in Europe.

Steel Stainless

A2 stainless screws shall be made from an austenitic stainless that

Class 4.8 machine screws shall be made from a carbon steel, conforms to the following chemical composition-- Carbon: 0.08%

Material partially or fully annealed as required, which conforms to the maximum; Silicon: 1.0% maximum; Manganese: 2.0% maximum;

following chemical composition-- Carbon: 0.55% maximum; Phosphorous: 0.05% maximum; Sulfur: 0.03% maximum;

Phosphorus: 0.05% maximum; Sulfur: 0.06% maximum. Chromium: 17.0 to 20.0%; Carbon: 0.55% maximum;

Nickel: 8.0 to 13.0%.

Hardness Rockwell B 71 - 99.5 (Vickers HV 130 - 250) Rockwell B85 - B95 (approximately)

Tensile Strength 420 N/mm2 minimum -

Stainless machine screws are usually provided plain or with a black

Plating See Appendix-A for plating information

oxide finish.

This page prints with a watermark.

388

Conversion

Machine Screws & SEMS METRIC Chart

Thread Pitch Comparison

Millimeters Threads per Inch

0.25 101.5

0.3 84.75

0.35 72.5

0.4 63.5

0.45 56.5

0.5 50.75

0.6 42.5

0.7 36.5

0.75 33.75

0.8 31.75

0.9 28.5

1 25.5

1.25 20.25

1.5 17

1.75 14.5

2 12.75

2.5 10.25

3 8.5

3.5 7.25

4 6.25

4.5 5.5

5 5.25

5.5 4.5

6 4.25

This page prints with a watermark.

You might also like

- Carpentry Canadian 3rd Edition Vogt Solutions Manual DownloadDocument13 pagesCarpentry Canadian 3rd Edition Vogt Solutions Manual DownloadKatherine Joseph100% (22)

- DIN13Document1 pageDIN13Mesut ÜnalNo ratings yet

- Minimum Thread Engagement With Respect To Material StrengthDocument10 pagesMinimum Thread Engagement With Respect To Material StrengthDarío CostasNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Assignment 1 - Brief - Unit 13 - LA 062016 No ComDocument4 pagesAssignment 1 - Brief - Unit 13 - LA 062016 No ComIsaiahNo ratings yet

- MetmachthreadDocument3 pagesMetmachthreadPatrick - Assist. Técnica - CetemNo ratings yet

- Screws Nuts Washer SizesDocument5 pagesScrews Nuts Washer SizesNanang RisdiantoNo ratings yet

- Bolt & Screw DetailsDocument6 pagesBolt & Screw Detailsjee01No ratings yet

- Metric hex nuts style 2 dimensions and propertiesDocument1 pageMetric hex nuts style 2 dimensions and propertiesRatendra kumarNo ratings yet

- Metric DIN 439 Spec PDFDocument4 pagesMetric DIN 439 Spec PDFHasib SejdinovicNo ratings yet

- Metric Coarse (Standard)Document3 pagesMetric Coarse (Standard)AJIT LONDHENo ratings yet

- Section 10 Useful Information: Iso General Purpose Metric ScrewthreadsDocument1 pageSection 10 Useful Information: Iso General Purpose Metric ScrewthreadsRicardo_CHES1986No ratings yet

- Screw DimensionDocument2 pagesScrew DimensionAbhijeet SinghNo ratings yet

- Metric Fasteners - DIN 985 Nylon Insert Stop Nuts - DimensionsDocument1 pageMetric Fasteners - DIN 985 Nylon Insert Stop Nuts - DimensionssnorklingmonkeyNo ratings yet

- Thread Tolerances For Screws and NutsDocument2 pagesThread Tolerances For Screws and NutsBill WhiteNo ratings yet

- NutsDocument8 pagesNutsGerry Dan ChanliongcoNo ratings yet

- Hex Key ChartDocument1 pageHex Key ChartMassimoNo ratings yet

- Zagar 7Document13 pagesZagar 7ratnakarNo ratings yet

- Tension RodDocument4 pagesTension RodMarkNo ratings yet

- Thread Geometry - Metric CoarseDocument4 pagesThread Geometry - Metric CoarseMociran FlorinNo ratings yet

- Dimensions of Metric Hex NutsDocument2 pagesDimensions of Metric Hex Nutsdidik sNo ratings yet

- Metric DIN 6797 Tooth Lock Washers: Visit Our For Product AvailabilityDocument5 pagesMetric DIN 6797 Tooth Lock Washers: Visit Our For Product AvailabilityShrikant DeshmukhNo ratings yet

- Din 933Document2 pagesDin 933Sugumar0% (1)

- Metric DIN 985 Nylon Insert Lock Nut Dimensions & SpecsDocument4 pagesMetric DIN 985 Nylon Insert Lock Nut Dimensions & Specsvikram jainNo ratings yet

- Metric DIN 433 Flat Washer Dimensions and SpecificationsDocument4 pagesMetric DIN 433 Flat Washer Dimensions and SpecificationsChris StefanouNo ratings yet

- DIN 934 Metric Hex Nuts SpecificationDocument1 pageDIN 934 Metric Hex Nuts SpecificationfastenersworldNo ratings yet

- Standard Pipe Specification EN 10255Document1 pageStandard Pipe Specification EN 10255Burak KececiNo ratings yet

- Metric nylon insert lock nuts DIN 985 guideDocument1 pageMetric nylon insert lock nuts DIN 985 guidemaicon sulivanNo ratings yet

- ASDO Structural Tie Bars Design CapDocument1 pageASDO Structural Tie Bars Design CapAjiboye MubarakNo ratings yet

- Asdo Tie Bar Design Capacities: Product DataDocument2 pagesAsdo Tie Bar Design Capacities: Product DatasivakumarNo ratings yet

- Pages From Astm-A194-2011pdf - CompressDocument1 pagePages From Astm-A194-2011pdf - CompressMuthazhagan SaravananNo ratings yet

- Bbs For Pier and Pear Cap of P1 at CH: 128+730Document25 pagesBbs For Pier and Pear Cap of P1 at CH: 128+730balaNo ratings yet

- Hex Jam Nut Metric (ISO 4035)Document1 pageHex Jam Nut Metric (ISO 4035)Abu IrfanNo ratings yet

- Metric DIN 939 Double End Studs (1.25xD) : Visit Our For Product AvailabilityDocument4 pagesMetric DIN 939 Double End Studs (1.25xD) : Visit Our For Product Availabilitysudarshan pugaliaNo ratings yet

- Metric DIN 432 SpecDocument4 pagesMetric DIN 432 SpecivanNo ratings yet

- Iso 965 2 1998Document8 pagesIso 965 2 1998Gerald CelisNo ratings yet

- Wrench ClearancesDocument2 pagesWrench ClearancesRowan JoguilonNo ratings yet

- Hex Key ChartDocument1 pageHex Key Charter lopNo ratings yet

- Metric Bolt Torque Table NM - CNCexpoDocument1 pageMetric Bolt Torque Table NM - CNCexponate anantathat100% (1)

- Metric Bolt Torque Table NmDocument1 pageMetric Bolt Torque Table NmninatenaNo ratings yet

- Metric DIN 609 SpecDocument4 pagesMetric DIN 609 SpecCAT MINING SHOVELNo ratings yet

- High Tensile Bolts TechnicalDocument6 pagesHigh Tensile Bolts Technicalventhan_kalaiNo ratings yet

- Technical Data Sheet For Mgs and MGSRDocument3 pagesTechnical Data Sheet For Mgs and MGSRFILID MADNo ratings yet

- ISO 7040 Material A4-80Document1 pageISO 7040 Material A4-80rijalharunNo ratings yet

- Hex Key Chart Provides Sizes and Dimensions for Allen KeysDocument1 pageHex Key Chart Provides Sizes and Dimensions for Allen KeysRoss EdwardNo ratings yet

- Metric Hexbolt Grades PDFDocument2 pagesMetric Hexbolt Grades PDFShamaNo ratings yet

- High Tensile: Hexagon Head Setscrews Fine Pitch EN ISO 8676 (DIN 961)Document2 pagesHigh Tensile: Hexagon Head Setscrews Fine Pitch EN ISO 8676 (DIN 961)jaison jacobNo ratings yet

- Metric, Hex Cap Screw, DIN 933 Fully Threaded, A4-70 Stainless SteelDocument2 pagesMetric, Hex Cap Screw, DIN 933 Fully Threaded, A4-70 Stainless Steelrobert_candra_tarunaNo ratings yet

- Metric: Hex Nut Style 2 Class 12Document1 pageMetric: Hex Nut Style 2 Class 12Ankit LonareNo ratings yet

- Table of Bolt SizesDocument5 pagesTable of Bolt Sizesnagaraj108No ratings yet

- 13.-En_NT_Bolts_UtilcellDocument3 pages13.-En_NT_Bolts_Utilcellnu.arabiaNo ratings yet

- Metric DIN 7349 SpecDocument6 pagesMetric DIN 7349 SpecANIRBANNo ratings yet

- G CAST - Catalogue Prestressed BeamDocument6 pagesG CAST - Catalogue Prestressed BeamFadhli ATZNo ratings yet

- Earnest Technical Bulletin: Comparison of ANSI, DIN and ISO Hex Head Cap ScrewsDocument2 pagesEarnest Technical Bulletin: Comparison of ANSI, DIN and ISO Hex Head Cap ScrewsMiguel EstevesNo ratings yet

- Torque SettingsDocument3 pagesTorque Settingsgamedbk002No ratings yet

- Socket Head Cap Screws Dimensions and Torque SpecsDocument4 pagesSocket Head Cap Screws Dimensions and Torque SpecssarbiniNo ratings yet

- Thread Dimensions 2Document1 pageThread Dimensions 2bcsf010% (1)

- DIN 7980 Spring Lock Washer - Fasteners ChinaDocument2 pagesDIN 7980 Spring Lock Washer - Fasteners ChinaHala Ibrahim El-BassyouniNo ratings yet

- Holding Down Bolts BS 7419 (Square Square) : Grade 4.6 & 8.8Document2 pagesHolding Down Bolts BS 7419 (Square Square) : Grade 4.6 & 8.8Thilan SenarathneNo ratings yet

- Fasten BoltDocument1 pageFasten BoltSara BookerNo ratings yet

- MV Cable Current Carrying Capacity NA2XSEYBY SucacoDocument1 pageMV Cable Current Carrying Capacity NA2XSEYBY SucacoharisNo ratings yet

- ETP Assessment GuideDocument79 pagesETP Assessment GuideAl Mamun HossainNo ratings yet

- Accreditation and Affiliation Guidelines PDFDocument54 pagesAccreditation and Affiliation Guidelines PDFHaribhaskar GovindarajuluNo ratings yet

- Brushless Servo Amplifier 19972007Document1 pageBrushless Servo Amplifier 19972007arvindspakNo ratings yet

- IGBT Junction Test ProcedureDocument1 pageIGBT Junction Test ProceduremherbakNo ratings yet

- Brushless Servo Amplifier 19972007Document1 pageBrushless Servo Amplifier 19972007arvindspakNo ratings yet

- bts3000 Ds PDFDocument2 pagesbts3000 Ds PDFarvindspakNo ratings yet

- Arc Welding Solution Arm PDFDocument2 pagesArc Welding Solution Arm PDFarvindspakNo ratings yet

- Brochure Solar Compact Street Light PDFDocument2 pagesBrochure Solar Compact Street Light PDFarvindspakNo ratings yet

- MBA-Project Guideline PDFDocument7 pagesMBA-Project Guideline PDFAbhi Singh100% (1)

- Book 4: Alternating Current Electric CircuitDocument566 pagesBook 4: Alternating Current Electric CircuitMAT JIBRUD100% (3)

- Book 4: Alternating Current Electric CircuitDocument566 pagesBook 4: Alternating Current Electric CircuitMAT JIBRUD100% (3)

- Milling MachineDocument43 pagesMilling MachineJUAN DAVID MOSQUERA GARCIANo ratings yet

- Lavanya Industries Tool Manufacturing Facility ProfileDocument11 pagesLavanya Industries Tool Manufacturing Facility ProfilepmlmkpNo ratings yet

- Press Working TerminologyDocument16 pagesPress Working TerminologyAadrika UmashankarNo ratings yet

- Metric ThreadDocument27 pagesMetric Threadlucian lunaNo ratings yet

- Broaching Machine Guide: Types, Operations & AdvantagesDocument8 pagesBroaching Machine Guide: Types, Operations & AdvantagesJaya RamanNo ratings yet

- WeldingDocument23 pagesWeldingSuneel Kumar MeenaNo ratings yet

- Welder Model QuestionDocument4 pagesWelder Model QuestionSaheed JdtNo ratings yet

- Hanro Tools Incorporation Delhi IndiaDocument10 pagesHanro Tools Incorporation Delhi IndiaHanro Tools IncorporationNo ratings yet

- Channel Nuts & HardwareDocument28 pagesChannel Nuts & HardwareicsNo ratings yet

- Inspection Report - Foundation BoltDocument4 pagesInspection Report - Foundation BoltvidyaNo ratings yet

- Internship Presentstion On: "CNC Programming and Operation"Document18 pagesInternship Presentstion On: "CNC Programming and Operation"Rathan Kumar SMNo ratings yet

- Metal WorksDocument16 pagesMetal WorksMAXINE DELA ROSANo ratings yet

- Repair ProcedureDocument5 pagesRepair ProcedureAndreas Schlager100% (3)

- Cast Iron Welding AlloysDocument4 pagesCast Iron Welding AlloysKhin Aung ShweNo ratings yet

- Machining Science: Jigs & FixturesDocument29 pagesMachining Science: Jigs & FixturesChidu KNo ratings yet

- European Steel and Alloy Grades: Gx3Crni13-4 (1.6982)Document2 pagesEuropean Steel and Alloy Grades: Gx3Crni13-4 (1.6982)farshid KarpasandNo ratings yet

- 1.2003 Datasheet, 1.2003 Chemical, 1Document2 pages1.2003 Datasheet, 1.2003 Chemical, 1Slobodan NocajNo ratings yet

- Kmini100us 3.2011 PDFDocument340 pagesKmini100us 3.2011 PDFnofearnemNo ratings yet

- Report Machining Report 2 DJJ10022 Dis 2020Document13 pagesReport Machining Report 2 DJJ10022 Dis 2020JxyaNo ratings yet

- Yo 8039Document25 pagesYo 8039Corneliu LeotescuNo ratings yet

- C45 Steel DatasheetDocument1 pageC45 Steel DatasheetEnter ExitNo ratings yet

- Pg1078-1109 - Products DataDocument32 pagesPg1078-1109 - Products DataRANJANI RAGHUNATHANNo ratings yet

- Normalizing Process For SteelsDocument3 pagesNormalizing Process For Steelsduazo2009No ratings yet

- Bench GrinderDocument1 pageBench GrinderSreejith S NairNo ratings yet

- Indian Standard Is CodeDocument5 pagesIndian Standard Is Codepriyanka236No ratings yet

- Metal Work Machines - Edu Delight Tutors - Jss 3Document15 pagesMetal Work Machines - Edu Delight Tutors - Jss 3ElliotNo ratings yet

- Traditional Machining Processes ExplainedDocument45 pagesTraditional Machining Processes Explainedhaile mehariNo ratings yet

- Management Process IIDocument200 pagesManagement Process IIPeeka Prabhakara RaoNo ratings yet