Professional Documents

Culture Documents

Powder Properties Test Method Alm Pa 650: Nylon 12 Laser Sintering Material

Uploaded by

Luiskar Medina0 ratings0% found this document useful (0 votes)

19 views1 pageOriginal Title

PA_650-Nylon-12

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

19 views1 pagePowder Properties Test Method Alm Pa 650: Nylon 12 Laser Sintering Material

Uploaded by

Luiskar MedinaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

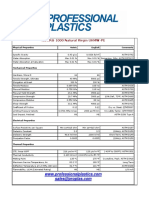

PA 650

Nylon 12 Laser Sintering Material

POWDER PROPERTIES TEST METHOD ALM PA 650

Bulk Density ASTM D1895 0.46 grams/CC

Average Particle Size (D50) Laser Diffraction 55 microns

Particle Size Range (D10-D90) Laser Diffraction 30 to 100 microns

Sintered Part Density ASTM D792 1.02 grams/CC

THERMAL PROPERTIES TEST METHOD ALM PA 650

Melting Point ASTM D3418 181 Deg C

Melt Flow Rate (3min, 5.0kg, 235C) ASTM D1238 50 grams/10min

MECHANICAL PROPERTIES TEST METHOD ALM PA 650

Heat Deflection Temp @ 0.45 MPa ASTM D648 177 Deg C

Heat Deflection Temp @ 1.82 MPa ASTM D648 86 Deg C

Ultimate Tensile Strength (XY) ASTM D638 48 MPa / 6,962 psi

Tensile Modulus (XY) ASTM D638 1,700 MPa / 247 kpsi

Flexural Modulus (XY) ASTM D790 1,500 MPa / 217 kpsi

Elongation at Break (XY) ASTM D638 24%

IZOD Impact Strength (Unnotched) ASTM D256 440 J/m

IZOD Impact Strength (Notched) ASTM D256 220 J/m

Volume Resistivity (22C, 50%RH, 500V) ASTM D257 3.1 x 10^14 ohm-cm

Surface Resistivity (22C, 50%RH, 500V) ASTM E257 3.0 x 10^14 ohm

Dielectric Constant (22C, 50%RH, 500V) ASTM D150 2.9

Actual part properties may vary slightly from those listed above based on processing parameters,

operating conditions, and material usage. The above properties were based on virgin ALM PA 650 using

nominal operating parameters on a 2500+ platform. Advanced Laser Materials, LLC makes no

warranties of materials for any particular application, nor does it make a warranty of any type, expressed

or implied, including, but not limited to, the warranties of merchantability for a particular purpose.

Advanced Laser Materials, LLC Tel: 254-773-3080 Fax: 254-773-3084

3115 Lucius McCelvey, Temple, TX 76504 www.alm-llc.com

ALM PA 650 Data Sheet: 09.28.2011

You might also like

- 3 mPE Leaflet en LH3750MDocument1 page3 mPE Leaflet en LH3750MfguastaNo ratings yet

- Polycarbonate-ABS Blend (PC-ABS) : Mechanical Properties Test Method Imperial MetricDocument1 pagePolycarbonate-ABS Blend (PC-ABS) : Mechanical Properties Test Method Imperial MetricIsabel Narloch CardosoNo ratings yet

- Metallocene Linear Low Density Polyethylene: Physical PropertiesDocument1 pageMetallocene Linear Low Density Polyethylene: Physical PropertiesAkoyoNo ratings yet

- Mitsubishi Chemical Advanced Materials Acetron ® Food Grade Blue 50 POM-C Copolymer Acetal, Extruded (ASTM Datasheet)Document2 pagesMitsubishi Chemical Advanced Materials Acetron ® Food Grade Blue 50 POM-C Copolymer Acetal, Extruded (ASTM Datasheet)jose lealNo ratings yet

- Lexan 9034 Data SheetDocument2 pagesLexan 9034 Data SheetAdrián PonceNo ratings yet

- TIVAR® 1000 Natural Virgin UHMW-PE: Physical Properties Metric English CommentsDocument2 pagesTIVAR® 1000 Natural Virgin UHMW-PE: Physical Properties Metric English CommentsVictor AguirreNo ratings yet

- Mitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedDocument2 pagesMitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedJuan Orlando Loaiza MurilloNo ratings yet

- SABIC® HDPE - C0549 - GlobalDocument2 pagesSABIC® HDPE - C0549 - Globaltechnical kmiNo ratings yet

- TDS Nylon101Document2 pagesTDS Nylon101wilderness_666No ratings yet

- Tds Ecozen t110gDocument1 pageTds Ecozen t110galfred quinNo ratings yet

- UHMW-PE Tivar 1000Document2 pagesUHMW-PE Tivar 1000centurion2988No ratings yet

- Solef PVDF 6008Document2 pagesSolef PVDF 6008topteam123No ratings yet

- Lexan™ 8010 Uncoated Polished Film DatasheetDocument3 pagesLexan™ 8010 Uncoated Polished Film DatasheetTeng Yan ChanNo ratings yet

- SABIC® PP - 5271K - Global - Technical - Data - SheetDocument1 pageSABIC® PP - 5271K - Global - Technical - Data - SheetjituniNo ratings yet

- 03-mPE Leaflet LH3750M (E) - 140325Document1 page03-mPE Leaflet LH3750M (E) - 140325Gabs GabrielaNo ratings yet

- Virgin Ptfe DatasheetDocument1 pageVirgin Ptfe DatasheetFelipe Zúñiga ParedesNo ratings yet

- Propriedades Das Matrizes PolimericasDocument7 pagesPropriedades Das Matrizes PolimericasllepsterlNo ratings yet

- Filament Specifications Unit ValueDocument4 pagesFilament Specifications Unit ValueRoberto Gonzalo PelazNo ratings yet

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsDocument2 pagesPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsvassaNo ratings yet

- Solvay - Halar 513 LCDocument3 pagesSolvay - Halar 513 LCRenan GadioliNo ratings yet

- Aludecor Al 45 Firewall En13501-1 Class A2 Technical SpecificationDocument2 pagesAludecor Al 45 Firewall En13501-1 Class A2 Technical Specificationsoham senNo ratings yet

- LLDPE-218BJ_edit (1)Document3 pagesLLDPE-218BJ_edit (1)Chu ChuNo ratings yet

- Technical Data Sheet for ABS HU651Document1 pageTechnical Data Sheet for ABS HU651hugo santiago chavez godoyNo ratings yet

- PBT GF17% DR48-7001Document2 pagesPBT GF17% DR48-7001pava16230.meNo ratings yet

- PMMA-20HRDocument2 pagesPMMA-20HRChu ChuNo ratings yet

- ABS-M30: Production-Grade Thermoplastic For FDM 3D PrintersDocument2 pagesABS-M30: Production-Grade Thermoplastic For FDM 3D PrintersSINo ratings yet

- Spec Sheet - ABS-M30 ENDocument2 pagesSpec Sheet - ABS-M30 ENTUSHAR BANGERANo ratings yet

- TKGR FLON (PTFE) density, properties, applicationsDocument1 pageTKGR FLON (PTFE) density, properties, applicationse.vicente.caballeroNo ratings yet

- BT 8602Document2 pagesBT 8602Shagun SharmaNo ratings yet

- Infino Pc-Abs Hp1000xa (Natural)Document1 pageInfino Pc-Abs Hp1000xa (Natural)Rhekron PlasticsNo ratings yet

- Stratasys - MSS FDM ABSplusP430Document2 pagesStratasys - MSS FDM ABSplusP430feltofsnakeNo ratings yet

- PP ARPP200-1 Black 14 Melt HomoDocument1 pagePP ARPP200-1 Black 14 Melt HomocountzeroaslNo ratings yet

- CYCOLOY™ Resin - LG9000 - Asia - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - LG9000 - Asia - Technical - Data - SheetBoby SaputraNo ratings yet

- LEXAN™ Resin - 123R - Americas - Technical - Data - SheetDocument2 pagesLEXAN™ Resin - 123R - Americas - Technical - Data - SheetRodrigoMachadoNo ratings yet

- Ajedium Films (Solvay)Document3 pagesAjedium Films (Solvay)hyper meshNo ratings yet

- CYCOLOY™ Resin - LG9000 - Americas - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - LG9000 - Americas - Technical - Data - SheetRodrigoMachadoNo ratings yet

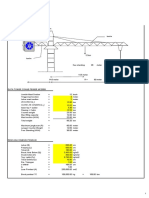

- Shear Flat SlabDocument1 pageShear Flat Slabadnan-651358No ratings yet

- Abs-Er460 EngDocument2 pagesAbs-Er460 Engjdstore99No ratings yet

- Mitsubishi Chemical Advanced Materials Nylatron ® GSM Nylon, Cast Mos2 Filled Type 6 (Astm Product Data Sheet)Document2 pagesMitsubishi Chemical Advanced Materials Nylatron ® GSM Nylon, Cast Mos2 Filled Type 6 (Astm Product Data Sheet)Irwan SaputraNo ratings yet

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)DiegoTierradentroNo ratings yet

- SABIC® LLDPE - 324CNJ - Global - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 324CNJ - Global - Technical - Data - Sheettechnical kmiNo ratings yet

- LEXAN™ Resin - 241R - Americas - Technical - Data - SheetDocument2 pagesLEXAN™ Resin - 241R - Americas - Technical - Data - Sheetr92g5478cxNo ratings yet

- KOPA KN126 enDocument1 pageKOPA KN126 enJagadeesh WaranNo ratings yet

- Mdpe Dx800: Application / Use CaseDocument1 pageMdpe Dx800: Application / Use CaseJaime222No ratings yet

- LUPOX TE5100: Description ApplicationDocument2 pagesLUPOX TE5100: Description Applicationhugo santiago chavez godoyNo ratings yet

- Datasheet - r680s - Randompp - e 3Document2 pagesDatasheet - r680s - Randompp - e 3Gulzar HossainNo ratings yet

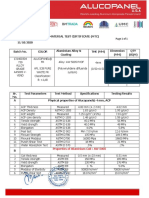

- Material Test Certificate (MTC) : Properties of Aluminium Coil: AW 5005Document4 pagesMaterial Test Certificate (MTC) : Properties of Aluminium Coil: AW 5005Waleed Obieden100% (1)

- SABIC® HDPE - M200056 - Global - Technical - Data - SheetDocument2 pagesSABIC® HDPE - M200056 - Global - Technical - Data - SheetAhmed Elgazar100% (1)

- Random PP R390Y: Application / Use CaseDocument1 pageRandom PP R390Y: Application / Use CaseEmre UzunogluNo ratings yet

- Kocetal K700 Property DataDocument1 pageKocetal K700 Property DataRanjan GnanaoliNo ratings yet

- PPS Ryton R-4-230Document3 pagesPPS Ryton R-4-230thegeneral2040No ratings yet

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)DiegoTierradentroNo ratings yet

- PolycarbonateDocument1 pagePolycarbonatezainudinNo ratings yet

- Absplus-P430: Production-Grade Thermoplastic For 3D PrintersDocument2 pagesAbsplus-P430: Production-Grade Thermoplastic For 3D PrinterscontrolorNo ratings yet

- Pmma-Lg Pmma Ih 830a (Natural)Document1 pagePmma-Lg Pmma Ih 830a (Natural)AVLight AutomotivesNo ratings yet

- Manufacturing Processes and Materials ExercisesDocument2 pagesManufacturing Processes and Materials ExercisesMedSparkNo ratings yet

- Microstructure Evolution in Metal Forming Processes (2012)Document2 pagesMicrostructure Evolution in Metal Forming Processes (2012)MedSparkNo ratings yet

- PBT Data SheetDocument2 pagesPBT Data Sheetabhishek chaudharyNo ratings yet

- 3 Property R3450 EngDocument1 page3 Property R3450 EngMohit MohataNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Boq 1X1 FootingDocument1 pageBoq 1X1 FootingnileshNo ratings yet

- Part Cat Dp70Document6 pagesPart Cat Dp70boy qsi100% (1)

- Rheomac GF300 Grout FluidifierDocument2 pagesRheomac GF300 Grout FluidifierDodik FKurniawanNo ratings yet

- Web TMK Up Ultra FJDocument3 pagesWeb TMK Up Ultra FJCarlos SanchezNo ratings yet

- Dualwatersystems DWFSOM145Document4 pagesDualwatersystems DWFSOM145Moyukh MoitraNo ratings yet

- Plan For Venice Island Reconstruction ProjectDocument20 pagesPlan For Venice Island Reconstruction ProjectdsrmanayunkNo ratings yet

- Full CalculationDocument8 pagesFull CalculationkprabishNo ratings yet

- Tpi 31 - VVKN - enDocument13 pagesTpi 31 - VVKN - enKundzoNo ratings yet

- Auxiliary Reinforcement Around Column Without Joints: Dramix Steel FibersDocument9 pagesAuxiliary Reinforcement Around Column Without Joints: Dramix Steel FibersLuis Fuertes ChamorroNo ratings yet

- ANSI Pad Mounted (Draft)Document8 pagesANSI Pad Mounted (Draft)Samer Abdulaziz SadaqaNo ratings yet

- Design Steps of One Way Slab RCCDocument7 pagesDesign Steps of One Way Slab RCCKosygin LeishangthemNo ratings yet

- 44AC9100-000-V.02-0110-A4 - Rev B - GENERAL SPECIFICATION FOR INSULATIONDocument51 pages44AC9100-000-V.02-0110-A4 - Rev B - GENERAL SPECIFICATION FOR INSULATIONAvinash ShuklaNo ratings yet

- Centrifuge Oilseperator ManualDocument82 pagesCentrifuge Oilseperator Manualmavericksailor100% (3)

- ECB Installation GuideDocument2 pagesECB Installation GuideRicardo HernandezNo ratings yet

- Sharing Housing for Sustainable LivingDocument3 pagesSharing Housing for Sustainable LivingFlávio GhilardiNo ratings yet

- Comapany Profile Gogreen OverseasDocument23 pagesComapany Profile Gogreen OverseasKunal SuhagiyaNo ratings yet

- Brochure Mastertile TilingDocument48 pagesBrochure Mastertile TilingMaha Mufleh100% (1)

- FC Installation SheetDocument4 pagesFC Installation SheetSamuel Lopez BenitesNo ratings yet

- Rekayasa Perkerasan JalanDocument64 pagesRekayasa Perkerasan JalanErizal BasaNo ratings yet

- App Exams PDF Studyguide CarpenterDocument29 pagesApp Exams PDF Studyguide CarpenterChris HorwoodNo ratings yet

- Pega Il 0310 TD VFC HoistDocument2 pagesPega Il 0310 TD VFC HoistsalesgglsNo ratings yet

- Overall Final Project Report PDFDocument115 pagesOverall Final Project Report PDFSuraj yadavNo ratings yet

- Line Punch-List for SWL-CA-2011-24000017460 ProjectDocument147 pagesLine Punch-List for SWL-CA-2011-24000017460 ProjectMITHUNNo ratings yet

- PM Heavy Equipment, AC, PC RecoveryDocument11 pagesPM Heavy Equipment, AC, PC Recoveryfadli arsyadaNo ratings yet

- Seismic design forces for a four-storey RC buildingDocument26 pagesSeismic design forces for a four-storey RC buildingjonnyprem100% (1)

- ASPE Fire Protection Systems, 3rd Ed.Document162 pagesASPE Fire Protection Systems, 3rd Ed.Mohamed AbdelAziz100% (2)

- Assignment 2-09Document2 pagesAssignment 2-09Felix HabarugiraNo ratings yet

- Dokumen - Tips - Perhitungan Pondasi TCDocument7 pagesDokumen - Tips - Perhitungan Pondasi TCAlex MartiknoNo ratings yet

- REXWAY PVC Coated Rigid Metal Conduit Catalogue (PVC Coated)Document7 pagesREXWAY PVC Coated Rigid Metal Conduit Catalogue (PVC Coated)Jeson Etorma0% (1)

- Design of reinforced concrete columns: Short column vs long columnDocument25 pagesDesign of reinforced concrete columns: Short column vs long columndashne134100% (4)