Professional Documents

Culture Documents

Desalt DPU-36-C Series: Titanium Plate Type Fresh Water Generator

Uploaded by

Dwi Tri CahyonoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Desalt DPU-36-C Series: Titanium Plate Type Fresh Water Generator

Uploaded by

Dwi Tri CahyonoCopyright:

Available Formats

Desalt DPU-36-C Series

Titanium plate type fresh water generator

Application

Conversion of seawater into freshwater by vacuum distillation

for the supply of high quality freshwater for domestic and

process utilization.

For installation on ships, rigs, and remote onshore locations.

The DPU-36-C is designed for automatic operation with

continuous control of freshwater quality.

Features

• Simple, compact design.

• Titanium heat exchanger plates and other seawater

resistant materials (non-coated).

• Combined condenser cooling, ejector water and feed

water system.

• Freshwater control system.

Benefits

• High quality freshwater, the low content of dissolved solids

(salinity) ensures the supply of pure water that can be used

directly as make-up for steam boilers.

• Long lifespan. High-grade corrosion resistant materials,

such as the titanium plates, ensure a long lifetime for the

equipment.

• Low operation and maintenance costs. Start-and-forget

operation, combined with the easy access to the interior,

reduces man-hours required for operation and maintenance Alfa Laval fresh water generator type DPU-36-C.

to a minimum.

• Simple installation due to compact design, low weight and

the possibility to assemble on the spot.

Capacity range

The DPU-36-C series covers a capacity Heating

medium °C

range from 10 to 55 m3/24h, depending

on the heating medium and cooling

85

water temperatures.

75 DPU-36-C125

The capacities shown in fig. 1 are 65

capacities at a cooling water tempera-

ture of 32°C.

85

The fresh water generator can be

75 DPU-36-C100

dimensioned to suit any jacket water

temperature from 55–90°C at any 65

cooling water temperature required.

5 10 15 20 25 30 35 40 45 50 55 60 m3/24h

The quantity of freshwater produced

can be altered simply by varying the Fig. 1. Capacity range for fresh water generator types DPU-36-C100/C125.

number of plates in the internal plate

heat exchanger.

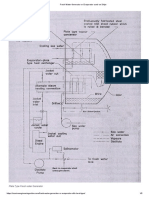

ated pass through a demister where The heating medium (see fig. 3) is either

Working principle any drops of seawater entrained are engine jacket cooling water or a closed

See fig. 2 removed and fall due to gravity to the circuit heated by steam.

brine sump at the bottom of the gener-

The feed water to be distilled is taken ator chamber. The clean freshwater The ejector pump is separately installed

from the sea cooling water outlet of the vapours continue to the condenser (9), and has separate suction from the sea.

condenser (1). It enters the evaporator where they condense into freshwater This pump supplies coolant in the form

(10) where it evaporates at about as they pass between the cold plates of seawater to the condenser, feed-

40–60°C as it passes between the cooled by the sea cooling water. water for evaporation and jet-water for

plates heated by the heating medium. the combined brine/air ejector.

Installation

The evaporating temperature corre- The DPU-36-C fresh water generator The freshwater produced is pumped

sponds to a vacuum of 85–95%, main- is designed for automatic operation in to the tank by the built-on freshwater

tained by the brine/air ejector (not periodically unmanned engine rooms pump.

shown on fig. 2). The vapours gener- and other automated operations.

The separately installed control panel,

with motor starters and salinometer,

supplies electrical power to the ejector

and freshwater pumps as well as

control voltage to the salinometer

and dump valve.

4

9

7

8

6

1. Seawater feed

2. Heating medium in

2 3. Heating medium out

4. Seawater cooling in

5. Seawater cooling out

10

6. Freshwater out

7. Evaporated steam

3

8. Demister

9. Condenser

10. Evaporator

11. Brine out

Fig. 2. Cross-section through Alfa Laval

11 fresh water generator chamber.

Heating medium in Heating medium out

Freshwater to tank

Overboard

From sea

Fig. 3. Installation layout of Alfa Laval fresh

water generator.

Basic equipment • Freshwater pH adjustment • Operating instructions

Fresh water generator unit, including (rehardening) filter.

titanium plate heat exchangers for • Chemical dosing of anti-scale

evaporator and condenser, generator • Freshwater disinfection equipment. chemicals

shell, two stage brine/air ejector, fresh-

water pump, freshwater control sensor • Connections according to DIN, JIS • Trouble shooting

and frame. & ANSI standard.

• Maintenance of major components

Additional equipment necessary

for operation Technical documentation • Spare parts drawings

• Combined cooling and ejector water Complete information and documen-

pump with electrical motor. tation accompany each fresh water • Technical data and drawings.

generator.

• Control panel with motor starters

and salinometer. The installation manual provides all Service support

information necessary for correct An international network of Alfa Laval

• Feed-water anti-scale chemical installation: service centers provides the availability

dosing unit (necessary at heating of spares and service wherever you are.

temperatures above 75°C). • Plant description

Our service engineers will be pleased to

Optional equipment • Installation assist you with any level of maintenance

• Steam heating system type CAS and will train your operation and main-

and CS with direct steam injection. • Technical data and drawings. tenance personnel, if desired. Further

information can be obtained from your

• Equipment for steam boosting and The instruction manual provides all local Alfa Laval representative.

hot water loop system. information necessary for operation

and maintenance:

• Extended control panel with motor

starters and salinometer. • Plant description

DPU-36-C series

Main dimensions and service area

D L SD

LD

Size L D H SD LD Weight* Pump

mm inches mm inches mm inches mm inches mm inches kg lbs mm inches

DPU-36-C100 1420 55.9 1510 59.4 1840 72.4 2220 87.4 2050 80.7 1580 3490

DPU-36-CAS100 1470 57.9 1810 71.3 1840 72.4 2520 99.2 2050 80.7 1660 3670 450 17.7

ALFA LAVAL is a trademark registered and owned by Alfa Laval Corporate AB.

DPU-36-CS100 1470 57.9 1810 71.3 1840 72.4 2520 99.2 2050 80.7 1690 3730

x x

DPU-36-C125 1420 55.9 1830 72.0 1840 72.4 2280 89.8 2370 93.3 1780 3930

DPU-36-CAS125 1470 57.9 2130 83.9 1840 72.4 2580 101.6 2370 93.3 1910 4220 821 32.3

DPU-36-CS125 1470 57.9 2130 83.9 1840 72.4 2580 101.6 2370 93.3 2080 4590

The designation, 100/125, in the type designation indicates the diameter of inlet and outlet flanges

for jacket water connections.

* Empty, when in operation add 85 kg (187 lbs).

EMD00089EN 0701 Alfa Laval reserves the right to change specifications without prior notification.

How to contact Alfa Laval

Up-to-date Alfa Laval contact details

for all countries are always available on

our website at www.alfalaval.com

You might also like

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Desalt JWP 26 C Series PDFDocument4 pagesDesalt JWP 26 C Series PDFRavindar AnandanNo ratings yet

- Desalt Dpu 2 36 C Series 2 StageDocument4 pagesDesalt Dpu 2 36 C Series 2 StageKamran AleemNo ratings yet

- Alfa LavalDocument29 pagesAlfa LavallipovanychNo ratings yet

- Plate Type Fresh Water Generator GuideDocument5 pagesPlate Type Fresh Water Generator GuideDan EzraNo ratings yet

- This Doc. Is in Used Base On Simulator Class TutorialsDocument9 pagesThis Doc. Is in Used Base On Simulator Class TutorialsFatih KayalarNo ratings yet

- Fresh Water Generator On ShipsDocument19 pagesFresh Water Generator On ShipsSheshraj VernekarNo ratings yet

- DOM9Document12 pagesDOM9Rajesh TipnisNo ratings yet

- Fresh Water GeneratorsDocument13 pagesFresh Water GeneratorsLeonardo AraujoNo ratings yet

- Technical Instructions: Form TI410-5 v3Document8 pagesTechnical Instructions: Form TI410-5 v3薛泽绵No ratings yet

- Generate Fresh Water at Sea with this GeneratorDocument13 pagesGenerate Fresh Water at Sea with this GeneratorNandu SNo ratings yet

- Fresh Water Generator: Shipboard Distillation SystemDocument11 pagesFresh Water Generator: Shipboard Distillation SystemGuruNo ratings yet

- Siwes 1Document14 pagesSiwes 1Judex OnyekabaNo ratings yet

- FWGDocument30 pagesFWGNor AshimyNo ratings yet

- Guidance Notes - Descaling Plate Heat Exchangers - FWF - 15iDocument2 pagesGuidance Notes - Descaling Plate Heat Exchangers - FWF - 15iOmid LarkiNo ratings yet

- 9 Cooling SystemDocument11 pages9 Cooling SystemMehar Tariq GoheerNo ratings yet

- Fresh Water Geberator and Osmosis ProcessesDocument62 pagesFresh Water Geberator and Osmosis ProcessesSuhas KassaNo ratings yet

- Manual final-FWG10-1Document36 pagesManual final-FWG10-1Leonid LeonovNo ratings yet

- Fresh Water GeneratorDocument13 pagesFresh Water GeneratorPrem Cesc NathNo ratings yet

- Alfa Laval AQUA Blue S-Type: Single-Stage Freshwater GeneratorDocument4 pagesAlfa Laval AQUA Blue S-Type: Single-Stage Freshwater GeneratorThái HọcNo ratings yet

- Water ChillerDocument74 pagesWater ChillerDimitri LyssiNo ratings yet

- Cooling Water System ProceduresDocument8 pagesCooling Water System ProceduresBoiler Scrubber50% (2)

- DPU, Two-Stage Titanium Plate Type Fresh Water GeneratorDocument4 pagesDPU, Two-Stage Titanium Plate Type Fresh Water GeneratorIvana SeputNo ratings yet

- Installation Manual Compac 12Document27 pagesInstallation Manual Compac 12turbojoNo ratings yet

- Technical Instructions: DescriptionDocument4 pagesTechnical Instructions: Description薛泽绵No ratings yet

- Exh 2100Document18 pagesExh 2100RogerNo ratings yet

- Production of Water: Low Pressure EvaporatorsDocument7 pagesProduction of Water: Low Pressure EvaporatorsDavid bhamNo ratings yet

- Types of Fresh Water GeneratorsDocument4 pagesTypes of Fresh Water GeneratorsalexdenychenkoNo ratings yet

- Week 1Document6 pagesWeek 1Daniel OpeñaNo ratings yet

- Sondex SFD6Document160 pagesSondex SFD6a.amangazinov1995No ratings yet

- Entrenamiento de Servicio Caterpillar Marino (205-255)Document51 pagesEntrenamiento de Servicio Caterpillar Marino (205-255)Edgar MaldonadoNo ratings yet

- FWG Explained (Autosaved)Document21 pagesFWG Explained (Autosaved)Junehenry YalduaNo ratings yet

- Operating Principles and Safety Devices of Freshwater GeneratorsDocument8 pagesOperating Principles and Safety Devices of Freshwater GeneratorsFe CaprichoNo ratings yet

- Alfa Laval JWP16CDocument4 pagesAlfa Laval JWP16CdhlinvaNo ratings yet

- EMD 645 Service Manual Sec. 11Document12 pagesEMD 645 Service Manual Sec. 11Elliot CapsonNo ratings yet

- Aqua Blue Freshwater Generator Mdd00056enDocument4 pagesAqua Blue Freshwater Generator Mdd00056enMuhd Khir RazaniNo ratings yet

- Section 2. Evaporators: 2.1 2 2.2 Scale Deposition 2 2.3 Scale Prevention 4 2.4 Approvals 5 2.5 Evaporator Layouts 5Document6 pagesSection 2. Evaporators: 2.1 2 2.2 Scale Deposition 2 2.3 Scale Prevention 4 2.4 Approvals 5 2.5 Evaporator Layouts 5Rohith UnniNo ratings yet

- Function of Flash Evaporator & Fresh Water Generators For Ship Service SystemDocument3 pagesFunction of Flash Evaporator & Fresh Water Generators For Ship Service Systemmister_no34No ratings yet

- 1553002028-ABB - ADU - Module 2 - PDFsDocument34 pages1553002028-ABB - ADU - Module 2 - PDFsNew TonNo ratings yet

- 21 SOP For Vacuum PumpDocument6 pages21 SOP For Vacuum PumpAmit Biswas100% (1)

- Operation - Manual Sondex A/S SFD 6: Customer: Newbuilding No: Order No.: Sondex Order No.: Encl.Document132 pagesOperation - Manual Sondex A/S SFD 6: Customer: Newbuilding No: Order No.: Sondex Order No.: Encl.AlexDor100% (1)

- Manual DestiladorDocument28 pagesManual DestiladorMaritza Josefina Colina RamonesNo ratings yet

- Quick BoilerB3 ManualDocument5 pagesQuick BoilerB3 ManualartemNo ratings yet

- Electric Valves: For Refrigerant ControlDocument16 pagesElectric Valves: For Refrigerant ControlMohamed HamadNo ratings yet

- Evaporators 2020Document28 pagesEvaporators 2020Rakesh SainiNo ratings yet

- Us2900792 PDFDocument4 pagesUs2900792 PDFAnonymous 43pDZuRNo ratings yet

- Startup Flow Chart PDFDocument1 pageStartup Flow Chart PDFNukul KumarNo ratings yet

- A. M. Buri Steam Power Plant Having A Forced Flow Steam Generator Filed May 28, 1956Document4 pagesA. M. Buri Steam Power Plant Having A Forced Flow Steam Generator Filed May 28, 1956Anonymous KzJcjGCJbNo ratings yet

- Fresh Water GeneratorDocument30 pagesFresh Water Generatorsrinidhi246100% (1)

- Evaluate Refrigeration Cycle Demonstration UnitDocument6 pagesEvaluate Refrigeration Cycle Demonstration UnitSamNo ratings yet

- Case Studies in Thermal Engineering: J.L. Tang, Z.R. OuyangDocument6 pagesCase Studies in Thermal Engineering: J.L. Tang, Z.R. OuyangkktayNo ratings yet

- Heat Recovery From Smelt Dissolving Tank Vent 2009-01-26Document3 pagesHeat Recovery From Smelt Dissolving Tank Vent 2009-01-26hanzancnc7No ratings yet

- Power Plant ValveDocument63 pagesPower Plant Valvenjc6151100% (2)

- Alfa Laval Spiral Heat Exchanger - Brochure PDFDocument12 pagesAlfa Laval Spiral Heat Exchanger - Brochure PDFnay denNo ratings yet

- Pharma-Line: Pharma-Line Double Tube Sheet Shell & Tube Heat ExchangerDocument4 pagesPharma-Line: Pharma-Line Double Tube Sheet Shell & Tube Heat ExchangerDwi Tri CahyonoNo ratings yet

- Alfa Laval Installation MaterialDocument6 pagesAlfa Laval Installation MaterialDwi Tri CahyonoNo ratings yet

- Alfa Disc For HVACDocument4 pagesAlfa Disc For HVACDwi Tri CahyonoNo ratings yet

- GegwDocument20 pagesGegwBoogi Andika TamamiNo ratings yet

- PHE Poster - With Application GuideDocument2 pagesPHE Poster - With Application GuideDwi Tri CahyonoNo ratings yet

- Sanitary Fittings and Tubes: The Complete LineDocument6 pagesSanitary Fittings and Tubes: The Complete LineFelipe Cruvinel DamascenoNo ratings yet

- Ese00612en Alfa Laval Heat ExchangersDocument16 pagesEse00612en Alfa Laval Heat ExchangersKaizenGirlNo ratings yet

- Alfa Laval in brief overviewDocument2 pagesAlfa Laval in brief overviewDwi Tri CahyonoNo ratings yet

- English 1000 Most Repeated MCQs by Learning With Rizwan - 083731Document145 pagesEnglish 1000 Most Repeated MCQs by Learning With Rizwan - 083731Athleteboy7No ratings yet

- PN15CS1S01Document4 pagesPN15CS1S01joadNo ratings yet

- Inas Faiqah BT Mohd Helmi (An Infant Suing Through Her Father and Next Friend, Mohd Helmi Bin Abdul Aziz) V Kerajaan Malaysia & OrsDocument15 pagesInas Faiqah BT Mohd Helmi (An Infant Suing Through Her Father and Next Friend, Mohd Helmi Bin Abdul Aziz) V Kerajaan Malaysia & Orsshukri77No ratings yet

- G.V. Black's Classification and Class I Cavity PreparationDocument57 pagesG.V. Black's Classification and Class I Cavity PreparationPrakuz Harmony SubedifiedNo ratings yet

- ResiboDocument1 pageResiboAlex RespicioNo ratings yet

- There Came A Gypsy RidingDocument45 pagesThere Came A Gypsy RidingMartin McNelisNo ratings yet

- Barriers To Nurse - Patient Communication in Saudi Arabia: An Integrative ReviewDocument10 pagesBarriers To Nurse - Patient Communication in Saudi Arabia: An Integrative Reviewmark3dasaNo ratings yet

- Screenshot 2021-06-06 at 11.13.56Document1 pageScreenshot 2021-06-06 at 11.13.56Momina Ibrahim AhmedNo ratings yet

- Palm Kernel Oil Mill ProjectDocument8 pagesPalm Kernel Oil Mill Projectsjr141071100% (2)

- Using Roger's Diffusion of Innovation Theory To Implement The Healthy Schools National AccreditationDocument6 pagesUsing Roger's Diffusion of Innovation Theory To Implement The Healthy Schools National AccreditationputriNo ratings yet

- Indian School Sohar Term II Examination 2018-19 EnglishDocument4 pagesIndian School Sohar Term II Examination 2018-19 EnglishRitaNo ratings yet

- Artificial Intelligence in Rheumatology: Applications and ChallengesDocument39 pagesArtificial Intelligence in Rheumatology: Applications and ChallengesMaryame BoutkhilNo ratings yet

- Choosing the Right Career and Job RequirementsDocument2 pagesChoosing the Right Career and Job RequirementsdinnahNo ratings yet

- Boq For Ifad Pump Project (Solar System With Drip & Microsprinkler Water Distribution)Document4 pagesBoq For Ifad Pump Project (Solar System With Drip & Microsprinkler Water Distribution)Mr. 420No ratings yet

- Self Esteem and The Real Body ImageDocument12 pagesSelf Esteem and The Real Body ImageChy Alcarde50% (2)

- Convey 1996Document8 pagesConvey 1996Moises Tinte100% (1)

- Rolling Stock Design CriteriaDocument17 pagesRolling Stock Design CriteriahamzaNo ratings yet

- Optimized Die Steel Reference GuideDocument16 pagesOptimized Die Steel Reference GuideKeattikhun ChaichanaNo ratings yet

- Time and Motion Study of OPDDocument15 pagesTime and Motion Study of OPDsaurabh100% (1)

- Why encouraging entrepreneurship to boost economies is flawedDocument9 pagesWhy encouraging entrepreneurship to boost economies is flawedLaureanoNo ratings yet

- Exe Summ RajatCement Eng PDFDocument12 pagesExe Summ RajatCement Eng PDFflytorahulNo ratings yet

- RMO Orientation AIRMEDDocument130 pagesRMO Orientation AIRMEDqueenartemisNo ratings yet

- Chapter 6Document2 pagesChapter 6Zhane CruzNo ratings yet

- Aircraft Surface Protection and Paint CoatingsDocument2 pagesAircraft Surface Protection and Paint CoatingsSarah SNo ratings yet

- Airworthiness Directives Record ControlDocument4 pagesAirworthiness Directives Record ControlJuan builesNo ratings yet

- Marketing Environment Analysis and Trends Impacting CompaniesDocument27 pagesMarketing Environment Analysis and Trends Impacting CompaniesSamoyed KalraNo ratings yet

- 1:21-cv-03674 Coomes, Williams, Slater & Tisbert vs. Centerra Group, LLCDocument16 pages1:21-cv-03674 Coomes, Williams, Slater & Tisbert vs. Centerra Group, LLCMichelle EdwardsNo ratings yet

- ProVent - MANN + HUMMEL ProVent - Oil Separator For Open and Closed Crankcase Ventilation SystemsDocument29 pagesProVent - MANN + HUMMEL ProVent - Oil Separator For Open and Closed Crankcase Ventilation SystemsJosephNo ratings yet

- Fy em - 1 Question Bank 2023-24Document9 pagesFy em - 1 Question Bank 2023-24raju.sharmqNo ratings yet

- Awwa-C302 (1995)Document28 pagesAwwa-C302 (1995)masoudNo ratings yet

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisFrom EverandHydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisNo ratings yet

- Practical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsFrom EverandPractical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsRating: 5 out of 5 stars5/5 (1)

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionFrom EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionRating: 4.5 out of 5 stars4.5/5 (16)

- Pipeline Integrity: Management and Risk EvaluationFrom EverandPipeline Integrity: Management and Risk EvaluationRating: 4.5 out of 5 stars4.5/5 (6)

- Biostratigraphic and Geological Significance of Planktonic ForaminiferaFrom EverandBiostratigraphic and Geological Significance of Planktonic ForaminiferaRating: 4 out of 5 stars4/5 (5)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesFrom EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesRating: 4 out of 5 stars4/5 (2)

- Risk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesFrom EverandRisk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsFrom EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo ratings yet

- Corrosion Control in the Oil and Gas IndustryFrom EverandCorrosion Control in the Oil and Gas IndustryRating: 4 out of 5 stars4/5 (12)

- Mooring System Engineering for Offshore StructuresFrom EverandMooring System Engineering for Offshore StructuresRating: 5 out of 5 stars5/5 (1)