Professional Documents

Culture Documents

Micro Batch Weighing Systems: Accessories

Uploaded by

Pedro Arquiñigo vegaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Micro Batch Weighing Systems: Accessories

Uploaded by

Pedro Arquiñigo vegaCopyright:

Available Formats

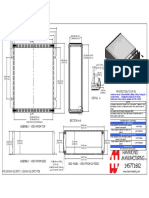

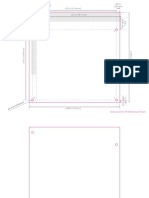

S t a n d a r d W e i g h t Gai n d im e n si o n s

Accessories

Above floor

(NUMBER OF BINS X 13 in) + 26 in 92.50 in

[NUMBER OF BINS X 330 mm) + 660 mm] [2350 mm]

(NUMBER OF BINS X 13 in) - 1 in 72.00 in

[(NUMBER OF BINS X 330 mm) - 25 mm] [1829 mm]

24.00 in

Micro Batch Weighing Systems

[610 mm]

24.50 in

[622 mm]

53.50 in

[1359 mm]

Micro Bin Dust

AS REQUIRED

Collection Hood

SIDE VIEW END VIEW

In-floor

(NUMBER OF BINS X 13 in) + 26 in 92.50 in

[NUMBER OF BINS X 330 mm) + 660 mm] [2350 mm]

(NUMBER OF BINS X 13 in) - 1 in 72.00 in

[(NUMBER OF BINS X 330 mm) - 25 mm] [1829 mm]

24.00 in

[610 mm]

24.50 in

[622 mm]

FLOOR

53.50 in

[1359 mm] Bulk Bag to Micro

Bin Adapter

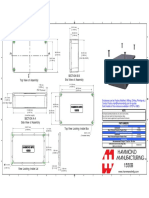

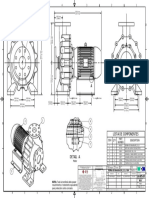

S t a n d a r d W e i g h t L o ss d im e n si o n s

Variable Depth

Pitch UHMW

(NUMBER OF BINS X 15 in) + 16 in 105.00 in

[(NUMBER OF BINS X 381 mm) + 406 mm] [2667 mm] Feeder Screws

(NUMBER OF BINS X 15 in) 89.00 in

[(NUMBER OF BINS X 381 mm)] [2261 mm]

30.00 in

[762 mm]

23.00 in Please contact

[584 mm]

Abel for many other

accessories and

options.

55.50 in

[1410 mm]

AS REQUIRED

Precision • Performance • Reliability

Abel Manufacturing Co., Inc.

PO Box 757 Appleton, WI 54912 USA

Phone: 920-734-4443 • Fax: 920-734-1084

sales@abelusa.com • www.abelusa.com

Automated micro batch weighing systems have become essential equipment Weight gain System

for all batch processing facilities. the improvement in accuracy, speed, efficiency,

the abel weight gain system is the most widely

error reduction, data logging and government compliance have made these used design in the market today. it’s combination

an important part of modern batching facilities. of performance and cost efficiency make it the

most popular choice for many applications.

Abel has been advancing the state-of-the-art in micro batch weighing systems • Exceptional scale accuracy

for over 30 years. Many of the advanced features in weighing systems today • Easy to maintain

were developed and introduced by Abel. • Bin capacities from 3 ft3 (0.08m3) through

75 ft3 (2.1m3)

• Scale capacities from 10 lbs (5 kg) through

Abel firsts include: 1000 lbs (500 kg)

• Trough or conical scales are available

ABel fIrSt: electric motor drive system using a Plc Abel is now pleased to introduce

and a variable frequency drive to provide economical a new generation of systems • Excellent scale dust containment

independent speed control of all feeders in a system. with many new advance features • Most immune to environment issues such as

vibration and air currents

including:

ABel fIrSt: optimized bin design with three vertical • Compatible with all automated control systems

walls and 45 degree corners provide excellent material • significant improvements in • Most economical

flow characteristics.

reliability and durability

ABel fIrSt: the first practical and commercially • full control though ethernet

trough type system electrical

successful weight loss system that provided accurate network control panel

inventory by weight capability, significantly faster scale hopper

• improved sanitary operation in dust enclosure with ethernet

batching speeds, complete material use data connected Plc

recording, reduced cross contamination and many • enhanced accuracy and capacity

government compliance features. through improved feeder design

ABel fIrSt: Development of a broad range of • reduced footprint

options including dust collection, bar code controlled • reduced costs through

bin lid locking systems, high precision feeders, feeder

discharge gates, a wide variety of bin and scale

improvements in manufacturability Weight loss System

capacities and many others. the abel weight loss system revolutionized the

micro weighing system market when it introduced its

inventory-by-weight capability. by helping customers

meet strict government regulations, it has become

Moving Scale System the standard in the industry where materials

must be tracked accurately, especially in high

abel introduced the moving scale weighing system for those applications that require the highest accuracy capacity facilities.

with the least amount of cross contamination. this is accomplished through a light weigh, high sensitivity

scale that is easy to clean. cross contamination is further reduced by the elimination of a transfer conveyor • Complete audit trail of all materials that

after the scale. pass through the system

• Very high speed operation due to multiple

• Scale configurations include hopper type scales with feeders operating simultaneously

discharge gates or platform scales with removable containers. • Reduced cross contamination

• Scale track extensions allows hopper scales to discharge • Flexible system layout

directly into a mixer. • Easy expansion

• Optional vibratory feeders provide accuracy down • Increased reliability through redundancy

to +/- 0.002 lbs (1g)

• Reduced machine height

Automated micro batch weighing systems have become essential equipment Weight gain System

for all batch processing facilities. the improvement in accuracy, speed, efficiency,

the abel weight gain system is the most widely

error reduction, data logging and government compliance have made these used design in the market today. it’s combination

an important part of modern batching facilities. of performance and cost efficiency make it the

most popular choice for many applications.

Abel has been advancing the state-of-the-art in micro batch weighing systems • Exceptional scale accuracy

for over 30 years. Many of the advanced features in weighing systems today • Easy to maintain

were developed and introduced by Abel. • Bin capacities from 3 ft3 (0.08m3) through

75 ft3 (2.1m3)

• Scale capacities from 10 lbs (5 kg) through

Abel firsts include: 1000 lbs (500 kg)

• Trough or conical scales are available

ABel fIrSt: electric motor drive system using a Plc Abel is now pleased to introduce

and a variable frequency drive to provide economical a new generation of systems • Excellent scale dust containment

independent speed control of all feeders in a system. with many new advance features • Most immune to environment issues such as

vibration and air currents

including:

ABel fIrSt: optimized bin design with three vertical • Compatible with all automated control systems

walls and 45 degree corners provide excellent material • significant improvements in • Most economical

flow characteristics.

reliability and durability

ABel fIrSt: the first practical and commercially • full control though ethernet

trough type system electrical

successful weight loss system that provided accurate network control panel

inventory by weight capability, significantly faster scale hopper

• improved sanitary operation in dust enclosure with ethernet

batching speeds, complete material use data connected Plc

recording, reduced cross contamination and many • enhanced accuracy and capacity

government compliance features. through improved feeder design

ABel fIrSt: Development of a broad range of • reduced footprint

options including dust collection, bar code controlled • reduced costs through

bin lid locking systems, high precision feeders, feeder

discharge gates, a wide variety of bin and scale

improvements in manufacturability Weight loss System

capacities and many others. the abel weight loss system revolutionized the

micro weighing system market when it introduced its

inventory-by-weight capability. by helping customers

meet strict government regulations, it has become

Moving Scale System the standard in the industry where materials

must be tracked accurately, especially in high

abel introduced the moving scale weighing system for those applications that require the highest accuracy capacity facilities.

with the least amount of cross contamination. this is accomplished through a light weigh, high sensitivity

scale that is easy to clean. cross contamination is further reduced by the elimination of a transfer conveyor • Complete audit trail of all materials that

after the scale. pass through the system

• Very high speed operation due to multiple

• Scale configurations include hopper type scales with feeders operating simultaneously

discharge gates or platform scales with removable containers. • Reduced cross contamination

• Scale track extensions allows hopper scales to discharge • Flexible system layout

directly into a mixer. • Easy expansion

• Optional vibratory feeders provide accuracy down • Increased reliability through redundancy

to +/- 0.002 lbs (1g)

• Reduced machine height

S t a n d a r d W e i g h t Gai n d im e n si o n s

Accessories

Above floor

(NUMBER OF BINS X 13 in) + 26 in 92.50 in

[NUMBER OF BINS X 330 mm) + 660 mm] [2350 mm]

(NUMBER OF BINS X 13 in) - 1 in 72.00 in

[(NUMBER OF BINS X 330 mm) - 25 mm] [1829 mm]

24.00 in

Micro Batch Weighing Systems

[610 mm]

24.50 in

[622 mm]

53.50 in

[1359 mm]

Micro Bin Dust

AS REQUIRED

Collection Hood

SIDE VIEW END VIEW

In-floor

(NUMBER OF BINS X 13 in) + 26 in 92.50 in

[NUMBER OF BINS X 330 mm) + 660 mm] [2350 mm]

(NUMBER OF BINS X 13 in) - 1 in 72.00 in

[(NUMBER OF BINS X 330 mm) - 25 mm] [1829 mm]

24.00 in

[610 mm]

24.50 in

[622 mm]

FLOOR

53.50 in

[1359 mm] Bulk Bag to Micro

Bin Adapter

S t a n d a r d W e i g h t L o ss d im e n si o n s

Variable Depth

Pitch UHMW

(NUMBER OF BINS X 15 in) + 16 in 105.00 in

[(NUMBER OF BINS X 381 mm) + 406 mm] [2667 mm] Feeder Screws

(NUMBER OF BINS X 15 in) 89.00 in

[(NUMBER OF BINS X 381 mm)] [2261 mm]

30.00 in

[762 mm]

23.00 in Please contact

[584 mm]

Abel for many other

accessories and

options.

55.50 in

[1410 mm]

AS REQUIRED

Precision • Performance • Reliability

Abel Manufacturing Co., Inc.

PO Box 757 Appleton, WI 54912 USA

Phone: 920-734-4443 • Fax: 920-734-1084

sales@abelusa.com • www.abelusa.com

You might also like

- Enclosures Can Be Factory Modified (Milling, Drilling, Printing Etc.) Solid Models of This Enclosure Available in STEP or IGESDocument1 pageEnclosures Can Be Factory Modified (Milling, Drilling, Printing Etc.) Solid Models of This Enclosure Available in STEP or IGESryuslkaNo ratings yet

- Enclosures Can Be Factory Modified (Milling, Drilling, Printing Etc.) Solid Models of This Enclosure Available in STEP or IGESDocument1 pageEnclosures Can Be Factory Modified (Milling, Drilling, Printing Etc.) Solid Models of This Enclosure Available in STEP or IGESryuslkaNo ratings yet

- RT530E 2 Product Guide Imperial PDFDocument16 pagesRT530E 2 Product Guide Imperial PDFsergio blandon lNo ratings yet

- 1983-SDEE - Foundation Vibrations STATE of The ARTDocument16 pages1983-SDEE - Foundation Vibrations STATE of The ARTJaime GuamanNo ratings yet

- 1550a PDFDocument1 page1550a PDFMatty EmmaNo ratings yet

- Product Options Advantages: 5131 Cash Road Dallas, TX 75247 P 214.631.8070 F 214.631.3673 800.847.0380Document2 pagesProduct Options Advantages: 5131 Cash Road Dallas, TX 75247 P 214.631.8070 F 214.631.3673 800.847.0380FREDDY YAJAMINNo ratings yet

- OTC 5 Series II Robotic Welding 2021 1Document16 pagesOTC 5 Series II Robotic Welding 2021 1richard ortega villasmilNo ratings yet

- Dimensions and Tolerances of a Pump ComponentDocument1 pageDimensions and Tolerances of a Pump ComponentJorge LNo ratings yet

- Cabinet Installation Instruction: DimensionsDocument1 pageCabinet Installation Instruction: DimensionsJohn Lee PettimoreNo ratings yet

- Cabinet Installation Step-by-Step GuideDocument1 pageCabinet Installation Step-by-Step GuideJohn Lee PettimoreNo ratings yet

- Cabinet Installation Instruction: DimensionsDocument1 pageCabinet Installation Instruction: DimensionsJohn Lee PettimoreNo ratings yet

- Enclosures Can Be Factory Modified (Milling, Drilling, Printing Etc.) Solid Models of This Enclosure Available in STEP or IGESDocument1 pageEnclosures Can Be Factory Modified (Milling, Drilling, Printing Etc.) Solid Models of This Enclosure Available in STEP or IGESZarkoffNo ratings yet

- Force Feedback Manipulator: Kraft TeleroboticsDocument6 pagesForce Feedback Manipulator: Kraft TeleroboticsnasrpooyaNo ratings yet

- Enclosures Can Be Factory Modified (Milling, Drilling, Printing Etc.) Solid Models of This Enclosure Available in STEP or IGESDocument1 pageEnclosures Can Be Factory Modified (Milling, Drilling, Printing Etc.) Solid Models of This Enclosure Available in STEP or IGESMatty EmmaNo ratings yet

- RM3U1913VBK: Section TT-TT UUDocument1 pageRM3U1913VBK: Section TT-TT UU123abcdefsdsdsdNo ratings yet

- RT540E ProductGuide Imperial 01 2020Document16 pagesRT540E ProductGuide Imperial 01 2020Leonardo LiraNo ratings yet

- Grove RT 540 e Manuel TechniqueDocument16 pagesGrove RT 540 e Manuel TechniqueMohamedNo ratings yet

- Architectural/Mechanical Product Specifications: GirbauDocument4 pagesArchitectural/Mechanical Product Specifications: GirbauLovely BautistaNo ratings yet

- Product Guide: FeaturesDocument16 pagesProduct Guide: FeaturesJavier Ignacio MacíasNo ratings yet

- Product Guide: FeaturesDocument24 pagesProduct Guide: FeaturesWesleyNo ratings yet

- Dimensions and assembly of an enclosureDocument1 pageDimensions and assembly of an enclosurepavanNo ratings yet

- C-6100-AC Cramer Hysteresis 11 09-2Document2 pagesC-6100-AC Cramer Hysteresis 11 09-2Eng KapoNo ratings yet

- Manzini to Mbadlane Highway Project Soil Testing ReportDocument12 pagesManzini to Mbadlane Highway Project Soil Testing ReportSoundar PachiappanNo ratings yet

- Machine Layout Drawing - UMC-750/SS/P: Operating DimensionsDocument5 pagesMachine Layout Drawing - UMC-750/SS/P: Operating DimensionsBolek ŻmigrodzkiNo ratings yet

- WIND TURBINE FINAL Layout 1Document1 pageWIND TURBINE FINAL Layout 1Matt TorresNo ratings yet

- Dimension Guide W10445545B D MTDocument2 pagesDimension Guide W10445545B D MTyukadooNo ratings yet

- Front-Load Washer Dimensions and Installation OptionsDocument1 pageFront-Load Washer Dimensions and Installation OptionsBilly TalaugonNo ratings yet

- Commercial Laundry Giant Dryer Leaflet (20200811 - 184015)Document2 pagesCommercial Laundry Giant Dryer Leaflet (20200811 - 184015)blueee archiveNo ratings yet

- Sandvik LH203-3 PDFDocument3 pagesSandvik LH203-3 PDFjuan carlos0% (1)

- Sandvik lh203 3 PDFDocument3 pagesSandvik lh203 3 PDFJhoncitoMartinezNo ratings yet

- Urban Double Stacker (Narrow Aisle) PDFDocument1 pageUrban Double Stacker (Narrow Aisle) PDFdio wongNo ratings yet

- 400B Product Guide ImperialDocument20 pages400B Product Guide ImperialChiheb BEN ABDALLAHNo ratings yet

- 6.1. Single Panel Enclosure - JT-ENC1PDocument1 page6.1. Single Panel Enclosure - JT-ENC1PThái Dương Trà100% (1)

- RL6055Document1 pageRL6055Dalius AugustinasNo ratings yet

- Datasheet Gocator 2000 Web enDocument2 pagesDatasheet Gocator 2000 Web enerNo ratings yet

- PEGSON - 'M' Series JAW Crusher (Curvas de Produccion) (+++)Document8 pagesPEGSON - 'M' Series JAW Crusher (Curvas de Produccion) (+++)Juan CarlosNo ratings yet

- QL - Bow Thruster CT900 (Eng)Document2 pagesQL - Bow Thruster CT900 (Eng)PT MarineNo ratings yet

- Husky DataSheet 2016Document1 pageHusky DataSheet 2016Christian CanchigniaNo ratings yet

- CRANE NATIONAL 800H-Data-Sheet-ImperialDocument12 pagesCRANE NATIONAL 800H-Data-Sheet-ImperialT ChandrashekarNo ratings yet

- mITX Motherboard Screw PatternDocument3 pagesmITX Motherboard Screw PatternjetzerNo ratings yet

- N/A NOTA: Toda La Torniller A Debe Poseer: BOMBA IE 080x065x250 - 2.2 - 4 50HDocument1 pageN/A NOTA: Toda La Torniller A Debe Poseer: BOMBA IE 080x065x250 - 2.2 - 4 50HTécnica AGNo ratings yet

- LGTitan DryerDocument1 pageLGTitan DryerKyle MartinNo ratings yet

- 101 Trench Installation Detail (N-12 Per AASHTO) - 0Document1 page101 Trench Installation Detail (N-12 Per AASHTO) - 0Zhenhe SongNo ratings yet

- P250024S1020 - HPS Post InsulatorDocument2 pagesP250024S1020 - HPS Post InsulatorYanuar WidyarsaNo ratings yet

- 3M Standart SeriesDocument4 pages3M Standart SeriesSerhan ÜnverNo ratings yet

- GCD15 Product GuideDocument28 pagesGCD15 Product Guideing.juantincoNo ratings yet

- RM3U0808SBK: Section NN-NN PPDocument1 pageRM3U0808SBK: Section NN-NN PPGustavo MaureiraNo ratings yet

- C - RP 7 - Tamper Switch TS-20 Series - StampedDocument2 pagesC - RP 7 - Tamper Switch TS-20 Series - Stampedebcunha.ptiNo ratings yet

- C - RP 7 - Tamper Switch TS-20 SeriesDocument2 pagesC - RP 7 - Tamper Switch TS-20 Seriesebcunha.ptiNo ratings yet

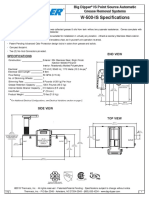

- W 750 IS Specification Sheet PDFDocument2 pagesW 750 IS Specification Sheet PDFAnonymous PCsoNCt0mFNo ratings yet

- Nov-0712-5-1000 Rev2Document1 pageNov-0712-5-1000 Rev2ĒDīson CevallosNo ratings yet

- 4X Leveling Pad Pin Dimension: Electrical Connection Air Connection 1 2Document3 pages4X Leveling Pad Pin Dimension: Electrical Connection Air Connection 1 2Edwin RodríguezNo ratings yet

- W 500 Is SpecDocument2 pagesW 500 Is SpecdjukalNo ratings yet

- THHN - THWN 90°C 600V - Columbia Wire & Cable CorporationDocument1 pageTHHN - THWN 90°C 600V - Columbia Wire & Cable CorporationDanilo BabolNo ratings yet

- Sentry Constant Pressure Cylinder: Automatic Sampling AccessoriesDocument2 pagesSentry Constant Pressure Cylinder: Automatic Sampling Accessoriesdilo0987No ratings yet

- 10-20 Belt Scale MT9101 8017.0113Document4 pages10-20 Belt Scale MT9101 8017.0113RickNo ratings yet

- New Robocut: Fast, Accurate, Multipurpose EDM With Rigid 800 MM Table For Even More VersatilityDocument2 pagesNew Robocut: Fast, Accurate, Multipurpose EDM With Rigid 800 MM Table For Even More VersatilityMAKHLOUKA IbrahimNo ratings yet

- Alimentador de Molino de MartillosDocument2 pagesAlimentador de Molino de MartillosPedro Arquiñigo vegaNo ratings yet

- Acondisionador Estandar GB - ConditionerDocument2 pagesAcondisionador Estandar GB - ConditionerPedro Arquiñigo vegaNo ratings yet

- Acondicionador HorizontalDocument2 pagesAcondicionador HorizontalPedro Arquiñigo vegaNo ratings yet

- High Speed Weigh Lorry SpecificationsDocument2 pagesHigh Speed Weigh Lorry SpecificationsPedro Arquiñigo vegaNo ratings yet

- Lucas 2K: The Heartbeat of The Mobile DJDocument24 pagesLucas 2K: The Heartbeat of The Mobile DJPedro Arquiñigo vegaNo ratings yet

- Lucas 2K15 Lucas 2K18: Manual 1.0Document36 pagesLucas 2K15 Lucas 2K18: Manual 1.0Pedro Arquiñigo vegaNo ratings yet

- Swissbit WORM SD CardDocument48 pagesSwissbit WORM SD CardLaurentiu M.No ratings yet

- 440-N4X Operations ManualDocument23 pages440-N4X Operations ManualRahul DevaNo ratings yet

- DsPIC DSC Motor Control WorkshopDocument177 pagesDsPIC DSC Motor Control Workshopgzdprlk100% (3)

- E2 E3 Infosphere Datastage - Introduction To The Parallel ArchitectureDocument36 pagesE2 E3 Infosphere Datastage - Introduction To The Parallel ArchitectureRMNo ratings yet

- COmputer LabDocument9 pagesCOmputer LabpnkjinamdarNo ratings yet

- OrgaTEX X1 Professional System Requirements EN 1101 01Document16 pagesOrgaTEX X1 Professional System Requirements EN 1101 01Pedro Miguel DinisNo ratings yet

- Object-Oriented Software Engineering: Mini Project On National Center of Information TechnologyDocument18 pagesObject-Oriented Software Engineering: Mini Project On National Center of Information TechnologyAbhishek MisraNo ratings yet

- AssignmentDocument6 pagesAssignmentsadasNo ratings yet

- Data Acquisition System (Idm Hathway)Document5 pagesData Acquisition System (Idm Hathway)Cepi SukmayaraNo ratings yet

- 001-84932 PSoC 5LP CY8C58LP Family Datasheet Programmable System-On-Chip PSoC DatasheetDocument139 pages001-84932 PSoC 5LP CY8C58LP Family Datasheet Programmable System-On-Chip PSoC DatasheetAENo ratings yet

- Digital Electronics and OpticsDocument90 pagesDigital Electronics and OpticsSteve MachariaNo ratings yet

- Course Slot and Faculty DetailsDocument26 pagesCourse Slot and Faculty DetailsPranjal RuhelaNo ratings yet

- Oracle Frequently Asked QuestionsDocument151 pagesOracle Frequently Asked Questionsmohd_sajjad25No ratings yet

- Intel McAfee AcquisitionDocument6 pagesIntel McAfee AcquisitionEbube AnizorNo ratings yet

- Data-Driven Design of Fog Computing Aided Process Monitoring System For Large-Scale Industrial ProceDocument10 pagesData-Driven Design of Fog Computing Aided Process Monitoring System For Large-Scale Industrial ProceSindhu PranathiNo ratings yet

- CM As-I Master ST Et200sp Manual 2013-04 En-UsDocument150 pagesCM As-I Master ST Et200sp Manual 2013-04 En-UsAbez FiveNo ratings yet

- 25 KW X-Band Transceiver DownmastDocument132 pages25 KW X-Band Transceiver DownmastArshad Jummani67% (3)

- Design of Analog CMOS Integrated Circuits: (1st Edition)Document4 pagesDesign of Analog CMOS Integrated Circuits: (1st Edition)Himaja DasariNo ratings yet

- Gamp 4 To Gamp 5Document3 pagesGamp 4 To Gamp 5Nitin KashyapNo ratings yet

- Under The Guidance Of: Smt. Lovee Jain Asst. Professor Department of CSEDocument27 pagesUnder The Guidance Of: Smt. Lovee Jain Asst. Professor Department of CSEdacchuNo ratings yet

- User Guide: Smart ThermostatDocument17 pagesUser Guide: Smart ThermostatMark WillisNo ratings yet

- Series 90 Programmable Coprocessor Module and Support Software User's Manual, GFK-0255Kgfk0255kDocument316 pagesSeries 90 Programmable Coprocessor Module and Support Software User's Manual, GFK-0255Kgfk0255kARTURO TZITZIHUA HERNANDEZ100% (1)

- Pt855tadm b112016Document406 pagesPt855tadm b112016viktorNo ratings yet

- Mosfet CharacteristicsDocument12 pagesMosfet CharacteristicsNavaneethaan NathamoorthyNo ratings yet

- Vsphere With KubernetesDocument12 pagesVsphere With Kubernetesleroy23No ratings yet

- RMFDocument245 pagesRMFsuryadiwaNo ratings yet

- Study of Discrete PID Controller For DC Motor Speed Control Using MATLABDocument6 pagesStudy of Discrete PID Controller For DC Motor Speed Control Using MATLABHarish rajanNo ratings yet

- HADR System With DR Node Users GuideDocument118 pagesHADR System With DR Node Users GuideCesar FonsecaNo ratings yet

- Project Report: Tools For Programming in Moocs: Assess Student'S KnowledgeDocument22 pagesProject Report: Tools For Programming in Moocs: Assess Student'S KnowledgeVijayalaxmiNo ratings yet

- Troubleshooting Service Manual For Elecys 2010Document118 pagesTroubleshooting Service Manual For Elecys 2010pranshu126545No ratings yet