Professional Documents

Culture Documents

CRCW080510K0FKEA

CRCW080510K0FKEA

Uploaded by

akshay rajCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CRCW080510K0FKEA

CRCW080510K0FKEA

Uploaded by

akshay rajCopyright:

Available Formats

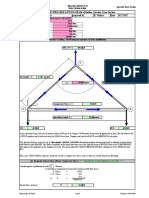

D/CRCW e3

www.vishay.com

Vishay

Standard Thick Film Chip Resistors

FEATURES

• Stability at different environmental conditions

R/R 1 % (1000 h rated power at 70 °C)

• 2 mm pitch packaging option for 0603 size

• AEC-Q200 qualified

• Material categorization: for definitions of compliance

please see www.vishay.com/doc?99912

APPLICATIONS

LINKS TO ADDITIONAL RESOURCES • Automotive

3D 3D • Industrial

3D Models • Telecommunication

D/CRCW e3 standard thick film chip resistors are the perfect

choice for most fields of modern electronics where high

reliability and stability are of major concern. Typical

applications include automotive, telecommunications, and

industrial.

TECHNICAL SPECIFICATIONS

DESCRIPTION D10/CRCW0402 D11/CRCW0603 D12/CRCW0805 D25/CRCW1206 CRCW1210 CRCW1218 CRCW2010 CRCW2512

e3 e3 e3 e3 e3 e3 e3 e3

Imperial size 0402 0603 0805 1206 1210 1218 2010 2512

Metric size code RR1005M RR1608M RR2012M RR3216M RR3225M RR3246M RR5025M RR6332M

1 to

Resistance 2.2 M; 1 to 10 M;

1 to 10 M; jumper (0 )

range jumper jumper (0 )

(0 )

Resistance ± 5 %; ± 1 %

tolerance

Temperature ± 200 ppm/K; ± 100 ppm/K

coefficient

Rated 0.063 W 0.10 W 0.125 W 0.25 W 0.5 W 1.0 W 0.75 W 1.0 W

dissipation, P70 (1)

Operating

voltage, 50 V 75 V 150 V 200 V 200 V 200 V 400 V 500 V

Umax. ACRMS/DC

Permissible film

temperature, 155 °C

F max. (1)

Operating

temperature -55 °C to +155 °C

range

Max. resistance

change at P70 for

resistance range,

|R/R|, after (2):

1000 h 1%

8000 h 2%

Permissible

voltage

against ambient

(insulation):

1 min, Uins 75 V 100 V 200 V 300 V 300 V 300 V 300 V 300 V

Failure rate: 0.1 x 10-9/h

FITobserved

Notes

(1) Please refer to “Application Information” below

(2) Apply to components with stability class 1

Revision: 23-Apr-2021 1 Document Number: 20035

For technical questions, contact: thickfilmchip@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

D/CRCW e3

www.vishay.com

Vishay

APPLICATION INFORMATION

When the resistor dissipates power, a temperature rise above the ambient temperature occurs, dependent on the thermal

resistance of the assembled resistor together with the printed circuit board. The rated dissipation applies only if the permitted

film temperature is not exceeded.

These resistors do not feature a limited lifetime when operated within the permissible limits. However, resistance value drift

increasing over operating time may result in exceeding a limit acceptable to the specific application, thereby establishing a

functional lifetime.

TEMPERATURE COEFFICIENT AND RESISTANCE RANGE

TYPE / SIZE TCR TOLERANCE RESISTANCE E-SERIES

± 200 ppm/K ±5% 1 to 10 M E24

D10/CRCW0402 e3 ± 100 ppm/K ±1% 1 to 10 M E24; E96

Jumper, Imax. = 1.5 A 20 m 0 -

± 200 ppm/K ±5% 1 to 10 M E24

D11/CRCW0603 e3 ± 100 ppm/K ±1% 1 to 10 M E24; E96

Jumper, Imax. = 2.0 A 20 m 0 -

± 200 ppm/K ±5% 1 to 10 M E24

D12/CRCW0805 e3 ± 100 ppm/K ±1% 1 to 10 M E24; E96

Jumper, Imax. = 2.5 A 20 m 0 -

± 200 ppm/K ±5% 1 to 10 M E24

D25/CRCW1206 e3 ± 100 ppm/K ±1% 1 to 10 M E24; E96

Jumper, Imax. = 3.5 A 20 m 0 -

± 200 ppm/K ±5% 1 to 10 M E24

CRCW1210 e3 ± 100 ppm/K ±1% 1 to 10 M E24; E96

Jumper, Imax. = 5.0 A 20 m 0 -

± 200 ppm/K ±5% 1 to 2.2 M E24

CRCW1218 e3 ± 100 ppm/K ±1% 1 to 2.2 M E24; E96

Jumper, Imax. = 7.0 A 20 m 0 -

± 200 ppm/K ±5% 1 to 10 M E24

CRCW2010 e3 ± 100 ppm/K ±1% 1 to 10 M E24; E96

Jumper, Imax. = 6.0 A 20 m 0 -

± 200 ppm/K ±5% 1 to 10 M E24

CRCW2512 e3 ± 100 ppm/K ±1% 1 to 10 M E24; E96

Jumper, Imax. = 7.0 A 20 m 0 -

Note

• The temperature coefficient of resistance (TCR) is not specified for 0 jumpers

Revision: 23-Apr-2021 2 Document Number: 20035

For technical questions, contact: thickfilmchip@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

D/CRCW e3

www.vishay.com

Vishay

PACKAGING

PACKAGING

TYPE / SIZE CODE QUANTITY PACKAGING STYLE WIDTH PITCH

DIMENSIONS

ED = ET7 10 000 Ø 180 mm / 7"

D10/CRCW0402 e3 8 mm 2 mm

EE = EF4 50 000 Ø 330 mm / 13"

EI = ET2 5000 Ø 180 mm / 7"

ED = ET3 10 000 Ø 180 mm / 7"

2 mm

EL = ET4 20 000 Ø 285 mm / 11.25"

D11/CRCW0603 e3 EE = ET8 50 000 8 mm Ø 330 mm / 13"

EA = ET1 5000 Ø 180 mm / 7"

EB = ET5 10 000 4 mm Ø 285 mm / 11.25"

EC = ET6 20 000 Paper tape acc. to Ø 330 mm / 13"

EA = ET1 5000 IEC 60286-3, Type 1a Ø 180 mm / 7"

D12/CRCW0805 e3 EB = ET5 10 000 8 mm 4 mm Ø 285 mm / 11.25"

EC = ET6 20 000 Ø 330 mm / 13"

EA = ET1 5000 Ø 180 mm / 7"

D25/CRCW1206 e3 EB = ET5 10 000 8 mm 4 mm Ø 285 mm / 11.25"

EC = ET6 20 000 Ø 330 mm / 13"

EA = ET1 5000 Ø 180 mm / 7"

CRCW1210 e3 EB = ET5 10 000 8 mm 4 mm Ø 285 mm / 11.25"

EC = ET6 20 000 Ø 330 mm / 13"

CRCW1218 e3 EK = ET9 4000 12 mm 4 mm Ø 180 mm / 7"

CRCW2010 e3 EF = E02 4000 Blister tape acc. to 12 mm 4 mm Ø 180 mm / 7"

EG = E67 2000 IEC 60286-3, Type 2a 8 mm

CRCW2512 e3 12 mm Ø 180 mm / 7"

EH = E82 4000 4 mm

PART NUMBER AND PRODUCT DESCRIPTION

Part Number: CRCW0603562RFKEA

Part Number: CRCW06030000Z0EA

C R C W 0 6 0 3 5 6 2 R F K E A

TYPE / SIZE RESISTANCE TOLERANCE TCR PACKAGING

D10/CRCW0402 R = decimal F=±1% K = ± 100 ppm/K EA, EB,

D11/CRCW0603 K = thousand J=±5% N = ± 200 ppm/K EC, ED,

D12/CRCW0805 M = million Z = jumper 0 = jumper EE, EF,

D25/CRCW1206 0000 = jumper EG, EH,

CRCW1210 EI, EK,

CRCW1218 EL

CRCW2010

CRCW2512

Product Description: D11/CRCW0603 100 562R 1% ET1 e3

Product Description: D11/CRCW0603 0R0 ET1 e3

D11/CRCW0603 100 562R 1% ET1 e3

TYPE / SIZE TCR RESISTANCE TOLERANCE PACKAGING LEAD (Pb)-FREE

D10/CRCW0402 ± 100 ppm/K 10R = 10 ±1% ET1, ET2, e3 = pure tin

D11/CRCW0603 ± 200 ppm/K 562R = 562 ±5% ET3, ET4, termination finish

D12/CRCW0805 1M = 1 M ET5, ET6,

D25/CRCW1206 0R0 = jumper ET8, ET9,

CRCW1210 EF4, E02,

CRCW1218 E67, E82

CRCW2010

CRCW2512

Revision: 23-Apr-2021 3 Document Number: 20035

For technical questions, contact: thickfilmchip@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

D/CRCW e3

www.vishay.com

Vishay

DESCRIPTION MATERIALS

Production is strictly controlled and follows an extensive set Vishay acknowledges the following systems for the

of instructions established for reproducibility. A cermet film regulation of hazardous substances:

layer and a glass-over are deposited on a high grade (Al2O3) • IEC 62474, Material Declaration for Products of and for the

ceramic substrate with its prepared inner contacts. A Electrotechnical Industry, with the list of declarable

special laser is used to achieve the target value by smoothly substances given therein (2)

fine trimming the resistive layer without damaging the • The Global Automotive Declarable Substance List

ceramics. The resistor elements are covered by a protective (GADSL) (3)

coating designed for electrical, mechanical and climatic

• The REACH regulation (1907/2006/EC) and the related list

protection. The terminations receive a final pure tin on nickel

of substances with very high concern (SVHC) (4) for its

plating.

supply chain

The result of the determined production is verified by an

extensive testing procedure on 100 % of the individual chip The products do not contain any of the banned

resistors. Only accepted products are laid directly into substances as per IEC 62474, GADSL, or the SVHC list,

the tape in accordance with IEC 60286-3 Type 1a and see www.vishay.com/how/leadfree.

Type 2a (1). Hence the products fully comply with the following

directives:

ASSEMBLY • 2000/53/EC End-of-Life Vehicle Directive (ELV) and

The resistors are suitable for processing on automatic SMD Annex II (ELV II)

assembly systems. They are suitable for automatic • 2011/65/EU Restriction of the Use of Hazardous

soldering using wave, reflow or vapor phase as shown in Substances Directive (RoHS) with amendment

IEC 61760-1 (1). The encapsulation is resistant to all 2015/863/EU

cleaning solvents commonly used in the electronics • 2012/19/EU Waste Electrical and Electronic Equipment

industry, including alcohols, esters and aqueous solutions. Directive (WEEE)

The suitability of conformal coatings, potting compounds

Vishay pursues the elimination of conflict minerals from its

and their processes, if applied, shall be qualified by

supply chain, see the Conflict Minerals Policy at

appropriate means to ensure the long-term stability of the

www.vishay.com/doc?49037.

whole system.

The resistors are RoHS-compliant, the pure tin plating APPROVALS

provides compatibility with lead (Pb)-free and

The resistors are qualified according to AEC-Q200.

lead-containing soldering processes. Solderability is

specified for 2 years after production or requalification. The Where applicable, the resistors are tested in accordance

permitted storage time is 20 years. The immunity of the with EN 140401-802 which refers to EN 60115-1,

plating against tin whisker growth has been proven under EN 60115-8 and the variety of environmental test

extensive testing. procedures of the IEC 60068 (1) series.

RELATED PRODUCTS

For more information about products with better TCR and

tighter tolerance please refer to the “Lead (Pb)-Free Thick

Film, Rectangular, Semi-Precision Chip Resistors”

datasheet (www.vishay.com/doc?20036).

The D/CRCW with SnPb termination plating is designed for

applications where lead bearing terminations are

mandatory. For ordering D/CRCW with SnPb terminations

please refer to latest edition of datasheet D/CRCW

(www.vishay.com/doc?20008).

Notes

(1) The quoted IEC standards are also released as EN standards with the same number and identical contents

(2) The IEC 62474 list of declarable substances is maintained in a dedicated database, which is available at http://std.iec.ch/iec62474

(3) The Global Automotive Declarable Substance List (GADSL) is maintained by the American Chemistry Council and available at www.gadsl.org

(4) The SVHC list is maintained by the European Chemical Agency (ECHA) and available at http://echa.europa.eu/candidate-list-table

Revision: 23-Apr-2021 4 Document Number: 20035

For technical questions, contact: thickfilmchip@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

D/CRCW e3

www.vishay.com

Vishay

FUNCTIONAL PERFORMANCE

Single Pulse

Axis Title

1000 10000

CRCW2512

CRCW1218

CRCW2010

100 CRCW1210

D25/CRCW1206

Pmax. - Pulse Load (W)

2nd line

D12/CRCW0805 1000

D11/CRCW0603

10

2nd line

D10/CRCW0402

1st line

1

100

^

0.1

0.01 10

0.000001 0.00001 0.0001 0.001 0.01 0.1 1 10 100

ti - Pulse Duration (s)

Maximum pulse load, single pulse; applicable if P 0 and n < 1000 and Û = Û max.;

for permissible resistance change equivalent to 8000 h operation

Continuous Pulse

Axis Title

1000 10000

CRCW2512

CRCW1218

Pmax. - Continuous Pulse Load (W)

2nd line

CRCW2010

100 CRCW1210

D25/CRCW1206

D12/CRCW0805 1000

10 D11/CRCW0603

2nd line

D10/CRCW0402

1st line

1

100

0.1

^

0.01 10

0.000001 0.00001 0.0001 0.001 0.01 0.1 1 10 100

ti - Pulse Duration (s)

Maximum pulse load, continuous pulses; applicable if P P (amb) and Û = Û max.;

for permissible resistance change equivalent to 8000 h operation

Pulse Voltage

Axis Title

2000 10000

CRCW2512

1800 CRCW2010

D25/CRCW1206, CRCW1210, CRCW1218

1600 D12/CRCW0805

Umax. - Pulse Voltage (V)

2nd line

D11/CRCW0603

1400 D10/CRCW0402 1000

1200

2nd line

1st line

1000

800

100

600

^

400

200

0 10

0.000001 0.00001 0.0001 0.001 0.01 0.1 1 10

ti - Pulse Duration (s)

Maximum pulse voltage, single and continuous pulses; applicable if P̂ = P̂ max.;

for permissible resistance change equivalent to 8000 h operation

Revision: 23-Apr-2021 5 Document Number: 20035

For technical questions, contact: thickfilmchip@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

D/CRCW e3

www.vishay.com

Vishay

Derating

Axis Title

1.2 10000

CRCW2512, CRCW1218

CRCW2010

1.0 CRCW1210

D25/CRCW1206

P - Power Dissipation (W)

D12/CRCW0805

0.8 D11/CRCW0603 1000

D10/CRCW0402

2nd line

1st line

2nd line

0.6

0.4 100

0.2

0 10

-70 -60 -50 -40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160

ϑamb - Ambient Temperature (°C)

Non-Linearity

Axis Title

120 10000

D25/CRCW1206, CRCW2010

Attenuation of 3rd Harmoinc A3 (dB)

D12/CRCW0805

100 D11/CRCW0603

D10/CRCW0402

80 1000

2nd line

1st line

2nd line

60

40 100

20

0 10

10 100 1K 10K 100K 1M 10M

R - Resistance Value (Ω)

Current Noise

Axis Title

100 10000

D10/CRCW0402

D11/CRCW0603

D12/CRCW0805

D25/CRCW1206

10

Current Noise A1 (μV/V)

CRCW2010

1000

2nd line

1st line

2nd line

100

0.1

0.01 10

100 1K 10K 100K 1M 10M

R - Resistance Value (Ω)

Revision: 23-Apr-2021 6 Document Number: 20035

For technical questions, contact: thickfilmchip@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

D/CRCW e3

www.vishay.com

Vishay

TESTS AND REQUIREMENTS

All executed tests are carried out in accordance with the The testing also covers most of the requirements specified

following specifications: by EIA/IS-703 and JIS-C-5201-1.

EN 60115-1, generic specification The tests are carried out under standard atmospheric

EN 60115-8 (successor of EN 140400), sectional conditions in accordance with IEC 60068-1, 4.3, whereupon

specification the following values are applied:

EN 140401-802, detail specification Temperature: 15 °C to 35 °C

IEC 60068-2-xx, test methods Relative humidity: 25 % to 75 %

The parameters stated in the Test Procedures and Air pressure: 86 kPa to 106 kPa (860 mbar to 1060 mbar).

Requirements table are based on the required tests and A climatic category LCT / UCT / 56 is applied, defined by the

permitted limits of EN 140401-802. The table presents only lower category temperature (LCT), the upper category

the most important tests, for the full test schedule refer to temperature (UCT), and the duration of exposure in the

the documents listed above. However, some additional damp heat, steady state test (56 days). The components are

tests and a number of improvements against those mounted for testing on boards in accordance with EN

minimum requirements have been included. 60115-8, 2.4.2 unless otherwise specified.

TEST PROCEDURES AND REQUIREMENTS

REQUIREMENTS PERMISSIBLE

CHANGE (R)

IEC PROCEDURE

EN STABILITY CLASS 1 STABILITY CLASS 2

60068-2

60115-1 (1) TEST TEST OR BETTER OR BETTER

CLAUSE

METHOD Stability for product types:

1 to 10 M

D/CRCW e3

4.5 - Resistance - ±1% ±5%

At (20 / -55 / 20) °C and

4.8 - Temperature coefficient ± 100 ppm/K ± 200 ppm/K

(20 / 155 / 20) °C

U = P 70 x R or U = Umax.

whichever is the less severe;

4.25.1 - Endurance at 70 °C 1.5 h on; 0.5 h off

70 °C; 1000 h ± (1 % R + 0.05 ) ± (2 % R + 0.1 )

70 °C; 8000 h ± (2 % R + 0.1 ) ± (4 % R + 0.1 )

Endurance at upper

4.25.3 - 155 °C; 1000 h ± (1 % R + 0.05 ) ± (2 % R + 0.1 )

category temperature

(40 ± 2) °C; 56 days;

4.24 78 (Cab) Damp heat, steady state ± (1 % R + 0.05 )

(93 ± 3) % RH

(85 ± 2) °C; (85 ± 5) % RH;

Damp heat, steady state,

4.37 67 (Cy) U = 0.1 x P 85 x R 100 V; ± (1 % R + 0.05 ) ± (2 % R + 0.1 )

accelerated

1000 h

4.23 - Climatic sequence:

4.23.2 2 (Bb) Dry heat 125 °C; 16 h

4.23.3 30 (Db) Damp 55 °C; 24 h; 90 % RH; 1 cycle

4.23.4 1 (Ab) Cold -55 °C; 2 h

± (1 % R + 0.05 ) ± (2 % R + 0.1 )

4.23.5 13 (M) Low air pressure 8.5 kPa; 2 h; (25 ± 10) °C

55 °C; 5 days;

4.23.6 30 (Db) Damp heat, cyclic

> 90 % RH; 5 cycles

4.23.7 - DC load U = P 70 x R Umax.; 1 min

- 1 (Aa) Cold -55 °C; 2 h ± (0.25 % R + 0.05 ) ± (0.5 % R + 0.05 )

Rapid change 30 min. at -55 °C and 30 min. at 125 °C ± (1 % R + 0.05 )

4.19 14 (Na)

of temperature 1000 cycles no visible damage

U = 2.5 x P 70 x R 2 x Umax.;

4.13 - Short time overload ± (2 % R + 0.05 )

whichever is the less severe; 5 s

Severity no. 4:

U = 10 x P 70 x R

Single pulse high voltage ± (1 % R + 0.05 )

4.27 - or U = 2 x Umax.;

overload no visible damage

whichever is the less severe;

10 pulses 10 μs / 700 μs

Revision: 23-Apr-2021 7 Document Number: 20035

For technical questions, contact: thickfilmchip@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

D/CRCW e3

www.vishay.com

Vishay

TEST PROCEDURES AND REQUIREMENTS

REQUIREMENTS PERMISSIBLE

CHANGE (R)

IEC PROCEDURE

EN STABILITY CLASS 1 STABILITY CLASS 2

60068-2

60115-1 (1) TEST TEST OR BETTER OR BETTER

CLAUSE

METHOD Stability for product types:

1 to 10 M

D/CRCW e3

U= 15 x P 70 x R or

U = 2 x Umax.; ± (1 % R + 0.05 )

4.39 - Periodic electric overload

whichever is the less severe; no visible damage

0.1 s on; 2.5 s off; 1000 cycles

IEC 61340-3-1 (1);

Electrostatic discharge

4.38 - 3 positive + 3 negative discharges; ± (1 % R + 0.05 )

(human body model)

ESD voltage acc. to size

Endurance by sweeping;

10 Hz to 2000 Hz;

± (0.25 % R + 0.05 ) ± (0.5 % R + 0.05 )

4.22 6 (Fc) Vibration no resonance;

no visible damage no visible damage

amplitude 1.5 mm or 200 m/s2;

7.5 h

Solder bath method,

SnPb40; non-activated flux

(235 ± 5) °C; (2 ± 0.2) s

Good tinning ( 95 % covered);

4.17 58 (Td) Solderability Solder bath method, no visible damage

Sn96.5Ag3Cu0.5;

non-activated flux

(245 ± 5) °C; (3 ± 0.3) s

Resistance to Soldering bath method;

4.18 58 (Td) ± (0.25 % R + 0.05 ) ± (0.5 % R + 0.05 )

soldering heat (260 ± 5) °C; (10 ± 1) s

Component solvent Isopropyl alcohol;

4.29 45 (XA) No visible damage

resistance +50 °C; method 2

CRCW0402 and CRCW0603: 9 N

4.32 21 (Uu3) Shear (adhesion) No visible damage

CRCW0805 to CRCW2512: 45 N

± (0.25 % R + 0.05 )

4.33 21 (Ue1) Substrate bending Depth 2 mm; 3 times no visible damage,

no open circuit in bent position

4.7 - Voltage proof U = 1.4 x Uins; 60 s No flashover or breakdown

Flammability, IEC 60695-11-5 (1);

4.35 - No burning after 30 s

needle flame test 10 s

Note

(1) The quoted IEC standards are also released as EN standards with the same number and identical contents

Revision: 23-Apr-2021 8 Document Number: 20035

For technical questions, contact: thickfilmchip@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

D/CRCW e3

www.vishay.com

Vishay

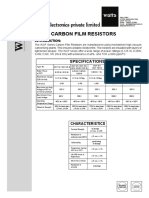

DIMENSIONS

L

T2

W

H

T1

DIMENSIONS AND MASS

L W H T1 T2 MASS

TYPE / SIZE

(mm) (mm) (mm) (mm) (mm) (mg)

D10/CRCW0402 e3 1.0 ± 0.05 0.5 ± 0.05 0.35 ± 0.05 0.25 ± 0.05 0.2 ± 0.10 0.65

D11/CRCW0603 e3 1.55 + 0.10 / - 0.05 0.85 ± 0.10 0.45 ± 0.05 0.3 ± 0.20 0.3 ± 0.20 2

D12/CRCW0805 e3 2.0 + 0.20 / - 0.10 1.25 ± 0.15 0.45 ± 0.05 0.3 + 0.20 / - 0.10 0.3 ± 0.20 5.5

D25/CRCW1206 e3 3.2 + 0.10 / - 0.20 1.6 ± 0.15 0.55 ± 0.05 0.45 ± 0.20 0.4 ± 0.20 10

CRCW1210 e3 3.2 ± 0.20 2.5 ± 0.20 0.55 ± 0.05 0.45 ± 0.20 0.4 ± 0.20 16

CRCW1218 e3 3.2 + 0.10 / - 0.20 4.6 ± 0.15 0.55 ± 0.05 0.45 ± 0.20 0.4 ± 0.20 29.5

CRCW2010 e3 5.0 ± 0.15 2.5 ± 0.15 0.6 ± 0.10 0.6 ± 0.20 0.6 ± 0.20 25.5

CRCW2512 e3 6.3 ± 0.20 3.15 ± 0.15 0.6 ± 0.10 0.6 ± 0.20 0.6 ± 0.20 40.5

SOLDER PAD DIMENSIONS

G X

Y

Z

RECOMMENDED SOLDER PAD DIMENSIONS

WAVE SOLDERING REFLOW SOLDERING

TYPE / SIZE G Y X Z G Y X Z

(mm) (mm) (mm) (mm) (mm) (mm) (mm) (mm)

D10/CRCW0402 e3 - - - - 0.45 0.6 0.6 1.65

D11/CRCW0603 e3 0.65 1.10 1.25 2.85 0.75 0.75 1.00 2.25

D12/CRCW0805 e3 0.90 1.30 1.60 3.50 1.00 0.95 1.45 2.90

D25/CRCW1206 e3 1.40 1.40 1.95 4.20 1.50 1.05 1.80 3.60

CRCW1210 e3 1.80 1.45 2.95 4.70 1.70 1.10 2.80 3.90

CRCW1218 e3 1.80 1.30 5.10 4.40 1.90 1.10 4.90 4.10

CRCW2010 e3 3.40 1.65 2.85 6.70 3.50 1.45 2.80 6.40

CRCW2512 e3 4.60 1.60 3.65 7.80 4.75 1.45 3.50 7.65

Note

• The rated dissipation applies only if the permitted film temperature is not exceeded. Furthermore, a high level of ambient temperature or of

power dissipation may raise the temperature of the solder joint, hence special solder alloys or board materials may be required to maintain

the reliability of the assembly.

The given solder pad dimensions reflect the considerations for board design and assembly as outlined e.g. in standards IEC 61188-5-x or

in publication IPC-7351. They do not guarantee any supposed thermal properties, particularly as these are also strongly influenced by many

other parameters. Still, the given solder pad dimensions will be found adequate for most general applications

Revision: 23-Apr-2021 9 Document Number: 20035

For technical questions, contact: thickfilmchip@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Legal Disclaimer Notice

www.vishay.com

Vishay

Disclaimer

ALL PRODUCT, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE TO IMPROVE

RELIABILITY, FUNCTION OR DESIGN OR OTHERWISE.

Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf (collectively,

“Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained in any datasheet or in any other

disclosure relating to any product.

Vishay makes no warranty, representation or guarantee regarding the suitability of the products for any particular purpose or

the continuing production of any product. To the maximum extent permitted by applicable law, Vishay disclaims (i) any and all

liability arising out of the application or use of any product, (ii) any and all liability, including without limitation special,

consequential or incidental damages, and (iii) any and all implied warranties, including warranties of fitness for particular

purpose, non-infringement and merchantability.

Statements regarding the suitability of products for certain types of applications are based on Vishay's knowledge of typical

requirements that are often placed on Vishay products in generic applications. Such statements are not binding statements

about the suitability of products for a particular application. It is the customer's responsibility to validate that a particular product

with the properties described in the product specification is suitable for use in a particular application. Parameters provided in

datasheets and / or specifications may vary in different applications and performance may vary over time. All operating

parameters, including typical parameters, must be validated for each customer application by the customer's technical experts.

Product specifications do not expand or otherwise modify Vishay's terms and conditions of purchase, including but not limited

to the warranty expressed therein.

Hyperlinks included in this datasheet may direct users to third-party websites. These links are provided as a convenience and

for informational purposes only. Inclusion of these hyperlinks does not constitute an endorsement or an approval by Vishay of

any of the products, services or opinions of the corporation, organization or individual associated with the third-party website.

Vishay disclaims any and all liability and bears no responsibility for the accuracy, legality or content of the third-party website

or for that of subsequent links.

Except as expressly indicated in writing, Vishay products are not designed for use in medical, life-saving, or life-sustaining

applications or for any other application in which the failure of the Vishay product could result in personal injury or death.

Customers using or selling Vishay products not expressly indicated for use in such applications do so at their own risk. Please

contact authorized Vishay personnel to obtain written terms and conditions regarding products designed for such applications.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this document or by

any conduct of Vishay. Product names and markings noted herein may be trademarks of their respective owners.

© 2022 VISHAY INTERTECHNOLOGY, INC. ALL RIGHTS RESERVED

Revision: 01-Jan-2022 1 Document Number: 91000

You might also like

- Example of SOAP Notes For Orthodontic ScreeningDocument2 pagesExample of SOAP Notes For Orthodontic ScreeningMavis100% (1)

- Ge Lunar Prodigy Dxse0012Document10 pagesGe Lunar Prodigy Dxse0012Jairo ManzanedaNo ratings yet

- MID 150 - Volvo Suspension Fault CodesDocument9 pagesMID 150 - Volvo Suspension Fault CodesJan Svein HammerNo ratings yet

- nRF52840 PS v1.5Document631 pagesnRF52840 PS v1.5Benyamin Farzaneh AghajarieNo ratings yet

- AMO UWB Module (SR150) : Amosense Co., LTDDocument19 pagesAMO UWB Module (SR150) : Amosense Co., LTDBenyamin Farzaneh Aghajarie100% (1)

- Unlocked 189537383 Spreader Beam BLOCK EDocument25 pagesUnlocked 189537383 Spreader Beam BLOCK EWalterNo ratings yet

- Construction Structure Design (Scheme) Approval: Jingmen Hongtu Special Aircraft Manufacturing Co., LTDDocument38 pagesConstruction Structure Design (Scheme) Approval: Jingmen Hongtu Special Aircraft Manufacturing Co., LTDAero Aero100% (1)

- 180 Ohm ResistorDocument11 pages180 Ohm ResistorNidhi PanditNo ratings yet

- RCS E3: VishayDocument10 pagesRCS E3: VishayMae MegumiNo ratings yet

- CRCW-HP E3: Vishay DraloricDocument10 pagesCRCW-HP E3: Vishay DraloricMohendra PatiNo ratings yet

- RCA-HP E3: Vishay DraloricDocument10 pagesRCA-HP E3: Vishay DraloricMohendra PatiNo ratings yet

- SMDDocument6 pagesSMDJose SCNo ratings yet

- Vishay Beyschlag: FeaturesDocument11 pagesVishay Beyschlag: FeaturesBích Trâm Đào HoàngNo ratings yet

- Sfr16S/25/25H: Vishay BccomponentsDocument11 pagesSfr16S/25/25H: Vishay BccomponentsMuhammad BilalNo ratings yet

- Resistor DatasheetDocument10 pagesResistor DatasheetEndradno KurniaNo ratings yet

- MPT 221Document3 pagesMPT 221marina anastasovaNo ratings yet

- CRCW0201 E3: VishayDocument5 pagesCRCW0201 E3: VishaycuperiniNo ratings yet

- D/CRCW E3: VishayDocument8 pagesD/CRCW E3: VishayFilipe BrendlerNo ratings yet

- D/CRCW E3: VishayDocument8 pagesD/CRCW E3: VishayelecompinnNo ratings yet

- UMA 0204, UMB 0207: Vishay BeyschlagDocument11 pagesUMA 0204, UMB 0207: Vishay BeyschlagManu MathewNo ratings yet

- Componete ElectronicoDocument5 pagesComponete ElectronicoStuxnetNo ratings yet

- MelfprofDocument14 pagesMelfprofFunnypoumNo ratings yet

- Inbound 1310313221Document2 pagesInbound 1310313221freedownNo ratings yet

- Is 15652Document3 pagesIs 15652IshanNo ratings yet

- Specification: CL 21 A 226 M A Q N N N FDocument3 pagesSpecification: CL 21 A 226 M A Q N N N Felias rangelNo ratings yet

- Vishay Resistors Precision mpr24Document7 pagesVishay Resistors Precision mpr24SamaelNo ratings yet

- Rogers MaterialDocument4 pagesRogers MaterialRobert ZmrzliNo ratings yet

- Amprobe - HD110Document4 pagesAmprobe - HD110djalmaNo ratings yet

- Thick Film Chip Resistors: DescriptionDocument1 pageThick Film Chip Resistors: DescriptionAutor AutorNo ratings yet

- Vishay Dale ResistorsDocument8 pagesVishay Dale Resistorsalko123No ratings yet

- MCS 0402, MCT 0603, MCU 0805, MCA 1206 - Professional: Vishay BeyschlagDocument13 pagesMCS 0402, MCT 0603, MCU 0805, MCA 1206 - Professional: Vishay BeyschlaglalithkumartNo ratings yet

- Digi SM300 ManualDocument3 pagesDigi SM300 ManualWilly Bracamonte TellesNo ratings yet

- CRCW25123K30JNTG DatasheetzDocument8 pagesCRCW25123K30JNTG DatasheetzVadim ZorinNo ratings yet

- Aluminum Single-Point Load Cell Aluminum Single-Point Load CellDocument3 pagesAluminum Single-Point Load Cell Aluminum Single-Point Load CellMakhis RifaiNo ratings yet

- Kem F3050 C44P Radial-1103058Document9 pagesKem F3050 C44P Radial-1103058Alexander MedinaNo ratings yet

- Model 65023: SensortronicsDocument3 pagesModel 65023: SensortronicsCarlos CatañoNo ratings yet

- Carbon Composition ResistorDocument2 pagesCarbon Composition ResistorEmmanuelSanzNo ratings yet

- Resistor SMD SizesDocument11 pagesResistor SMD Sizescarlos.antouryNo ratings yet

- Carbon Film ResistorsDocument2 pagesCarbon Film ResistorsGopichandNo ratings yet

- 3310 Aluminum Sheer Beam Load Cell: Vishay Tedea-HuntleighDocument3 pages3310 Aluminum Sheer Beam Load Cell: Vishay Tedea-Huntleighsweet boy play boyNo ratings yet

- ETEC225 Lecture 9Document22 pagesETEC225 Lecture 9none of urNo ratings yet

- Topflex - Emv-2Yslcy-J: For Power Supply Connections To Frequency Converters, Double Screened, 0,6/1kV, Meter MarkingDocument2 pagesTopflex - Emv-2Yslcy-J: For Power Supply Connections To Frequency Converters, Double Screened, 0,6/1kV, Meter MarkingMarcosNo ratings yet

- Célula de Carga Balança IkeaDocument3 pagesCélula de Carga Balança IkeatrutleptNo ratings yet

- IEC 60502-2 Cu-XLPE-SWA-PVC Cable 18-30 (36) KVDocument2 pagesIEC 60502-2 Cu-XLPE-SWA-PVC Cable 18-30 (36) KVeletec.steNo ratings yet

- Celda Huntleigt Modelo 1263Document3 pagesCelda Huntleigt Modelo 1263Fam. Alarcon RojasNo ratings yet

- Beha-Amprobe HD110C PDFDocument3 pagesBeha-Amprobe HD110C PDFhus7No ratings yet

- Eng DS 1773193 1 B-2888555Document4 pagesEng DS 1773193 1 B-2888555diego234.axelNo ratings yet

- Bourns CRM2512 DatasheetDocument5 pagesBourns CRM2512 DatasheetbarisNo ratings yet

- T491 Series Industrial Grade Mno: Tantalum Surface Mount Capacitors - Standard TantalumDocument24 pagesT491 Series Industrial Grade Mno: Tantalum Surface Mount Capacitors - Standard TantalumSebastian ChaileNo ratings yet

- HVR 2537Document7 pagesHVR 2537Damián PastreNo ratings yet

- High-Power, High-Current Grid ResistorsDocument2 pagesHigh-Power, High-Current Grid ResistorsDenny Firmansyah ZNo ratings yet

- Fixed Carbon Composition Resistors: CharacteristicsDocument3 pagesFixed Carbon Composition Resistors: CharacteristicsHiru SegwayNo ratings yet

- 66kV Aluminium Large Conductor XLPE CSA PE HS CablesDocument1 page66kV Aluminium Large Conductor XLPE CSA PE HS CablesIppiNo ratings yet

- Tension Compression Load Cell Tension Compression Load Cell: Model 614Document3 pagesTension Compression Load Cell Tension Compression Load Cell: Model 614Juan Carlos BallinariNo ratings yet

- FNR 05K180 JohansonDielectricsDocument7 pagesFNR 05K180 JohansonDielectricsgulrez1991No ratings yet

- Crcw0805390rfkta PDFDocument8 pagesCrcw0805390rfkta PDFManu MathewNo ratings yet

- Specification: CL 21 F 223 Z B A N N N CDocument3 pagesSpecification: CL 21 F 223 Z B A N N N Csam2976No ratings yet

- Diclad Series: Ptfe/Woven Fiberglass LaminatesDocument5 pagesDiclad Series: Ptfe/Woven Fiberglass LaminatesmaamriaNo ratings yet

- High Power Resistors: Type Bds 100 SeriesDocument2 pagesHigh Power Resistors: Type Bds 100 Seriesmanjubd1No ratings yet

- TNPW E3-1761965Document15 pagesTNPW E3-1761965João JoséNo ratings yet

- CMP ADocument8 pagesCMP AFotos WD DiacoNo ratings yet

- High Voltage 2xs FL 2y A2xs FL 2y 123kv Power CableDocument3 pagesHigh Voltage 2xs FL 2y A2xs FL 2y 123kv Power CableShailendra Kumar VermaNo ratings yet

- VJ.... W1BC Basic Commodity Series: VishayDocument15 pagesVJ.... W1BC Basic Commodity Series: VishaymmNo ratings yet

- CrmaDocument4 pagesCrmavahid hajihasaniNo ratings yet

- IEC 60502-2 Cu-XLPE-AWA-PVC Cable 18-30 (36) KVDocument2 pagesIEC 60502-2 Cu-XLPE-AWA-PVC Cable 18-30 (36) KVeletec.steNo ratings yet

- MWR CapsDocument4 pagesMWR CapsMartien BakkerNo ratings yet

- App PolarDocument5 pagesApp PolarBenyamin Farzaneh AghajarieNo ratings yet

- App PCB Environment v1Document10 pagesApp PCB Environment v1Benyamin Farzaneh AghajarieNo ratings yet

- 06 Library Dokumentation v2.0 enDocument13 pages06 Library Dokumentation v2.0 enBenyamin Farzaneh AghajarieNo ratings yet

- IPC 7351 Pad Stack Naming Convention - 2039898Document6 pagesIPC 7351 Pad Stack Naming Convention - 2039898Benyamin Farzaneh AghajarieNo ratings yet

- NXP 8mpluslpd4-Evk QSDocument12 pagesNXP 8mpluslpd4-Evk QSBenyamin Farzaneh AghajarieNo ratings yet

- Tutorial Altium To q3d 2020Document8 pagesTutorial Altium To q3d 2020Benyamin Farzaneh AghajarieNo ratings yet

- Presentation 2006 027 PDFDocument25 pagesPresentation 2006 027 PDFBenyamin Farzaneh AghajarieNo ratings yet

- Five Via-In-Pad Myths: by Duane Benson, Screaming Circuits Marketing ManagerDocument4 pagesFive Via-In-Pad Myths: by Duane Benson, Screaming Circuits Marketing ManagerBenyamin Farzaneh AghajarieNo ratings yet

- 07 FAQ v2.0 enDocument4 pages07 FAQ v2.0 enBenyamin Farzaneh AghajarieNo ratings yet

- En 528035Document31 pagesEn 528035Benyamin Farzaneh AghajarieNo ratings yet

- Ipc Standard PCB Library Expert Changelogs 2016Document12 pagesIpc Standard PCB Library Expert Changelogs 2016Benyamin Farzaneh AghajarieNo ratings yet

- Plug & Trust Secure Element: Rev. 1.2 - 15 December 2020 Product Data Sheet 577312Document36 pagesPlug & Trust Secure Element: Rev. 1.2 - 15 December 2020 Product Data Sheet 577312Benyamin Farzaneh AghajarieNo ratings yet

- Ces UserDocument445 pagesCes UserBenyamin Farzaneh AghajarieNo ratings yet

- Switched Mode Power SupplyDocument54 pagesSwitched Mode Power SupplyBenyamin Farzaneh AghajarieNo ratings yet

- Layer 1 Microvia Layer and PTH Nominal Thickness 2 Microvia Layer and PTH 3 Microvia Layer and PTHDocument10 pagesLayer 1 Microvia Layer and PTH Nominal Thickness 2 Microvia Layer and PTH 3 Microvia Layer and PTHBenyamin Farzaneh AghajarieNo ratings yet

- Dram Controller: Mahdi Nazm BojnordiDocument28 pagesDram Controller: Mahdi Nazm BojnordiBenyamin Farzaneh AghajarieNo ratings yet

- LDFO SiP For Wearables IoT With Hetrogeneous IntegrationDocument6 pagesLDFO SiP For Wearables IoT With Hetrogeneous IntegrationBenyamin Farzaneh AghajarieNo ratings yet

- Main Memory System: Mahdi Nazm BojnordiDocument28 pagesMain Memory System: Mahdi Nazm BojnordiBenyamin Farzaneh AghajarieNo ratings yet

- Ventec: Professional Manufacturer in Copper Clad LaminatesDocument3 pagesVentec: Professional Manufacturer in Copper Clad LaminatesBenyamin Farzaneh AghajarieNo ratings yet

- BGA Breakout Challenges: by Charles Pfeil, Mentor GraphicsDocument4 pagesBGA Breakout Challenges: by Charles Pfeil, Mentor GraphicsBenyamin Farzaneh AghajarieNo ratings yet

- Ipc 2226Document63 pagesIpc 2226Benyamin Farzaneh AghajarieNo ratings yet

- Mentor InstroductionDocument200 pagesMentor InstroductionBenyamin Farzaneh AghajarieNo ratings yet

- CS698Y: Modern Memory Systems Lecture-15 (DRAM Organization)Document18 pagesCS698Y: Modern Memory Systems Lecture-15 (DRAM Organization)Benyamin Farzaneh AghajarieNo ratings yet

- Generic Exception CapabilitiesDocument3 pagesGeneric Exception CapabilitiesBenyamin Farzaneh AghajarieNo ratings yet

- Dosimetry: Film Badge DosimetersDocument3 pagesDosimetry: Film Badge DosimetersmahaNo ratings yet

- The Emmaus Connection Volume 10Document4 pagesThe Emmaus Connection Volume 10Jillian KittrellNo ratings yet

- FlaresDocument18 pagesFlaresEric WanNo ratings yet

- LIGHTrun Brochure GATCDocument4 pagesLIGHTrun Brochure GATCXiaojie LiuNo ratings yet

- Transcend New Stock & Update Price: Items SKU DiscriptionsDocument4 pagesTranscend New Stock & Update Price: Items SKU DiscriptionsAbu Bakar Siddik RajNo ratings yet

- Bawang Merah and Bawang PutihDocument6 pagesBawang Merah and Bawang PutihEmir MahfuddinNo ratings yet

- Delem: Installation Manual V3Document73 pagesDelem: Installation Manual V3Marcus ChuaNo ratings yet

- Induction Heating Lab ManualDocument7 pagesInduction Heating Lab ManualAshish VermaNo ratings yet

- Chapter 16 Acid Base Equilibria and Solubility EquilibriaDocument120 pagesChapter 16 Acid Base Equilibria and Solubility Equilibriaroxy8marie8chanNo ratings yet

- Maternal and Child Health Nursing Exam Drill Aug 2011Document4 pagesMaternal and Child Health Nursing Exam Drill Aug 2011nikko042790100% (1)

- Ac-Induced Corrosion in Pipelines Detection, Characterisation and Mitigation PDFDocument16 pagesAc-Induced Corrosion in Pipelines Detection, Characterisation and Mitigation PDFBraulio Vanegas HernandezNo ratings yet

- Neonatal History and Physical ExamDocument2 pagesNeonatal History and Physical ExamMuhammad Farhan KhaliqNo ratings yet

- Identification of Fibers in Textiles: Standard Test Methods ForDocument17 pagesIdentification of Fibers in Textiles: Standard Test Methods ForAnilNo ratings yet

- Truth and Consequences Solvent Entrapment and Osmotic Blistering PDFDocument3 pagesTruth and Consequences Solvent Entrapment and Osmotic Blistering PDFCristian Cisternas100% (1)

- Vegetables BookDocument148 pagesVegetables Bookvenucold0% (1)

- Pola Operasi PLTU MamujuDocument20 pagesPola Operasi PLTU MamujuKunyuk KunyukNo ratings yet

- United States Court of Appeals, Third CircuitDocument43 pagesUnited States Court of Appeals, Third CircuitScribd Government DocsNo ratings yet

- API 5L - 43rd and 44th Ed - Comparison r1Document68 pagesAPI 5L - 43rd and 44th Ed - Comparison r1gopidhan100% (1)

- Chapter 6 Practice TestDocument5 pagesChapter 6 Practice TestLogan ParkisonNo ratings yet

- Company Profile-Falcon CompDocument9 pagesCompany Profile-Falcon Compamit.mandalNo ratings yet

- Production - JD - FinalDocument30 pagesProduction - JD - FinalMemories & Moments Payel & SwastikNo ratings yet

- TNBDocument21 pagesTNBAhmad FauziNo ratings yet

- 4 5918214429920462111Document3 pages4 5918214429920462111rmdarisaNo ratings yet

- Conector RSCDocument2 pagesConector RSCCesar MuñozNo ratings yet

- Root Cause AnalysisDocument1 pageRoot Cause AnalysisTri Hastuti HendrayaniNo ratings yet