Professional Documents

Culture Documents

IcoR200 Replacement-1

Uploaded by

mrscribdOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IcoR200 Replacement-1

Uploaded by

mrscribdCopyright:

Available Formats

lz

o

h

s

a

V

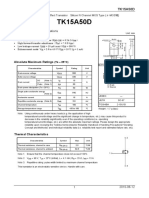

AXIOM Iconos R200

AX

Replacement of Parts

Iconos R200

Basic Unit and Collimator

07030930

07030518

07030500

© Siemens AG 1999

The reproduction, transmission or use

of this document or its contents is not

permitted without express written

authority. Offenders will be liable for

damages. All rights, including rights

created by patent grant or registration

of a utility model or design, are

reserved.

Print No.: AXD3-340.841.01.06.02 English

Replaces: AXD3-340.841.01.05.02 Doc. Gen. Date: 11.02

2 Revision / Disclaimer

1Revision / Disclaimer

Document revision level

The document corresponds to the version/revision level effective at the time of system

delivery. Revisions to hardcopy documentation are not automatically distributed.

Please contact your local Siemens office to order current revision levels.

Disclaimer

The installation and service of equipment described herein is to be performed by qualified

personnel who are employed by Siemens or one of its affiliates or who are otherwise

authorized by Siemens or one of its affiliates to provide such services.

Assemblers and other persons who are not employed by or otherwise directly affiliated

with or authorized by Siemens or one of its affiliates are directed to contact one of the

local offices of Siemens or one of its affiliates before attempting installation or service pro-

cedures.

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 2 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

Table of Contents 3

1- 0Table of Contents

1 _______ Requirements___________________________________________________ 6

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Required Aids and Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Product-specific Remarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

General Remarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 _______ Tilt Drive ______________________________________________________ 11

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Checking Play between the Sprockets and Chains . . . . . . . . . . . . . . . . . . . . . . . . . 11

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Checking Play between the Sprockets and Chains . . . . . . . . . . . . . . . . . . . . . . . . . 15

Adjusting the Safety Limit Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3 _______ Replacement Adjustment ________________________________________ 17

I.I. Contact Safety Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

For 20/90° AXIOM Iconos R200 Units Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4 _______ Lift Base ______________________________________________________ 18

Contact Safety Device / Chain Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Replacing the Plastic Strips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5 _______ Spotfilm Devices, Long. and Column, Long. ________________________ 21

Replacing the Spotfilm Device Longitudinal Drive or Motor . . . . . . . . . . . . . . . . . . . . . . 21

Adjusting the Spotfilm Device Longitudinal Drive Chain Tension. . . . . . . . . . . . . . . . . . 24

Replacing the Column Longitudinal Drive or Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Adjusting the Column Longitudinal Drive Chain Tension . . . . . . . . . . . . . . . . . . . . . . . . 29

Replacing the Master Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Removing the Column Drive if there is no Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6 _______ Tabletop ______________________________________________________ 38

Replacing the Table Frame, Complete. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Measuring the distance of the table frame to the spotfilm device . . . . . . . . . . . . . . . 39

Replacing the Tabletop Transverse Drive and Potentiometers . . . . . . . . . . . . . . . . . . . 41

Adjusting the Range Limit Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Adjusting the Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Removing the Protective Panel under the Tabletop . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Replacing the Tabletop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Tabletop Longitudinal Drive Chain Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Replacing the Tabletop Longitudinal Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Siemens AG AXD3-340.841.01.06.02 Page 3 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

4 Table of Contents

7 _______ SID Drive ______________________________________________________ 51

Replacing the Drive and Gas Spring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Adjusting the Limit Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Adjusting the Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8 _______ Replacing the Tomo Rod and Clamping Ring ________________________ 56

9 _______ Tube Rotation Assembly _________________________________________ 60

Replacing the Tube Rotation Assembly, Complete. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

10 ______ Tube Assembly ________________________________________________ 65

Replacing the Tube Assembly on the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

11 ______ Centering of Central Beam _______________________________________ 67

Centering the Central Beam to the Image Receptor System . . . . . . . . . . . . . . . . . . . . . 67

General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Function Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Checking the Central Beam Vertically to the Image Receptor in the Table Transverse

Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Checking the Central Beam Perpendicular to the Image Receptor in the Table Longitu-

dinal Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Adjusting the Central Beam Centered to the Image Receptor in the Table Transverse

Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Checking the Central Beam Centered to the Image Receptor in the Table Longitudinal

Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Adjustment of I.I. Center to Center of Spotfilm Device . . . . . . . . . . . . . . . . . . . . . . . 74

Coincidence of the radiation field and the center of the film . . . . . . . . . . . . . . . . . . . 77

Central Beam Drift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Central Beam to Bucky Wall Stand and for Bed-side Exposures . . . . . . . . . . . . . . . . . . 81

12 ______ Control Consoles _______________________________________________ 82

Remote Control Console. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Complete Replacement of the Remote Control Console. . . . . . . . . . . . . . . . . . . . . . 82

Replacing the Joystick in the Remote Control Console. . . . . . . . . . . . . . . . . . . . . . . 82

Tableside Control Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

13 ______ Collimator _____________________________________________________ 84

Replacement of Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Adjusting the Grid in Units without a Spotfilm Device . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

14 ______ Compression __________________________________________________ 87

Replacing the Compression Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Function Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Adjusting the Limit Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 4 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

Table of Contents 5

50 N Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

150 N Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

15 ______ Electrical Assemblies ___________________________________________ 91

Removing the Cover Panels on the M1/M2 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Replacing Electrical Assemblies in the Lifting Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Replacing the D1 BUC Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Replacing the G1 and G2 Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Replacing the Z1 Power Line Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Replacing the Micromaster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Replacing Electrical Assemblies general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Replacing the Master Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Replacing the D2 Spotfilm Device Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Replacing the D41 Spotfilm Device Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

16 ______ Changes to Previous Version____________________________________ 120

Siemens AG AXD3-340.841.01.06.02 Page 5 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

6 Requirements

2-

Requirements

1Requirements

Required Aids and Tools 0

All tools, test equipment and aids, with the exception of the “standard service tool kit”, are

listed and specified in the Service Tools Catalogue.

• ICONOS SSW

• Digital-Multimeter (e.g. Fluke 8060A) 97 02 101 RE999

• cm ruler

• Slide calipers

• Spring balance, 100 N 44 29 122 MH029

• Longtime PD2 (20 gr.) 34 91 271

• Loctite 221 20 48 874

• Torque wrench, up to 100 Nm 44 30 906 MH029

• Allen wrench set for flat-head screws 81 02 980 RE999

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 6 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

Requirements 7

Notes 0

Safety Information 0

General Safety Information

When carrying out the work steps and checks, the general safety information contained in

ARTD (General Guidelines for Technical Service) must be observed.

CAUTION Only for ICONOS R200

The BUC (Basic Unit Controller) can be destroyed by “ground

loops”. The BUC inputs for potentiometers as well as for limit

switches are not protected against short-circuits or ground loops.

¹ When replacing parts or when performing checks, it is

absolutely necessary to switch off the system.

NOTE Use only the paneling screws that secure those cover panels in

place, otherwise there is a risk that cables can be damaged when

there are unit movements.

WARNING Dangerous X-radiation during checks and adjustment work steps.

Risk of death or serious bodily injury.

¹ For checks and adjustments that must be performed with

radiation switched on, the prescribed radiation safety

measures must be observed; if necessary, wear radiation

protective clothing (see also ARTD-002.731.02... and

ARTD-002.731.38... General Guidelines for Technical Ser-

vice). These checks and adjustments are explicitly

labeled on the following pages with the radiation warning

symbol x.

Product-specific Safety Information

When carrying out the work steps and checks, the product-specific safety information con-

tained in the documents must be observed.

Product-specific Remarks 0

• Depending the version, the illustrations and drawings can appear slightly different from

what has been shipped.

• Damaged or worn parts may be replaced only with original parts.

• If there is a malfunction, first check the mechanical parts of the drive.

• Special attention should be paid to easy movement of all movable parts.

Siemens AG AXD3-340.841.01.06.02 Page 7 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

8 Requirements

• Jamming will cause a switch-off by the safety software.

• For this reason, check the cleanliness and lubrication of rails and guide parts, check the

chain and toothed belt tension for the particular drive, the function of the brakes, and if

needed, clean off any wear residue and adjust the air gap.

Lubrication Locations

All accessible chains and gear drives, glide and roller bearing guides must be checked for

their condition prior to performing the particular adjustment and, if needed, lubricated with

Longtime PD2 (unless otherwise indicated).

Adjusting Ball Bearings

The support and roller bearings are adjusted so that the roller bearing that is not under

load can still just be turned by hand.

Securing Screws

All screws that have been removed for adjustment purposes must be secured again to

their original condition. Secure screws with appropriate lock washers, counternuts or Loc-

tite 221, Part No. 20 48 874. Securing screws with Loctite, if required, is specified in the

text.

When working with Loctite, make absolutely sure that the material does not unintention-

ally get into any bearings.

A bearing that would seize up because of this would become apparent only after several

days.

Loctite can be freed up again with heat (hot air gun, etc.).

Remarks Regarding Adjustment

NOTE After every parts replacement or adjustment, the function test de-

scribed in the SSW absolutely must be performed.

Replacement of Mechanical Parts and Adjustments

Must be observed:

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 8 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

Requirements 9

Mech. parts For the most part, a description of how to access the component to

be replaced is provided here. A detailed description (e.g. removing

all screws on a drive) is not provided, because this can be seen

clearly by actually performing the work step.

Concluding function tests, as well as movements of drives to certain

positions in exceptional cases, are described in the SSW. Only ref-

erences to the appropriate screens are made in this document.

Mech. Adjust- All mechanical adjustments are described.

ments Prerequisites (accessibility) are only briefly indicated. Exact infor-

mation is provided in Replacement of Parts. Concluding function

tests, as well as movements of drives to certain positions in excep-

tional cases, are described in the SSW. Only references to the

appropriate SSW screen are made in this document.

Corrective Measures/Adjustments

References are made in this document several times to the SSW for corrective measures

or adjustments.

For the adjustments, etc., start the XCS SSW program under “Components/ICONOS”.

General Remarks 0

Tolerance Data

General tolerances for linear dimensions per ISO 2768

These tolerances apply for all dimensions listed in these instructions as long as no other

tolerance is expressly listed next to the value.

Limit value for over over over over over over over

the nominal 3 mm to 6 mm to 30 mm to 120 mm 400 mm 1000 mm 2000 mm

range 6 mm 30 mm 120 mm to to to to

400 mm 1000 mm 2000 mm 4000 mm

Adm. toler- ± 0,5 mm ± 1 mm ± 1,5 mm ± 2,5 mm ± 4 mm ± 6 mm ± 8 mm

ance

Maximum Torque Values

Nominal Screw material Steel per DIN 267 Brass CuZn

thread diame- alloy

ter

Hardness rating 4,6 4,8 5,8 8,8 10,9 12,9

M3 0,5 0,67 0,83 1,3 1,9 2,2 0,62

M 3.5 0,76 1,0 1,3 2,0 2,8 3,4 0,95

M4 1,1 1,5 1,9 3,0 4,2 5,1 1,4

Siemens AG AXD3-340.841.01.06.02 Page 9 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

10 Requirements

M5 2,2 3,0 3,7 6,0 8,4 10,1 2,8

M6 3,8 5,1 6,4 10,2 14,4 17,3 4,8

M8 9,5 12,6 15,8 25,3 35,6 42,7 11,9

M 10 18,7 24,8 31,1 49,8 70,0 84,0 23,3

M 12 32,9 43,8 54,8 87,6 123,3 147,9 41,1

When checking tightness, use the corresponding torque values for hardness rating 8.8.

A tolerance of 10% is permissible for torque values.

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 10 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

Tilt Drive 11

3-

Replacement

2Tilt Drive

Checking Play between the Sprockets and Chains 0

Fig. 1: Play in tilt drive

NOTE If the motor is defective, the complete drive must be replaced.

It is absolutely necessary to use the “Tilt Drive Service Kit ” as

specified in the Spare Parts Catalogue.

• Move the spotfilm device and column to the foot end.

• Carefully raise the unit to approx. the 70° position (unit support in center of gravity).

• Check and make a note of the play by manually tilting the unit support to

(Fig. 1 / p. 11).

Procedure 0

• Move the unit into the -15° position and position the spotfilm device is approx. the mid-

dle of the movement range.

• Exactly mark the position of the drive support plate at the corners at the foot end.

• Move the unit into the 0° position.

Siemens AG AXD3-340.841.01.06.02 Page 11 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

12 Tilt Drive

1 5

Fig. 2: Mounting screws Fig. 3: Install the bracket

3 2

1 4

Fig. 4: Replacement aid Fig. 5: Tilt drive

• Remove the first two mounting screws on the tilt segment at the foot end on the opera-

tor's side of the unit support (1/Fig. 2 / p. 12).

• Move the unit into the 80° position.

• Exactly mark the position of the drive support plate at the corners at the head end.

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 12 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

Tilt Drive 13

• Install the tilt drive replacement aid as follows:

- Place the bracket (1/Fig. 3 / p. 12) (1/Fig. 4 / p. 12) on the strut (2/Fig. 3 / p. 12). In-

sert the M8 screws included in the shipment with washers (3/Fig. 3 / p. 12)

(3/Fig. 4 / p. 12), if needed, move the unit accordingly.

- Install the clamping bracket (4/Fig. 4 / p. 12) over the support strut with the bracket

(M8 screws with washers).

- Tighten the two screws (3/Fig. 3 / p. 12) (3/Fig. 4 / p. 12).

• Remove the cover panel (5/Fig. 3 / p. 12) over the switch assembly.

• In the SSW: read out and make a note of the potentiometer value of the tilt drive

ICONOS SSW/ Adjustment/ Calibration/ Tilt drive/ Tilt drive: Potentiometer ad-

justment read out and make a note of the "Current value".

• Remove the cover panels on the unit base.

• Switch the system OFF.

• Remove the unit foot-end cover for the M1 assembly.

• Remove the 4 Allen screws on the drive support plate (1/Fig. 5 / p. 12) (10 mm Allen

wrench).

• Remove the fan cover (3/Fig. 5 / p. 12) for the motor.

• Remove the cover panel (4/Fig. 5 / p. 12) over the potentiometer assembly.

3

3

4 2

2 1

Fig. 6: Potentiometer pinion marking Fig. 7: Potentiometer assembly

• Remove the 3 Allen-head countersunk screws on the switch assembly (3/Fig. 6 / p. 13).

• Mark the position of the potentiometer on the pinion gear and on the unit base

(Fig. 6 / p. 13).

• Remove the mounting screws (1/Fig. 7 / p. 13), secure the potentiometer assembly

along with the switch assembly to the motor with insulation tape.

• Loosen the chain cover strip (3/Fig. 7 / p. 13) at the head end (remove the 2 Allen

screws from the flat piece).

Siemens AG AXD3-340.841.01.06.02 Page 13 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

14 Tilt Drive

• Pull back the drive slightly and while doing so, turn the the motor fan wheel manually to

the right (clockwise) until the sprockets disengage.

NOTE To make sure the floor plate does not get scratched, make abso-

lutely sure to place the foam packing under the drive support plate.

• Disconnect the motor.

• To assure that the plastic gear does not hit against the strut (5/Fig. 5 / p. 12)

(5/Fig. 7 / p. 13), lift the drive out of the base over the strut and place it down on a foam

plastic mat.

• Remove the chain cover strip (3/Fig. 7 / p. 13) from the return guide.

• Remove the chain cover strip return guide (4/Fig. 7 / p. 13).

• Remove the drive mounting screws. To do this, use the short wrench and the extension

attachment.

• Carefully tilt the drive the drive support plate onto its head (place a foam plastic mat un-

der it).

• Pry the drive support plate off the roll pins.

Fig. 8: Drive support plate

• Place on a new gear (drive).

• Apply Loctite 221 to the 4 new Allen screws and loosely thread them inwithout plate

washers, only with lock washers.

• Secure the drive support plate in place using the 4 new roll pins (1/Fig. 8 / p. 14) from

below.

• Tilt the drive again.

• Tighten the drive mounting screws.

NOTE Use the jumpers in the motor terminal box from the original.

• Install the return guide for the chain cover strip and tighten the chain cover strip.

• Raise the drive above the strut (5/Fig. 5 / p. 12) (5/Fig. 7 / p. 13) in the base.

• Connect the motor.

• Remove the plastic foam.

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 14 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

Tilt Drive 15

• Insert the drive at the head end; to do this, turn the fan gear to the left until the sprocket

engages securely in the chain links.

• Align the drive support plate to the markings and retighten the 4 Allen screws; turn the

fan gear accordingly to align it.

• Install the switch assembly.

• Remove the two brackets for the tilt drive replacement aid.

Checking Play between the Sprockets and Chains 0

• Move the spotfilm device and column to the foot end.

• Carefully raise the unit to approx. the 70° position (unit support in center of gravity).

• Check the play by manually tilting the unit support to (Fig. 1 / p. 11).

Correction:

• Move the drive to the foot end

¹ the play is reduced

• Move the drive to the head end

¹ the play is increased

• Apply Loctite 221 to the first two head-end, operator's side mounting screws for the tilt

segment and thread them into the unit support. Torque: 25 Nm.

• Switch the system ON.

• Install the potentiometer assembly.

- To perform a coarse adjustment of the tilt potentiometer using the SSW: StartI-

CONOS SSW/ Adjustment/ Calibration/ Tilt drive/ Tilt drive: Potentiometer ad-

justment and preset the potentiometer to the "Current value" that was noted.

• Disengage the emergency stop switch.

• Move the unit into the 0° position.

• Perform an adjustment or a check of the tilt drive potentiometer. ICONOS SSW/ Ad-

justment/ Calibration/ Tilt drive/ Tilt drive: Potentiometer adjustment

• When doing so, observe the following work steps:

- To adjust the potentiometer, loosen the two screws (1/Fig. 7 / p. 13) and move the

potentiometer assembly (2/Fig. 7 / p. 13).

- Turn the pinion gear (1/Fig. 6 / p. 13) accordingly and by doing this, preadjust the

potentiometer using the zero adjustment method.

- Press the potentiometer assembly with slight pressure against the plastic gear

(2/Fig. 6 / p. 13), so that if there is a possible deflection movement of the plastic gear,

both pinion gears remain securely meshed.

• Perform the check and the function check described in Online Help under ICONOS

SSW/ Adjustment/ Calibration/ Tilt drive/ Tilt drive: Potentiometer adjustment.

• Install all cover panels. Make sure that the ground wires provided are connected to the

cover panels.

Siemens AG AXD3-340.841.01.06.02 Page 15 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

16 Tilt Drive

Adjusting the Safety Limit Switches 0

• Tilt the unit up all the way.

Fig. 9:

Check the distance (Fig. 9 / p. 16) between the particular limit switch and the switch

strike plate.

• Press the limit switch.

¹ The safety breaker(s) must audibly deenergize.

• Move the longitudinal carriage all the way to the foot end.

• Tilt the unit down all the way.

• Check the distance (Fig. 9 / p. 16) between the particular limit switch and the switch

strike plate.

• Press the limit switch.

¹ The safety breaker(s) must audibly deenergize.

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 16 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

Replacement Adjustment 17

4-

I.I. Contact Safety Device

3Replacement Adjustment

For 20/90° AXIOM Iconos R200 Units Only 0

Fig. 10: 40 cm I.I. carriage

With some units, it is possible that the switch in the I.I. contact safety device will actuate

during normal movement, or that the switch cannot be moved up far enough in a replace-

ment situation.

In such cases only, the piston (1/Fig. 10 / p. 17) can be cut off by up to 10 mm. It is critical

that the switch reliably protects the I.I.

• It is absolutely necessary to perform the following test:

- Unit in the 0° position.

- Move the spotfilm device all the way to the foot end.

- Move the unit into the max. Trendelenburg position.

- Move the spotfilm device all the way to the head end.

- The switch may not touch the floor. The spacing from the I.I. to the floor depends on

the system:

min. 4 cm = standard

A spacing of min. 2 cm must be maintained only in systems configured with the

40 cm I.I. and spotfilm device.

When in doubt, see SSW/ICONOS R200 “Adjustment/ Room Dimensions”.

Siemens AG AXD3-340.841.01.06.02 Page 17 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

18 Lift Base

5-

Contact Safety Device / Chain Switch

4Lift Base

Adjusting the Safety Limit Switches

X

1

3

3

4

6 4

Fig. 11: Fig. 12:

Fig. 13: Fig. 14:

• Move the unit to approx. 70 degree position.

• Remove both front lift base cover panels (4/Fig. 11 / p. 18).

• The switch bracket (2/Fig. 12 / p. 18) must be at the bottom of the lift base.

• If necessary, loosen Allen screws (3/Fig. 12 / p. 18) fort it and adjust the switch bracket

by the nutr (4/Fig. 12 / p. 18). Then retighten the Allen screws.

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 18 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

Lift Base 19

• Loosen the two Allen screws (5/Fig. 13 / p. 18) and reposition the mounting bracket

(6/Fig. 13 / p. 18) so that the edge of the switch plates are flush with the top edge of the

mounting plate (X/Fig. 12 / p. 18). Secure the mounting bracket with the two Allen

screws (5/Fig. 13 / p. 18).

• The microswitches should now be approximately in the middle of the switch strike plate

(Fig. 14 / p. 18). If necessary, slightly change the position of the mounting bracket

(6/Fig. 13 / p. 18).

• Reinstall the cover panels in the reverse order of the instructions above.

Siemens AG AXD3-340.841.01.06.02 Page 19 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

20 Lift Base

Replacing the Plastic Strips 0

1 2

5 1

3

2

1

6

4

Fig. 15: Fig. 16:

• Remove the top lift base cover panel (1/Fig. 15 / p. 20).

• Move the unit to approx. the 70 degree position.

• Remove both front lift base cover panels (4/Fig. 15 / p. 20).

• Pull up the top plastic strip and remove the counterweight (2 flat pieces).

• Remove both plates (1, 2/Fig. 16 / p. 20) (2 Allen screws on each).

• The plastic strip with the plate can now be removed by pulling them up or down.

• When inserting the new plastic strips, make sure that they are in the guide track.

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 20 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

Spotfilm Devices, Long. and Column, Long. 21

6-

Replacing the Spotfilm Device Longitudinal Drive or Motor

5Spotfilm Devices, Long. and Column, Long.

4

10 9

3

7

6

Fig. 17: Unit support cover panel

Remove the following cover panels:

• Head-end table support cover panel (5 paneling screws) (1/Fig. 17 / p. 21).

• Foot-end table support cover panel (8 paneling screws) (2/Fig. 17 / p. 21).

• Chain cover panel (3/Fig. 17 / p. 21) and plastic strip.

• Move the unit into the 0° position

• If possible, move the spotfilm device all the way to the head end.

• System OFF.

Siemens AG AXD3-340.841.01.06.02 Page 21 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

22 Spotfilm Devices, Long. and Column, Long.

8

9

Fig. 18: Replacement of the spotfilm device longitudinal drive

• Loosen the 5 Allen-head mounting screws (6/Fig. 18 / p. 22).

• Loosen both tension screws (10/Fig. 17 / p. 21) and (8/Fig. 18 / p. 22) on the inside of

the unit support.

• Completely remove the 5 Allen-head mounting screws (6/Fig. 18 / p. 22).

• Remove the support bearing (9/Fig. 18 / p. 22).

• Remove the I.I. carriage cover panel on the foot end (2 paneling screws).

• Disengage the chain grabber block from the I.I. carriage (2 Allen screws and guide

pins).

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 22 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

Spotfilm Devices, Long. and Column, Long. 23

• Press the chain grabber block towards the wall and move the spotfilm device (I.I. car-

riage) so that the chain master links (1/Fig. 19 / p. 23) are easily accessible.

2

1

Fig. 19: Chain master links

• Open both master links (1/Fig. 19 / p. 23) and take out the chains.

• Take both chains off the drive sprocket.

• Remove the potentiometer.

• The drive can now be removed. Pay attention to the cabling to the master drive assem-

bly.

• Completely replace the drive or only the motor (5/Fig. 18 / p. 22) on the gear

(7/Fig. 18 / p. 22).

Installing the drive:

• Take out the master drive assembly (Replacing the Master Drive Assembly / p. 31).

• It may be necessary to manually move the spotfilm device towards the head end so that

there is only 1-2 cm spacing to the switch-off strip.

• Move the chains (chain grabber blocks) so that the chain grabber block is just in front of

the spotfilm device at the foot end.

• Carefully insert the drive; while doing so, pull through the cables to the master drive as-

sembly.

• Place both chains on the drive sprocket.

• Reinstall the chains with the master links.

• Place on the support bearing (9/Fig. 18 / p. 22).

• Loosely install the 5 Allen-head mounting screws (6/Fig. 18 / p. 22).

• Loosely install the potentiometer; when doing so, the pinion may not come out of mesh

under any circumstances.

• Engage the chain grabber block on the I.I. carriage.

Siemens AG AXD3-340.841.01.06.02 Page 23 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

24 Spotfilm Devices, Long. and Column, Long.

Adjusting the Spotfilm Device Longitudinal Drive Chain Tension 0

• The spotfilm device must be all the way to the head end.

• It may be necessary to loosen the 5 Allen-head mounting screws (6/Fig. 18 / p. 22).

NOTE The tension can only be adjusted on one chain; the tension of the

other chain is automatically set. The value for the chain tension ap-

plies for the most highly tensioned chain.

Kette / chain

6

Fig. 20: Longitudinal drive chain

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 24 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

Spotfilm Devices, Long. and Column, Long. 25

Fig. 21: Spotfilm device / column longitudinaldrive chain tension

• Adjust the chain tension using the tension screws (8/Fig. 20 / p. 24) on the inside of the

table support (Fig. 21 / p. 25) of the spotfilm device longitudinal drive.

• Tighten the 5 Allen-head mounting screws (6/Fig. 18 / p. 22).

Check the cables laid to the master drive:

NOTE The cable is visible through the opening in the air vent grate.

• Install the master drive assembly (Replacing the Master Drive Assembly / p. 31).

• Switch the system ON

• Press the EMERGENCY STOP.

• After the system has booted up, disengage the EMERGNCY STOP switch.

• Adjust the potentiometer.

- SSW: Adjustment/ Calibration/ Spotfilm Device and column longitudinal drive/

Spotfilm Device longitudinal drive/ Potentiometer adjustment

- SSW: Adjustment/ Calibration/ Spotfilm Device and column longitudinal drive/

Column longitudinal drive/ Potentiometer adjustment

• Recheck the chain tension because the position of the spotfilm device was not “max.

head end” during the adjustment. As a rule, a readjustment is not necessary.

• Install the cover panels in the reverse order of the instructions above.

Siemens AG AXD3-340.841.01.06.02 Page 25 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

26 Spotfilm Devices, Long. and Column, Long.

Replacing the Column Longitudinal Drive or Motor 0

4

10 9

3

7

6

Fig. 22: Unit support cover panel

Remove the following cover panels:

• Head-end table support cover panel (5 paneling screws) (1/Fig. 22 / p. 26).

• Foot-end table support cover panel (8 paneling screws) (2/Fig. 22 / p. 26).

• Both foot-end aluminum cover panels (4/Fig. 22 / p. 26).

• Both head-end aluminum cove panels (5/Fig. 22 / p. 26).

• Move the tabletop all the way to the operator’s side.

• Move the unit into the 0° position.

• If possible, move the column longitudinally all the way to the head end.

• Switch the system OFF

NOTE If the column is covering the middle screws on the aluminum cover

panel, perform the procedure according to “Removing the Column

Drive, if there is no Access”.

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 26 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

Spotfilm Devices, Long. and Column, Long. 27

7

6 8

5

11

9

Fig. 23: Replacement of the column longitudinal drive

• Loosen the 2 Allen screws (7/Fig. 23 / p. 27) and (6/Fig. 23 / p. 27) at both the top and

bottom.

• Loosen the tension screw (9/Fig. 22 / p. 26).

- Accessible through the long hole, wall side, next to the chain on the inside of the ta-

ble support.

• Remove the potentiometer.

• Completely remove the 2 Allen screws (6/Fig. 23 / p. 27) from both the top and bottom.

• Loosen the guide plates (8/Fig. 23 / p. 27) by turning out the 2 Allen screws

(7/Fig. 23 / p. 27) at the top and bottom.

2

1

Fig. 24: Chain master links

Siemens AG AXD3-340.841.01.06.02 Page 27 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

28 Spotfilm Devices, Long. and Column, Long.

• Open both master links (2/Fig. 24 / p. 27) and pull out the chain.

• Take both chains off the drive sprocket.

• Take out the master drive assembly .

• Take the drive with the guide plates. Pay attention to the cabling to the master drive as-

sembly.

• Completely replace the drive or only the motor (11/Fig. 23 / p. 27) on the gear

(9/Fig. 23 / p. 27).

Installing the drive:

• If may be necessary to manually move the column to the head end so that there is only

1-2 cm distance to the switch-off strip (absolutely guide the chain through).

• Carefully insert the drive with the guide plates (8/Fig. 23 / p. 27); when doing so, pull

through the cables to the master drive assembly.

• Place both chains on the drive sprocket.

• Reinstall the chains with the master links.

• Loosely insert the 2 Allen screws (6/Fig. 23 / p. 27) at the top and bottom.

• Align the guide plates so that the drive sprocket with chain or the chain return sprocket

lines up. Tighten the 2 Allen screws (6/Fig. 23 / p. 27) at the top and bottom.

• Loosely thread in the 2 Allen screws (7/Fig. 23 / p. 27) at the top and bottom.

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 28 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

Spotfilm Devices, Long. and Column, Long. 29

Adjusting the Column Longitudinal Drive Chain Tension 0

• Move the column longitudinally to the max. head end.

• Loosen the 2 Allen screws (4/Fig. 25 / p. 29) at the top and bottom.

NOTE The tension can only be adjusted on one chain; the tension of the

other chain is automatically set. The value for the chain tension ap-

plies for the most highly tensioned chain.

Kette / Chain 11 4

Fig. 25: Column chain

Fig. 26: Spotfilm device / column longitudinaldrive chain tension

Siemens AG AXD3-340.841.01.06.02 Page 29 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

30 Spotfilm Devices, Long. and Column, Long.

• Use the chain tension screws (11/Fig. 25 / p. 29) to adjust the chain tension

(Fig. 26 / p. 29).

- Accessible through the long hole, wall side, next to the chain on the inside of the ta-

ble support.

• Tighten the mounting screws (4/Fig. 25 / p. 29) 4 Allen screws, top and bottom.

Check how the cables are laid to the master drive:

NOTE The cable is visible through the opening in the air vent grate.

• Install the Masterdrive- Baugruppe (Replacing the Master Drive Assembly / p. 31).

• Switch the system ON

• Press EMERGENCY STOP.

• Loosely install the potentiometer; when doing this, the pinion absolutely may not mesh.

• After the system has booted up completely, disengage the EMERGENCY STOP

switch.

• Adjust the potentiometer.

- SSW: Adjustment/ Calibration/ Spotfilm Device and column longitudinal drive/

Spotfilm Device longitudinal drive/ Potentiometer adjustment

- SSW: Adjustment/ Calibration/ Spotfilm Device and column longitudinal drive/

Column longitudinal drive/ Potentiometer adjustment

• Reinstall the cover panels by following the instructions above in reverse order.

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 30 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

Spotfilm Devices, Long. and Column, Long. 31

Replacing the Master Drive Assembly 0

4

10 9

3

7

6

Fig. 27: Unit support cover panel

Fig. 28: Master drive assembly Fig. 29: Masterdrive

• Position the unit in the 0° position

• Move the spotfilm device all the way to the foot end.

• Switch the system OFF

Siemens AG AXD3-340.841.01.06.02 Page 31 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

32 Spotfilm Devices, Long. and Column, Long.

CAUTION Life threatening!

¹ There is still high voltage present at the terminals of the

master drive assembly up to 5 min. after switching off

power to the system.

• Remove the head-end unit table support cover panel (5 paneling screws)

(1/Fig. 27 / p. 31).

• Remove the fan grill (6/Fig. 27 / p. 31).

• Slighly loosen the two top Allen screws (7/Fig. 27 / p. 31).

• Remove the Allen screw (8/Fig. 27 / p. 31).

• Remove the two top Allen screws (7/Fig. 27 / p. 31), remove the flat piece

(5/Fig. 28 / p. 31) in the unit support.

• Remove the grounding strap on the unit support.

• Take out the complete master drive assembly approx. 10 cm. While doing this, pay at-

tention to how the cables are led into the unit support (6/Fig. 29 / p. 31) (cables are visi-

ble through the opening in the air vent grid).

• Place a support under the master drive assembly (chair or a similar object).

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 32 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

Spotfilm Devices, Long. and Column, Long. 33

• Pull out the assembly as far as required.

1 2 3

U80

U90

Fig. 30: Master drive, side view

Pos. 1 CAN connector

Pos. 2 Potentiometer cables

Pos. 3 Resolver cables

2 M80.X

1 4

M90.X1 5

1 3

Fig. 31: Master drive, top-down view

Pos. 1 X9/24 V power supply

Pos. 2 “Brake” connector with diode

Pos. 3 “Brake” connector with diode

Pos. 4 K80/K90 relays (brake circuit)

Pos. 5 K100 relay (safety circuit relay)

Pos. 6 Motor cables

• Replacement of individual parts or of assemblies is now possible.

• Before inserting it, lay the cables below the assembly so that no cables cross over each

other.

Siemens AG AXD3-340.841.01.06.02 Page 33 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

34 Spotfilm Devices, Long. and Column, Long.

• Carefully insert the assembly. While doing this, pay attention to how the cables are led

into the unit support (6/Fig. 29 / p. 31) (cables are visible through the opening in the air

vent grid).

• Loosely install the flat piece (5/Fig. 28 / p. 31) using the two top Allen screws

(7/Fig. 27 / p. 31) in the unit support.

• Move the Masterdrive Baugruppe so that the two bottom Allen screws

(8/Fig. 27 / p. 31) can be inserted.

• Tighten the 3 Allen screws (7,8/Fig. 27 / p. 31).

• Attach the grounding strap to the unit support.

• Install the cover panels in the reverse order of the instructions above.

• Download the parameters into both master drives using the. See SSW / Help.

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 34 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

Spotfilm Devices, Long. and Column, Long. 35

Removing the Column Drive if there is no Access 0

7

6 8

5

11

9

Fig. 32: Replacement of the column longitudinal drive

• Move the unit into the 0° position

• Also remove the foot-end I.I. carriage cover panel.

Since the chain tension cannot be changed, the following work procedure should be fol-

lowed:

• Completely loosen the drive; when this is done, the drive will turn slightly and the chain

tension will be slightly lower.

• The return chain sprockets are removed at the head end.

• The column can then be moved into an optimum unit position.

• Remove the R80 potentiometer.

• Remove the 2 Allen screws (7/Fig. 32 / p. 35) at the top and bottom.

• It is absolutely necessary to secure the drive against turning by inserting a large screw-

driver between the gears and the plate, otherwise there is a risk that the threads of the

screws will be damaged.

• Remove the 2 Allen screws (6/Fig. 32 / p. 35) on both the top and bottom.

Siemens AG AXD3-340.841.01.06.02 Page 35 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

36 Spotfilm Devices, Long. and Column, Long.

2

1

Fig. 33: Column chain bearing block Fig. 34: Chain master links

• Pull out the Masterdrive assembly (see Replacing the Masterdrive Assembly).

NOTE The return pulley / chain sprockets (1/Fig. 33 / p. 36) and the stud

are accessible from below in the unit support, behind the master

drive assembly.

• Use a short screwdriver to remove the snap ring from the stud on the operator’s side.

• Use a rubber mallet to tap the studs out in the direction of the wall.

• Use an open-end wrench to completely remove the studs toward the wall.

• To make it possible for the sprockets to be moved easily, insert a 10 mm Allen wrench

in place of the stud.

• Loosen the chain grabber block on the I.I. carriage (2 Allen screws)

• Press the chain grabber to the wall side and move the I.I. carriage to the head end.

• Take both column chains off the gear and place them down under the sprockets. To do

this, it may be necessary to move the column or to move the gear to one side.

• The column can now be moved carefully towards the head end (make absolutely sure

to feed the chain through) so that the middle screws on the aluminum cover panel are

accessible.

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 36 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

Spotfilm Devices, Long. and Column, Long. 37

4

10 9

3

7

6

Fig. 35: Unit support cover panel

• Both foot-end aluminium cover panels (4/Fig. 35 / p. 37).

• Both head-end aluminium cover panels (5/Fig. 35 / p. 37).

• Remove the master links on the column chain (2/Fig. 34 / p. 36).

• Move the column and I.I.carriage so that the chain return pulley mount is accessible

from above.

• Mark the position of the chain return pulley mount (1/Fig. 33 / p. 36).

• Remove the screws from the mount. Remove the 10 mm Allen wrench from the mount.

• Reinsert the stud.

• Make absolutely sure to reinsert the holder at the position that was marked and secure

it in place.

Continue with installation of the drive

Siemens AG AXD3-340.841.01.06.02 Page 37 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

38 Tabletop

7-

Replacing the Table Frame, Complete

6Tabletop

1

X

X

Fig. 36: Replacement of the tabletop transversedrive

Fig. 37: Disassebling the table frame

The following work steps can be performed by 1 technician and 2 helpers (weight to be

lifted, approx. 120 kg).

• Move the tabletop all the way to the operator’s side.

• Move the tabletop so it is flush with the table frame.

• Remove the foot-end unit cover panels (2/Fig. 36 / p. 38).

• Move the tabletop all the way to the operator’s side.

• Remove the cover panel on the transverse drive (1/Fig. 36 / p. 38).

• Remove all Allen screws (1/Fig. 37 / p. 38) from the linear guide. To do this, move the

tabletop transversely as needed.

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 38 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

Tabletop 39

• Switch off the system.

• Disconnect all cables to both motors as well as to the potentiometer (if needed, label the

cables).

• Using 3 persons, lightly pull the tabletop towards the foot end and then take it out to-

wards the top.

NOTE Transfer the jumpers in the motor terminal box from the original.

• Installation of the new table frame is performed in the same way.

Measuring the distance of the table frame to the spotfilm device 0

Fig. 38: Tabletop spacing

• Perform the measurement under following conditions:

- Move the unit into the 0° position with no load on the table frame.

Distance X Distance Y

1. Move the spotfilm device all the way to the min. 4.5 mm min. 4.5 mm

head end.

Tabletop must be flush with the frame

2. Move the spotfilm device all the way to the min. 4.5 mm min. 4.5 mm

foot end

Tabletop must be flush with the frame

Siemens AG AXD3-340.841.01.06.02 Page 39 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

40 Tabletop

3. Move the spotfilm device the middle of the min. 4.5 mm min. 4.5 mm

movement range

Move the tabletop all the way to the head

end.

4. Move the spotfilm device the middle of the min. 4.5 mm min. 4.5 mm

movement range

Move the tabletop all the way to the foot end

Correction:

If the difference between spaces 3 and 4 is more than 1 mm, the table frame is bent

(moved into the floor or an object). Replace the table frame.

Distance 1 is too little.

Fig. 39: Spacer plate

• Install spacer shims (3/Fig. 39 / p. 40) (Part No. 70 32 605).

- To do this, loosen the Allen screws that are accessible from below and insert the

shim.

- When tightening the screws, it is absolutely necessary to press the guide rails from

the outside against the profile rail.

• Perform the following adjustment:

- Chapter “Adjusting the Range Limit Switches” (Adjusting the Range Limit

Switch / p. 43) Tabletop, Transverse

- Chapter “Adjusting the Speed” (Adjusting the Speed / p. 55) Tabletop, Transverse

- Adjusting the Tabletop Longitudinal Potentiometer.

SSW/ Adjustment/ Calibration/ Tabletop, longitudinal/.....

• Install the cover panels in the reverse sequence.

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 40 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

Tabletop 41

Replacing the Tabletop Transverse Drive and Potentiometers 0

1

X

X

Fig. 40: Replacement of the tabletop transversedrive

• Remove the switch strip (3/Fig. 40 / p. 41) on the foot end.

• Remove the safety switch (operator’s side) under the switch strip.

• Move the tabletop to the max. operator’s side.

If the motor is defective, carry out the following work steps:

• Remove the boot-end unit cover panel (8 paneling screws) (2/Fig. 40 / p. 41).

• Remove the bottom motor mounting screws (5/Fig. 41 / p. 42).

• When the tabletop is at the max. wall side position, the screw on the operator’s side is

accessible only with a pair of pliers inserted between the unit strut and the cover panel

for the transverse drive!

• By turning the drive in the strut, disengage the drive gear (8/Fig. 41 / p. 42) from the

rack.

• Move the tabletop so that the motor mounting screws (6/Fig. 41 / p. 42) are accessible

and remove the screws. When doing this, move the tabletop transversely so that the

head-end brakes release.

Siemens AG AXD3-340.841.01.06.02 Page 41 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

42 Tabletop

• Move the tabletop all the way to the operator’s side.

8

6

7

5

Fig. 41: Switch segment, table transverse drive

• Remove the cover panel on the transverse drive (1/Fig. 40 / p. 41).

• Remove the motor.

• Install the new motor and turn it so that there is minimum play between the rack and the

drive pinion.

• Tighten the mounting screws.

• Install the safety switch under the switch strip.

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 42 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

Tabletop 43

Adjusting the Range Limit Switch 0

• Adjust the limit switch strike plate (7/Fig. 41 / p. 42) so that a movement range of

35, +1 cm results.

• Install the cover panels in the reverse of the instructions above.

Siemens AG AXD3-340.841.01.06.02 Page 43 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

44 Tabletop

Adjusting the Speed 0

Only for ICONOS R200

• Adjust the speed.

- SSW: Adjustment/ Calibration/ Tabletop, transverse/ Tabletop, transverse:

Speed

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 44 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

Tabletop 45

Removing the Protective Panel under the Tabletop 0

• Move the tabletop all the way to the operator’s side.

• Remove the 9 Allen-head countersunk screws from the safety cover panel on the oper-

ator"s side under the tabletop.

• On the wall side, if the safety panel is present, remove the 9 Allen-head countersunk

screws or the 9 paneling screws.

• Move the tabletop out towards the head end.

• Remove the 4 mounting screws at the foot end from above.

• Move the tabletop to the foot end.

• Remove the 3 mounting screws at the head end from above.

• Move the spotfilm device all the way to the foot end.

• Make a belly in the protective plate and take it out towards the operator’s side.

• Installation is in the reverse order of the instructions above.

Siemens AG AXD3-340.841.01.06.02 Page 45 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

46 Tabletop

Replacing the Tabletop 0

1

3 2

1

Fig. 42: Table support with tabletop

4

5

6

Fig. 43: Tabletop viewed from below

NOTE In addition to the tabletop itself, a sealer material is required. For

the Part Numbers of the tabletop and the sealer material (silicon

rubber), see the Spare Parts Catalogue.

• Unit in the 0° position.

The tabletop must be moved out so that work can be performed from below on the table-

top.

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 46 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

Tabletop 47

• Cut through the sealer seam (1/Fig. 42 / p. 46) (silicon rubber) with a knife and remove

the residual adhesive material.

• Remove the stoppers (4/Fig. 43 / p. 46) on the head and foot ends.

• Remove the cover panels (2 und 3/Fig. 42 / p. 46) above and below the tabletop at the

head end and foot end.

• Completely remove the 12 Allen-head countersunk screws (5/Fig. 43 / p. 46) at both

the head and foot ends.

• Move the tabletop out to the head end.

NOTE If the tabletop is still fixed, the adhesive locations were not suffi-

ciently cut through.

Take note of the installation location of the tabletop.

• Remove the remaining adhesive residues.

• Insert the new tabletop positioned correctly.

• Place on the cover panels (2 und 3/Fig. 42 / p. 46) above and below on the tabletop.

• Tighten the 2 Allen-head countersunk screws (4/Fig. 43 / p. 46) at both the head and

foot ends.

• Install the 12 Allen-head countersunk screws (5/Fig. 43 / p. 46) at both the head and

foot ends.

NOTE Place a thin adhesive strip to the right and left of the gap.

• Fill in the gap between the tabletop and the aluminum profile rail with “Silicon rubber”.

Use a rounded object, or use your finger dipped in wet soapy water to make the caulking

seam smooth and flat.

The caulking material can cure overnight. Remove any traces of adhesive.

Siemens AG AXD3-340.841.01.06.02 Page 47 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

48 Tabletop

Tabletop Longitudinal Drive Chain Tension 0

• Remove the following cover panels:

remove the protective plate under the tabletop.

• Move the tabletop so that it is flush with the table frame.

• Disengage the tabletop from the chain grabber block (6/Fig. 44 / p. 48).

4

5

6

Fig. 44: Tabletop viewed from below

• Manually move the tabletop towards the foot end.

• Hook a spring balance onto the chain grabber block.

• The chain tension can be adjusted using the Allen screw (1/Fig. 45 / p. 48) accessible

at the head end in the wall-side profile. To do this, first loosen the counternut

(2/Fig. 45 / p. 48).

;;; 2

1

Fig. 45: Tensioning the tabletopchain

Adjustment dimensions: X 13 - 15 mm and F=95 to 100 N (Skizze/Fig. 46 / p. 49)

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 48 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

Tabletop 49

Fig. 46: Tabletop chain tension

Siemens AG AXD3-340.841.01.06.02 Page 49 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

50 Tabletop

Replacing the Tabletop Longitudinal Drive 0

1

X

X

Fig. 47: Replacement of the tabletop transversedrive

• Remove the following items:

Remove the cover panel, see “Removing the Protective Panel under the Tabletop”.

Foot-end unit support cover panel (2/Fig. 47 / p. 50).

Remove the cover panel on the transverse drive (1/Fig. 47 / p. 50).

Remove the two nuts and washers on the plate from below (4/Fig. 47 / p. 50).

• Move the tabletop towards the head end. It may be necessary to disengage the table-

top from the chain grabber block (6/Fig. 44 / p. 48).

The mounting screws for the drive will now be completely accessible.

NOTE Transfer the jumpers in the motor terminal box from the original.

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 50 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

SID Drive 51

8-

Replacing the Drive and Gas Spring

7SID Drive

Fig. 48: Replacement of the drive and gas spring

Procedure:

The following work steps can be performed by 1 technician and 1 assistant.

CAUTION Risk of crushing from the outward pressure of the gas spring.

¹ The gas spring or the drive may only be released

between the -20° and +20° unit positions (console display

or on the tableside control) (load compensation).

• To remove or install the column rear cover panel, the unit must be in the 0° position, oth-

erwise the central beam will change.

• Remove the rear column panel (10 Allen screws and countersunk screws)

(1/Fig. 48 / p. 51).

Siemens AG AXD3-340.841.01.06.02 Page 51 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

52 SID Drive

NOTE If there is a defective drive and very little room, the tilt movement

can be blocked. if the SID is moved out slightly, the SID 115 posi-

tion switch can be actuated. When this is done, tilt movement can

be performed carefully. Depending on the space conditions and

the position of the SID, it may be necessary to move the unit into

the - 20° to + 20° unit position using the SSW.

• Move the unit into the -20° to + 20° unit position (display on the console or on the table-

side controller.

• Remove the 2 nuts on the gas spring bracket (2/Fig. 48 / p. 51).

• Remove the 2 nuts on the drive bracket (3/Fig. 48 / p. 51).

• The must be moved to approx. 40 degrees as shown in the display.

NOTE Stuff cloths or paper (9/Fig. 48 / p. 51) between the gas spring

(10/Fig. 48 / p. 51), the drive (11/Fig. 48 / p. 51) and the column

tube (12/Fig. 48 / p. 51), otherwise the gas spring or the drive will

fall against the tube when the SID is moved out.

• Move the unit to 90° (when this is done, the moves out on its own).

• Pull the SID out manually to the mechanical stop.

Replacing the Gas Spring

• Hold the gas spring in the column tube and remove the 4 Allen-head countersunk

screws (4/Fig. 48 / p. 51).

• Take out the gas spring; while doing so, pay attention to the cables in the tube column.

• Remove the old gas spring from the bracket and the attachment point and install the

parts on the new gas spring. While doing so, make absolutely sure to pay attention to

the position of the gas spring bracket (2/Fig. 48 / p. 51) versus the top attachment point

(5/Fig. 48 / p. 51).

• Installation is in the reverse order of above; while doing so, pay attention to the cables in

the column tube.

Replacing the Drive

• Loosen the 4 Allen-head countersunk screws (6/Fig. 48 / p. 51). Hold the drive in the

column tube and take out the mounting screws.

• Take out the drive; while doing so, pay attention to the cables in the column tube.

• Remove the old drive from the studs (7/Fig. 48 / p. 51) and slide the new one onto it.

When doing this, make absolutely sure to pay attention to the position of the drive

bracket (3/Fig. 48 / p. 51) versus the top mounting point (8/Fig. 48 / p. 51).

• Installation is in the reverse order of above; when doing this, pay attention to the cables

in the column tube.

• Carefully move the SID manually into position and while doing so, align the gas spring

bracket (2/Fig. 48 / p. 51) with the mounting stud.

• Install the gas spring bracket (2/Fig. 48 / p. 51).

• Move the unit carefully to approx. 60°.

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 52 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

SID Drive 53

• Between 60° and 40°, the SID moves on its own. When this happens, align the drive

bracket (3/Fig. 48 / p. 51) with the mounting stud.

• Install the drive bracket (3/Fig. 48 / p. 51).

Siemens AG AXD3-340.841.01.06.02 Page 53 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

54 SID Drive

Adjusting the Limit Switches 0

Adjust the limit switches so that the following dimensions are obtained with the unit in the

0° position:

• At SID 115: use the tape measure in the collimator to set a distance of 106.5 mm to

107.5 mm to the tabletop.

• At the max. SID: the tape measure in the collimator must show a distance of141.5 mm

to 142.5 mm to the tabletop.

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 54 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

SID Drive 55

Adjusting the Speed 0

Only for ICONOS R200

• Adjusting the speed.

- SSW: Adjustment/ Calibration/ SID drive/ SID drive/ Speed

• If the speed was changed, the SID must be rechecked using the tape measure in the

collimator.

• A readjustment of the position may be necessary.

• To remove or install the column rear cover panel, the unit must be in the 0° position, oth-

erwise the central beam will change.

• Reinstall the cover panels in the reverse order of the instructions above.

Siemens AG AXD3-340.841.01.06.02 Page 55 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

56 Replacing the Tomo Rod and Clamping Ring

9-

8Replacing the Tomo Rod and Clamping Ring

NOTE Always replace the tomo rod, the clamping ring and the tomo rod

safety catch (catch mechanism for the tomo rod) together.

9 11 5 12 10

<

X 8

3 6

7

3

1

A

2

Fig. 49: Replacing the Tomo Rod and Clamping Ring

• Move the unit into the 0° position.

• Switch the system OFF.

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 56 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

Replacing the Tomo Rod and Clamping Ring 57

• Hold the tomo rod profile (1/Fig. 49 / p. 56) and remove the bottom 4 Allen screws

(2/Fig. 49 / p. 56).

If compression is configured: Remove the bracket for the flexible plastic chain on the

tomo rod profile (2 Allen screws), hold the tomo rod profile (1/Fig. 49 / p. 56) including

compression and remove the bottom 4 Allen screws (2/Fig. 49 / p. 56).

• Remove the tomo rod profile and place it to the side.

If compression is configured: Place the tomo rod profile (1/Fig. 49 / p. 56) including

compression down on a soft surface on the spotfilm device.

• Remove the tomo rod (3/Fig. 49 / p. 56) using an Allen wrench (A/Fig. 49 / p. 56) from

the clamping ring (5/Fig. 49 / p. 56).

• Remove the clamping screw (6/Fig. 49 / p. 56) on the clamping ring.

• Switch the system ON.

• Carefully move the unit into the + 90° or - 90 position. When this is done, tube unit rota-

tion also turns.

If compression is configured: Hold the tomo rod profile including compression and

carefully move the unit into the + 90° or - 90 position. When this is done, tube unit

rotation also turns.

• Support the collimator, e.g. with a cart and place it down on a soft surface. To do this, it

may be necessary to move the column accordingly.

• Remove both cover panels (7/Fig. 49 / p. 56) on the tube unit rotation assembly.

• Switch the system OFF.

• Measure the distance from the tube unit rotation (8/Fig. 49 / p. 56) to the tube unit

(X/Fig. 49 / p. 56) and note the value. This dimension will be used later to adjust the

central beam in the table transverse direction.

• Loosen both Allen-head set screws in the adjustment ring (9/Fig. 49 / p. 56).

• Pull out the tube unit rotation (8/Fig. 49 / p. 56) with shaft (10/Fig. 49 / p. 56) so that the

clamping ring (5/Fig. 49 / p. 56) can be removed. To do this, it may be necessary to in-

sert a board between the tube rotation and the tube unit to pry out the shaft.

• Lightly lubricate the new clamping ring (5/Fig. 49 / p. 56), e.g. with Longtime PD2 and

place it on the shaft (10/Fig. 49 / p. 56).

• Slide the shaft into the tube unit rotation up to the dimension that was noted

(X/Fig. 49 / p. 56) and tighten the two Allen-head set screws in the adjustment ring

(9/Fig. 49 / p. 56).

• Turn the clamping ring and the tube rotation in opposite directions until the middle hole

(11/Fig. 49 / p. 56) in the clamping ring lines up with the slot (12/Fig. 49 / p. 56) in the

shaft.

• Insert the clamping screw (6/Fig. 49 / p. 56) and only lightly tighten it.

• Apply Loctite 221 to the thread on the tomo rod, turn the tomo rod (3/Fig. 49 / p. 56) with

an Allen wrench (A/Fig. 49 / p. 56) into the thread (11/Fig. 49 / p. 56) of the clamping

ring (5/Fig. 49 / p. 56) and tighten it to a torque of 50 Nm.

Siemens AG AXD3-340.841.01.06.02 Page 57 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

58 Replacing the Tomo Rod and Clamping Ring

• Bend open the clamp (2/Fig. 50 / p. 58) and slide it onto the tomo rod.

EH111509-260902-00-02

Fig. 50: Safety wire

• Insert the screw (3/Fig. 50 / p. 58) and the nut and slide up the clamp to the clamping

ring (4/Fig. 50 / p. 58) and tighten it.

• Wrap the safety wire included in the shipment around the rotation shaft.

• Tighten the safety wire (5/Fig. 50 / p. 58) around one eyelet.

• Slide the second eyelet over the screw and thread on the self-locking nut so that the

safety wire can move a max. of 1 mm and thus has some play.

• Lightly lubricate the tomo rod (3/Fig. 49 / p. 56) e.g. with Longtime PD2 and slide the

tomo rod profile (1/Fig. 49 / p. 56), with the compression if it is configured, onto the

tomo rod.

• Lightly secure the tomo rod profile (1/Fig. 49 / p. 56) in place with the 4 Allen screws

(2/Fig. 49 / p. 56).

If compression is configured: Hole the tomo rod profile(1/Fig. 49 / p. 56) including

compression and lightly secure it in place with the 4 Allen screws (2/Fig. 49 / p. 56).

Also reinstall the bracket for the flexible plastic chain on the tomo rod profile (2 Allen

screws).

• Switch the system ON.

• Move the unit into the 0° position.

• Insert the cone and align it to the collimator.

- Do do this, slightly loosen the 4 lightly-tightened Allen screws (2/Fig. 49 / p. 56), turn

the tomo rod profile and then retighten the Allen screws.

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 58 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

Replacing the Tomo Rod and Clamping Ring 59

• Under fluoroscopy, perform a quick check of the central beam on the monitor. If need-

ed, turn the tube unit, and align the tomo rod (3/Fig. 49 / p. 56) parallel to the column.

- Tighten the clamping screw (6/Fig. 49 / p. 56).

• Perform an exact check and adjustment of the central beam per the instructions, Re-

placement of Parts, Basic Unit, "Central Beam".

Siemens AG AXD3-340.841.01.06.02 Page 59 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

60 Tube Rotation Assembly

10-

Replacing the Tube Rotation Assembly, Complete

9Tube Rotation Assembly

3 4

Fig. 51: Fig. 52:

The following steps can be performed by 1 technician and 1 assistant.

• Remove the two cover panels (1/Fig. 51 / p. 60) on the tube rotation assembly.

Only with the ICONOS R200

• Remove the two Allen screws (2/Fig. 52 / p. 60) in the mounting bracket.

• Turn the mounting bracket in the direction of the collimator.

The further work steps apply for all ICONOS units

• Remove the top tube unit cover panel (3/Fig. 51 / p. 60).

• Tilt the unit up or down all the way.

• Turn the tube unit to face towards the floor.

• Switch the system OFF

• Disconnect the cables to the collimator.

• If the Diamentor chamber is installed, unplug the connector.

• Remove the collimator and place it down in a secure locations.

• Unsolder the cables to the fan.

• Disconnect the cables from the two position switches, M9.S198 and S199.

Are the designations readable? If necessary, label the cables.

• Remove the cable holder (4/Fig. 52 / p. 60).

• Pull the cables out through the tube rotation assembly.

• Remove the Allen screws from the tube unit mount ((5/Fig. 52 / p. 60), for access, see

the arrow).

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 60 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

Tube Rotation Assembly 61

• Remove the tube unit with mount and place it down in a safe location.

Fig. 53:

• Remove the screw (6/Fig. 53 / p. 61).

• The tube rotation assembly can be pulled off the shaft. When doing this pay attention to

the Woodruff keys; these should be used when the new tube rotation assembly is in-

stalled.

• Lightly grease the shaft with Longtime PD 2.

Preparing the New Tube Rotation Assembly

2

3

Fig. 54: Tube rotation, R200 E-component Fig. 55: Tube rotation, R200 mechanism

Siemens AG AXD3-340.841.01.06.02 Page 61 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

62 Tube Rotation Assembly

1 2

Fig. 56: Tube rotation, R200 complete Fig. 57: Tube rotation, R100 complete

The tube rotation assembly is comprised of the parts shown in (Fig. 54 / p. 61), all other

parts, cover panels, etc. should be taken from the old assembly.

ICONOS R100

• All parts shown in (Fig. 55 / p. 61) such as the spring (3/Fig. 55 / p. 61), connection

(2/Fig. 55 / p. 61) of the right to the left mount, as well as the left mount itself

(1/Fig. 55 / p. 61) must be removed without replacing them.

ICONOS R200

• To install the mounting bracket, the parts listed in (Fig. 55 / p. 61) such as the spring

(1/Fig. 55 / p. 61), connection (1/Fig. 55 / p. 61) of the right to the left mount, as well as

the left mount itself (1/Fig. 55 / p. 61) must be removed without replacing them.

• Slide the mounting bracket on the right onto the studs.

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 62 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

Tube Rotation Assembly 63

• Then install the parts (Fig. 55 / p. 61) such as the spring (3/Fig. 55 / p. 61), the connec-

tion of the right with the left mount (2/Fig. 55 / p. 61)as well as the left mount

(1/Fig. 55 / p. 61).

Fig. 58: Detent disk

• Install the new detent disk (Fig. 58 / p. 63). When this is done, the Allen screw

(1/Fig. 58 / p. 63) must be pointing in the direction of the limit switch.

• Slide the new tube rotation assembly onto the shaft; when doing this, press the center-

ing stud so that the centering stud does not get pressed against the stop (Woodruff

key).

• Apply Loctite 221 to the screw (6/Fig. 53 / p. 61) and tighten it to the required torque.

• Reinstall the tube unit with the mount.

• Insert the Allen screws for the tube unit mount (5/Fig. 52 / p. 60) and tighten them.

• Connect all "limit switch" cables.

• Install the collimator on the tube unit flange.

• Connect the collimator.

• If a Diamentor chamber is installed, connect it.

• Apply Loctite 221 to the screw in the release lever (1/Fig. 57 / p. 62).

• Install the release lever (1/Fig. 57 / p. 62)and (2/Fig. 57 / p. 62) the stopper.

• Turn the mounting bracket (1/Fig. 56 / p. 62) as shown in (Fig. 56 / p. 62) and turn in

the Allen screws on the side.

• Perform a brief function test of the position switches (7/Fig. 53 / p. 61).

To do this, turn the tube rotation assembly to 0° and 180°, acoustically check the S198

switch function for 0° and S199 for 180°.

The Bowden cable should already have been adjusted at the factory; because of this, per-

form only a brief function check:

• The stop stud should engage securely in the stop plate, the Bowden cable may not be

tensioned.

Siemens AG AXD3-340.841.01.06.02 Page 63 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

64 Tube Rotation Assembly

• The release lever (ICONOS R100) or mounting bracket (ICONOS R200) may not be

too loose.

• Correction: Adjust the Bowden cable accordingly.

• Install the fan assembly. Solder the leads to the fan.

• Mechanical adjustment (not including installation of the cover panels!) is performed per:

Center the central beam to the image receptor system.

Final Work Steps

• The position switches (7/Fig. 53 / p. 61) should actuate symmetrically from the stop po-

sition.

S198 for 0°

S199 for 180°

The test can be performed acoustically as well as with the SSW:

Monitoring/Monitoring: Unit positions

• Install the cover panels in the reverse order of the instructions above.

AXIOM Iconos R200 AXD3-340.841.01.06.02 Page 64 of 120 Siemens AG

11.02 CS SD 21 Medical Solutions

Tube Assembly 65

11-

Replacing the Tube Assembly on the Unit

10Tube Assembly

3 4

Fig. 59: Fig. 60:

The following work steps can be performed by 1 technician and 1 assistant.

• Remove the two cover panels (1/Fig. 59 / p. 65) on the tube rotation assembly.

• Only with the ICONOS R200

- Remove the two Allen screws (2/Fig. 60 / p. 65) in the mounting bracket.

- Turn the mounting bracket in the direction of the collimator.

The following work steps apply for all ICONOS units

• Remove the top tube unit cover panel (3/Fig. 59 / p. 65).

• Tilt the unit up or down all the way.

• Turn the tube unit towards the floor.

• Switch the system OFF

• Remove the connection cables on the collimator.

• Remove the collimator and place it down in a safe place.

• Remove the cable plate (4/Fig. 59 / p. 65) (4/Fig. 60 / p. 65).

• Disconnect the cables (high voltage cables, rotating anode...) on the tube unit.

• Remove the Allen screws from the tube mount ((5/Fig. 60 / p. 65), for access, see ar-

row).

• Remove the tube unit with mount and place it down in a safe place.

• Replace the tube unit assembly.

• Reinstall the tube unit with the mounting.

• Instal the Allen screws on the tube unit mount (5/Fig. 60 / p. 65) and tighten them.

• Install the collimator on the tube unit flange.

Siemens AG AXD3-340.841.01.06.02 Page 65 of 120 AXIOM Iconos R200

Medical Solutions 11.02 CS SD 21

66 Tube Assembly

• Connect the collimator.

• Connect the tube unit, see the generator documents.

• Mechanical adjustment (without installing the cover panels!) is performed per: