Professional Documents

Culture Documents

Requirements For Authorization of Industrial Radiography (Industrial X-Ray Based) Practice

Uploaded by

aakashOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Requirements For Authorization of Industrial Radiography (Industrial X-Ray Based) Practice

Uploaded by

aakashCopyright:

Available Formats

INTERNAL

PROCEDURE

Print No.: 1 AUTHORIZED BY: Revision No.: 0

NNRA REQUIREMENTS FOR AUTHORIZATION OF

INDUSTRIAL RADIOGRAPHY PRACTICE

(INDUSTRIAL X-RAY BASED)

Effective Date: January, 2006 Ref. No.: Identification code:

NNRA REQUIREMENTS FOR AUTHORIZATION OF INDUSTRIAL RADIOGRAPHY

(INDUSTRIAL X-RAY BASED) PRACTICE

ADMINISTRATIVE AND MEDICAL REQUIREMENTS

2.1 An application for a licence to possess and use a X-ray unit must be submitted to the

Directorate on form HT001. The applicant must show that he possesses the necessary

equipment, facilities and trained personnel to ensure that the radiographic work will be

performed in a safe manner.

2.2 Should a Responsible Person change at any stage, the Directorate must be informed of the

change in writing.

2.3 An application for registration with the Directorate as an industrial radiographer must be

made. Certified copies of documents must be included to show that a course at an

approved educational institution has been successfully completed, and that 6 months

practical experience (under the direct supervision of a qualified industrial radiographer)

has been acquired subsequent to the completion of the course.

2.4 The holder of the licence must ensure that a document is drawn up outlining correct

working procedures. The document must include details of all relevant safety procedures

laid down by the Directorate (i.e. it is recommended that this code form a major part of

the document) and must specify what actions are to be taken in the event of an

emergency. The holder of the licence must take steps to ensure that his employees

adhere to the correct working procedures.

2.5 A separate health register must be established for each radiation worker, and must be

retained by the holder of the licence.

2.6 When the SABS reports to the licence holder that an employee's personal dosimeter (TLD)

has registered more than the pro rata dose allocation for the wearing period, the holder

must complete form G6/10 and forward it to the Directorate. The holder must

furthermore ensure that a copy of this form is entered into the health register of the

worker in question.

2.7 Radiation workers must be declared medically fit by a company appointed doctor before

employment. A copy of this pre-employment medical evaluation must be entered into the

health register of the worker concerned.

2.8 Medical examinations must also be carried out:

2.8.1 where it is confirmed or suspected that a worker has, in any one year, received a

radiation dose which exceeds twice the annual limit (i.e 20 mSv per year, averaged

over 5 years, and not more than 50 mSv in any 1 year);

2.8.2 where a medical practitioner deems it necessary;

2.8.3 where the licence holder or the Director-General deems it necessary; or

2.8.4 where a worker suspects that his health has been or will be detrimentally affected

by occupational factors and such worker deems a medical examination necessary

and requests such examination from the licence holder concerned.

2.9 When a radiation worker ceases to be employed by the licence holder, the holder must

provide that worker with a copy of his complete dose record. Such complete records can

be obtained from the SABS on request.

EQUIPMENT SPECIFICATIONS ANDPERIODIC TESTING

3.1 An X-ray tube must be enclosed in a tube housing in such away that the dose equivalent

rate from leakage radiation measured at a distance of one meter from the focus does not

exceed the following values for the given applied voltages and the corresponding

maximum tube currents:

- up to 150 kV:1 000 µSv/h (100 mR/h)

- above 150 up to 200 kV:2500 µSv/h (250 mR/h)

- above 200 kV:5000 µSv/h (500 mR/h)

For discharge X-ray equipment, the dose equivalent rate shall be defined as the dose equivalent in

one hour at the highest pulse rate.

3.2 A lead cap to be used for covering the radiation window during testing and start up

preparation of the tube must be supplied. The lead cap must attenuate the primary beam

so that the leakage radiation limits are not exceeded.

3.3 The lead cap must be easy to mount correctly. For panoramic X-ray equipment the lead

cap (belt) must be mechanically strong.

3.4 Diaphragms giving different field sizes of the primary beam must be supplied.

3.5 The diaphragms must be easy to mount correctly. Panoramic X-ray equipment must be

supplied with diaphragms enabling directional beam exposure. This is not required for X-

ray crawlers.

3.6 X-ray equipment must be equipped with an extension cable for remote exposure control.

The length of this cable must be at least 20 m for X-ray equipment exceeding 200 kV, and

10 m for kV's of 200 and lower.

3.7 The control panel must be provided with a key activated control. Without this key the

control panel must be inoperable. Removal of the key after exposure must not result in

any damage to the equipment, e.g. overheating.

3.8 Proper operation of the unit via the control panel must be the only way of controlling

exposures. Accidental grounding of an electrical conductor must not result in generation

of X-rays.

3.9 Two independent means which indicate when X-rays are being generated must be

provided on the control panel. One of these indicators must be a red lamp of reliable

design.

3.10 The control panel must be provided with door switch connectors for use on enclosed

installations. This system must be designed in such a way that, when exposure has been

interrupted by the opening of a door altering the switch circuit status, it shall be possible

to resume generation of X-rays only by activation from the control panel after all doors

have been closed again.

3.11 The control panel must be provided with a connection to an external warning lamp.

3.12 The tube head must be distinctly marked with the following information: location

of focus; primary beam angle; and for panoramic units the cylindrical window

must be marked with a colour distinctly different from

that of the rest of the housing.

3.13 Periodic testing on the radiography equipment specified above must be carried out at

intervals not exceeding 24 months. All items of equipment which do not meet the

requirements specified above, must be replaced, or repaired and retested.

3.14 The holder of the licence must keep documentary evidence of all of the above-mentioned

tests for a period of at least 5 years. Such documents must be available for inspection

purposes.

3.13 A brief guidance, written in one of the official languages of the country, shall accompany

the unit (if convenient, in the control panel cover). The guidance shall contain a warning

concerning radiation hazards, and an indication that the installation must be operated by

qualified personnel only.

3.14 The instruction manual for the use of x-ray installations shall be written in one of the

official languages of the country and shall only deal with the type of apparatus concerned.

SPECIFICATIONS FOR ENCLOSED EXPOSUREFACILITIES

Any facility that does not comply with the following requirements is considered to be an open

area (for example an exposure bay with walls, maze and portable equipment).

4.1 The remote control shall be placed outside the enclosure.

4.2 An enclosed exposure facility may not be located in an area zoned for domestic use.

4.3 The facility must be clearly marked with radiation warning signs, and the name and

telephone number of a person to be contacted in the event of an emergency, must appear

at the entrance to the facility.

4.4 The facility must incorporate a means to indicate positively that an exposure is underway.

The facility must incorporate warning lights linked to the on-off mechanism of the unit.

4.5 Facilities in which X-ray equipment are installed must have interlock systems which

prevent exposure if one of the entrance doors is opened before exposure or opened

during exposure. Resumption of exposure must be possible only after manual restart at

the control panel, after the door has been closed.

4.6 Enclosed exposure facilities must be provided with a device which makes it possible for a

person accidentally left in the room, to open one of the doors easily and leave.

4.7 In facilities having more than one entrance door, the doors that are not controlled by the

operator must be lockable from the inside, and the door under his control, lockable from

the outside. If the facility has only one door it must be lockable from the outside.

4.8 The radiation dose rate outside the exposure facility must comply with the requirements

of paragraphs 8.1 to 8.3, and at a distance of 1 m from the outer surface of an enclosed

installation should preferably not exceed 2.5 µSv/h (0.25 mR/h), but must not exceed 7.5

µSv/h (0.75 mR/h) when the properties of the radiation source correspond to the

maximum ratings stated for that enclosed installation.

4.9 Enclosed installations must be provided with a sign stating the maximum rating and

limitations on the primary beam directions established for that installation.

TRAINING REQUIREMENTS

Responsible Person

5.1.1 The Responsible Person must ensure that all persons performing industrial radiography or

who act as radiographic operators and assistants have the necessary training and are

familiar with the correct operating and safety procedures. In particular the training

requirements specified below must be met.

Initial Training requirements

5.2.1 Persons wishing to work as industrial radiographers must successfully complete a course

in industrial radiography at an approved institution, and must subsequently undergo a

practical training period of 6 months under the supervision of a qualified and authorised

industrial radiographer.

You might also like

- Fundraising & Sponsorship GuideDocument8 pagesFundraising & Sponsorship GuideMichelle MannNo ratings yet

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- MX4000/6000 Dual: 4550 193 80281 Revision ADocument31 pagesMX4000/6000 Dual: 4550 193 80281 Revision AMarco MantovaniNo ratings yet

- Accounting Principles Chapter 7 Solution ManualDocument123 pagesAccounting Principles Chapter 7 Solution ManualKitchen UselessNo ratings yet

- UT Equipment Calibration ProcedureDocument14 pagesUT Equipment Calibration ProcedureSantanu Saha100% (4)

- Radiation Safety RadiographicDocument7 pagesRadiation Safety RadiographicNur Subhi HanggiNo ratings yet

- TEC5600 Service Manual PDFDocument303 pagesTEC5600 Service Manual PDFwamala benjaminNo ratings yet

- Ð ÑƒÐºÐ Ð Ð Ð Ñ Ñ Ð Ð Ð¿Ð Poskom PXP60-HF Ра Ð°Ð Ð Ð Ð Ð Ñ ÐºÐ Ð Ñ Ð Ñ ÐºÐDocument37 pagesÐ ÑƒÐºÐ Ð Ð Ð Ñ Ñ Ð Ð Ð¿Ð Poskom PXP60-HF Ра Ð°Ð Ð Ð Ð Ð Ñ ÐºÐ Ð Ñ Ð Ñ ÐºÐTulus Arisono100% (3)

- Ritual of The Order of KnighthoodDocument20 pagesRitual of The Order of KnighthoodCristian Cristi100% (1)

- Apelem Baccara 90 Table - User Manual PDFDocument54 pagesApelem Baccara 90 Table - User Manual PDFJorge AnayaNo ratings yet

- ASTM E1002 Leaks Using UltrASTM E1002 Leaks Using Ultrasonics Airborneasonics AirborneDocument4 pagesASTM E1002 Leaks Using UltrASTM E1002 Leaks Using Ultrasonics Airborneasonics AirborneSebastiánRodrigoPérezHenríquezNo ratings yet

- 005 (Method Statement For Installation and Inspection of Clean Agent system-FM 200Document4 pages005 (Method Statement For Installation and Inspection of Clean Agent system-FM 200Wahid HusainNo ratings yet

- UT MIS AWS Rev 00 TKYDocument27 pagesUT MIS AWS Rev 00 TKYSantanu Saha100% (2)

- Welder Wise Repair PercentageDocument135 pagesWelder Wise Repair PercentageaakashNo ratings yet

- Rev 1 - FONA ART Plus Operator Manual GB PDFDocument32 pagesRev 1 - FONA ART Plus Operator Manual GB PDFjose_mario1128No ratings yet

- EN - Operation Instructions Rayence 1417WGC-WCC - V3 - 2015-06Document118 pagesEN - Operation Instructions Rayence 1417WGC-WCC - V3 - 2015-06Muhammad Denny KartikoNo ratings yet

- 1744 - UT PROCEDURE (For Final) PDFDocument27 pages1744 - UT PROCEDURE (For Final) PDFpvdang8453100% (1)

- POX-100BT High Powered Mobile X-Ray System Product Manual (Operation & 0DQXDO)Document47 pagesPOX-100BT High Powered Mobile X-Ray System Product Manual (Operation & 0DQXDO)Mirwansyah Tanjung100% (1)

- AERB Guidelines PDFDocument7 pagesAERB Guidelines PDFAaquib Mahfuz100% (1)

- Guide to Operating the Orthoralix 9200 Dental Panoramic X-Ray UnitDocument73 pagesGuide to Operating the Orthoralix 9200 Dental Panoramic X-Ray UnitLuis Alberto Díaz Olmedo0% (1)

- Building Construction Agreement Format in MalayalamDocument15 pagesBuilding Construction Agreement Format in Malayalamachusmohan100% (1)

- RPSE CHECKLIST - General RadiographyDocument3 pagesRPSE CHECKLIST - General RadiographyGladys Matira33% (9)

- 3 Labor Reviewer - Labor StandardsDocument25 pages3 Labor Reviewer - Labor StandardsBiboy GSNo ratings yet

- Agnostica vs. Reverentia MemorialDocument50 pagesAgnostica vs. Reverentia MemorialDennis CastroNo ratings yet

- Manual Usuario Humastar 600Document152 pagesManual Usuario Humastar 600Wilson Peralta Montecinos50% (2)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Philippines x-ray checklist requirementsDocument3 pagesPhilippines x-ray checklist requirementsJulian Felipe50% (4)

- Testy Maturalne - Klucz OdpowiedziDocument4 pagesTesty Maturalne - Klucz OdpowiedziOla Sobańtka100% (1)

- ABX Micros 60-ManualDocument132 pagesABX Micros 60-ManualAmanda Eloy100% (1)

- Power Transformer Online Monitoring Using Electromagnetic WavesFrom EverandPower Transformer Online Monitoring Using Electromagnetic WavesNo ratings yet

- Bureau of Health Devices and TechnologyDocument3 pagesBureau of Health Devices and TechnologyNikki Mariz Depay100% (1)

- Department of HealthDocument91 pagesDepartment of Healthsalmachodree100% (3)

- Guidelines for Starting X-Ray InstallationDocument3 pagesGuidelines for Starting X-Ray InstallationmansooracNo ratings yet

- Operation Manual RI 2031aaDocument81 pagesOperation Manual RI 2031aaathanasiosmNo ratings yet

- Radiation Protection Survey and Evaluation (Rpse) Checklist: Mammography FacilityDocument16 pagesRadiation Protection Survey and Evaluation (Rpse) Checklist: Mammography FacilityBarnes, Eduardo3BSRTNo ratings yet

- Medical Refrigerator ManualDocument44 pagesMedical Refrigerator ManualGary Kenmore100% (2)

- Radiation Protection: Test Protocol For Medical and Veterinary Fluoroscopy X-Ray Apparatus 2016Document16 pagesRadiation Protection: Test Protocol For Medical and Veterinary Fluoroscopy X-Ray Apparatus 2016Tuankiet TruongNo ratings yet

- Getting Started SSR-8 - 16 PDFDocument136 pagesGetting Started SSR-8 - 16 PDFVeronicaHidalgoNo ratings yet

- UWB-D00142 MiMAX-Pro V-Series User Guide-Rev EDocument68 pagesUWB-D00142 MiMAX-Pro V-Series User Guide-Rev Ewilmer marquezNo ratings yet

- Contec CMS800G - User Manual PDFDocument31 pagesContec CMS800G - User Manual PDFDea GarNo ratings yet

- Wireless LAN regulatory notes and safety informationDocument38 pagesWireless LAN regulatory notes and safety informationArnolis Rodriguez MembradoNo ratings yet

- 7ML19981GC61 1Document59 pages7ML19981GC61 1Andres ColladoNo ratings yet

- SSR-2000 CLI Reference ManualDocument1,076 pagesSSR-2000 CLI Reference ManualГеннадийNo ratings yet

- sp360 - 4k Manual en PDFDocument71 pagessp360 - 4k Manual en PDFJORGE MONTESNo ratings yet

- RICOH PJ WUL6280 Service ManualDocument150 pagesRICOH PJ WUL6280 Service Manualwilliam lozadaNo ratings yet

- SSR-2000 Getting Started GuideDocument92 pagesSSR-2000 Getting Started GuideГеннадийNo ratings yet

- 8102141-000 - RevF - ALR-F800 Guide, Hardware SetupDocument28 pages8102141-000 - RevF - ALR-F800 Guide, Hardware SetupSergei BaskakovNo ratings yet

- User Manual: LTE Home StationDocument31 pagesUser Manual: LTE Home StationDSP "Ivan Lučić - Lucius"No ratings yet

- 100-00251MicroLab 30 - 40 User - S Guide Rev BDocument94 pages100-00251MicroLab 30 - 40 User - S Guide Rev BReng feninlambirNo ratings yet

- EON600 UsersGuide 11 20 14 LowDocument26 pagesEON600 UsersGuide 11 20 14 LowCristian Javier Rangel OrtízNo ratings yet

- Tetra 3 Personal Multigas Monitor - User Manual (Issue 7)Document36 pagesTetra 3 Personal Multigas Monitor - User Manual (Issue 7)Imran MahmudNo ratings yet

- SSZZ027B EVM Additional TermsDocument4 pagesSSZZ027B EVM Additional TermsUsman KhanNo ratings yet

- JSP 392 Chapter 26 - MEDICAL X-RAY Alt TextDocument5 pagesJSP 392 Chapter 26 - MEDICAL X-RAY Alt Textk0601828No ratings yet

- Fire Detection and Alarm System - Psme BulacanDocument86 pagesFire Detection and Alarm System - Psme BulacanMike100% (1)

- WV - RadiationProgram - VariousDocs (2019!08!08 16-04-16 UTC)Document18 pagesWV - RadiationProgram - VariousDocs (2019!08!08 16-04-16 UTC)rick.pepper3948No ratings yet

- User's Manual - Gun Type Handheld CCD - Laser ScannerDocument92 pagesUser's Manual - Gun Type Handheld CCD - Laser ScannerJohnOaksNo ratings yet

- Nihon Kohden TEC-5600 Defibrillator - Service Manual - Compressed-1-144Document144 pagesNihon Kohden TEC-5600 Defibrillator - Service Manual - Compressed-1-144Francisco BaezNo ratings yet

- vc5020 5040atDocument10 pagesvc5020 5040atfei gaoNo ratings yet

- AVL 439 Opacimeter Operating ManualDocument196 pagesAVL 439 Opacimeter Operating ManualSasidharan100% (3)

- FEEDBACK-Maglev User ManualDocument36 pagesFEEDBACK-Maglev User ManualSree SreejuNo ratings yet

- Hydrosense HSCP Installation ManualDocument18 pagesHydrosense HSCP Installation Manualben_splNo ratings yet

- Explorer 7100 ACU ManualDocument78 pagesExplorer 7100 ACU ManualMuhammad Shahroz AfzalNo ratings yet

- Radiation Hazards: Section XiDocument34 pagesRadiation Hazards: Section Xipopsy69No ratings yet

- Regulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsFrom EverandRegulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsNo ratings yet

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- Dosimetry in Brachytherapy – An International Code of Practice for Secondary Standards Dosimetry Laboratories and HospitalsFrom EverandDosimetry in Brachytherapy – An International Code of Practice for Secondary Standards Dosimetry Laboratories and HospitalsNo ratings yet

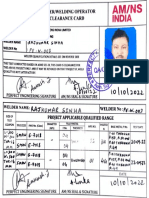

- Anand Welder IdDocument1 pageAnand Welder IdaakashNo ratings yet

- Rajkumar Welder IdDocument1 pageRajkumar Welder IdaakashNo ratings yet

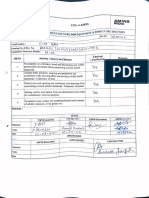

- Foundation Release Note for Equipment Structure ErectionDocument2 pagesFoundation Release Note for Equipment Structure ErectionaakashNo ratings yet

- Santosh Welder IdDocument1 pageSantosh Welder IdaakashNo ratings yet

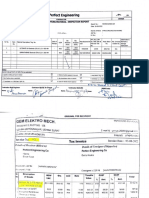

- CRM High BayDocument4 pagesCRM High BayaakashNo ratings yet

- Foundation release note for AM/NS India equipment erectionDocument2 pagesFoundation release note for AM/NS India equipment erectionaakashNo ratings yet

- r?SD@n9o: FL/PLDocument2 pagesr?SD@n9o: FL/PLaakashNo ratings yet

- Oli D 5 ?,: Am/NsDocument2 pagesOli D 5 ?,: Am/NsaakashNo ratings yet

- Imir 004Document5 pagesImir 004aakashNo ratings yet

- Schedule Upcoming Project InspectionDocument1 pageSchedule Upcoming Project InspectionaakashNo ratings yet

- Foundation Bolt Coordinates VerifiedDocument3 pagesFoundation Bolt Coordinates VerifiedaakashNo ratings yet

- I/1/2-2-J.. / J C - V , - Goz - : Peje9.IwDocument2 pagesI/1/2-2-J.. / J C - V , - Goz - : Peje9.IwaakashNo ratings yet

- TextDocument1 pageTextaakashNo ratings yet

- Ijuaa .:I..+-/: Ri" T-E0Document2 pagesIjuaa .:I..+-/: Ri" T-E0aakashNo ratings yet

- Mechanical Engineer with 10+ years inspection experienceDocument4 pagesMechanical Engineer with 10+ years inspection experienceaakashNo ratings yet

- GD227116 OD.G97i BLADE NDT INSP - UT - SHELL IN CAP ZONE-WEB JOINDocument33 pagesGD227116 OD.G97i BLADE NDT INSP - UT - SHELL IN CAP ZONE-WEB JOINaakashNo ratings yet

- Mechanical Engineer with 10+ years inspection experienceDocument4 pagesMechanical Engineer with 10+ years inspection experienceaakashNo ratings yet

- Text 3Document1 pageText 3aakashNo ratings yet

- Text 6Document1 pageText 6aakashNo ratings yet

- Text 2Document1 pageText 2aakashNo ratings yet

- IMIR PerfectDocument1 pageIMIR PerfectaakashNo ratings yet

- Text 4Document1 pageText 4aakashNo ratings yet

- DANGOTE FERTILIZER PROJECT RT/PAUT AND MPT/DPT COVERAGE PERCENTAGESDocument2 pagesDANGOTE FERTILIZER PROJECT RT/PAUT AND MPT/DPT COVERAGE PERCENTAGESaakashNo ratings yet

- Aux Boiler RT SummeryDocument7 pagesAux Boiler RT SummeryaakashNo ratings yet

- RT Internal RepairDocument25 pagesRT Internal RepairaakashNo ratings yet

- Calibration Block Summary For Materials With Diameters 20" (500 MM) & LessDocument3 pagesCalibration Block Summary For Materials With Diameters 20" (500 MM) & LessaakashNo ratings yet

- Corroded Spool List Train 1 - 2Document63 pagesCorroded Spool List Train 1 - 2aakashNo ratings yet

- NDT (RT, PAUT) Percentage List WELDER WiseDocument82 pagesNDT (RT, PAUT) Percentage List WELDER WiseaakashNo ratings yet

- N BandyopadhyayDocument1 pageN BandyopadhyayaakashNo ratings yet

- VICROADS - 269 - STU - 01760 Notice of Incident and Claim Form UPDATE - V2 A - WEBDocument6 pagesVICROADS - 269 - STU - 01760 Notice of Incident and Claim Form UPDATE - V2 A - WEBpalomacqNo ratings yet

- FinalDocument15 pagesFinalapi-214410838No ratings yet

- OIC Claim FormDocument4 pagesOIC Claim FormPrashant SinghNo ratings yet

- May 2009 DWIDocument2 pagesMay 2009 DWIAlbuquerque JournalNo ratings yet

- An Introdcution To AWS Cloud Security-ETDADocument33 pagesAn Introdcution To AWS Cloud Security-ETDAkavinduNo ratings yet

- Law Reading For Executive Magistrate Volume IDocument235 pagesLaw Reading For Executive Magistrate Volume IManishNo ratings yet

- Regulatory Framework and Legal Issues in Business Course SyllabusDocument7 pagesRegulatory Framework and Legal Issues in Business Course SyllabusCarl Joseph OrtegaNo ratings yet

- Maruti SuzukiDocument30 pagesMaruti SuzukiChaitanya KulkarniNo ratings yet

- RC Design EC2 v1.9Document64 pagesRC Design EC2 v1.9mohammed alebiedNo ratings yet

- SB Sec-PirDocument6 pagesSB Sec-PirJomidy MidtanggalNo ratings yet

- Qualification Standards of OSG Plantilla Positions With Job DescriptionDocument1 pageQualification Standards of OSG Plantilla Positions With Job DescriptionAlfred Bryan AspirasNo ratings yet

- Cincinnati ARPA Allocations As of May 19, 2021Document1 pageCincinnati ARPA Allocations As of May 19, 2021WVXU NewsNo ratings yet

- Vishal Shimpi: Hotel Bandra MetroDocument3 pagesVishal Shimpi: Hotel Bandra MetroNikhil BaviskarNo ratings yet

- The Ubique Faculty To Hear ConfessionsDocument5 pagesThe Ubique Faculty To Hear ConfessionsbtafsspNo ratings yet

- Folder 9/10: 18 1/2 Minute Gap NotesDocument106 pagesFolder 9/10: 18 1/2 Minute Gap NotesPrologue MagazineNo ratings yet

- Msds 51910419745 Titan SilverDocument6 pagesMsds 51910419745 Titan SilverAnonymous fXWzyInNo ratings yet

- Survey of Accounting 4th Edition Edmonds Test BankDocument12 pagesSurvey of Accounting 4th Edition Edmonds Test BankJulieMorrisfazg100% (21)

- Keep Dreaming: Parashat Miketz - English VersionDocument4 pagesKeep Dreaming: Parashat Miketz - English Versionshlomo01No ratings yet

- Labour Law - NotesDocument190 pagesLabour Law - NotesAkshat YadavNo ratings yet

- APGCL Tender for Annual Maintenance of Hydraulic GatesDocument26 pagesAPGCL Tender for Annual Maintenance of Hydraulic Gatesrs2operNo ratings yet

- Form Degree Certificate and Duplicate Certificate 2009Document3 pagesForm Degree Certificate and Duplicate Certificate 2009Brince MathewsNo ratings yet

- Paul's Prison Epistles - Lesson 4 - Forum TranscriptDocument22 pagesPaul's Prison Epistles - Lesson 4 - Forum TranscriptThird Millennium MinistriesNo ratings yet

- B.law PresentaionDocument15 pagesB.law PresentaionMohsin AtifNo ratings yet