Professional Documents

Culture Documents

Technical Specification Lifepo Battery Module Ztt4850 (15S)

Uploaded by

Christian Giancarlo Castro MuchaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Specification Lifepo Battery Module Ztt4850 (15S)

Uploaded by

Christian Giancarlo Castro MuchaCopyright:

Available Formats

Spec No.

: ZTT 20-4850

Technical specification

LiFePO4

Battery module

ZTT4850(15S)

Revision Date Prepared Checked Approved Remarks

1 13.02.2020 Sean Sun

Jiangsu Zhongtian Technology Co., Ltd.

No.36 East Hongxing Road, NETDA, Nantong City, Jiangsu province, China

1. GENERAL

This listed specification covers the general requirements, test information and

performance of LiFePO4 battery as manufactured by Jiangsu Zhongtian Technology Co.,

Ltd. (ZTT). Matters not mentioned in this technical specification shall be negotiated by

purchaser & supplier. This document confirms the two Parties agreement, as technical

agreement of contract unless otherwise in official written annexes.

2. STANDARDS

The LiFePO4 battery which ZTT offered shall be designed, manufactured and tested

according to international standards as follows:

Standards for quality control

ISO 9001:2008 Quality Management Systems

ISO 14001:2004 Environmental Management Systems

Standard

EN 61000-6-1:2007 Electromagnetic compatibility. Part 6. Common

standards. Section 1. Noise immunity

EN 61000-6-3:2007+A1:2011 Electromagnetic compatibility. Part 6. Common

standards. Section 3. Emission for residential,

commercial and industrial environments.

LiFePO4 Battery modules and Battery system for

YD/T 2344.1-2011

Telecom Part1: Integrated battery module

IEC 62620:2014, IDT Secondary cells and batteries containing alkaline or

other non-acid electrolytes – Secondary lithium cells

and batteries for use in industrial applications

Note: ZTT shall comply with the latest version standards

www.zttcable.com All Rights Reserved Copyright © 2020 Page 2 of 8

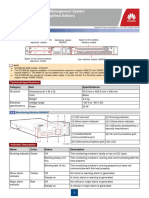

3. PARAMETERS OF THE BATTERY MODULE ZTT4850

Item Value

Type / model / (structure) ZTT4850 / ZTT 48V50Ah Lithium Battery / (15s)

Height 19" rack 3U (19" rack)

Weight 24 kg ± 2 kg

Rated voltage 48 V

Maximum charge voltage 54 V ± 0,2 V

Charge Voltage in Floating Mode 51…52 V ± 0,2 V

Final discharge voltage 40.5 V (adjustable)

Minimum allowable final discharge

37.5 V

voltage

Rated capacity 50 А·h

Internal resistance ≤ 45 mΩ

Rated charging current 0,2C (10 А, adjustable)

Rated discharge current 0,5C (25 А, adjustable)

Maximum discharge current 1C (50 А)

Working Сharge +3~+55°C

temperature Discharge -20~+55°C

Permissible ambient humidity

≤ 85%

during operation

Optimal storage temperature -10~+45°C

Permissible humidity of the

5% ~ 95%

environment during storage

Cycle life

≥ 2 000 Cycles

(0,2C charge & discharge,

(≥80% SOC)

80% DOD, at +25℃)

Protection: from increased charging and low

Functions BMS discharge voltage, from high charge and discharge

current, overheating, short circuit, etc.

www.zttcable.com All Rights Reserved Copyright © 2020 Page 3 of 8

Item Value

BMS ports RS232, RS485

The software BMS - checking

Has software that can connect to a computer

parameters and service works

Dry contacts (Alarm – dry contact) Option

Class IP Indoor type IP20

The dimensions of the battery 482х420х132 mm± 2 mm (3U height), 420 depth

module case (WxDxH) does not include handles, terminals, fuses

The color of the battery module

The black (Option – Color can be changed)

case

- a trademark of the manufacturer;

- symbol of the battery module (model);

- rated voltage in volts;

- nominal capacity in ampere-hours;

Marking on the battery module - voltage of the floating mode at a temperature of

body (indelible and indelible in use) +25°C in volts;

- date of issue (month, year);

- serial number of the battery module in the form of

an individual alphanumeric code;

- signs of recycling and recycling

* - battery module operating time at a temperature of + 65°C not more than 250 h per year

4. APPEARANCE OF THE BATTERY MODULE ZTT4850

The battery module ZTT4850 (15s) should be made for a nominal voltage of 48V.

Inside the battery module case, in front of it is a BMS board must be placed. On the

front panel of the battery module there are terminals, RS232 and RS485 communication

ports, LED indicators, RESET button, ADDR switch, fuse, ground terminal, steel handles,

dry contacts (Option).

www.zttcable.com All Rights Reserved Copyright © 2020 Page 4 of 8

5. PACKING, TRANSPORTATION, STORAGE AND MAINTENANCE BATTERY

MODULE ZTT4850

5.1. Packing

The ZTT4850 battery module must be packed in a shipping container to ensure its

safety during transportation and storage.

Each package of ZTT4850 battery modules must be accompanied by a packing list

with the following information: the manufacturer's name, battery module type, the total

number of modules in the lot, the packing date and the set of technical documentation

At each packing place (carton box) there must be a sticker (nameplate) indicating: the

manufacturer's name, the type of battery module, the quantity in this packing place, the

packing date.

Each packing box must be marked with minipulation signs:

"Fragile. Caution";

"Protect from moisture";

"Top".

Standardly, each ZTT4850 battery module is packed in a separate cardboard box. In

each box, a package with accompanying documentation is placed inside or outside. When

transporting long distances by rail, sea, road or air transport, a box or boxes are placed in

wooden boxes or wooden pallet selected by manufacturer.

5.2. Transportation

During transport, the ZTT4850 battery module and accessories must be packed.

During transportation, any serious vibrations, shocks, rain and sunlight should be avoided.

The battery module can be transported by car, train, ship, airplane, etc.

5.3. Storage

The ZTT4820 battery module should be stored in a dry, ventilated place, every three

months to do one discharge-charge cycle.

When storing the ZTT4850 battery module, avoid any contact with corrosive materials.

Keep the battery module away from fire, heat and sunlight.

When storing, it is necessary to maintain the capacity of the battery module ZTT4850

www.zttcable.com All Rights Reserved Copyright © 2020 Page 5 of 8

at 40-60% of the nominal capacity.

If the battery module ZTT4850 is stored for a long time, recharge it with 50% of the

nominal capacity. To do this: completely discharge it to an equivalent load, then charge it

with a constant current of 8 A for 3-4 hours.

5.4. Maintenance

5.4.1. If the ZTT4850 battery module is not used for a long time at the facility, it is

necessary to connect it to the charger every 3 months and charge it with 8 A for 2 hours.

5.4.2. Do not disassemble the battery module while servicing.

5.4.3. It is forbidden to replace the cells (batteries) inside the battery module, to open

the cells (accumulators) in the battery module.

6. PRECAUTION FOR INSTALLATION

Installation instructions:

The installation of the ZTT4850 battery module must be carried out by specially trained

people authorized to carry out these works:

1) Carefully remove the battery module and other accessories from the shipping

carton (box, box), check if the packaging has been damaged;;

2) Check the completeness, according to the packing list;

3) Install the battery module in the 19 "cabinet (customer or ZTT battery cabinet, if

included);

4) Connect the battery wires "plus", "minus" and the commutation cable / cables (for

data exchange) to the battery module, paying special attention to the "plus" and

"minus", and the order of connecting the signal wires (RS232 or RS485) .

Batteries and patch cables should not cause short circuits, and must be properly

connected. For laying wires and cables in cabinets you can use plastic ties;

5) Connect the battery wires "plus" and "minus" to the battery switch (fuse) or the

terminals of the charger, the power supply device with which the battery module

will operate. Connect the patch cable to the RS232 port of the battery module and

the computer port for setting up and checking the parameters of the battery

module, as well as the communication cable to the RS485 port of the battery

module and the analogous port of the controller (see ZTT4850 Battery Pack

www.zttcable.com All Rights Reserved Copyright © 2020 Page 6 of 8

Operator's Manual).

Safety during installation:

1) Metal decorations such as rings, bracelets, watches in metal casing, etc. are not

allowed to be worn during installation and adjustment.;

2) It is not allowed to use not insulated tools such as a wrench, a screwdriver;

3) It is not allowed to measure the size of the battery module with metal objects,

including measuring;

4) In the case of using clamps (bolts) to secure the battery module to the cabinet, it is

not allowed to fasten them without washers between the clamp (bolt) and the

cabinet of the customer's cabinet;

5) It is not allowed to measure the parameters of the battery module on a metal table;

6) It is not allowed to measure the parameters of the battery module with a suitable

set of power tools and instruments;

7) Do not collect the battery module with wet hands;

8) It is not allowed to touch the battery module housing when heated above + 50°C;

9) Do not operate the battery module on an uneven surface or if there are burrs on

the work surface (table);

10) Do not place the battery module on temporary storage on a surface that does not

stand the weight of the battery module;

11) Do not place containers of water such as a mug, glass, on a battery module, and

leave containers with water closer than 3 m from the battery module.

www.zttcable.com All Rights Reserved Copyright © 2020 Page 7 of 8

7. TEST REQUIREMENTS

No Name of test

1 Standard charge

2 Standard discharge

3 Checking the capacity of the battery

4 Checking the electrical strength and insulation

5 Checking the protection functions

6 Verification of environmental indicators

www.zttcable.com All Rights Reserved Copyright © 2020 Page 8 of 8

You might also like

- TBC300A-TCA3 (TEC) Outdoor Datasheet 01-20161129Document1 pageTBC300A-TCA3 (TEC) Outdoor Datasheet 01-20161129Mohammed Awaluddin Al-islamiNo ratings yet

- Site Model MTS9300 & EMS-4850A1 Kalimantan Region (Direct Connection) New Site 1800Document45 pagesSite Model MTS9300 & EMS-4850A1 Kalimantan Region (Direct Connection) New Site 1800halim.abdulkhaliq.xyz100% (1)

- Lihtium Battery Solution 20200622Document30 pagesLihtium Battery Solution 20200622Phairot Kueanun100% (1)

- Huawei Embedded Power System BrochureDocument20 pagesHuawei Embedded Power System BrochureyacasiestaNo ratings yet

- Engineering Preparations Key PointsDocument17 pagesEngineering Preparations Key PointsImran MalikNo ratings yet

- F01S200 Quick Installation GuideDocument50 pagesF01S200 Quick Installation GuideMohammadBakir100% (1)

- Brochure Battery Lithium 48NPFC100Document2 pagesBrochure Battery Lithium 48NPFC100eddywidjaya9No ratings yet

- Lithium Battery Solution For Telkomsel - V0.0.0 PDFDocument9 pagesLithium Battery Solution For Telkomsel - V0.0.0 PDFDaman HuriNo ratings yet

- Huawei g630 Repair ManualDocument65 pagesHuawei g630 Repair Manualthiszmine0% (2)

- Odp2-065r07m12j13u03-Gq DS 0-0-1Document1 pageOdp2-065r07m12j13u03-Gq DS 0-0-1Alex PereiraNo ratings yet

- Eltek Flatpack enDocument10 pagesEltek Flatpack enZafar KhanNo ratings yet

- User Manual BALI48100 V1.4Document44 pagesUser Manual BALI48100 V1.4Brent ScottNo ratings yet

- Installation guide for ZXDU68 B201 DC power systemDocument4 pagesInstallation guide for ZXDU68 B201 DC power systemclaudio100% (1)

- EPC 4860 Datasheet v01Document2 pagesEPC 4860 Datasheet v01tuananh1965No ratings yet

- ESM-48100U2, ESM-48100U4 and ESM-48100U5 V100R022 Regulatory Compliance StatementDocument7 pagesESM-48100U2, ESM-48100U4 and ESM-48100U5 V100R022 Regulatory Compliance Statementluis meyaNo ratings yet

- DPU30A-N06A1, DPU30D-N06A1, and DPU40D-N06A1 Distributed Power Quick GuideDocument14 pagesDPU30A-N06A1, DPU30D-N06A1, and DPU40D-N06A1 Distributed Power Quick GuidePhyo Kyaw Swar100% (1)

- Ttb-709016-172718-172718de-65f (MTS46)Document1 pageTtb-709016-172718-172718de-65f (MTS46)yevobimNo ratings yet

- SCC800-B2 SmartSite Management System Installation Guide (Simplified Edition)Document9 pagesSCC800-B2 SmartSite Management System Installation Guide (Simplified Edition)Hamza OsamaNo ratings yet

- 5G Indoor Blade Power EPS100D-N01D1 (01074612) Datasheet 04 - (2019071...Document2 pages5G Indoor Blade Power EPS100D-N01D1 (01074612) Datasheet 04 - (2019071...adrienNo ratings yet

- Zxdupa-Wr01 (v4.0r02m02) &zxdupa-Wr01 (v4.0r02m03) DC Power System Installation GuideDocument4 pagesZxdupa-Wr01 (v4.0r02m02) &zxdupa-Wr01 (v4.0r02m03) DC Power System Installation GuideMichael WongNo ratings yet

- DC Distribution Expansion Unit DCDB48-200-16B (01074731) DatasheetDocument1 pageDC Distribution Expansion Unit DCDB48-200-16B (01074731) DatasheetJorge SandovalNo ratings yet

- FLexi BTS Battary SystemDocument12 pagesFLexi BTS Battary SystemАнатолий Петьков100% (1)

- ZXD3000 V5.5 (R03) Rectifier Datasheet-UpDocument4 pagesZXD3000 V5.5 (R03) Rectifier Datasheet-UpLê Hữu ÁiNo ratings yet

- Hi3136 Satellite Digital TV Channel Receiver Chipset: Key SpecificationsDocument4 pagesHi3136 Satellite Digital TV Channel Receiver Chipset: Key SpecificationsSami AslamNo ratings yet

- r48-2000 - Datasheet - Rev3 1 - 20100113 PDFDocument2 pagesr48-2000 - Datasheet - Rev3 1 - 20100113 PDFАлександр Жебровский100% (1)

- TP48200A-D12A1 Quick Installation Guide V300R001 01 PDFDocument2 pagesTP48200A-D12A1 Quick Installation Guide V300R001 01 PDFPavelKuzovkinNo ratings yet

- R4850G2 Rectifier Data Sheet 05 PDFDocument2 pagesR4850G2 Rectifier Data Sheet 05 PDFDeyaniraOjeda100% (1)

- Win1d User'S Manual: Date: 02.10.00Document28 pagesWin1d User'S Manual: Date: 02.10.00Ahmed Nabeeh100% (1)

- Durasol Models UpdateDocument14 pagesDurasol Models UpdateSoud AbdallahNo ratings yet

- ZXDU48 H002 V5.0 ©outdoor Wall-Mounted DC Power Supply System H7+F.4.5kW.220P1.C.LB.10011 ©product Description PDFDocument13 pagesZXDU48 H002 V5.0 ©outdoor Wall-Mounted DC Power Supply System H7+F.4.5kW.220P1.C.LB.10011 ©product Description PDFAbqary Property MamminasataNo ratings yet

- B.4.9 S4850G1 Solar Power Module User ManualDocument4 pagesB.4.9 S4850G1 Solar Power Module User ManualGrover David Perez Huanca100% (1)

- ZXD3000 Rectifier Technical SpecificationsDocument2 pagesZXD3000 Rectifier Technical SpecificationsMohammed Ghaleb100% (1)

- RM3048HEDocument2 pagesRM3048HEonlybrijeshNo ratings yet

- Huawei Indoor Power System TP48300-A-N07A3 L07A3 DatasheetDocument2 pagesHuawei Indoor Power System TP48300-A-N07A3 L07A3 DatasheetAnnBlissNo ratings yet

- Etisalat Wireless Network Modernization Project IntroductionDocument57 pagesEtisalat Wireless Network Modernization Project IntroductionDerbyNo ratings yet

- R48100G1Document2 pagesR48100G1Cristopher Rojas100% (1)

- Engineer Manual TP PDFDocument44 pagesEngineer Manual TP PDFAngga IndrawanNo ratings yet

- TP48300B & TP48600B Maintenance Guide (V100R001 - 02)Document44 pagesTP48300B & TP48600B Maintenance Guide (V100R001 - 02)Alvaro Avila Sanchez0% (1)

- 3-5.5KVA Inverter User ManualDocument29 pages3-5.5KVA Inverter User ManualAron IonutNo ratings yet

- Automatic Transfer Switch Controller ATS104SPDocument2 pagesAutomatic Transfer Switch Controller ATS104SP0960803095390% (1)

- EasyPact MVS - MVS08H3MF2LDocument3 pagesEasyPact MVS - MVS08H3MF2Ldyan emejasNo ratings yet

- MA5600T Hardware Description ISSUE1.00Document52 pagesMA5600T Hardware Description ISSUE1.00Eduard DorneanuNo ratings yet

- Enetek Moduflex+ 12kW Power SystemDocument2 pagesEnetek Moduflex+ 12kW Power SystemSteven SeNo ratings yet

- Claro Battery Soft-Lock ActivationDocument10 pagesClaro Battery Soft-Lock ActivationAntonio MilianNo ratings yet

- 24kW PowerCore ETP48400-C9A4 User Manual (Claro, Peru)Document82 pages24kW PowerCore ETP48400-C9A4 User Manual (Claro, Peru)Ray PillacaNo ratings yet

- APM200 System DescriptionDocument16 pagesAPM200 System DescriptionOliber ContrerasNo ratings yet

- User Manual: ETP48200-C5B4 and ETP48200-C5B5 Embedded PowerDocument93 pagesUser Manual: ETP48200-C5B4 and ETP48200-C5B5 Embedded PowerDmitry059No ratings yet

- Flatpack1500 - MCU User ManualDocument68 pagesFlatpack1500 - MCU User ManualBenyNoerBackboneNo ratings yet

- Tp48200a Hx09a5Document2 pagesTp48200a Hx09a5Anonymous 7AGR2HMl100% (1)

- Delta TPS Brochure 13-05-2019Document27 pagesDelta TPS Brochure 13-05-2019thepimpo100% (1)

- Outdoor Directional Quad-Band Antenna: ODI4-065R18J02-GQ V1Document2 pagesOutdoor Directional Quad-Band Antenna: ODI4-065R18J02-GQ V1Jhon Edisson JimenezNo ratings yet

- Intelligent Lithium Battery ESM 48100B1 Datasheet Draft A 01074746 010 ...Document2 pagesIntelligent Lithium Battery ESM 48100B1 Datasheet Draft A 01074746 010 ...Eduardo Morales Ferrer100% (1)

- Amflifier 2Document3 pagesAmflifier 2keumala rizkyNo ratings yet

- HL800Document2 pagesHL800azzura12100% (1)

- PowerCube 1000 (With DCB) Quick Installation Guide (V300R001 - 03) - USF 5 PDFDocument25 pagesPowerCube 1000 (With DCB) Quick Installation Guide (V300R001 - 03) - USF 5 PDFsamirhammoud100% (3)

- EverExceed EV Series Lithium Battery User Manual V3.2 20220723Document36 pagesEverExceed EV Series Lithium Battery User Manual V3.2 20220723Muhammad RifkiNo ratings yet

- TP48300-A-N07A3 Maintenance Guide (V100R001 - 04)Document53 pagesTP48300-A-N07A3 Maintenance Guide (V100R001 - 04)SamirTam0% (1)

- ZXDU68 B451 (V6.0R20M02) Embedded Power System PDDocument5 pagesZXDU68 B451 (V6.0R20M02) Embedded Power System PDVictor Artica100% (1)

- Manual Ess II 4810Document27 pagesManual Ess II 4810Sergio Recabarren100% (1)

- Mannual SDC10 Box5Document20 pagesMannual SDC10 Box5DZ RdNo ratings yet

- Solar Power PlantDocument100 pagesSolar Power Plantbaaziz2015100% (3)

- Thermodynamics efficiency calculationsDocument3 pagesThermodynamics efficiency calculationsInemesit EkopNo ratings yet

- Module #5 Formal Post-Lab ReportDocument10 pagesModule #5 Formal Post-Lab Reportaiden dunnNo ratings yet

- Ael Coal To PVCDocument2 pagesAel Coal To PVCdeepak saxenaNo ratings yet

- Narration KIPS Academy (Free Download)Document17 pagesNarration KIPS Academy (Free Download)AyshahNo ratings yet

- Angle Beam Transducer Dual ElementDocument5 pagesAngle Beam Transducer Dual ElementWilliam Cubillos PulidoNo ratings yet

- Analie T. Caro: Personal ParticularsDocument4 pagesAnalie T. Caro: Personal ParticularsAnalie Tañamor CaroNo ratings yet

- Quantum Dot PDFDocument22 pagesQuantum Dot PDFALI ASHRAFNo ratings yet

- Product Brand Management 427 v1Document484 pagesProduct Brand Management 427 v1Adii AdityaNo ratings yet

- Business PlanDocument8 pagesBusiness PlanyounggirldavidNo ratings yet

- Disaccharides and PolysaccharidesDocument17 pagesDisaccharides and PolysaccharidesAarthi shreeNo ratings yet

- Rizal's Extensive Travels Abroad for Education and Revolution (1882-1887Document6 pagesRizal's Extensive Travels Abroad for Education and Revolution (1882-1887Diana JeonNo ratings yet

- Shwebo District ADocument280 pagesShwebo District AKyaw MaungNo ratings yet

- Business Research Study Material - Calicut UniversityDocument50 pagesBusiness Research Study Material - Calicut UniversityDr Linda Mary SimonNo ratings yet

- azezew(1)Document48 pagesazezew(1)temesgen AsmamawNo ratings yet

- BTechSyllabus EC PDFDocument140 pagesBTechSyllabus EC PDFHHNo ratings yet

- Key Responsibilities On Skill.: Curriculum Vitae PersonalDocument3 pagesKey Responsibilities On Skill.: Curriculum Vitae PersonalLAM NYAWALNo ratings yet

- Unit 2 GEC 106Document132 pagesUnit 2 GEC 106fernando.gl559No ratings yet

- Centrifuge PDFDocument11 pagesCentrifuge PDFسراء حيدر كاظمNo ratings yet

- Macroeconomics: University of Economics Ho Chi Minh CityDocument193 pagesMacroeconomics: University of Economics Ho Chi Minh CityNguyễn Văn GiápNo ratings yet

- India's Fertilizer IndustryDocument15 pagesIndia's Fertilizer Industrydevika20No ratings yet

- Appendix A. Second QuantizationDocument24 pagesAppendix A. Second QuantizationAgtc TandayNo ratings yet

- Introduction To AIX Mirror Pools 201009Document11 pagesIntroduction To AIX Mirror Pools 201009Marcus BennettNo ratings yet

- En Eco-Drive Panel ConnectionDocument4 pagesEn Eco-Drive Panel ConnectionElectroventica ElectroventicaNo ratings yet

- Coding and Decoding Practice TestDocument13 pagesCoding and Decoding Practice TestRaja SubramanianNo ratings yet

- Benefics & Malefics ExplanationDocument1 pageBenefics & Malefics ExplanationkrastromanNo ratings yet

- Media ExercisesDocument24 pagesMedia ExercisesMary SyvakNo ratings yet

- Connected Topological Spaces: Definition 3.1.1Document22 pagesConnected Topological Spaces: Definition 3.1.1WilmerAlexanderVivasNogueraNo ratings yet

- Assurance Question Bank 2013 PDFDocument168 pagesAssurance Question Bank 2013 PDFIan RelacionNo ratings yet