Professional Documents

Culture Documents

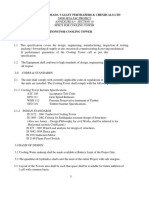

AHM 971 Self Propelled Lavatory Service Vehicle

Uploaded by

ArvindSinghCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AHM 971 Self Propelled Lavatory Service Vehicle

Uploaded by

ArvindSinghCopyright:

Available Formats

TATA Airport Handling Manual

4.2 The lowest point of the structure of the

AHM 971 loaded tunt

not be less than 0.2 m (8 in) above the ground

level. shal

4.3 The unit shall be capable of turning with a

FUNCTIONAL SPECIFICATION swept rar

of less than 12.2 m (40 ft). radus

FOR A SELF-PROPELLED 4.4 Except for the driver's cabin, the unit shall be

non-corrosive material or treated against corrosion. made o

LAVATORY SERVICE VEHICLE 4.5 It shall be possible to drive the unit with a

full Inad

public roads at speeds compatible with local regulations on

WITH REAR OR FRONT

SERVICING 5. TANKS

5.1 The unit shall have a minimum of tO

separate, indepen.

1. PURPOSE dent tanks

The purpose of this AHM is to define an industry standard for 5.1.1 a waste collection tank, and

a self propelled lavatory vehicle. 5.1.2 a rinsing water tank.

2. SCOPE 5.2 The tanks shall have the following features:

5.2.1 they shall be easily cleanable;

2.1 This specification outlines the functional requirements for

5.2.2 the inside fittings, weldings, joints

a self-propelled lavatony service vehicle capable of following

a

and rivets shall have

smooth finish in order to avoid accumulation of waste;

functions:

5.2.3 the ends shall be preferably dished spherically and the

2.1.1 provide adequate ground service to aircraft lavatory

corners adequately rounded;

connections;

2.1.2 transport and dispose of the lavatory waste removed 5.2.4 the bottom of the tanks shall be sloped towards the

from the aircraft; drain;

2.1.3 allow for quick flushing and cleaning of the waste tank 5.2.5 baffles shall be installed inside the tanks;

and be pre charged in short time. 5.2.6 the tanks shall have at their top a leak-proof man-hole

of at least 500 mm (20 in) diameter to allow cleaning and

3. GENERAL inspection;

3.1 These requirements are to be read in conjunction with 5.2.7 the tanks shall be vented in a manner to avoid spillage:

the following documents: 5.2.8 the tanks shall have liquid level indicators suitably

General aircraft system servicing specifications for protected

ground support equipment (AHM 904); 5.2.9 the tanks shall be mounted on the chassis by means of

Basic a floating type suspension to absorb the impacts and e

Requirements for Aircraft Ground Support Equip-

ment (AHM 910); vibrations during operation;

Basic Safety Requirements for Aircraft Ground 5.2.10 the tanks shall be covered with panels of noe

Support

Equipment (AHM 913); corrosive material mounted on a separate structural

frame

Standard Controls (AHM 915); 5.2.11 two walkways shall be provided with suitable acces

ISO 9666 Self propelled lavatory service vehicle. steps.

ISO 17775 Aircraft fluid 5.3The waste collection tank shall have the following

systems-Ground-service

interfaces-Potable water, toilet-flush water and toilet additional features:

drain.

5.3.1 the tank capacity shall be in the range of 400-3.500

Note: Additional reference material is given international

in (106-925 gal);

(ICAO, WHO) and local regulations for water used for 5.3.2 a dump valve of at least 100 mm (4 in) diameter

sanitary purposes and for vehicles used for this service. at the lowest point of the tank, preferaoy at

Deprovided

3.2 This piece of equipment basically consists of rear

Independent tanks (rinsing, drain); 5.3.3 the operating handle of the dump valve shall be locate

such that the operator is not splashed when emptyine

a flushing system for the waste tank; tank;

A water pumping system; .3.4 the tank shall be equipped with a fiushing system

A operators platform for

adequately access to the alc .4 The rinsing water tank shall have the following ad

dditional

service panel; features:

A suitable self propelled chassis. of

5.4.1 the tank to 50%

3.3 The unit shall be labelled "AIRCRAFT the waste tank;

capacity shall be in the range of 25

LAVATORY

SERVICE" in minimum 75 mm (3 in) capital letters. 5.4.2 the tank shall be

nd a filer

equipped with a drain plug a

4. cap.

STRUCTURE AND OVERALL

DIMENSIONS 6. RINSE PUMP

he

4.1 The overall dimensions shall be kept to a minimum. 6.1 The pump shall be directly connected to the i n e or

Areas of the vehicle intended to operate under any part of rinsing water tank and driven either by the venie

the aircraft should leave a minimum of 0.5 m clearance. by an auxiliary power source.

J A R Y2 0 2 0

1130 40TH EDITION, JANUAKR

Airport Handling Ground Support Equipment Specifications-AHM 971

.When

nthe pump is driven by the power take-off of the

it shall not be ssible to operate the Power Take-off 9. OPTIONS

vehicle

nless

hifting lever of the vehicles driving gear is in 9.1 A lifting working platform. to 3 m

or park

position.

shall range from

0.4 m (16 in)

neutral

The capacity of the water pump shall be as follows: .(118 The

1 in) lifting height

above ground level.

6 ast 90 /min (4 gal/min) at 345 kPa kg (440 Ib).

(50 psi) 9.1.2 The lifting capacity shall be 200

measured at the end of the water delivery hose. the workin9

and lower

manual to raise

pump

&4 The

he rinsing system shall be capable of flushing both A

platform. movement

waste tank and aircraft waste tank. prevent vehicle

ehicle 9.1.4 A transmission interlock to

hall be a elief valve located in proximity of the when the platform is raised.

65 Tneaform. It should be adjustable between 150 kPa fluid.

9.2 An additional tank for disinfecting

W345 KPa (21 and 50 psi) to regulate the pressure as water

heater, pump

weather equipment such

cording to the requiremer of the different aircraft types. 9.3 Extreme

heater, insulation etc.

trols shall be located in such a way that the unit water temperature

66 The

A heating system to maintain the

b e operated from the grOund as well as from the

can

9.4

above the freezing point.

elevated working platform.

9.5 A manual rinse pump.

s7 A meter shall be provided to indicate the quantity of

water delivered to the aircraft. The meter shall be 9.6 A self-rewinding reel for the

water hose.

rinsing

zero reset readable from the elevated work connectable with the ground drainage

enuipped with a

9.7 A dump valve

platorm. system.

min. height of 1100

mm

A stowable guardrails with a

7. HOSESS 9.8 around the

(43 in) top of the body frame.

hose shall be connected to the water instead of the lifting workin9

11 The rinsing water 9.9 Adjustable height steps

suitable control valve. platform.

pump via a connector to store and

7.1.1 The hose shall be flexible. 9.10 Dummy waste hose coupling

seal the end of the waste hose.

and have

The hose shall be at least 5m (16 ft) Iong an

71.2

inside diameter of 25 mm (1 in). 9.11 A vacuum waste extraction system

compatible with the

standard aircraft aircraft system.

7.1.3 The hose shall have, at its end, a

2m (79 in) long for

9.12 A second waste hose approximately

COupling. ground level servicing.

1.1.4 The hose shall be stowed on a hose reel. 9.13 Couplings and vents to suit pressure filling.

of the

12 The waste hose shall be connected with the top 9.14 Waste coupling height 1 accommodate commuter type

Waste tank.

aircraft.

12.1 The hose shall be flexible and made of

a non-

9.15 An interlock system toprevent the vehicle from moving

colapsible material. when hoses are not in stowed position.

(16 ft) and have an

12.2 The hose shallI be at least 5 m

9.16 A breakaway fitting on the hoses to prevent aircraft

nside diameter of 100 mm (4 in). in case of movement of the unit whilst still connec-

standard aircraft damage

23 The hose shalI have, at its end,allowing

a

the waste to

ted to the aircraft.

in accordance with ISO R47,

uling

Iow by gravity into the waste tank. 9.17 A lifting work platform integrated with driver's position on

vehicles with front servicing area.

the unit

suitable stowage location

on

4There shall be a

for a separate 9.18 Pump delivery pressure of 150 kPa (21 psi) to 850 kPa

Une waste hose with its coupling and

aircraft adapter. (125 psi).

9.19 Anti collision sensors.

be such that there is no

fene location of the hoses shallmovement of the Working 9.20 Means to deice frozen servicing panel.

Dlatfamaging the hoses by

form.

the

14 An adequate should be provided to prevent

system connected to

ement of the vehicle while any hose still

he alc.

8. WORK PLATFORM

of 800 mm *

work platform with minimum dimensions the

mm provided at rear or

OrWar 1 in * 31 in) shall be

Guardrails

be installed with

shall

Mini or the vehicle.

u m height of 1100 mm (43 in).

constructed of

shall be

OOr of the working platform

8 material to allow self-cleaning. on the

be installed

upports for securir

uring the hoses shall

Working platform.

OITION, JANUARY 2020 1131

You might also like

- A330 Normal Law: Putting Fly-by-Wire Into PerspectiveFrom EverandA330 Normal Law: Putting Fly-by-Wire Into PerspectiveRating: 5 out of 5 stars5/5 (2)

- 951 PDFDocument15 pages951 PDFSONU SINGHNo ratings yet

- Section 10 Specs For Cooling TowerDocument13 pagesSection 10 Specs For Cooling Towermjmehta81No ratings yet

- Chapter 5 - On-Site DetentionDocument34 pagesChapter 5 - On-Site DetentionNur Ain HarunNo ratings yet

- EN81-1 Clause No Requirement EN81-20 Clause No Requirement CommentDocument2 pagesEN81-1 Clause No Requirement EN81-20 Clause No Requirement CommentSupri AdiNo ratings yet

- Handling of Unmanned Aircraft Systems at Divert Airfields: Standard Practice ForDocument2 pagesHandling of Unmanned Aircraft Systems at Divert Airfields: Standard Practice ForAhmad Zubair RasulyNo ratings yet

- CAR Sec 4 Ser B Part 5 PDFDocument6 pagesCAR Sec 4 Ser B Part 5 PDFMukund PatilNo ratings yet

- Part FChapt 10 Sect 08Document2 pagesPart FChapt 10 Sect 08nonamepleaseNo ratings yet

- Bulkhandlingequipment-Boom Typebucketwheelreclaimer - Railmounted-Design, Manufactureanderection - CodeofpracticeDocument17 pagesBulkhandlingequipment-Boom Typebucketwheelreclaimer - Railmounted-Design, Manufactureanderection - CodeofpracticezahoorNo ratings yet

- RA3531 Initial IssueDocument8 pagesRA3531 Initial IssuechristopherNo ratings yet

- b300 UnshcheduleDocument16 pagesb300 UnshcheduleWisuit SookthaweeNo ratings yet

- Caab ANO All Weather Approval RequirementsDocument17 pagesCaab ANO All Weather Approval Requirementsdinglee1No ratings yet

- Disclosure To Promote The Right To InformationDocument18 pagesDisclosure To Promote The Right To InformationVikash Kumar SinghNo ratings yet

- ML C 650 c65mm765Document22 pagesML C 650 c65mm765operacionesNo ratings yet

- RDSO-2017-CG 06 Draft Spec of Vacuum Toilet With Bio Toilets in LHB Type Coaches 04.09.17Document11 pagesRDSO-2017-CG 06 Draft Spec of Vacuum Toilet With Bio Toilets in LHB Type Coaches 04.09.17Venkatesh KamathNo ratings yet

- Limitacion TripulantesDocument1 pageLimitacion Tripulantess.tamayo.aqsNo ratings yet

- Rfi Naval Light Utility HelicoptersDocument14 pagesRfi Naval Light Utility Helicoptersrajeshthepilot100% (1)

- Sampling Dispensing BoothDocument8 pagesSampling Dispensing BoothAndreas StathatosNo ratings yet

- Technical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01Document2 pagesTechnical Specification of Agitators - Dadri 2 X 490 MW Dadri:Fgd:Agitators:R01ThylaneNo ratings yet

- Astm F31172Document1 pageAstm F31172JGarridoRubioNo ratings yet

- Tender No: RCC/NR/UPSO-II/ENG/PT-07/19-20 Public Tender:-: Page 76 of 200Document7 pagesTender No: RCC/NR/UPSO-II/ENG/PT-07/19-20 Public Tender:-: Page 76 of 200Shilpa SinghNo ratings yet

- 002 - 30 - 20 - 03 ChecklistDocument1 page002 - 30 - 20 - 03 Checklistnasrulsalman9883No ratings yet

- Chapter 5Document15 pagesChapter 5rona putriNo ratings yet

- Section 5 Safety RequirementsDocument9 pagesSection 5 Safety RequirementsJ T Mendonça SantosNo ratings yet

- 2009 IMO MODU Code AmendmentsDocument9 pages2009 IMO MODU Code AmendmentsPraveen Balachandran100% (1)

- 14 CFR Ch. I (1-1-12 Edition) Pt. 25, App. F: Ppendix TO ARTDocument51 pages14 CFR Ch. I (1-1-12 Edition) Pt. 25, App. F: Ppendix TO ARTANA CAROLINA DOS SANTOSNo ratings yet

- Section 8 - Handling, Servicing and Maintenance: Z 242 L Flight ManualDocument10 pagesSection 8 - Handling, Servicing and Maintenance: Z 242 L Flight ManualJuan Carlos Sanchez MaldonadoNo ratings yet

- AS4775 Checklist AVIDocument2 pagesAS4775 Checklist AVIahmar javedNo ratings yet

- Service Manual CE-172 - 1969 - 1976Document13 pagesService Manual CE-172 - 1969 - 1976Kyle BrandonNo ratings yet

- Data Sheet - PetroGuard Modular ScreensDocument2 pagesData Sheet - PetroGuard Modular ScreensMatheus Simões100% (1)

- Abs Rules - 2855Document1 pageAbs Rules - 2855rishabhk28995No ratings yet

- Ground Operational Checks For Avionics EquipmentDocument12 pagesGround Operational Checks For Avionics EquipmentDumitru EninNo ratings yet

- SB 1411Document7 pagesSB 1411Svtorrent SvtorrentNo ratings yet

- BopDocument46 pagesBophfdshy12No ratings yet

- Diaphrag Mtype (Plasticbody) Float Forc LD Ater Services-SpecificationDocument11 pagesDiaphrag Mtype (Plasticbody) Float Forc LD Ater Services-SpecificationSunnil JhaNo ratings yet

- YSE MIN: Jeppesen Sanderson, Inc., 1999, 2005. All Rights ReservedDocument1 pageYSE MIN: Jeppesen Sanderson, Inc., 1999, 2005. All Rights ReservedRamBabuMeenaNo ratings yet

- Chapter 5 Design Guidelines Section 5.7 Utilities Subsection 5.7.1 Potable WaterDocument2 pagesChapter 5 Design Guidelines Section 5.7 Utilities Subsection 5.7.1 Potable WaterkapsarcNo ratings yet

- Heaters For Bitumen (Tar) and Emulsion - Specification: Indian StandardDocument6 pagesHeaters For Bitumen (Tar) and Emulsion - Specification: Indian StandardAmanulla KhanNo ratings yet

- 2) Spray Nozzle Specification PDFDocument41 pages2) Spray Nozzle Specification PDFkasvikrajNo ratings yet

- Low Visibility OperationsDocument18 pagesLow Visibility Operationsali4957270100% (1)

- Water Aerodromes RequirementsDocument7 pagesWater Aerodromes Requirementsemon jenusiNo ratings yet

- Sec 06 - Process VesselsDocument4 pagesSec 06 - Process VesselseujualNo ratings yet

- Is-951 Crash Fire Tender For Air FieldsDocument15 pagesIs-951 Crash Fire Tender For Air FieldsCharls JamesNo ratings yet

- ComplianceDocument19 pagesComplianceQuality Manager Jet ServeNo ratings yet

- Pilot Boat Section 4Document3 pagesPilot Boat Section 4Aamir SirohiNo ratings yet

- High-Speed Craft: Guide For Building and ClassingDocument5 pagesHigh-Speed Craft: Guide For Building and ClassingAlessandra ChavesNo ratings yet

- 5.2.31 Valve ActuatorsDocument1 page5.2.31 Valve ActuatorsSingh MastermindNo ratings yet

- Silo - Tips - Added Additional Inspection RequirementsDocument5 pagesSilo - Tips - Added Additional Inspection RequirementsJ DaugNo ratings yet

- Ils SpecDocument51 pagesIls Speczelalem azizNo ratings yet

- Rules For The Installation, Inspection & Testing of Air Reservoirs (Other Than On Locomotives)Document9 pagesRules For The Installation, Inspection & Testing of Air Reservoirs (Other Than On Locomotives)Rich Mhar ManguiatNo ratings yet

- Exceptional Use of Work Platforms With Industrial Trucks 2010 (E)Document9 pagesExceptional Use of Work Platforms With Industrial Trucks 2010 (E)EduNo ratings yet

- IS 9429 1999 Drainage System For Embankment DamsDocument21 pagesIS 9429 1999 Drainage System For Embankment DamsJan Bakos100% (1)

- 10-1108 Eb034274Document3 pages10-1108 Eb034274vcNo ratings yet

- 4 BLDocument5 pages4 BLLucas JerichoNo ratings yet

- BV Rules PtE Ch3 Sec1 AUT-UMSDocument21 pagesBV Rules PtE Ch3 Sec1 AUT-UMSJon LopezNo ratings yet

- Li Lo Underground-Tank-Installation-GuideDocument9 pagesLi Lo Underground-Tank-Installation-GuideBarrasons Engineers TeamNo ratings yet

- Technical Specifications R2Document19 pagesTechnical Specifications R2Alejandro PerezNo ratings yet

- Ur D9rev4Document7 pagesUr D9rev4Maan MrabetNo ratings yet

- F2006B04585Document1 pageF2006B04585rotibuayaNo ratings yet

- Hydraulic and Pneumatic Power SystemsDocument4 pagesHydraulic and Pneumatic Power Systemsajrio1785No ratings yet

- Advt 052018Document1 pageAdvt 052018ArvindSinghNo ratings yet

- Qualification Pack - Occupational Standards For Aerospace & Aviation IndustryDocument41 pagesQualification Pack - Occupational Standards For Aerospace & Aviation IndustryArvindSinghNo ratings yet

- LERAP Local Emergency and Accident Procedures - AusfüllbarDocument25 pagesLERAP Local Emergency and Accident Procedures - AusfüllbarArvindSinghNo ratings yet

- 4.2 Effects of Air Pollutants On Human and EnvironmentDocument52 pages4.2 Effects of Air Pollutants On Human and EnvironmentArvindSinghNo ratings yet

- Booklet - Dangerous Goods in GA v2Document16 pagesBooklet - Dangerous Goods in GA v2ArvindSinghNo ratings yet

- Do's and Dont's - Official Website of National Center For Seismology, Ministry of Earth Sciences, Government of IndiaDocument3 pagesDo's and Dont's - Official Website of National Center For Seismology, Ministry of Earth Sciences, Government of IndiaArvindSinghNo ratings yet

- Aviation Safety Manager Interview Questions and Answers GuideDocument14 pagesAviation Safety Manager Interview Questions and Answers GuideArvindSingh100% (1)

- Aviation Safety Quality Job Interview Questions and AnswersDocument12 pagesAviation Safety Quality Job Interview Questions and AnswersArvindSinghNo ratings yet

- Managing Hangar Construction From Start To FinishDocument17 pagesManaging Hangar Construction From Start To FinishArvindSinghNo ratings yet

- Hangar PlanningDocument39 pagesHangar Planningmonocrome fajar tjahyonoNo ratings yet

- ODF-2 - Learning MaterialDocument24 pagesODF-2 - Learning MateriallevychafsNo ratings yet

- T&B Detailed Plan: Ceiling LineDocument1 pageT&B Detailed Plan: Ceiling LineKuthbert NoceteNo ratings yet

- Brand Guidelines Oracle PDFDocument39 pagesBrand Guidelines Oracle PDFMarco CanoNo ratings yet

- MSDS Bisoprolol Fumarate Tablets (Greenstone LLC) (EN)Document10 pagesMSDS Bisoprolol Fumarate Tablets (Greenstone LLC) (EN)ANNaNo ratings yet

- Prepositions Below by in On To of Above at Between From/toDocument2 pagesPrepositions Below by in On To of Above at Between From/toVille VianNo ratings yet

- S200 For Sumber RezekiDocument2 pagesS200 For Sumber RezekiIfan JayusdianNo ratings yet

- INTERNATIONAL BUSINESS DYNAMIC (Global Operation MGT)Document7 pagesINTERNATIONAL BUSINESS DYNAMIC (Global Operation MGT)Shashank DurgeNo ratings yet

- Drug Study TemplateDocument2 pagesDrug Study TemplateKistlerzane CABALLERONo ratings yet

- Musings On A Rodin CoilDocument2 pagesMusings On A Rodin CoilWFSCAO100% (1)

- Fcode 54 en El SytucDocument2 pagesFcode 54 en El SytucAga MenonNo ratings yet

- Channel System: Presented byDocument78 pagesChannel System: Presented bygrace22mba22No ratings yet

- La Bugal-b'Laan Tribal Association Et - Al Vs Ramos Et - AlDocument6 pagesLa Bugal-b'Laan Tribal Association Et - Al Vs Ramos Et - AlMarlouis U. PlanasNo ratings yet

- T R I P T I C K E T: CTRL No: Date: Vehicle/s EquipmentDocument1 pageT R I P T I C K E T: CTRL No: Date: Vehicle/s EquipmentJapCon HRNo ratings yet

- SCHEDULE OF FEES - FinalDocument1 pageSCHEDULE OF FEES - FinalAbhishek SunaNo ratings yet

- Is 778 - Copper Alloy ValvesDocument27 pagesIs 778 - Copper Alloy ValvesMuthu KumaranNo ratings yet

- Erickson Transformer DesignDocument23 pagesErickson Transformer DesigndonscogginNo ratings yet

- WWW - Manaresults.co - In: Internet of ThingsDocument3 pagesWWW - Manaresults.co - In: Internet of Thingsbabudurga700No ratings yet

- 1 075 Syn4e PDFDocument2 pages1 075 Syn4e PDFSalvador FayssalNo ratings yet

- Pharaoh TextDocument143 pagesPharaoh Textanon_31362848No ratings yet

- Step-7 Sample ProgramDocument6 pagesStep-7 Sample ProgramAmitabhaNo ratings yet

- DFUN Battery Monitoring Solution Project Reference 2022 V5.0Document50 pagesDFUN Battery Monitoring Solution Project Reference 2022 V5.0A Leon RNo ratings yet

- Land Degradetion NarmDocument15 pagesLand Degradetion NarmAbdikafar Adan AbdullahiNo ratings yet

- Software Hackathon Problem StatementsDocument2 pagesSoftware Hackathon Problem StatementsLinusNelson100% (2)

- Rideable Segway Clone - Low Cost and Easy Build: Digital MPU6050 Accelerometer/gyro IMU BoardDocument45 pagesRideable Segway Clone - Low Cost and Easy Build: Digital MPU6050 Accelerometer/gyro IMU BoardpaolaNo ratings yet

- Database Management System and SQL CommandsDocument3 pagesDatabase Management System and SQL Commandsdev guptaNo ratings yet

- Irrig in AfricaDocument64 pagesIrrig in Africaer viNo ratings yet

- Tech Mahindra Sample Verbal Ability Placement Paper Level1Document11 pagesTech Mahindra Sample Verbal Ability Placement Paper Level1Madhav MaddyNo ratings yet

- Aisc Research On Structural Steel To Resist Blast and Progressive CollapseDocument20 pagesAisc Research On Structural Steel To Resist Blast and Progressive CollapseFourHorsemenNo ratings yet

- For Email Daily Thermetrics TSTC Product BrochureDocument5 pagesFor Email Daily Thermetrics TSTC Product BrochureIlkuNo ratings yet

- Alphacenter Utilities: Installation GuideDocument24 pagesAlphacenter Utilities: Installation GuideJeffersoOnn JulcamanyanNo ratings yet