Professional Documents

Culture Documents

312 1 Alternate Products For The Penstock

Uploaded by

Abdul wahid ButtOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

312 1 Alternate Products For The Penstock

Uploaded by

Abdul wahid ButtCopyright:

Available Formats

IEA Implementing Agreement for Hydropower Technologies and Programmes

Annex-2: Small-Scale Hydropower; Subtask B2 "Innovative Technologies for Small-Scale Hydro"

IEA Annex-2 STB2 Data Sheet about Innovative Technology(312-1)

1 Project Title Subject Alternate products for the Penstock (FRP/FRPM Pipe) Attachments and Additional Remarks

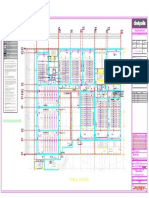

Table 1 Classification of FRP(M) pipes Table 2 Type of internal pressure pipes

Commercial Name FRP/FRPM Pipe

Unit: Mpa {kgf/cm 2}

Classification FRP pipe FRPM pipe Type Internal test pressure

2 Project Technological Categories 3. Construction (Civil Work, E&M)

by structure (Fiberglass Reinforced Plastic Pipe) (Fiberglass Reinforced Plastic Mortar Pipe) 2.6 {27}

Classification Type-1

Target Categories 31. Cost/Time Reduction 2.1 {21}

Classification Type-2

Key Categories 312. Use of New Materials FW pipe CC pipe FW pipe CC pipe Internal

by production method

Key Words Penstock, Steel pipes, Fiberglass Reinforced Plastic Mortar pipes pressure Type-3 1.4 {14}

pipes

Type-4 1.0 {10}

3 Organizations Funding Organization Japanese Ministry of Economy, Trade and Industry (formerly Japanese Ministry of International Trade and Industry) Type-5 0.5 { 5}

Development Organization

Pro tective layer Outside protective layer

Chop layer

Reinforcement layer (FRP layer)

Hoop layer

4 Abstract Because hydropower pipes manufactured using fiberglass reinforced plastic (mortar) have a number of benefits in terms of economy at small and medium- Cut layer Strength layer

Hoop layer

scale hydropower sites and construction safety, it is planned to promote their use at small and medium-scale hydropower plants through use in power- Chop layer Inside protective layer

generating pressure pipes. Pro tective layer

(FW pipe) (CC pipe)

5 Features and Technological Performance Compared to iron pipes, they

Fig. 1 Cross section structure of FRP pipe

Advantages ・are lightweight and easy to transport

・do not require advanced installation techniques

・are excellent in terms of abrasion resistance, acid resistance, electrolytic corrosion resistance etc. Protective layer

・have a low inner surface coefficient of roughness Chop layer

・deteriorate little with age, and require almost no maintenance and repair such as coating Outside protective layer

Hoop layer Outside FRP layer

・maintain high water-tightness even in the case angular movements to joints caused by changes in the supporting soil, while still Reinforcement layer (FRP layer)

Cut layer Plural layer

enabling a degree of following Plastic mortar layer

Plastic mortr layer

Cut layer Plural layer Reinforcement layer (FRP layer)

Hoop layer Inside FRP layer Inside protective layer

Cost Performance ・Because fiberglass reinforced polymer mortar pipes are highly durable and can remain viable even in the case angular Chop layer

movements to joints caused by changes in the supporting soil while still enabling a degree of following, there is a reduction in Protective layer

terms of excavation and installation costs

(FW pipe) (CC pipe)

Fig. 2 Cross section structure of FRPM pipe

Environmental Performance Nothing in particular

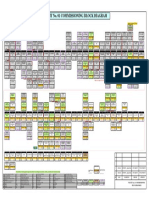

Table 3 Performance

Plant Specification Equipment/Facilities Specification

Max. Max. Effective Start of New facility Piping length Max. Design

Diameter Thickness

6 Scope of Basic Specifications FRP (FW pipe/CC pipe), FRPM (FW pipe/CC pipe) (Table1, Fig. 1) Operator Plant River system Type of

Ooutput Discharg Head Operation /Renewal x Branches

Type of

Pipe type Internal

/River name Power Generation Piping

Application (kW) 3

(m /s) (m) /Renewal /Upgrade (m) Branches (kgf/cm )

2

(m) (mm)

Hokkaido Hoyaishikawa Conduit

Hoya Ishikawa 170 0.18 134.44 1987 Upgrade 178.30 1 Exposed FRP 21.90 0.30 9

EPCo /Hoyaishikawa /Pondage

Purpose of Application Penstock

Tohoku Tsutsumigawa Conduit

Daifudo 1,500 2.33 82.10 1986 Upgrade 96.20 1 Exposed FRP 14.40 1.10 20.0~18.0

EPCo /Tsutsumigawa /Run-off-river

Technological Conditions Depending on the design requirements, to decide thickness or to sellect pipe type by the strength calculation on water charging,

Tohoku Abukumagawa Conduit

for Application full capacity and emptiness. (Table 2) EPCo

Ozaso

/Matsukawa /Run-off-river

11,400 6.50 215.20 1991 New facility 480.00 1 Exposed FRP 17.40 1.65~1.50 28.0~23.5

Tohoku Tsutsumigawa Conduit

Yabetsu 2,100 2.68 95.24 1992 Upgrade 85.00 1 Exposed FRP 8.20 1.00 19~18

EPCo /Tsutsumigawa /Run-off-river

7 Status of Project Present Status Commercial Stage Tokyo

Tsugane

Fujigawa Conduit

700 0.70 133.37 1986 Upgrade 221.00 1 Exposed FRP 15.60 0.80 14.5~6.0

EPCo /Daimongawa /Run-off-river

Tokyo Nakagawa Conduit

Period Year of Commencement:1984 Year of Completion:1989 (completion of development) Kurokawa 920 3.62 30.30 1987 Upgrade 55.00 1 Exposed FRP 1.95 1.35 14

EPCo /Kurokawa /Run-off-river

Chubu Kisogawa Conduit

Okumino 420 0.70 83.83 1995 New facility 84.47 1 Embedded FRPM 93.37 0.60~0.594 12~8

EPCo /Neohigashitanigawa /Run-off-river

8 Results of Results of Experiments or - Study period: November 1988 - August 1989 36.12 1 Exposed FRPM 53.25 0.60 12

Application Demonstration Tests ・Understanding of long term strength Chubu

Higashigouchi

Oigawa Dam

170 0.55 40.62 2001 New facility

2.53 1 Exposed FRP 53.25 0.60 8

・Confirmation of safety of supporting parts and pipe joints EPCo /Oigawa /Run-off-river 39.61 1 Embedded FRPM 53.25 0.60 12

7.54 1 Embedded FRP 53.25 0.60 6

・Confirmation of safety in the case of vibration

・Confirmation of water cut-off at joints Kansai

Mannami

Jintsugawa Dam and Conduit

12,400 5.00 303.60 1987 New facility 167.88 1 Exposed FRP 7.70 1.50 22~27

EPCo /Mannamigawa /Run-off-river

Chugoku Hiigawa Conduit

Kawate 900 3.00 40.80 1995 New facility 36.00 1 Exposed FRPM 45.14 1.35 27

EPCo /Fukanogawa /Run-off-river

Results of Sales/Practical Table 3: Performance

Shikoku Niyodogawa Conduit

Applications EPCo

Kurokawa No. 5

/Kurokawa /Run-off-river

5,300 3.50 192.92 1993 Upgrade 39.00 1 Embedded FRPM 0.70

Shikoku Tsuga Dokawa River / Dam

550 1.91 37.10 1998 New facility 120.60 1 Embedded FRPM 5.00 1.20 24

EPCo (No. 3 extension) Yusuharagawa River /Run-off-river

9 Evaluation Contribution to Cost Quality is comprable to iron pipes while ensuring a high degree of water-tightness against joint angular movement caused by Toseikogyo Komagome

Tsutsumigawa Conduit

4,000 8.15 60.60 1989 New facility 84.00 1 Exposed FRP 6.85 1.80 23

Reduction changes in the supporting soil. These factors can contribute to reductions of the drilling cost and installation cost. /Komagomegawa /Run-off-river

Nasogawa Conduit 91.60 1 Exposed FRP 14.96 1.65 18.5~21.0

Toseikogyo Shin-kotaki 4,100 5.00 100.80 1996 Renewal

/Nasogawa /Run-off-river 1,847.00 1 Embedded FRPM 14.96 1.65 33

Enlargement of Applicability The application can be expanded because the strength is comparative to that of metallic products. Besides the weight being light, Aganogawa Conduit

the corrosion resistance is high. Toseikogyo Shin-koara 11,000 17.00 77.10 2003 Renewal 112.00 1 Embedded FRPM 10.50 2.60 52

/Sanekawa /Run-off-river

Iwate Kitakamigawa Dam

Irihata 2,100 3.50 74.16 1990 New facility 262.52 1 Exposed FRP 8.12 1.50 16

Pref. /Getogawa /Reservoir

Improvement of Efficiency Compared to iron pipes, the pipes of this technology can improve the roughness coefficient. In addition, these light-weight pipes

are easy to transport, and they do not require advanced installation techniques. Iwate Kitakamigawa Conduit 163.71 1 Exposed FRPM 14.70 1.35 27

Matsukawa 4,600 3.00 188.00 1996 New facility

Pref. /Matsukawa /Run-off-river 1,564.84 1 Embedded FRPM 14.70 1.35 27

Iwate Kitakamigawa Conduit

Kashiwadai 2,600 7.60 42.30 2002 New facility 725.00 1 Embedded FRPM 5.10 1.80 36

Support for Operation & The pipes of this technology show smaller secular changes than iron pipes, and these pipes require almost no maintenance and Pref. /Matsukawa /Run-off-river

Maintenance repair such as re-painting. Akita Yoneshirogawa Conduit

Hachimantai No. 2 1,500 1.80 99.70 1985 New facility 881.34 1 Embedded FRPM 13.00 1.20 24

Pref. /Kumazawagawa /Run-off-river

Akita Yoneshirogawa Dam

Yamase 2,100 5.50 48.85 1991 New facility 100.69 1 Embedded FRPM 8.40 2.00 40

Pref. /Iwasegawa /Reservoir

10 References ・Technical development of FRPM pipes as alternate products for the penstock (March 1990) New Energy Foundation

Hukushima Abukumagawa Conduit

・Handbook of new technology for medium-small scale hydropower (January 1993) New Energy Foundation Niwasaka 1,500 1.60 111.20 2001 New facility 349.00 1 Embedded FRPM 27.00 1.00 25

Pref. /Amatogawa /Run-off-river

・Investigative report into design of model plants for standardizing small and medium-scale hydropower (March 2002) Japanese METI/ANRE, NEF Toyama Onagatani No. 5 Jintsugawa Conduit 1,380.71 1 Embedded FRPM 7.80 1.10 22

1,200 2.60 62.90 1991 New facility

・Technical standards for hydraulic gates and penstocks/FRP(M) pipes (January 1997) Japan Hydraulic Gate and Penstock Association Pref. (Idagawa, Sodenotani) /Idagawa /Run-off-river 453.10 1 Embedded FRPM 5.79 0.80~0.70 16~14

Kanazawa Saikawa Conduit

Shin-Uchikawa No. 2 3,000 3.70 100.60 1989 New facility 114.00 1 Exposed FRP 1.35 20

City /Uchikawa /Run-off-river

Nagano Tenryugawa Conduit

11 Appendices Table 1 Classification of FRP(M) pipes Pref.

Oshika No. 2

/Shiogawa /Run-off-river

5,000 1.70 356.20 1999 New facility 485.76 1 Embedded FRPM 10.19 1.10 22

Table 2 Type of internal pressure pipes Tottori Sendaigawa Conduit 1,537.38 1 Embedded FRP 28.00 0.60 6~16

Kaji 1,100 0.55 242.10 1996 New facility

Table 3 Performance Pref. /Kajigawa /Run-off-river 539.61 1 Embedded FRPM 28.00 0.60 12

Fig. 1 Cross section structure of FRP pipe Okinawa sea water Recirculating pumped

EPDC - 30,000 26.00 136.00 1999 New facility 300.00 1 Embedded FRP・FRPM 22.47 2.40 51~35

Fig. 2 Cross section structure of FRPM pipe pumped-storage storage type

Gojo land Shinanogawa Conduit

Gojo 1,100 5.44 24.01 2000 New facility 671.05 1 Embedded FRPM 1.80

improvement district /Sagurigawa /Run-off-river

Kurokawa Village, Tainaigawa Conduit

12 Inquires Organization and New Energy Foundation, Hydropower Head Office, Technical Department Niigata Prf.

Kanomata

/Kanomatagawa /Run-off-river

960 2.00 60.25 2002 New facility 2,580.60 1 Embedded FRPM/SS 12.32 1.20~0.90 24~18

Department

Kajikawa land Kajikawa Dam and Conduit

Uchinokura 2,900 5.00 70.50 1990 New facility FRP

Address 3-13-2 Higashi-Ikebukuro, Toshima-ku, Tokyo 170-0013 improvement district /Uchikuragawa /Run-off-river

TEL・FAX Tel: 03-6810-0364 Fax: 03-3982-5101 Koyoshigawa Conduit

Nishime Town Nishime 740 0.80 116.00 1989 New facility FRP/FRPM

URL・Email http://www.nef.or.jp/ /Hiwatashigawa /Run-off-river

Table 8 Performance

Plant Specification Equipment/Facilities Specification

Max.

Max.

Max. Effective Start of New Piping length Design

Operator Plant River system Type of Discharg Diameter Thickness

Ooutput Head Operatio facility x Branches Type of

Pipe type Internal

/River name Power Generation e n /Renewal Piping

(kW) (m /s)

3

(m) (m) Branches Pressure

(kgf/cm2) (m) (mm)

/Renewal /Upgrade

Hokkaido Hoyaishikawa Conduit

Hoya Ishikawa 170 0.18 134.44 1987 Upgrade 178.30 1 Exposed FRP 21.90 0.30 9

EPCo /Hoyaishikawa /Pondage

Tohoku Tsutsumigawa Conduit

Daifudo 1,500 2.33 82.10 1986 Upgrade 96.20 1 Exposed FRP 14.40 1.10 20.0~18.0

EPCo /Tsutsumigawa /Run-off-river

Tohoku Abukumagawa Conduit New

Ozaso 11,400 6.50 215.20 1991 480.00 1 Exposed FRP 17.40 1.65~1.50 28.0~23.5

EPCo /Matsukawa /Run-off-river facility

Tohoku Tsutsumigawa Conduit

Yabetsu 2,100 2.68 95.24 1992 Upgrade 85.00 1 Exposed FRP 8.20 1.00 19~18

EPCo /Tsutsumigawa /Run-off-river

Tokyo Fujigawa Conduit

Tsugane 700 0.70 133.37 1986 Upgrade 221.00 1 Exposed FRP 15.60 0.80 14.5~6.0

EPCo /Daimongawa /Run-off-river

Tokyo Nakagawa Conduit

Kurokawa 920 3.62 30.30 1987 Upgrade 55.00 1 Exposed FRP 1.95 1.35 14

EPCo /Kurokawa /Run-off-river

Chubu Kisogawa Conduit New

Okumino 420 0.70 83.83 1995 84.47 1 Embedded FRPM 93.37 0.60~0.594 12~8

EPCo /Neohigashitanigawa /Run-off-river facility

36.12 1 Exposed FRPM 53.25 0.60 12

Chubu Oigawa Dam New 2.53 1 Exposed FRP 53.25 0.60 8

Higashigouchi 170 0.55 40.62 2001

EPCo /Oigawa /Run-off-river facility 39.61 1 Embedded FRPM 53.25 0.60 12

7.54 1 Embedded FRP 53.25 0.60 6

Kansai Jintsugawa Dam and Conduit New

Mannami 12,400 5.00 303.60 1987 167.88 1 Exposed FRP 7.70 1.50 22~27

EPCo /Mannamigawa /Run-off-river facility

Chugoku Hiigawa Conduit New

Kawate 900 3.00 40.80 1995 36.00 1 Exposed FRPM 45.14 1.35 27

EPCo /Fukanogawa /Run-off-river facility

Shikoku Niyodogawa Conduit

Kurokawa No. 5 5,300 3.50 192.92 1993 Upgrade 39.00 1 Embedded FRPM 0.70

EPCo /Kurokawa /Run-off-river

Dokawa River /

Shikoku Tsuga Dam New

Yusuharagawa 550 1.91 37.10 1998 120.60 1 Embedded FRPM 5.00 1.20 24

EPCo (No. 3 extension) /Run-off-river facility

River

Tsutsumigawa Conduit New

Toseikogyo Komagome 4,000 8.15 60.60 1989 84.00 1 Exposed FRP 6.85 1.80 23

/Komagomegawa /Run-off-river facility

Nasogawa Conduit 91.60 1 Exposed FRP 14.96 1.65 18.5~21.0

Toseikogyo Shin-kotaki 4,100 5.00 100.80 1996 Renewal

/Nasogawa /Run-off-river ### 1 Embedded FRPM 14.96 1.65 33

Aganogawa Conduit

Toseikogyo Shin-koara 11,000 17.00 77.10 2003 Renewal 112.00 1 Embedded FRPM 10.50 2.60 52

/Sanekawa /Run-off-river

Iwate Kitakamigawa Dam New

Irihata 2,100 3.50 74.16 1990 262.52 1 Exposed FRP 8.12 1.50 16

Pref. /Getogawa /Reservoir facility

Iwate Kitakamigawa Conduit New 163.71 1 Exposed FRPM 14.70 1.35 27

Matsukawa 4,600 3.00 188.00 1996

Pref. /Matsukawa /Run-off-river facility ### 1 Embedded FRPM 14.70 1.35 27

Iwate Kitakamigawa Conduit New

Kashiwadai 2,600 7.60 42.30 2002 725.00 1 Embedded FRPM 5.10 1.80 36

Pref. /Matsukawa /Run-off-river facility

Akita Yoneshirogawa Conduit New

Hachimantai No. 2 1,500 1.80 99.70 1985 881.34 1 Embedded FRPM 13.00 1.20 24

Pref. /Kumazawagawa /Run-off-river facility

Akita Yoneshirogawa Dam New

Yamase 2,100 5.50 48.85 1991 100.69 1 Embedded FRPM 8.40 2.00 40

Pref. /Iwasegawa /Reservoir facility

Hukushima Abukumagawa Conduit New

Niwasaka 1,500 1.60 111.20 2001 349.00 1 Embedded FRPM 27.00 1.00 25

Pref. /Amatogawa /Run-off-river facility

Onagatani No. 5 ### 1 Embedded FRPM 7.80 1.10 22

Toyama Jintsugawa Conduit New

(Idagawa, 1,200 2.60 62.90 1991

Pref. /Idagawa /Run-off-river facility 453.10 1 Embedded FRPM 5.79 0.80~0.70 16~14

Sodenotani)

Kanazawa Saikawa Conduit New

Shin-Uchikawa No. 2 3,000 3.70 100.60 1989 114.00 1 Exposed FRP 1.35 20

City /Uchikawa /Run-off-river facility

Nagano Tenryugawa Conduit New

Oshika No. 2 5,000 1.70 356.20 1999 485.76 1 Embedded FRPM 10.19 1.10 22

Pref. /Shiogawa /Run-off-river facility

Tottori Sendaigawa Conduit New ### 1 Embedded FRP 28.00 0.60 6~16

Kaji 1,100 0.55 242.10 1996

Pref. /Kajigawa /Run-off-river facility 539.61 1 Embedded FRPM 28.00 0.60 12

Recirculating

Okinawa sea water New

EPDC - pumped storage 30,000 26.00 136.00 1999 300.00 1 Embedded FRP・FRPM 22.47 2.40 51~35

pumped-storage facility

type

Gojo land Shinanogawa Conduit New

Gojo 1,100 5.44 24.01 2000 671.05 1 Embedded FRPM 1.80

improvement district /Sagurigawa /Run-off-river facility

Kurokawa Village, Tainaigawa Conduit New

Kanomata 960 2.00 60.25 2002 ### 1 Embedded FRPM/SS 12.32 1.20~0.90 24~18

Niigata Prf. /Kanomatagawa /Run-off-river facility

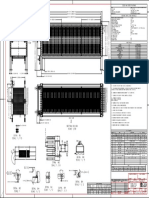

Table 1 Classification of FRP(M) pipes

Classification FRP pipe FRPM pipe

by structure (Fiberglass Reinforced Plastic Pipe) (Fiberglass Reinforced Plastic Mortar Pipe)

Classification FW pipe CC pipe FW pipe CC pipe

by production method

※ FW:Filament Winding Mold

CC:Centrifugal Casting Mold

Outside protective layer

Protective layer Reinforcement layer (FRP layer)

Chop layer

Hoop layer

Cut layer Strength layer

Hoop layer Inside protective layer

Chop layer

Protective layer

Protective layer Outside protective layer

Chop layer Reinforcement layer (FRP layer)

Hoop layer Outside FRP layer Plastic mortar layer

Cut layer Plural layer

Plastic mortr layer Reinforcement layer (FRP layer)

Cut layer Plural layer Inside protective layer

Hoop layer Inside FRP layer

Chop layer

Protective layer

Table 2 Type of internal pressure pipes

Unit: Mpa {kgf/cm2}

Type Internal test pressure

Type-1 2.6 {27}

Type-2 2.1 {21}

Internal

pressure Type-3 1.4 {14}

pipes

Type-4 1.0 {10}

Type-5 0.5 { 5}

You might also like

- Differentiated Reading for Comprehension, Grade 2From EverandDifferentiated Reading for Comprehension, Grade 2Rating: 4 out of 5 stars4/5 (1)

- Format: Pdd-He - 01 Supply List For Heat Exchangers As Per Tema Supplier NameDocument11 pagesFormat: Pdd-He - 01 Supply List For Heat Exchangers As Per Tema Supplier NameJitendra BhatewaraNo ratings yet

- NDT SpecsDocument3 pagesNDT SpecsRam Shankar SahuNo ratings yet

- Gas Collection Unit 3 Section 1 - 1 Gas Collection Unit 3 Cross Section 3 - 3Document1 pageGas Collection Unit 3 Section 1 - 1 Gas Collection Unit 3 Cross Section 3 - 3yonie prasetyoNo ratings yet

- PlanDocument1 pagePlanmuhdmuneer09No ratings yet

- Bleach and Bromine Skid LayoutDocument1 pageBleach and Bromine Skid LayouteegNo ratings yet

- Fabrication Materials: Saudi Arabian Oil CompanyDocument8 pagesFabrication Materials: Saudi Arabian Oil CompanyD7mey XNo ratings yet

- NS2 - Common and Unit #1 Commissioning Block Diagram - Matching With Adjusted Plan - REV.1Document1 pageNS2 - Common and Unit #1 Commissioning Block Diagram - Matching With Adjusted Plan - REV.1Do Ngoc TriuNo ratings yet

- IEA Annex-2 STB2 Data Sheet About Innovative Technology 312-1Document3 pagesIEA Annex-2 STB2 Data Sheet About Innovative Technology 312-1Gertjan DuniceriNo ratings yet

- Conveyor Belts - Fire Resistant Conveyor Belting For Underground Mines and Such Other Hazardous Applications - SpecificationDocument27 pagesConveyor Belts - Fire Resistant Conveyor Belting For Underground Mines and Such Other Hazardous Applications - SpecificationARAVINDRAJ V RNo ratings yet

- Thiết Kế Kỹ Thuật: Typical Distribution BoardDocument1 pageThiết Kế Kỹ Thuật: Typical Distribution BoardAn BuiNo ratings yet

- For Construction: 1 383-L-ISO-17870-00Document3 pagesFor Construction: 1 383-L-ISO-17870-00Ranish P. KurianNo ratings yet

- 5950040-E-PME-578A DB-O-24-01 R03 (Reply)Document5 pages5950040-E-PME-578A DB-O-24-01 R03 (Reply)phyo7799No ratings yet

- Base Metal Grouping:: Welding VariablesDocument8 pagesBase Metal Grouping:: Welding VariablesVivekanandan JNo ratings yet

- Pipes Selection Chart - Modified-1Document3 pagesPipes Selection Chart - Modified-1Eslam ElsayedNo ratings yet

- 820234-05-050-A4-2 Pipeline TableDocument20 pages820234-05-050-A4-2 Pipeline Tablerantonio mz smgNo ratings yet

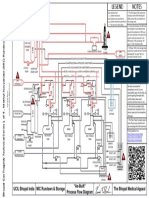

- MIC Rundown & Storage "As-Built" Process Flow Diagram The Bhopal Medical Appeal UCIL Bhopal IndiaDocument1 pageMIC Rundown & Storage "As-Built" Process Flow Diagram The Bhopal Medical Appeal UCIL Bhopal IndiapstindiaNo ratings yet

- Me-2001b (3) - 231004-Basement 2 Layout Plan Sheet BDocument1 pageMe-2001b (3) - 231004-Basement 2 Layout Plan Sheet BhumcanopNo ratings yet

- R-216G-311 - 0 Manual Valve With Limit SwitchDocument3 pagesR-216G-311 - 0 Manual Valve With Limit SwitchFahmi HaidiNo ratings yet

- SA04C2-03-WP-D-43101-01-2: Shuqaiq 3 Independent Water ProjectDocument1 pageSA04C2-03-WP-D-43101-01-2: Shuqaiq 3 Independent Water ProjectABAID ULLAHNo ratings yet

- An Overview of API 579-1/ASME FFS-1 Fitness-For-Service Assessment Standard With Applications To Case StudiesDocument57 pagesAn Overview of API 579-1/ASME FFS-1 Fitness-For-Service Assessment Standard With Applications To Case StudiesLeonardo PestanaNo ratings yet

- EagleBurgmann - ED01081 - ED4 - Table of Materials For Mechanical Seals - 02.10Document2 pagesEagleBurgmann - ED01081 - ED4 - Table of Materials For Mechanical Seals - 02.10calr207186No ratings yet

- Absensi Untuk Dosen D-III (II-A) Polbit (2020)Document75 pagesAbsensi Untuk Dosen D-III (II-A) Polbit (2020)ZipronNo ratings yet

- Asco Valves Series T298Document2 pagesAsco Valves Series T298OceanexNo ratings yet

- SA04C2-03-WP-D-42201-01-3: Shuqaiq 3 Independent Water ProjectDocument1 pageSA04C2-03-WP-D-42201-01-3: Shuqaiq 3 Independent Water ProjectABAID ULLAHNo ratings yet

- Sterling Fluid Systems: LPG Pumps - UEA List of Recommended Selling PricesDocument3 pagesSterling Fluid Systems: LPG Pumps - UEA List of Recommended Selling Pricesrebelde1986No ratings yet

- Mapping SymbolsDocument35 pagesMapping SymbolsSparkPar0% (1)

- Sizing CableDocument73 pagesSizing CableM Luqman HakimNo ratings yet

- Reference List ACHE PDFDocument8 pagesReference List ACHE PDFMarakanaMaheshNo ratings yet

- Slab Design SheetDocument8 pagesSlab Design SheetMano CivilengineerNo ratings yet

- Comments - Bulk Material Inspection For VRF and Electrical - Transcom - 21.09.01Document2 pagesComments - Bulk Material Inspection For VRF and Electrical - Transcom - 21.09.01Pritam MitraNo ratings yet

- JB MC STR CA 203 r0Document1 pageJB MC STR CA 203 r0Fatih ArıkanNo ratings yet

- Ilovepdf MergedDocument21 pagesIlovepdf MergedNITHIN MATHEWNo ratings yet

- Innovance H2U Data SheetDocument2 pagesInnovance H2U Data SheetAmr samir ShahinNo ratings yet

- Hall LevelDocument1 pageHall LevelBN YADAVNo ratings yet

- 8-1282-11 Pipe Class HF 4 PDFDocument4 pages8-1282-11 Pipe Class HF 4 PDFJesus MendezNo ratings yet

- BB BB: Code and SpecificationsDocument1 pageBB BB: Code and SpecificationsandersonNo ratings yet

- 011 012 MergedDocument12 pages011 012 MergedAli HusseinNo ratings yet

- 01 25284124-8230-26-000-0003 REV.02 Piping List EPCM6 PIPE RACKDocument1 page01 25284124-8230-26-000-0003 REV.02 Piping List EPCM6 PIPE RACKRajeev KumarNo ratings yet

- Alfa NK (C)Document4 pagesAlfa NK (C)ppglNo ratings yet

- 100 PAT A4AC Model PDFDocument1 page100 PAT A4AC Model PDFAshish ShahNo ratings yet

- Solarizer Elite BrochureDocument2 pagesSolarizer Elite BrochureEmmvee SolarNo ratings yet

- SPEC SHEET 005 AeroGlass LensDocument1 pageSPEC SHEET 005 AeroGlass LensMarco GalindoNo ratings yet

- Polypropylene 4720WZ: DescriptionDocument1 pagePolypropylene 4720WZ: DescriptionChivuAlexandruNo ratings yet

- Bongyas Sheet 13Document1 pageBongyas Sheet 13Odinde Dabon EncaroNo ratings yet

- In0126 GB PF 2008 05 BDocument2 pagesIn0126 GB PF 2008 05 BCuong Hoang100% (1)

- Johnson Matthey CSF Line Expansion: Project Scope MatrixDocument5 pagesJohnson Matthey CSF Line Expansion: Project Scope MatrixchanjunkaiNo ratings yet

- Elec 3Document1 pageElec 3Shiela Tala-oc Sapois-AndoNo ratings yet

- CX330 Hyd Scematic 9-94040 - NA - DecrDocument1 pageCX330 Hyd Scematic 9-94040 - NA - Decrthebrowns5165No ratings yet

- The Piping GuideDocument214 pagesThe Piping GuideMohamed RjebNo ratings yet

- CO2 Pre-Test & Functional Test SheetDocument10 pagesCO2 Pre-Test & Functional Test SheetChowKC03No ratings yet

- Panel PETROTECH Modificado - SAL 14Document1 pagePanel PETROTECH Modificado - SAL 14Alvaro Reimar Ferrufino MartinezNo ratings yet

- Mitsubishi VRF Interior Mascat Tavan Pefy P Vma E3Document3 pagesMitsubishi VRF Interior Mascat Tavan Pefy P Vma E3Ilie-valentinGanciarovNo ratings yet

- B31.3 Process Piping Course - 02 Metallic Pipe & Fitting SelectionDocument44 pagesB31.3 Process Piping Course - 02 Metallic Pipe & Fitting SelectionRyan Goh Chuang Hong0% (1)

- ManifoldsDocument1 pageManifoldsIshan RanganathNo ratings yet

- Hot Water Circulating Pump Cal2Document2 pagesHot Water Circulating Pump Cal2Nghia100% (1)

- Cable MT NFC 33 226 18 30 36 KV PDFDocument2 pagesCable MT NFC 33 226 18 30 36 KV PDFSourav BhattacharyaNo ratings yet

- Nasm8846 Rev 1Document10 pagesNasm8846 Rev 1Ravindra ErabattiNo ratings yet

- Webinar Registration Success - ZoomDocument2 pagesWebinar Registration Success - ZoomAbdul wahid ButtNo ratings yet

- Muhammad Ali CVDocument3 pagesMuhammad Ali CVAbdul wahid ButtNo ratings yet

- Implications of Biofouling On Cross Flow Turbine PerformanceDocument13 pagesImplications of Biofouling On Cross Flow Turbine PerformanceAbdul wahid ButtNo ratings yet

- FEM IntroDocument17 pagesFEM IntroAbdul wahid ButtNo ratings yet

- Sheil Et Al 2021 Pipe Jacking ForcesDocument37 pagesSheil Et Al 2021 Pipe Jacking ForcesAbdul wahid ButtNo ratings yet

- Mesh Convergence ExercisesDocument10 pagesMesh Convergence ExercisesAbdul wahid ButtNo ratings yet

- Mesh Convergence StudyDocument8 pagesMesh Convergence StudyAbdul wahid ButtNo ratings yet

- Mat Lab Simulation Procedure For DesignDocument15 pagesMat Lab Simulation Procedure For DesignAbdul wahid ButtNo ratings yet

- Article1380536646 - Taghvaei Et AlDocument9 pagesArticle1380536646 - Taghvaei Et AlAbdul wahid ButtNo ratings yet

- Akbar DistyDocument16 pagesAkbar DistyAbdul wahid ButtNo ratings yet

- Tables For ComparisonDocument2 pagesTables For ComparisonAbdul wahid ButtNo ratings yet

- Ufgs 41 22 13.15Document60 pagesUfgs 41 22 13.15Abdul wahid ButtNo ratings yet

- A Review On Analysis Monitoring and Detection of Weld Defect Products IJERTV4IS110556 2Document4 pagesA Review On Analysis Monitoring and Detection of Weld Defect Products IJERTV4IS110556 2Abdul wahid ButtNo ratings yet

- The Knowledge Stream: Research UpdateDocument2 pagesThe Knowledge Stream: Research UpdateAbdul wahid ButtNo ratings yet

- Penstock Design (Chapree Charkhil)Document13 pagesPenstock Design (Chapree Charkhil)Abdul wahid ButtNo ratings yet

- Turbine Testing Laboratory and Its Role in Hydropower DevelopmentDocument6 pagesTurbine Testing Laboratory and Its Role in Hydropower DevelopmentAbdul wahid ButtNo ratings yet

- Demographic Data: ST ND RD TH THDocument2 pagesDemographic Data: ST ND RD TH THAbdul wahid ButtNo ratings yet

- Suchintya Kumar Sur (Author) - A Practical Guide To Construction of Hydropower Facilities-CRC Press (2019)Document457 pagesSuchintya Kumar Sur (Author) - A Practical Guide To Construction of Hydropower Facilities-CRC Press (2019)Abdul wahid ButtNo ratings yet

- Vertical Gates Design PDF FreeDocument33 pagesVertical Gates Design PDF FreeAbdul wahid ButtNo ratings yet

- DKD-R5-1-vol 2017 (Temp) PDFDocument35 pagesDKD-R5-1-vol 2017 (Temp) PDFAbdul wahid ButtNo ratings yet

- 2019-06 Marriott Hotel Design Standards - HVACDocument39 pages2019-06 Marriott Hotel Design Standards - HVACSvetla Nikolova100% (6)

- MCWM 1 89Document51 pagesMCWM 1 89Hazzel LonzagaNo ratings yet

- Madura Coats-12th RA Bill - R1Document17 pagesMadura Coats-12th RA Bill - R1keizenbaluNo ratings yet

- Stairwell PR SyDocument21 pagesStairwell PR SySameera GamageNo ratings yet

- Pertcpm - Construction of Flood Mitigation Structure - Construction of Budiong River ControlDocument7 pagesPertcpm - Construction of Flood Mitigation Structure - Construction of Budiong River ControlMichael Jorge BernalesNo ratings yet

- Presented To The Civil Engineering Department de La Salle University - Manila First Term, A.Y. 2020 - 2021Document8 pagesPresented To The Civil Engineering Department de La Salle University - Manila First Term, A.Y. 2020 - 2021Ritik NihalaniNo ratings yet

- Maitriya Foundation Nepal: Summary of CostDocument62 pagesMaitriya Foundation Nepal: Summary of CostRoshan KejariwalNo ratings yet

- Handbook On Concrete Admixtures PDFDocument25 pagesHandbook On Concrete Admixtures PDFPrasanta ParidaNo ratings yet

- Checklist For Slab Design & DrawingDocument6 pagesChecklist For Slab Design & DrawingRupesh KhandekarNo ratings yet

- Final Project TRNSYSDocument2 pagesFinal Project TRNSYSAlex AutoconsumamosNo ratings yet

- It's in The Air ... ... Quality Does Indeed Make A Difference!Document2 pagesIt's in The Air ... ... Quality Does Indeed Make A Difference!XIN NIUNIUNo ratings yet

- Retrofitting of Reinforced Concrete Structural Elements - Recent Technologies and Future ScopeDocument15 pagesRetrofitting of Reinforced Concrete Structural Elements - Recent Technologies and Future Scope48Tathagata Koley100% (1)

- Question Paper Code:: Reg. No.Document2 pagesQuestion Paper Code:: Reg. No.raghavendran mNo ratings yet

- Design of TiesDocument6 pagesDesign of TiesNATHAN NATENo ratings yet

- Summary Doc (Issue 4)Document2 pagesSummary Doc (Issue 4)hanane sellamNo ratings yet

- KithausDocument4 pagesKithausZulaikah MontecinosNo ratings yet

- Maximum Cover Heights For RCP FDOTDocument5 pagesMaximum Cover Heights For RCP FDOTgemotorresNo ratings yet

- Investigating The Application of Waste Plastic Bottle As A Construction Material-A ReviewDocument14 pagesInvestigating The Application of Waste Plastic Bottle As A Construction Material-A ReviewYoi HNo ratings yet

- DGS-2010-001 Design BasisDocument19 pagesDGS-2010-001 Design BasisJose ManjooranNo ratings yet

- Channel and Bolt Fixings: For The Construction IndustryDocument20 pagesChannel and Bolt Fixings: For The Construction Industrybelu diazNo ratings yet

- Din en 13084-7:2006-06 (E)Document1 pageDin en 13084-7:2006-06 (E)Romeo Di SarioNo ratings yet

- High Chrome Steel - PresentationDocument22 pagesHigh Chrome Steel - PresentationNargis KhanNo ratings yet

- Solar Thermal Tube Collectors Vitosol 300-Tm: Industrial Systems Refrigeration SystemsDocument4 pagesSolar Thermal Tube Collectors Vitosol 300-Tm: Industrial Systems Refrigeration SystemssonysrgNo ratings yet

- Introduction To ConcreteDocument16 pagesIntroduction To ConcreteShehzad BachaniNo ratings yet

- Bahir Dar University BIT: Faculity of Mechanical and Industrial EngineeringDocument13 pagesBahir Dar University BIT: Faculity of Mechanical and Industrial Engineeringfraol girmaNo ratings yet

- LCP MULTIDECK SpecificationDocument2 pagesLCP MULTIDECK SpecificationGarfieldNo ratings yet

- EstimateDocument10 pagesEstimatekennysawegNo ratings yet

- 1 Design Code: Loading Considerations SR No DescriptionDocument4 pages1 Design Code: Loading Considerations SR No DescriptionVishal TiwariNo ratings yet

- Wallcare CatalogueDocument2 pagesWallcare Catalogueali razaNo ratings yet

- Stone CladdingDocument10 pagesStone CladdingNavya BhardwajNo ratings yet