0% found this document useful (0 votes)

347 views6 pagesInlet Gas Compressor Sizing Guide

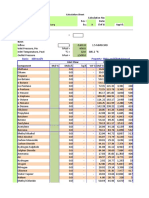

The document provides information for sizing an inlet gas compressor for an OGPE oil field project. It includes inlet gas flow rate and properties, compressor specifications including polytropic efficiency and pressure ratio, and calculations of fluid power required, shaft power, discharge temperature and flow rate. Conversion factors are also provided. The summary is:

1) The document provides inlet gas properties and calculations to size a compressor for an OGPE oil field project.

2) It calculates the fluid power, shaft power, discharge temperature and flow rate based on the inlet gas flow rate and properties, and compressor specifications including polytropic efficiency and pressure ratio.

3) Conversion factors for various units are included at the end.

Uploaded by

sterlingCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

347 views6 pagesInlet Gas Compressor Sizing Guide

The document provides information for sizing an inlet gas compressor for an OGPE oil field project. It includes inlet gas flow rate and properties, compressor specifications including polytropic efficiency and pressure ratio, and calculations of fluid power required, shaft power, discharge temperature and flow rate. Conversion factors are also provided. The summary is:

1) The document provides inlet gas properties and calculations to size a compressor for an OGPE oil field project.

2) It calculates the fluid power, shaft power, discharge temperature and flow rate based on the inlet gas flow rate and properties, and compressor specifications including polytropic efficiency and pressure ratio.

3) Conversion factors for various units are included at the end.

Uploaded by

sterlingCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

- Calculation Sheet

- Compressor Sizing Instructions

- Revision Notes