Professional Documents

Culture Documents

Metallic Tanks - Sample ITP

Uploaded by

Suraj ShettyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Metallic Tanks - Sample ITP

Uploaded by

Suraj ShettyCopyright:

Available Formats

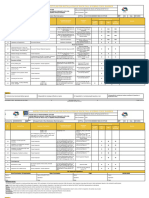

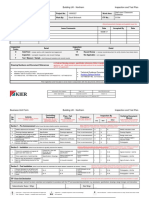

Document ID No:

Page:

Rev. No.:

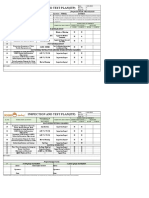

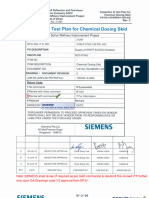

QA/QC Inspections: Inspection Test Plan

Date of Issue:

Consultant::

Company:

Project name:

Project Code:

ITP no:

Rev No:

Date:

Type of ITP

Fabric

✘

Vendor

METALLIC TANKS ation Site Construction

Item Description

Manufacturer

Shop

Inspection by

Technical

Activity Activity/ Specification/ SWCC

Inspection/ Test Acceptance criteria Frequency documents RECORD Remark

Number Inspection drawings Supplier Metito / TPI SEPCO 3 Consultant

(if applicable)

▪ PO acknowledgement by

Approved drawing / Data PO Acknowledgement

vendor

Sheet / PO / Volume VI – Part A5 by Vendor/ Approved

Documents ▪ Submission of Drawings, Approved drawing /

1

Approval Data Sheets, Inspection &

UL 142 - for Diesel Oil -

Data Sheet / PO

-Inspection and Drawings, Data H R R R R

Storage tank / testing Sheets & Test

Test Procedure by vendor for

API 650 -for other tanks Procedures

review and approval

▪ Verification of Material test

certificates.

Material ▪ Material shall be Drawing / Data Sheet/ Drawing / Data Sheet/ Material test certificate

2 Verification incompliance with approved Equivalent International 100% Equivalent International - according to EN R R R R R

drawings & datasheets. standard standard 10204 Type 3.1

▪ PMI testing to be carried out

on all alloy steel material

WPS/ PQR/ ▪ WPS/PQR/WPQR shall be as ASME SEC IX ASME SEC IX WPS/PQR/

3

WPQR per applicable standards API 650 / UL 142

100%

API 650 / UL 142

-

WPQR

H R R R R

Visual and ▪ 100% visual inspection to be

Visual and

dimensional carried out Approved Drawing / Approved Drawing /

4

inspection of ▪ Check over all dimensions API 650 / UL 142

100%

API 650 / UL 142

- dimensional H H H H H

inspection Reports

completed tank as per approved drawing

Non Destructive ▪ Extent of NDT shall be as per Approved Drawing / Approved Drawing /

5

Testing approved drawing API 650 / UL 142

-

API 650 / UL 142

- NDE Reports H R R R R

▪ Hydrostatic test to be carried

out as per approved procedure Approved drawing / Test Approved drawing / Test

6 Hydrostatic testing ▪ Draining, drying and cleaning procedure / API 650 / 100% procedure / - Hydrostatic Test report H H H H H

to be carried out after UL 142 API 650 / UL 142

hydrostatic test.

Page 1 of 2 ITP No.: 19SWCG30204-1-200-R14GES-KEM-IT-300026

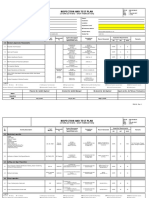

Inspection by

Technical

Activity Activity/ Specification/ SWCC

Inspection/ Test Acceptance criteria Frequency documents RECORD Remark

Number Inspection drawings Supplier Metito / TPI SEPCO 3 Consultant

(if applicable)

Pickling & ▪ Pickling & pasivation to be

Approved drawing / Approved drawing / Pickling & pasivation

7 pasivation (as carried out as per approved

Approved procedure

100%

Approved procedure

-

report

H R R R R

applicable) procedure

▪ Final Painting inspection

Final Painting

(visual, DFT & RAL color ) to Drawing /Approved Drawing / Approved

8 inspection (as

be carried out as per approved painting procedure

100%

painting procedure

- Painting Report H H H H H

applicable)

procedure

Name plate ▪ Verify name plate details with

9

verification approved drawing

Approved drawing 100% Approved drawing - Name plate H R R R R

Inspection of

▪ Check for packing & shipping

packing and Inspection Release

10

shipping

details. P.O / Project specs. 100% P.O / Project specs. -

Note

H R R R R

▪ Storage recommendations

protections

▪ Verification of Inspection and

Final Submission Test records signed by all Inspection Reports as per

11

of MRB concerned and compiled as ITP

100% Metito PO/ ITP - Final MRB H R R R R

per ITP Sections

Legend : H - Hold ; W - Witness ; R - Review ; S - Spot Inspection; A - Approval; I - Information; M - Monitoring

This ITP Plan meets the requirements of the SWCC Specifications and the minimum requirements of indicative Inspection Test Plan

SIGNED SIGNED/ STAMPED SIGNED/STAMPED

PREP/CHK BY : REVIEWED BY: APPROVED BY :

Page 2 of 2 ITP No.: 19SWCG30204-1-200-R14GES-KEM-IT-300026

You might also like

- Vendor Fabrica Tion Shop Site Construction: QA/QC Inspections: Inspection Test PlanDocument3 pagesVendor Fabrica Tion Shop Site Construction: QA/QC Inspections: Inspection Test PlanSuraj ShettyNo ratings yet

- Vendor Fabrication Shop Site Construction: QA/QC Inspections: Inspection Test PlanDocument2 pagesVendor Fabrication Shop Site Construction: QA/QC Inspections: Inspection Test PlanSuraj ShettyNo ratings yet

- Skid Sample ITPDocument2 pagesSkid Sample ITPSuraj ShettyNo ratings yet

- 8015-0151-00-Al-Cd 1133-19-Gf-Ogf4-J-Vd-9503-00001 - 00 - ItpDocument5 pages8015-0151-00-Al-Cd 1133-19-Gf-Ogf4-J-Vd-9503-00001 - 00 - ItpRami KsidaNo ratings yet

- Inspection and Test Plan Piping Work ActivitiesDocument2 pagesInspection and Test Plan Piping Work ActivitiesAbram Berkat100% (2)

- Inspection and Testing Plan For Cable TrayDocument2 pagesInspection and Testing Plan For Cable TrayJohn Rey Perlas100% (2)

- Rock Fall Barrier ITPDocument2 pagesRock Fall Barrier ITPVishnudas MgNo ratings yet

- Protection Wire Mesh ITPDocument3 pagesProtection Wire Mesh ITPVishnudas MgNo ratings yet

- Itp Jib Crane Rev.1Document1 pageItp Jib Crane Rev.1Roger MahilumNo ratings yet

- ITP Low Tempt Test - RevDocument6 pagesITP Low Tempt Test - RevAgus GunawanNo ratings yet

- Field Quality PlanDocument1 pageField Quality PlantanmayascribdNo ratings yet

- 0000100324/17-Civil Inspection and Test Plan: 0000100324/17 03-100000-0000100324 - FTC-CIV-ITP-xxxxxxDocument1 page0000100324/17-Civil Inspection and Test Plan: 0000100324/17 03-100000-0000100324 - FTC-CIV-ITP-xxxxxxMeshaal ALBalharithNo ratings yet

- Water Tank ItpDocument5 pagesWater Tank Itptuan mai vanNo ratings yet

- Inspection & Test Plan: Project Name: Main Activity: Date: W Witness H Hold Point T Test R RandomDocument1 pageInspection & Test Plan: Project Name: Main Activity: Date: W Witness H Hold Point T Test R RandomKasinadh KarraNo ratings yet

- Itp TankageDocument7 pagesItp TankageIr FankovicNo ratings yet

- S96029-F07C-ITP-006 Rev0-OSM Exhaust Duct WorkDocument2 pagesS96029-F07C-ITP-006 Rev0-OSM Exhaust Duct WorktinzarmoeNo ratings yet

- Inspection and Test Plan (Itp)Document2 pagesInspection and Test Plan (Itp)Abdul Gafoor ShaikhNo ratings yet

- ICC-DS-1132 Erection ITP-GFRC Steel Sub FramesDocument3 pagesICC-DS-1132 Erection ITP-GFRC Steel Sub FramesAnwar MohiuddinNo ratings yet

- Tank Erection Itp Org ChartDocument34 pagesTank Erection Itp Org Chartvasantha kumar100% (1)

- Inspection and Test Plan: Form No.: Revision No.: ITP Scope Description: Page No.: DateDocument2 pagesInspection and Test Plan: Form No.: Revision No.: ITP Scope Description: Page No.: DatetayyabNo ratings yet

- 01 - Asf-Qc-Itp-002Document4 pages01 - Asf-Qc-Itp-002Sherif YehiaNo ratings yet

- Quality Control Form "Sample"Document23 pagesQuality Control Form "Sample"BernathTurnipNo ratings yet

- HTG365. QAC. Inspection and Test Plan REV 2. 2022 06 24 (2) MRADocument10 pagesHTG365. QAC. Inspection and Test Plan REV 2. 2022 06 24 (2) MRAGreg Rabulan100% (1)

- Quality Control Plan TemplateDocument1 pageQuality Control Plan TemplateDavid GeorgeNo ratings yet

- Inspection & Test Plan FOR Wrapping / Coating of External Metal Surface (C.S Fire Hydrant Spools)Document5 pagesInspection & Test Plan FOR Wrapping / Coating of External Metal Surface (C.S Fire Hydrant Spools)Daniel Martinez50% (2)

- Vessel ItpDocument3 pagesVessel ItpVineet KhanduriNo ratings yet

- Inspection Test Plan For Stat XDocument4 pagesInspection Test Plan For Stat XGinish KumarNo ratings yet

- Material Inspection SheetDocument3 pagesMaterial Inspection Sheetrahid iqubalNo ratings yet

- PP-FR-03 Route CardDocument1 pagePP-FR-03 Route Cardchandra100% (1)

- Rock Dowels & Rock Nails ITPDocument7 pagesRock Dowels & Rock Nails ITPVishnudas MgNo ratings yet

- Material Receiving Inspection Report: Project TitleDocument2 pagesMaterial Receiving Inspection Report: Project TitleGomathyselviNo ratings yet

- ITPDocument2 pagesITPKarthikeyan Shanmugavel100% (1)

- Appendix 2 - Inspection & Test Plan, Forms and Check Lsit, and Method of StatementDocument37 pagesAppendix 2 - Inspection & Test Plan, Forms and Check Lsit, and Method of StatementMohammed AlbayatiNo ratings yet

- Project: EXPO 2020 - OV016 - USA PAVILION Inspection and Test Plan (Itp)Document5 pagesProject: EXPO 2020 - OV016 - USA PAVILION Inspection and Test Plan (Itp)qc_531040655No ratings yet

- ITP Sample For Piping Assembly WorksDocument7 pagesITP Sample For Piping Assembly WorksTee Klong RungNo ratings yet

- F0189 Supplier Assessment ReportDocument3 pagesF0189 Supplier Assessment ReportSerena Mat SunyNo ratings yet

- 14C. 2082-PM-ITP-7017 Rev.0 - SITE ITP PaintingDocument6 pages14C. 2082-PM-ITP-7017 Rev.0 - SITE ITP PaintingAmarKumarNo ratings yet

- ITP-Steel Door (G I Mr. Nguyên) - 15.9.2023 CTV1Document13 pagesITP-Steel Door (G I Mr. Nguyên) - 15.9.2023 CTV1todove12345No ratings yet

- Inspection and Test PlanDocument2 pagesInspection and Test PlantayyabNo ratings yet

- ITP-Application of PaintingDocument2 pagesITP-Application of PaintingMuthu Saravanan100% (1)

- Itp FinalDocument5 pagesItp Finalchristopher Adajo100% (1)

- ITP SampleDocument4 pagesITP SampleKarthik S100% (1)

- CP-SS BLK-01Document5 pagesCP-SS BLK-01yogesh WakchaureNo ratings yet

- Water Tank ItpDocument5 pagesWater Tank ItpHgagselim SelimNo ratings yet

- P-0001-Ph01-D01-01a001-Alec-Pqs-Civ-000005-00 BDocument476 pagesP-0001-Ph01-D01-01a001-Alec-Pqs-Civ-000005-00 Bحسام رسميNo ratings yet

- Only Upon GA Drawings Code 1/2 Approval From DPJV.: by Sekar - Rajesh at 6:43 PM, Aug 25, 2015Document4 pagesOnly Upon GA Drawings Code 1/2 Approval From DPJV.: by Sekar - Rajesh at 6:43 PM, Aug 25, 2015Rahmat BasukiNo ratings yet

- Inspection-Test-plan For Block WorkDocument3 pagesInspection-Test-plan For Block WorkAbdulrahman Alkilani100% (2)

- QMS-17-SF Inspection and Test Plan TemplateDocument3 pagesQMS-17-SF Inspection and Test Plan TemplatearavinNo ratings yet

- Inspection Test Plan (Itp) at Site: Disciplin RevDocument5 pagesInspection Test Plan (Itp) at Site: Disciplin RevEnryan Oreski RiyadiNo ratings yet

- Quality Assurance Plan: Raw Material ProcurmentDocument2 pagesQuality Assurance Plan: Raw Material ProcurmentHuỳnh Ngọc HiệpNo ratings yet

- 2.ITP For Excavation & Laying of 33kV & FO CableDocument2 pages2.ITP For Excavation & Laying of 33kV & FO Cabletahirsaleem100% (1)

- Steel TankDocument4 pagesSteel TankRanu JanuarNo ratings yet

- Product RangeDocument1 pageProduct RangeRaju MistryNo ratings yet

- Sample QAPDocument3 pagesSample QAPArjun ChouhanNo ratings yet

- Control PlanDocument4 pagesControl PlanJosué PérezNo ratings yet

- Control Plan - 608 2RS C3Document28 pagesControl Plan - 608 2RS C3trandangbkNo ratings yet

- Itp Brickwork and BlockworkDocument2 pagesItp Brickwork and Blockworkapi-3722518100% (1)

- Heat Exchanger QAPDocument3 pagesHeat Exchanger QAPRajnikant PatelNo ratings yet

- ITP-MEP-006 Dismantling of MEPDocument1 pageITP-MEP-006 Dismantling of MEPjagathmukundhan00No ratings yet

- Codification of Statements on Standards for Attestation Engagements, January 2018From EverandCodification of Statements on Standards for Attestation Engagements, January 2018No ratings yet

- Final FIM Contract Template - 10102022 Outotec Comments - Points AcceptableDocument94 pagesFinal FIM Contract Template - 10102022 Outotec Comments - Points AcceptableSuraj ShettyNo ratings yet

- Comments Resolution Sheet For Commented QAPDocument10 pagesComments Resolution Sheet For Commented QAPSuraj ShettyNo ratings yet

- Deviation Sheet On Standard Quality Plan: Project Package Manufacturer Item Name SQP NoDocument5 pagesDeviation Sheet On Standard Quality Plan: Project Package Manufacturer Item Name SQP NoSuraj ShettyNo ratings yet

- Gamsberg Phase II, Contract Template ReviewDocument4 pagesGamsberg Phase II, Contract Template ReviewSuraj ShettyNo ratings yet

- Approved Vendor List-MechanicalDocument4 pagesApproved Vendor List-MechanicalSuraj ShettyNo ratings yet

- Master Format For Itp's Front PagesDocument1 pageMaster Format For Itp's Front PagesSuraj ShettyNo ratings yet

- Book 1Document1 pageBook 1Suraj ShettyNo ratings yet

- Master Format For Itp's Second PageDocument2 pagesMaster Format For Itp's Second PageSuraj ShettyNo ratings yet

- Inspection & Test Plan For Equipment Erection (Static) : HZA-1010-MC-Q-M-ITP-002Document5 pagesInspection & Test Plan For Equipment Erection (Static) : HZA-1010-MC-Q-M-ITP-002Suraj ShettyNo ratings yet

- Quality PolicyDocument1 pageQuality PolicySuraj ShettyNo ratings yet

- E&I QAP's - Submitted To Contractor HZADocument33 pagesE&I QAP's - Submitted To Contractor HZASuraj ShettyNo ratings yet

- Book 5Document13 pagesBook 5Suraj ShettyNo ratings yet

- Inspection Test Plan For Civil Works: Rev - A 28.05.2022Document17 pagesInspection Test Plan For Civil Works: Rev - A 28.05.2022Suraj ShettyNo ratings yet

- SL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1 2 ADocument2 pagesSL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1 2 ASuraj Shetty100% (1)

- Itp For Pipes CS<CSDocument1 pageItp For Pipes CS<CSSuraj ShettyNo ratings yet

- SL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1 2 ADocument2 pagesSL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1 2 ASuraj Shetty100% (1)

- 100 KLPD of 2G Ethanol From Biomass at Iocl PanipatDocument7 pages100 KLPD of 2G Ethanol From Biomass at Iocl PanipatSuraj ShettyNo ratings yet

- Itp For Equipment Erection - StaticDocument5 pagesItp For Equipment Erection - StaticSuraj ShettyNo ratings yet

- Itp For ValvesDocument2 pagesItp For ValvesSuraj ShettyNo ratings yet

- Itp For Pipes CS<CSDocument1 pageItp For Pipes CS<CSSuraj ShettyNo ratings yet

- Itp For FastenersDocument1 pageItp For FastenersSuraj ShettyNo ratings yet

- SL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1 2 ADocument2 pagesSL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1 2 ASuraj Shetty100% (1)

- SL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1 2 3Document1 pageSL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1 2 3Suraj ShettyNo ratings yet

- Itp For Pipes CS<CSDocument1 pageItp For Pipes CS<CSSuraj ShettyNo ratings yet

- SL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1 2 ADocument2 pagesSL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1 2 ASuraj Shetty100% (1)

- SL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1Document2 pagesSL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1Suraj ShettyNo ratings yet

- International Internet Gateway (IIG) ServicesDocument3 pagesInternational Internet Gateway (IIG) Servicessofiullah sohagNo ratings yet

- Amity University Rajasthan: Amity School of EngineeringDocument15 pagesAmity University Rajasthan: Amity School of EngineeringRewa ShankarNo ratings yet

- AAC-004 Technical LogDocument12 pagesAAC-004 Technical LogMohammed HamidNo ratings yet

- Engineering Drafting Prelim AnswersheetDocument2 pagesEngineering Drafting Prelim AnswersheetfebwinNo ratings yet

- AD-330 AD-320 Parts Manual PN 450239 (Rev-1) 042803Document46 pagesAD-330 AD-320 Parts Manual PN 450239 (Rev-1) 042803naokito AkemiNo ratings yet

- PC800SE-7-M1 S/N 40001-UP: Travel Motor (4/4)Document2 pagesPC800SE-7-M1 S/N 40001-UP: Travel Motor (4/4)midalllNo ratings yet

- Perkins1104D E44TA1106D E70TAElectronicAIGuide PDFDocument115 pagesPerkins1104D E44TA1106D E70TAElectronicAIGuide PDFa1n2w3a4r5100% (9)

- MECH5 GETTING STARTEDv3Document6 pagesMECH5 GETTING STARTEDv3Justin JacksonNo ratings yet

- EC1Document3 pagesEC1Umair FayyazNo ratings yet

- Cool Infographics Table of Contents PDFDocument5 pagesCool Infographics Table of Contents PDFCarolina ShortNo ratings yet

- Internet and E-MailingDocument19 pagesInternet and E-Mailingbhargava1_mukeshNo ratings yet

- PowerpointDocument39 pagesPowerpointMOHAMMAD KAIF AHMEDNo ratings yet

- Student HandbookDocument200 pagesStudent HandbookRyan LatteryNo ratings yet

- Oracle EBS R12.2.6 Application Tier Cloning With Step by StepDocument10 pagesOracle EBS R12.2.6 Application Tier Cloning With Step by Stepdoyenblog100% (1)

- Tube StructuresDocument30 pagesTube StructuresBurhanAhmadWani100% (3)

- Traffic Mechanical Supervisor NotificationsDocument4 pagesTraffic Mechanical Supervisor NotificationsPrasad KvNo ratings yet

- HLeiteDocument6 pagesHLeiteLê Trung DũngNo ratings yet

- Short-Term Scheduling of Battery in A Grid-Connected PV-Battery SystemDocument9 pagesShort-Term Scheduling of Battery in A Grid-Connected PV-Battery SystemEric GalvánNo ratings yet

- ME 361 Unit 6Document53 pagesME 361 Unit 6Dennis ArhinNo ratings yet

- 00 LSPU Stage 2 Audit Report 2018 PDFDocument21 pages00 LSPU Stage 2 Audit Report 2018 PDFRolando Cruzada Jr.No ratings yet

- SiH4 N2 and NH3 Plasma ALDDocument2 pagesSiH4 N2 and NH3 Plasma ALDVikrant RaiNo ratings yet

- TDS - Terluran GP-22 PDFDocument3 pagesTDS - Terluran GP-22 PDFebercueNo ratings yet

- VoxStudio ManualDocument59 pagesVoxStudio ManualhmeyoyanNo ratings yet

- S. No. Name Faculty No. Qualification Percentage % GradeDocument6 pagesS. No. Name Faculty No. Qualification Percentage % GradeShameem MohammedNo ratings yet

- Test Bank For Equipment Theory For Respiratory Care 5th Edition by WhiteDocument28 pagesTest Bank For Equipment Theory For Respiratory Care 5th Edition by WhiteJohn Smoldt100% (29)

- SM - VOLVO G970 MOTOR GRADER Service RepairDocument9 pagesSM - VOLVO G970 MOTOR GRADER Service RepairKai FebNo ratings yet

- Accessories For Copper Communication Networks: CatalogDocument88 pagesAccessories For Copper Communication Networks: CatalogefecastNo ratings yet

- Modified UCT Chemo SphereDocument7 pagesModified UCT Chemo SpherevaiopoulouNo ratings yet

- 821g - Wheel Loader - Tier 4b (Na) (10/16 - ) 10 - Engine 10.400.010 (01) - Var - 482585 - 482931 - Cooling System Line InstallationDocument3 pages821g - Wheel Loader - Tier 4b (Na) (10/16 - ) 10 - Engine 10.400.010 (01) - Var - 482585 - 482931 - Cooling System Line InstallationVladimirCarrilloNo ratings yet

- BSIT WEB Technology FINAL CURRICULUM PDFDocument1 pageBSIT WEB Technology FINAL CURRICULUM PDFGinard GuakiNo ratings yet