Professional Documents

Culture Documents

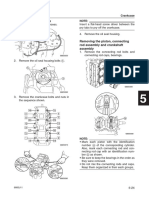

GEN Info: Disassembly and Assembly

Uploaded by

PHUONG NGUYEN0 ratings0% found this document useful (0 votes)

4 views1 pageThis document provides guidelines for disassembly, assembly, and general maintenance practices. It recommends using compressed air and lint-free cloths to clean parts during disassembly. Apply engine oil to contact surfaces and install bearings as indicated, ensuring they are lubricated. Tighten fasteners in a systematic way following torque specifications. Always use new seals and gaskets when assembling.

Original Description:

Original Title

010

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides guidelines for disassembly, assembly, and general maintenance practices. It recommends using compressed air and lint-free cloths to clean parts during disassembly. Apply engine oil to contact surfaces and install bearings as indicated, ensuring they are lubricated. Tighten fasteners in a systematic way following torque specifications. Always use new seals and gaskets when assembling.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views1 pageGEN Info: Disassembly and Assembly

Uploaded by

PHUONG NGUYENThis document provides guidelines for disassembly, assembly, and general maintenance practices. It recommends using compressed air and lint-free cloths to clean parts during disassembly. Apply engine oil to contact surfaces and install bearings as indicated, ensuring they are lubricated. Tighten fasteners in a systematic way following torque specifications. Always use new seals and gaskets when assembling.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

GEN

INFO General information

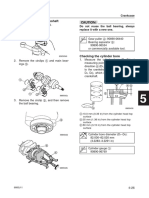

6. Keep a supply of clean, lint-free cloths for Disassembly and assembly

wiping up spills, etc. 1. Use compressed air to remove dust and

dirt during disassembly.

Good working practice

Special service tool 2. Apply engine oil to the contact surfaces

Use the recommended special service tools of moving parts before assembly.

to protect parts from damage. Use the right

tool in the right manner–do not improvise.

3. Install bearings with the manufacture

identification mark in the direction indicat-

Tightening torque ed in the installation procedure. In addi-

Follow the tightening torque specifications tion, be sure to lubricate the bearings lib-

provided throughout the manual. When tight- erally.

ening nuts, bolts, and screws, tighten the

large sizes first, and tighten fasteners starting 4. Apply a thin coat of water-resistant

in the center and moving outward. grease to the lip and periphery of an oil

Non-reusable part seal before installation.

Always use new gaskets, seals, O-rings, cot-

5. Check that moving parts operate normal-

ter pins, circlips, etc., when installing or

ly after assembly.

assembling parts.

1-5 6885J11

You might also like

- 6WG1 e 01 (2 - 2)Document266 pages6WG1 e 01 (2 - 2)mohan100% (8)

- Truck Crane 1: GT-900XLDocument270 pagesTruck Crane 1: GT-900XLJulio Ramos100% (1)

- Chiksan Swivel Joints Repacking Instructions Longsweep Standard Service PDFDocument2 pagesChiksan Swivel Joints Repacking Instructions Longsweep Standard Service PDFCikalong Yard100% (1)

- PW160 7E0 - S - CSS Net - 2007 05 04Document1,140 pagesPW160 7E0 - S - CSS Net - 2007 05 04tinphuloiNo ratings yet

- Manual de Servicio CX 350B 84355067-Dmc Site OnlyDocument127 pagesManual de Servicio CX 350B 84355067-Dmc Site Onlyabel jairo santos cabello100% (2)

- Service Manual 6Wg1-Tc (Common Rail) Isuzu EngineDocument224 pagesService Manual 6Wg1-Tc (Common Rail) Isuzu EngineVladis0710100% (1)

- Dresser Roots Tri-Nado TM 1125 DVJ Tri-Lobe Blower - ManualDocument10 pagesDresser Roots Tri-Nado TM 1125 DVJ Tri-Lobe Blower - Manualpablo.matulic9471No ratings yet

- GR-700EXL-1 S2-2E Repair Manual PDFDocument416 pagesGR-700EXL-1 S2-2E Repair Manual PDFAhmed Trabelsi100% (1)

- Neary 550Document73 pagesNeary 550Anonymous Qjk4NlwaafNo ratings yet

- Motor 6UDocument250 pagesMotor 6UequiptecmaqNo ratings yet

- DX50 Engine ServiceManualDocument285 pagesDX50 Engine ServiceManualjonathanrioscNo ratings yet

- NoteDocument18 pagesNotepikipelukiNo ratings yet

- Motor 95eDocument448 pagesMotor 95eFútbol y másNo ratings yet

- Repair InstructionprecautionDocument23 pagesRepair InstructionprecautionEdson CRNo ratings yet

- TimkenTT en Vol1 Iss3Document2 pagesTimkenTT en Vol1 Iss3grupa2904No ratings yet

- Isuzu 4hk1 6hk1Document38 pagesIsuzu 4hk1 6hk1atakan0% (1)

- VS2005 V2 DFC30817Document2 pagesVS2005 V2 DFC30817ko koNo ratings yet

- Engine 12V140E-3 Series: 00 Index and ForewordDocument40 pagesEngine 12V140E-3 Series: 00 Index and ForewordЕгор100% (1)

- Idler Service Manual 2016-08-31Document8 pagesIdler Service Manual 2016-08-31Sergio Rodrigo Miranda GuajardoNo ratings yet

- Page 25Document1 pagePage 25Theodor PocovnicuNo ratings yet

- Ex400-5, Ex400lc-5, Ex450lc-5 WMDocument598 pagesEx400-5, Ex400lc-5, Ex450lc-5 WMAnonymous vxpVVAcjJ8No ratings yet

- Repairinstruction PDFDocument23 pagesRepairinstruction PDFAmal TharakaNo ratings yet

- Reparacion Motor 4JJ1Document255 pagesReparacion Motor 4JJ1Cristobal Henriquez100% (1)

- WP136 ZF Re-Build Instr Rev BDocument2 pagesWP136 ZF Re-Build Instr Rev BAntonio Guzman ArciniegaNo ratings yet

- Manual de Serviço CX210B CX240BDocument971 pagesManual de Serviço CX210B CX240BKleiton Bizuti100% (1)

- 7 ReductorDocument9 pages7 ReductorArielNo ratings yet

- 04en R2 ENGINE Workshop ManualDocument148 pages04en R2 ENGINE Workshop ManualIbrahim PagbelemNo ratings yet

- Hitachi 4hk1 6hk1 Engine SMDocument20 pagesHitachi 4hk1 6hk1 Engine SMwillie100% (56)

- 6106100901ACCU 610 Bedknife Grinder6107953Operator ManualEnglish09 95Document30 pages6106100901ACCU 610 Bedknife Grinder6107953Operator ManualEnglish09 95Pedro Pablo Giraldo NuñezNo ratings yet

- Proper Handling Practice of BearingsDocument16 pagesProper Handling Practice of Bearingszakizaki100% (1)

- 545 RXDocument66 pages545 RXJosipJosipNo ratings yet

- TM ZR860 1 - S1 1eDocument134 pagesTM ZR860 1 - S1 1ekit10167% (3)

- 6326320931ACCU Pro Spin Relief Grinder With Accu Touch115 230 VAC6327962Assembly Service Manual New SpinEnglish04 14 PDFDocument96 pages6326320931ACCU Pro Spin Relief Grinder With Accu Touch115 230 VAC6327962Assembly Service Manual New SpinEnglish04 14 PDFPedro Pablo Giraldo NuñezNo ratings yet

- Wheel Loss Sensor WHeely SafeDocument4 pagesWheel Loss Sensor WHeely SafevijayNo ratings yet

- KM 6WG1 e 02 (2 - 2) PDFDocument272 pagesKM 6WG1 e 02 (2 - 2) PDFDick Gii100% (2)

- Geared Coupling Manual PDFDocument5 pagesGeared Coupling Manual PDFSatNo ratings yet

- Vespa Service Manual 08-04-2021Document322 pagesVespa Service Manual 08-04-2021Julio Borrero100% (1)

- Installation Work Instructions For Mechanical SealDocument2 pagesInstallation Work Instructions For Mechanical SealAnees Ud DinNo ratings yet

- Preparation and Installation of The ULTRX HP (DD) Rupture Disc / ULTRX Double Disc Holder AssemblyDocument6 pagesPreparation and Installation of The ULTRX HP (DD) Rupture Disc / ULTRX Double Disc Holder AssemblyPaul LauNo ratings yet

- Troy Bilt Squall 521 OpMan (EN)Document32 pagesTroy Bilt Squall 521 OpMan (EN)Gisell ZapataNo ratings yet

- Manual Post Hole DiggerDocument10 pagesManual Post Hole DiggerFlorin BostinNo ratings yet

- Craftsman Blower 24cc ManualDocument13 pagesCraftsman Blower 24cc ManualChristian HumeNo ratings yet

- 6D140 3Document234 pages6D140 3anon_964686176No ratings yet

- Workshop Tips 2Document4 pagesWorkshop Tips 2Jonnathan SpringNo ratings yet

- Bản Sao Của Emailing PW148!8!1Document1,158 pagesBản Sao Của Emailing PW148!8!1Trung LêNo ratings yet

- DB800 Instruction Manual PDFDocument24 pagesDB800 Instruction Manual PDFJoffre Lautaro Benavides SeminarioNo ratings yet

- I-009N VictauicDocument8 pagesI-009N VictauicbhinekahanggardhohokediriNo ratings yet

- Dalton Sleeve Honda - ManualDocument43 pagesDalton Sleeve Honda - ManualRayseanKangNo ratings yet

- Mentor Repair Manual 2 ND VersionDocument21 pagesMentor Repair Manual 2 ND VersionJDNo ratings yet

- Safe Work Procedure in Cold SawDocument1 pageSafe Work Procedure in Cold SawCyril AngkiNo ratings yet

- Installing A Mechanical Seal 1Document9 pagesInstalling A Mechanical Seal 1ZakNo ratings yet

- TB 23 RDocument20 pagesTB 23 RSrdjan NikolicNo ratings yet

- Jet Manual-321860 - Man - ENDocument104 pagesJet Manual-321860 - Man - ENProfCarlos GamaNo ratings yet

- Safe Operating Procedures 03 Chainsaw OperationDocument2 pagesSafe Operating Procedures 03 Chainsaw OperationVictorNo ratings yet

- TM 1000 1 - S2 1eDocument72 pagesTM 1000 1 - S2 1ekit101100% (1)

- Rough Terrain Crane: GR-300EXDocument335 pagesRough Terrain Crane: GR-300EXIynsmla100% (1)

- PHCT400 DataDocument14 pagesPHCT400 DataGabriel AguerNo ratings yet

- SOP of Low Profile CreeperDocument7 pagesSOP of Low Profile CreeperGyanendra Narayan NayakNo ratings yet

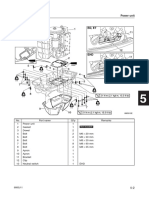

- Power UnitDocument1 pagePower UnitPHUONG NGUYENNo ratings yet

- Power UnitDocument1 pagePower UnitPHUONG NGUYENNo ratings yet

- CrankcaseDocument1 pageCrankcasePHUONG NGUYENNo ratings yet

- Disassembling The Oil Seal Housing: Power UnitDocument1 pageDisassembling The Oil Seal Housing: Power UnitPHUONG NGUYENNo ratings yet

- Assembling The Upper Bearing Checking The Connecting Rod Small End Axial PlayDocument1 pageAssembling The Upper Bearing Checking The Connecting Rod Small End Axial PlayPHUONG NGUYENNo ratings yet

- Checking The Piston Diameter Checking The Piston Pin Boss BoreDocument1 pageChecking The Piston Diameter Checking The Piston Pin Boss BorePHUONG NGUYENNo ratings yet

- Assembling The Power Unit: CrankcaseDocument1 pageAssembling The Power Unit: CrankcasePHUONG NGUYEN100% (1)

- Removing The CrankcaseDocument1 pageRemoving The CrankcasePHUONG NGUYENNo ratings yet

- Removing The Reed Valve Assembly: Intake ManifoldDocument1 pageRemoving The Reed Valve Assembly: Intake ManifoldPHUONG NGUYENNo ratings yet

- Assembling The Crankshaft Assembling The Piston and Connect-Ing Rod AssemblyDocument1 pageAssembling The Crankshaft Assembling The Piston and Connect-Ing Rod AssemblyPHUONG NGUYENNo ratings yet

- Disassembling The Piston and Con-Necting Rod Assembly: Power UnitDocument1 pageDisassembling The Piston and Con-Necting Rod Assembly: Power UnitPHUONG NGUYENNo ratings yet

- Checking The Connecting Rod Big End Side Clearance: CrankcaseDocument1 pageChecking The Connecting Rod Big End Side Clearance: CrankcasePHUONG NGUYENNo ratings yet

- Disassembling The Crankshaft: CrankcaseDocument1 pageDisassembling The Crankshaft: CrankcasePHUONG NGUYENNo ratings yet

- Crankcase: Power UnitDocument1 pageCrankcase: Power UnitPHUONG NGUYENNo ratings yet

- Cyilnder Head, Exhaust CoverDocument1 pageCyilnder Head, Exhaust CoverPHUONG NGUYENNo ratings yet

- Removing The Cylinder Head: Cyilnder Head, Exhaust CoverDocument1 pageRemoving The Cylinder Head: Cyilnder Head, Exhaust CoverPHUONG NGUYENNo ratings yet

- Crankcase: Loosen CompletelyDocument1 pageCrankcase: Loosen CompletelyPHUONG NGUYENNo ratings yet

- Power UnitDocument1 pagePower UnitPHUONG NGUYENNo ratings yet

- Power Unit: Removing The Exhaust CoverDocument1 pagePower Unit: Removing The Exhaust CoverPHUONG NGUYENNo ratings yet

- Removing The Power UnitDocument1 pageRemoving The Power UnitPHUONG NGUYENNo ratings yet

- Cyilnder Head, Exhaust Cover: No. Part Name Q'ty Remarks 18 Screw 2 Ø4 × 15 MM 19 Anode 2Document1 pageCyilnder Head, Exhaust Cover: No. Part Name Q'ty Remarks 18 Screw 2 Ø4 × 15 MM 19 Anode 2PHUONG NGUYENNo ratings yet

- Intake Manifold: Power UnitDocument1 pageIntake Manifold: Power UnitPHUONG NGUYENNo ratings yet

- Cylinder Head, Exhaust Cover: Power UnitDocument1 pageCylinder Head, Exhaust Cover: Power UnitPHUONG NGUYENNo ratings yet

- Power Unit: 160 N M (16.0 KGF M, 118 FT LB)Document1 pagePower Unit: 160 N M (16.0 KGF M, 118 FT LB)PHUONG NGUYENNo ratings yet

- Power UnitDocument1 pagePower UnitPHUONG NGUYENNo ratings yet

- Power UnitDocument1 pagePower UnitPHUONG NGUYENNo ratings yet

- Power Unit: 30 N M (3.0 KGF M, 22.1 FT LB)Document1 pagePower Unit: 30 N M (3.0 KGF M, 22.1 FT LB)PHUONG NGUYENNo ratings yet

- 7 N M (0.7 KGF M, 5.2 FT LB) : Power UnitDocument1 page7 N M (0.7 KGF M, 5.2 FT LB) : Power UnitPHUONG NGUYENNo ratings yet

- Power Unit: 7 N M (0.7 KGF M, 5.2 FT LB)Document1 pagePower Unit: 7 N M (0.7 KGF M, 5.2 FT LB)PHUONG NGUYENNo ratings yet

- Ed, Et: Power UnitDocument1 pageEd, Et: Power UnitPHUONG NGUYENNo ratings yet