Professional Documents

Culture Documents

Process Design Sheet: Simulator Basic Assy

Uploaded by

Ruang BengkelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Design Sheet: Simulator Basic Assy

Uploaded by

Ruang BengkelCopyright:

Available Formats

MODEL MACHINE ASSEMBLING SECTION .

PROCESS DESIGN 5

D A T E MANAGER CHECK WRITTEN . 6

SHEET SIMULATOR BASIC ASSY

[ A S S E M B L Y ] 10 OKT 14 P.

F-PES-08 ASEP S YUSRIONO SUWITNO

U N I T W O R K Kit

No. CODE UNIT(GROUP)No. PARTS NUMBER PARTS NAME P=Pallet Grp Qty

K=Kit

COVER DAN FLUIDA

① H0120 X211149430 2086274130 TUBE LH SB2 P QC1 1

② H0120 X211149430 2086274120 TUBE RH SB2 P QC1 1

③ H0120 X211149430 0700073035 O-RING SB2 K QB1 1

EQUIPMENTS

④ H0120 X211149430 0700073030 O-RING SB2 K QB1 1

・

TOOLS

IMPACT WRENCH 8SH ⑤ H0120 X211149430 0737221040 BOLT SB2 K QB1 8

SOCKET 1/2 X 8

SOCKET 1/2 X 14

⑥ H0120 X211149430 0164351032 WASHER SB2 K QB1 8

RING 12 - 14

X

⑦ H0120 X211149430 0726043218 HOSE SB2 P QC1 1

5

⑧ H0120 X211149430 0728900045 CLAMP SB2 K QB1 4

⑨ H0120 X211149430 0707401009 HOSE SB2 P QC1 1

EQUIPMENTS ⑩ H0120 X211149430 0700013032 O-RING SB2 K QB1 1

・

JIG

MISTAR ⑪

MAGIK PEN H0120 X211149430 0737131049 FLANGE SB2 K QB1 4

⑫ H0120 X211149430 0737221035 BOLT SB2 K QB1 4

⑬ H0120 X211149430 0164351032 WASHER SB2 K QB1 4

Pemasangan O-Ring

pada grove hose

⑨⑪⑫⑬ Quality point :

X

Lakukan adjustment

3

Quality point : jarak dari ujung Hose

Lakukan adjustment ke Clamp 5~10 mm

jarak antar Clamp

Pemasangan Tube Pemasangan Hose 5~10 mm , posisian

LH/RH dan Hose Main Attachment pada kepala clamp tidak

Pump pada Machine Machine sejajar 90 ~ 270⁰

5 ~ 10

② ①

③ ⑦⑧ ⑤⑥

④

Pemasangan O-Ring Quality point : Lakukan

pada grove tube pemasangan Hose ke tube , tube

di olesi grease ,masukan hose

X

hingga menutupi area yg tidak di

1

HISTORY

PROCESS BASE STD SPEC. STD

No. SM06 MACHINE OPT MACHINE OPT

SALES CODE

PROCESS

COVER & FLUIDA SPEC. NAME TAKUMI'Sept 2018

NAME

PT.KOMATSU INDONESIA ISSUED : 04/10/2019

You might also like

- Ssp431 Audi Rs 6Document44 pagesSsp431 Audi Rs 6gil_cs100% (1)

- Tooling List Machine Shop Line WiseDocument55 pagesTooling List Machine Shop Line WiseazadNo ratings yet

- RME ReviewerDocument354 pagesRME ReviewerRene100% (1)

- Machine Guarding PDFDocument133 pagesMachine Guarding PDFbrsharmaNo ratings yet

- C70 C90 PDFDocument50 pagesC70 C90 PDFSuricata LeandroNo ratings yet

- CE ON HAND Manfacturer Manfacturer Part No ACTUATOR AUMADocument87 pagesCE ON HAND Manfacturer Manfacturer Part No ACTUATOR AUMASakahi SharmaNo ratings yet

- York Ylcs 725 HaDocument52 pagesYork Ylcs 725 HaDalila Ammar100% (2)

- The Dark WebDocument23 pagesThe Dark Webnoussa100% (1)

- Reefer ContainerDocument23 pagesReefer ContainertholeNo ratings yet

- The Running and Maintenance ofDocument459 pagesThe Running and Maintenance ofantonigor100% (1)

- Windchill Business Administrator's GuideDocument395 pagesWindchill Business Administrator's GuidevundavilliravindraNo ratings yet

- TGB Hde Blade 550 Efi FL WBC SloveniaDocument122 pagesTGB Hde Blade 550 Efi FL WBC SloveniaEnes Karagić100% (1)

- Parts Catalogue: SUPER Splendor (May, 2012)Document96 pagesParts Catalogue: SUPER Splendor (May, 2012)JimJiang100% (3)

- Stone MasonaryDocument23 pagesStone MasonarypurvaNo ratings yet

- Well Control Manual - DRILL0108W01 - 24-3-08Document93 pagesWell Control Manual - DRILL0108W01 - 24-3-08hosam aliNo ratings yet

- MF-131 NANIWA Make Pump (Booklet Including Test Record)Document136 pagesMF-131 NANIWA Make Pump (Booklet Including Test Record)Thanh Nghị BùiNo ratings yet

- Curriculum Review - PrinciplesDocument8 pagesCurriculum Review - Principlesa_magomnangNo ratings yet

- 9976 Implement Pump A10VO100DFR1-31R-PSC62K07 R910911026 PDFDocument12 pages9976 Implement Pump A10VO100DFR1-31R-PSC62K07 R910911026 PDFmorusNo ratings yet

- Tokopedia Engineer CultureDocument25 pagesTokopedia Engineer CultureDIna LestariNo ratings yet

- Simulator Basic Assy: 1.pasang Grommet Dan Hose ValveDocument1 pageSimulator Basic Assy: 1.pasang Grommet Dan Hose ValveRuang BengkelNo ratings yet

- PDS Basic Assy 3Document1 pagePDS Basic Assy 3Ruang BengkelNo ratings yet

- GSTN No: 27aacch5714p1z7: T o T A LDocument10 pagesGSTN No: 27aacch5714p1z7: T o T A LPinak ProjectsNo ratings yet

- Stiga: Collector 45 S Combi (2002)Document17 pagesStiga: Collector 45 S Combi (2002)bruNo ratings yet

- Um2kc1 Cylinder HeadDocument3 pagesUm2kc1 Cylinder HeadBurik8No ratings yet

- Catalogo de Partes Hero Splendor Ismart 14Document63 pagesCatalogo de Partes Hero Splendor Ismart 14Yessenia Chavez BernedoNo ratings yet

- Est-J TGB 1000 Euro4 Euro5 LTXDocument90 pagesEst-J TGB 1000 Euro4 Euro5 LTXvalentingalicNo ratings yet

- MXer150 LA30CEDocument82 pagesMXer150 LA30CEhellenaSRNo ratings yet

- Angle Grinder 3 601 C88 171 GWS 7-115 230V, GBDocument3 pagesAngle Grinder 3 601 C88 171 GWS 7-115 230V, GBmichaelmangaaNo ratings yet

- 871ED-AL40 4" Gravity Coupler, Buna-N: Leading The Way in Tank Truck Equipment Innovation WorldwideDocument1 page871ED-AL40 4" Gravity Coupler, Buna-N: Leading The Way in Tank Truck Equipment Innovation WorldwideVic MoNo ratings yet

- UM2AB1 Cylinder HeadDocument2 pagesUM2AB1 Cylinder HeadBurik8No ratings yet

- Caja de Mandos Grupo Range y EspliterDocument3 pagesCaja de Mandos Grupo Range y EspliterAlex BravoNo ratings yet

- Sr30je E01Document3 pagesSr30je E01freddy1115No ratings yet

- 2200 SERIES: Jabiru Engine Parts BookDocument64 pages2200 SERIES: Jabiru Engine Parts BookEduardo BacilioNo ratings yet

- Catálogo Pleassure 2014Document81 pagesCatálogo Pleassure 2014Piero Andres Chong MoriNo ratings yet

- Isuzu Parts Catalog 4HK1Document62 pagesIsuzu Parts Catalog 4HK1Ko ZayNo ratings yet

- Spare Parts: Circuit D'Eau Hydrabolt/Wib Assemblé - NssDocument28 pagesSpare Parts: Circuit D'Eau Hydrabolt/Wib Assemblé - Nssmarcos.esquivelNo ratings yet

- Bob-Tach S650Document3 pagesBob-Tach S650ferneyNo ratings yet

- Air Intake and Exhaust System 13-20-1 (Hino Engine Type J08etm-Ksda)Document4 pagesAir Intake and Exhaust System 13-20-1 (Hino Engine Type J08etm-Ksda)Oecox Cah DjadoelNo ratings yet

- Air Intake and Exhaust System 13-20-1 (Hino Engine Type J08etm-Ksda) PDFDocument4 pagesAir Intake and Exhaust System 13-20-1 (Hino Engine Type J08etm-Ksda) PDFOecox Cah DjadoelNo ratings yet

- Splendor Pro (Mar, 2012)Document75 pagesSplendor Pro (Mar, 2012)Kishonkumar KishonNo ratings yet

- XCITING250i SB50AEDocument94 pagesXCITING250i SB50AEFurtună MariusNo ratings yet

- Yanmar 4jh2-Dte, 4jh2e, 4jh2-Hte, 4jh2-Te, 4jh2-Ute (B)Document12 pagesYanmar 4jh2-Dte, 4jh2e, 4jh2-Hte, 4jh2-Te, 4jh2-Ute (B)David dounaiNo ratings yet

- Eco DeluxeDocument80 pagesEco DeluxeAkshay LalwaniNo ratings yet

- Volvo Construction Equipment Monteringsanvisningar Installation InstructionsDocument14 pagesVolvo Construction Equipment Monteringsanvisningar Installation InstructionsDmitryNo ratings yet

- KF6C Sec6 FRDDocument24 pagesKF6C Sec6 FRDMauro PerezNo ratings yet

- Title: Transmission Control Installation Model Number: T35100SL Serial Number: 366211001 & Above, 366311001 & Above, 366611001 & AboveDocument2 pagesTitle: Transmission Control Installation Model Number: T35100SL Serial Number: 366211001 & Above, 366311001 & Above, 366611001 & AbovecristianNo ratings yet

- XL2B PumpDocument2 pagesXL2B PumpJuan NietoNo ratings yet

- Parts View Kss1 Self Steer TN Axle: Drum BrakeDocument6 pagesParts View Kss1 Self Steer TN Axle: Drum Brakeyongjun xiaNo ratings yet

- SX-4 Scorpio-Z Cylinder HeadDocument2 pagesSX-4 Scorpio-Z Cylinder Headimcrazzz69No ratings yet

- Blackmer Parts List Pump Model: Xl3B: Discontinued Models: Xl3A-N, Xls3A-NDocument2 pagesBlackmer Parts List Pump Model: Xl3B: Discontinued Models: Xl3A-N, Xls3A-NJuan David Triana SalazarNo ratings yet

- Passion Pro 100 TR 2014Document94 pagesPassion Pro 100 TR 2014Faker FockerNo ratings yet

- TGB FBG Hdle Blade 550 Efi LT FL WBC SloveniaDocument122 pagesTGB FBG Hdle Blade 550 Efi LT FL WBC SloveniaEnes KaragićNo ratings yet

- BR250 - V8 Catálogo Peças-Recambios Jan11Document69 pagesBR250 - V8 Catálogo Peças-Recambios Jan11Francisco Haro Garcia100% (1)

- Reject RBC UpgradationDocument9 pagesReject RBC Upgradationirfan.ali0463No ratings yet

- Sr30je E04Document2 pagesSr30je E04freddy1115No ratings yet

- Control Val Serv DP115Document3 pagesControl Val Serv DP115TECNILOGISTICOS SASNo ratings yet

- Attachment 2 ConsumableDocument8 pagesAttachment 2 ConsumableabbigtsNo ratings yet

- Jabiru 3300 Series IPCDocument47 pagesJabiru 3300 Series IPCTEdNo ratings yet

- ILUK 33, 44, 55, 66: Parts Break DownDocument14 pagesILUK 33, 44, 55, 66: Parts Break DownAlexNo ratings yet

- Passion-Pro-Spare-Parts 2019Document71 pagesPassion-Pro-Spare-Parts 2019Faker FockerNo ratings yet

- Eco Deluxe Euro II PartsDocument86 pagesEco Deluxe Euro II PartsRobinson GuanemeNo ratings yet

- LGL4 PartsDocument2 pagesLGL4 PartsCarlos Rafael Rondon AbreuNo ratings yet

- Air Intake and Exhaust System 13-20-2 (Hino Engine Type J08etm-Ksda)Document4 pagesAir Intake and Exhaust System 13-20-2 (Hino Engine Type J08etm-Ksda)Oecox Cah DjadoelNo ratings yet

- 3A194 - Simplex Hoist Cylinder G PDFDocument2 pages3A194 - Simplex Hoist Cylinder G PDFPepe AlNo ratings yet

- Super Splendor (May, 2012)Document75 pagesSuper Splendor (May, 2012)Kishonkumar KishonNo ratings yet

- Home Gardener: Outdoor Power EquipmentDocument5 pagesHome Gardener: Outdoor Power EquipmentjamesNo ratings yet

- Catálogo Pleassure 2012Document75 pagesCatálogo Pleassure 2012Yessenia Chavez BernedoNo ratings yet

- Splendor NXG Euro II PDFDocument92 pagesSplendor NXG Euro II PDFedwardNo ratings yet

- Auxiliary Hydraulics (S - N 514449564, 514541073, 514641176 & Above) - 863 PDFDocument3 pagesAuxiliary Hydraulics (S - N 514449564, 514541073, 514641176 & Above) - 863 PDFPartagon PowNo ratings yet

- Cylinder Head 10-00-2 (Hino Engine Type J08etm-Ksda)Document4 pagesCylinder Head 10-00-2 (Hino Engine Type J08etm-Ksda)Oecox Cah DjadoelNo ratings yet

- Cylinder Head 10-00-2 (Hino Engine Type J08etm-Ksda)Document4 pagesCylinder Head 10-00-2 (Hino Engine Type J08etm-Ksda)eshopmanual Tiga100% (1)

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- Nilai Ijazah 2023 Xii TM 1Document49 pagesNilai Ijazah 2023 Xii TM 1Ruang BengkelNo ratings yet

- Daftar Nama Kelas XiiDocument2 pagesDaftar Nama Kelas XiiRuang BengkelNo ratings yet

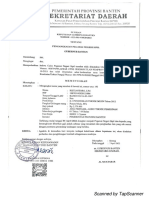

- SK PnsDocument1 pageSK PnsRuang BengkelNo ratings yet

- NILAI IJAZAH 2023 XII BDP RevDocument49 pagesNILAI IJAZAH 2023 XII BDP RevRuang BengkelNo ratings yet

- Foro Alumni 2020.2021.22Document3 pagesForo Alumni 2020.2021.22Ruang BengkelNo ratings yet

- Data Siswa Kelas XII SMKN 1 CipanasDocument4 pagesData Siswa Kelas XII SMKN 1 CipanasRuang BengkelNo ratings yet

- Template Nilai Akhir Mata Pelajaran Gambar Teknik Manufaktur Kelas XI TM 2Document82 pagesTemplate Nilai Akhir Mata Pelajaran Gambar Teknik Manufaktur Kelas XI TM 2Ruang BengkelNo ratings yet

- PDS Basic Assy 4Document1 pagePDS Basic Assy 4Ruang BengkelNo ratings yet

- Be Paper 1Document852 pagesBe Paper 1Vishal Gaurav100% (2)

- Standing Seam Installation-23-11-21Document35 pagesStanding Seam Installation-23-11-21Gokulnath TgNo ratings yet

- Oil Checks On Linde Reach Stacker Heavy TrucksDocument2 pagesOil Checks On Linde Reach Stacker Heavy TrucksmliugongNo ratings yet

- Humboldt Triaxial Equipment Guide-LR0417Document21 pagesHumboldt Triaxial Equipment Guide-LR0417Dilson Loaiza CruzNo ratings yet

- Savitha S. Panikar, PH.DDocument4 pagesSavitha S. Panikar, PH.Diboorose7No ratings yet

- Data Management: Quantifying Data & Planning Your AnalysisDocument38 pagesData Management: Quantifying Data & Planning Your AnalysisSaqlain TariqNo ratings yet

- ANSI-IEEE, NEMA and UL Requirements For SwitchgearDocument4 pagesANSI-IEEE, NEMA and UL Requirements For Switchgearefmartin21No ratings yet

- COVID-19 Vaccination Appointment Details: CenterDocument1 pageCOVID-19 Vaccination Appointment Details: CenterMohit MittalNo ratings yet

- File Handling in C PDFDocument86 pagesFile Handling in C PDFDeepak ShakyaNo ratings yet

- SL Description Type Shape QTY WEIGHT (KGS) 001 Self Supporting Cone Roof Vertical Cylindrical 01 NODocument1 pageSL Description Type Shape QTY WEIGHT (KGS) 001 Self Supporting Cone Roof Vertical Cylindrical 01 NOthreedlabsNo ratings yet

- PGPX 2008 09 Placement BrochureDocument60 pagesPGPX 2008 09 Placement BrochureTom JerryNo ratings yet

- Workbook Answer Key Unit 9 Useful Stuff - 59cc01951723dd7c77f5bac7 PDFDocument2 pagesWorkbook Answer Key Unit 9 Useful Stuff - 59cc01951723dd7c77f5bac7 PDFarielveron50% (2)

- An Overview of Transceiver SystemsDocument11 pagesAn Overview of Transceiver SystemssurvivalofthepolyNo ratings yet

- CSC712 - Questions On Chapter 10 - Project ManagementDocument3 pagesCSC712 - Questions On Chapter 10 - Project ManagementKhairiBudayawanNo ratings yet

- R1 6a Training r2Document95 pagesR1 6a Training r2dot16eNo ratings yet

- Conceptual ModelingDocument24 pagesConceptual ModelinggellymelyNo ratings yet

- Ficha Tecnica Talesun 410WDocument2 pagesFicha Tecnica Talesun 410WIes IngenieriaNo ratings yet

- RRP NoticeDocument6 pagesRRP NoticeLucky TraderNo ratings yet