Professional Documents

Culture Documents

Innovance H2U Data Sheet

Uploaded by

Amr samir ShahinCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Innovance H2U Data Sheet

Uploaded by

Amr samir ShahinCopyright:

Available Formats

1 2 3 4

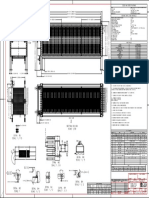

H2U Series PLC User Manual ◆ The specification and installation requirement of external cables must Environment Parameters

Use Transportation Storage ■ Product Structure

comply with the local safety regulations and related IEC standards. The Type Parameter Unit 1 2 3 4

Code: 19010034 V2.0 1. Foldaway

size in the table below is for recommendation. 3.5

Shift mm - - 2. Power supply, auxiliary

Copper Wire Cross-section Area Recommended Code Sine (5–9 Hz)

power supply and detachable

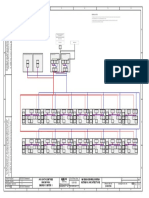

AC power wire 1.0–2.0 mm² AWG 12, 18 vibration 10 S/S 0V 0V X00 X02 X04 X06 X10 X12 X14 X16 X20 X22 X24 X26 X30 X32 X34 X36

Acceleration m/s2 - - terminals for signal input

L N 24V 24V X01 X03 X05 X07 X11 X13 X15 X17 X21 X23 X25 X27 X31 X33 X35 X37

Earthing wire 2.0 mm² AWG12 (9–150 Hz) IN

00 01 02 03 04 05 06 07 20 21 22 23 24 25 26 27

3. Input status indicators

Mechanical stres

10 11 12 13 14 15 16 17 30 31 32 33 34 35 36 37

Input signal wire 0.8–1.0 mm² AWG18, 20 Acceleration m2/s3 5–20 Hz: 1.92 dB

- - RUN

◆ The terminal of wire must be insulated according to the local safety Random spectral density (dB/Oct) 20–200 Hz: -3 dB 4. Running status indicators

ERR

vibration Frequency range Hz - 5–200 - H 2U-3232MR-XP

Thank you for purchasing the H2U series programmable logic controller regulations. Ensure that the insulation distance shall not be reduced RELAY UNIT OUT00 01 02 03 04 05 06 07 20 21 22 23 24 25 26 27 PWR: Power indicator; RUN:

when the wire is connected to the terminals. Otherwise, electric shock or Vibration direction - - X/Y/Z - 10 11 12 13 14 15 16 17 30 31 32 33 34 35 36 37

Running indicator: Flashing

(PLC) independently developed by Inovance Control Technology Co., Ltd. Y00 Y02 Y04 Y06 Y10 Y12 Y14 Y16 Y20 Y22 Y24 Y26 Y30 Y32 Y34 Y36 COM6

COM1 Y01 Y03 COM2 Y05 Y07 COM3 Y11 Y13 COM4 Y15 Y17 COM5 Y21 Y23 Y25 Y27 Y31 Y33 Y35 Y37

damage to circuit may result. Type - - Half-sine - indicates PLC normal running);

Read the manual carefully to be familiar with the product features and be Shock

Acceleration m/s2 - 180 - B AT: B a t t e r y l o w - v o l t a g e

able to use the product safely. ■ During Running and Maintenance Dip Dip height m - 1 -

This manual describes the specification, features and usage of the H2U 10 9 8 7 6 5 indicator; ERR: Fault indicator

DANGER

series PLC. For the developing environment and design method of user Mechanical Design 5. Mounting holes x 4; 6. Cover of extension module interface (R: Relay;

programs, see the Autoshop On-line Help of Inovance. ◆ Connection or removal of the communication cable, cables of the T: Transistor) 7. DIN rail slot dampers x 2; 8. Output status indicator LEDs;

extension card and cables of the control unit, or other servicing can be W

The H2U series PLC has the following features: D 9. Detachable terminals for signal output; 10. Cover of user program

performed only after power-off. Failure to comply may result in damage to A

downloading port (COM0)

◆ The built-in program memory space reaches up to 16K steps. the equipment or malfunction. 11 12 13 14 15 16

◆ The internal large-capacity power supply can directly apply power to ◆ Operations such as online modification, forcible output, RUN and STOP

sensors, HMI, and external auxiliary relays. can be performed only after you read the manual and guarantee safety. B H 485+ 485-485+ 485-

COM2 COM1

◆ It provides multiple high-speed I/O terminals, and has rich motion and

S/S 0V 0V X00 X02 X04 X06 X10 X12 X14 X16 X20 X22 X24 X26 X30 X32 X34 X36

L N 24V 24V X01 X03 X05 X07 X11 X13 X15 X17 X21 X23 X25 X27 X31 X33 X35 X37

positioning control functions. WARNING +

BAT

-

IN

00 01 02 03 04 05 06 07 20 21 22 23 24 25 26 27

10 11 12 13 14 15 16 17 30 31 32 33 34 35 36 37

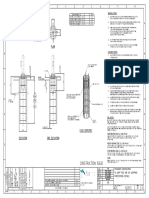

Mounting

◆ It has four independent communication ports and supports various ◆ Installation or removal of the extension card can be performed only after Hole Ф5 × 4

RUN

communication protocols including Modbus, facilitating system power-off. OUT00 01 02 03 04 05 06 07

ERR

20 21 22 23 24 25 26 27

integration. ◆ Make sure to replace button cell after power-off. If replacement at power- Model Total I/Os

Mounting Dimension Dimension Y00 Y02 Y04 Y06 Y10 Y12 Y14 Y16 Y20 Y22 Y24 Y26 Y30

10 11 12 13 14 15 16 17 30 31 32 33 34 35 36 37

Y32 Y34 Y36 COM6

W × H × D (mm)

COM1 Y01 Y03 COM2 Y05 Y07 COM3 Y11 Y13 COM4 Y15 Y17 COM5 Y21 Y23 Y25 Y27 Y31 Y33 Y35 Y37

on is required, only authorized electrical technician is allowed to complete A (mm) B (mm)

COM0

◆ The comprehensive encryption function protects intellectual property

replacement within 30 seconds. Failure to comply may result in data loss. H2U-1010M_ 20 120 80 130 x 90 x 88

rights of the user.

◆ Treat scrapped PLC as ordinary industrial waste. H2U-1616M_ 32 160 80 170 x 90 x 88 17 18 19

◆ It comes with fast execution speed and supports up to 128

H2U-2416M_ 40 160 80 170 x 90 x 88 11. Special function adapter board knock-down hole (It need be cut off before

subprograms and 21 interrupt subprograms. Each subprogram has the Product Information H2U-3624M_ 60 210 80 220 x 90 x 88 installation of the board.); 12. Wiring terminal for RS485 communication port

parameter call and independent password security functions.

■ Designation Rules H2U-3232M_ 64 210 80 220 x 90 x 88 (COM1/COM2); 13. Special function extension card and special function

Safety Information and Precautions H2u-3232MRAX-XP H2U-4040M_ 80 275 80 285 x 90 x 88 adapter board interface; 14. System program downloading port (Unauthorized

H2U-6464M_ 128 340 80 350 x 90 x 88 operation is prevented here.); 15. Battery socket (BAT) (Neber reverse the

■ In Design 1 2 3 4 5 6 7 8 9

No. Name Description ■ Requirements on Installation Position polarity.); 16. Coin battery (provided by Inovance); 17. Special function

DANGER extension card and special function adapter board fixed bolts; 18. RUN/STOP

1 Product information H: Inovance controller 1) Do not remove the paper tape that prevents foreign objects from dropping

2 Series No. 2U: Second generation of controller into the unit during installation. Once installation is completed, remove switch; 19. User program downloading port (COM0)

◆ Provide a safety circuit outside the PLC in the application so that the

control system can still work safely even if external power failure or 3 Input points 32: 32 inputs the paper tape before power-on so as to prevent overheating. ■ Communication Interface Definition

PLC fault occurs. 4 Output points 32: 32 outputs 2) To prevent overheating inside the PLC, wall-mount PLC with 300 mm The H2U series PLC has two communication ports and H2U-XP has four

Module M: Main module of general-purpose controller, P: Positioning clearance at top and bottom for heat dissipation, as shown in Figure 2.

◆ In the external circuit of the PLC, an emergency stop circuit, a 5 communication ports. The COM0 hardware is standard RS485 and RS422,

classification controller, N: Network controller, E: Extension module

protection circuit, an interlock circuit of forward/reverse rotation 3) Leave 50 mm or more space between PLC and other devices or determined by jumper JP0. If JP0 is connected, RS422 is selected. If JP0

6 Output type R: Relay, T: Transistor

operation, and position upper/lower limit interlock circuit are necessary structures. Keep PLC far away from high-voltage cables and devices, is disconnected, the RS422 and RS485 are compatible. COM0 hardware

A: 220 VAC (220 VAC by default if null), B: 110 VAC, C: 24

to prevent equipment damage 7 Power supply type and power devices. of H2U-XP is standard RS422, which does not require jumper connection.

VAC output, D: 24 VDC

◆ The PLC is designed for indoor electric environment and is installed in ■ Mounting Methods Otherwise, the PLC cannot work normally.

8 Special function High-speed input/output, analog function

an overvoltage category 2 environment. A lightning protection device 1) Mounting or removing PLC The terminal interface is mini-DIN8 socket.

9 XP auxiliary version -

must be installed for the power supply system, so that lightening

Figure 1 Mount or remove PLC 4 3 2 1 5 4 3 2 1

overvoltage is not applied on terminals of the PLC, avoiding damage to ◆ Basic Parameters ① ②

the equipment. I/O Features (Input Voltage: 24 VDC) ③④ ⑤

1. Fix the DIN rail onto the

Total Order

■ During Installation PLC Model

I/Os

Total Hi-Speed Total High-Speed Output

Code

mounting plate ⑥⑦ ⑧

485+ 485- 485+ 485- GND

485+ 485- 485+ 485-

Inputs Inputs Outputs Outputs Type 2. Buckle the catching groove COM2 COM1 COM2 COM1

WARNING H2U-1010MR-XP 2 x 60 kHz - Relay 01022078 of PLC base into the DIN rail. Figure 3 User program downloading port Figure 4 RS485 communication port Figure 5 RS485 communication port

20 10 10

◆ Install the PLC in places free from dust, oil smoke, conducting dust, H2U-1010MT-XP 6 x 10 kHz 3 x 100 kHz Transistor 01022079 Note: Figure 4 is the communication port of H2U-XP. Figure 5 is the communication port

corrosive gas, combustible gas, high temperature, condensation, wind H2U-1616MR-XP - Relay 01022040 of H2U-1010M_XP. COM2 is the COM0 of H2U.

32 16 6 x 60 kHz 16

& rain, vibration and shock. In addition, electric shock, fire, malfunction H2U-1616MT-XP 3 x 100 kHz Transistor 01022041

may also cause damage and deterioration to the equipment. PLC can be connected to PC or HMI through COM0 in the following ways:

H2U-2416MR-XP 2 x 60 kHz - Relay 01022048

◆ During screw hole processing and wiring, ensure that no metal filing H2U-2416MT-XP 40 24 4 x 10 kHz 16 2 x 100 kHz 01022049 2. Lift the PLC 1) (JP0 connected): PLC side is RS422 and PC side is USB. PC is

Transistor Mounting plate

and cable end fall into the ventilation hole of the controller, because H2U-2416MTQ-F01 6 x 100 kHz 5 x 100 kHz 01028063 3. Press PLC vertically

toward you. connected to the PLC COM0 port via the dedicated USB downloading

1. Pull down the tongue

such stuff may cause a fire, fault, or malfunction. H2U-3624MR-XP 2 x 60 kHz - Relay 01022046

4. Ensure that the PLC down to the DIN rail. shape card to make PLC cable (see Figure 3). (The H2U-XP does not require JP0 connection.)

60 36 24 tongue shaped card is

H2U-3624MT-XP 4 x 10 kHz 2 x 100 kHz Transistor 01022047 away from the DIN rail. 2) (JP0 connected): PLC side is RS422 and the PC side is RS232. PC is

◆ After installation of the newly purchased PLC is complete, ensure that locked into the DIN rail.

there is no foreign stuff on the surface of ventilation. Failure to comply H2U-3232MR-XP - Relay 01022050 connected to the PLC COM0 port via the dedicated serial port download

6 x 60 kHz Note: Fix PLC at both ends with DIN rail slot dampers to prevent it from

may result in poor cooling effect during running, which may lead to a H2U-3232MT-XP

64 32 32

3 x 100 kHz 01022045 cable (see Figure 3). (The H2U-XP does not require JP0 connection.)

H2U-3232MTQ 6 x 100 kHz 5 x 100 kHz Transistor 01022015 sliding left and right.

fire, fault or malfunction. 3) (JP0 disconnected): PLC side is RS485 and PC side is RS485. They are

◆ The installation and wiring must be secure and reliable. Poor contact H2U-3232MTP - 8 x 100 kHz 01022061 2) Mounting and fixing PLC with screws (wall-mounting mode) connected through the terminal as shown in Figure 4. The connecting

H2U-4040MR-XP - Relay 01022042 In applications with big impct, mount and fix PLC with four M4 screws. cable is determined by the user.

may cause malfunction. 80 40 6 x 60 kHz 40

H2U-4040MT-XP 3 x 100 kHz Transistor 01022062

■ At Wiring Figure 2 Mount and fix PLC with four M4 screws COM1/COM2 hardware is standard RS485 and is interface terminal. For

H2U-6464MR-XP - Relay 01022043

128 64 6 x 60 kHz 64 definition of COM1/COM2 , see Figure 4. They are connected to other devices

H2U-6464MT-XP 3 x 100 kHz Transistor 01022044

DANGER via on-site wiring by the user. Both support the half-duplex communication

◆ Ensure that all power supplies are cut off before installation or wiring. Note: Total inputs include hi-speed inputs. High-speed input terminals can be mode only. COM3 of H2U-XP can be available through extension card.

◆ During screw hole processing and wiring, ensure that no metal filings used for common inputs. Total frequency of H2U-XP high-speed inputs cannot

Pin No. Signal Description

Pin No. Signal Description

or cable end drops into ventilation holes of the controller. Failure to exceed 70 kHz. Total frequency of H2U-3232MTQ and H2U-2416MTQ high-

Provide power supply +5 V

comply may result in a fire, fault or malfunction. speed inputs cannot exceed 600 kHz. Total frequency of high-speed inputs of to external devices.

1 RXD- Receive negative data. 5 +5V

other H2U models cannot exceed 100 kHz. It is the same with the

◆ Perform wiring or plug/remove the cable connector only after power-off. internal logic +5 V.

Failure to comply may result in electric shock or damage to the circuit. ■ General Specifications

Communication direction

2 RXD+ Receive positive data. 6 CCS

Environment Parameters control cable

WARNING Use Transportation Storage M4 screws

Type Parameter Unit Mounting plate Send positive data to

Must be grounded.

◆ Use shielded cables for high-frequency signal input/output in Ambient Low temperature °C -5 -40 -40 TXD+/ external devices.

Climate condition

3 GND No electrical connections for 7

applications with severe interference to enhance anti-interference RXD+ If it is RS485, it can receive

temperature High temperature °C 55 70 70 9 and 10

capacity of the system. 95 95

Electrical Design positive data.

Humidity Relative humidity % - Send negative data to

◆ Suitable earthing connection shall be provided by the end system. The (30 ± 2 °C) ( 40 ± 2 °C) The following figures show the I/O terminals of the main H2U series PLC unit. TXD-/ external devices.

4 8 NC Non-pin

earth wire must be connected only to the earthing point on terminal RXD- If it is RS485, it can receive

Low pressure kPa 70 70 70 The H2U series PLC has different output types, relay and transistor, but has negative data (H2U).

Air pressure

which is marked with the earth symbol. The earth must be over 2 mm². High pressure kPa 106 106 106 the same terminal configuration.

5 6 7 8

■ Input Specifications

The internal signal circuit composition and external wiring mode of the H2U

The following figure shows the internal

equivalent circuit of PLC in the relay

The following figure shows the

internal equivalent circuit of PLC in

■ Terminal Block Definition Programming

◆◆ Terminal block definition of H2U-1010MR-XP and H2U-1010MT-XP Description of functions of soft components

Series PLC are desribed here. The terminal names in the wiring example vary output mode. The output terminals are the transistor output mode.The output

When using H2U-1010MT-XP, Y0,

with the PLC models. divided into several groups, and the terminals are divided into several 0V S/S X1 X3 X5 X7 X11 [M500 to [M1024 to M8000 to

Y1 and Y2 require external power

groups are electrically isolated. The groups, and the groups are electrically Auxiliary M0 to M499, 500 points M1023], M3071], M8255,

Item Hi-speed Inputs X0-X5 General Inputs

L N 24V X0 X2 X4 X6 X10 supply. The user can connect 24VDC Relay (M) (general use) (Note 1) 524 points 256 points

output contacts of different groups are isolated. The transistor output can be 2048 points

Sink/Source mode (24 V ± 20%) power supply to (storing) (Note 2) (storing) (Note 3) (special use)

connected with different power circuits. used for 24 VDC load circuit only.

Y11 terminals V+ and V-. Terminal V- has

Signal input mode It is sink input when the terminal S/S is shorted to 24V. It is V+ Y0 Y2 Y3 Y5 Y6 Y10

S0 to S499, 500 points [S900 to S999],

source input when the terminal s/s is shorted to COM. Figure 8 Internal equivalent circuit of Figure 9 Internal equivalent circuit of [S500 to S899], 400 points

been shorted to COM0 internally. State (S) (Note 1),

(retentive at power-down) (Note 2) 100

V- COM0 Y1 COM1 Y4 COM2 Y7 COM3 points

Detection voltage 24 VDC PLC in the relay output mode PLC in the transistor output mode S0-S9 (initialization) (alarm) (Note 2)

Electrical Input resistance 3.3 kΩ 4.3 kΩ ◆◆ Terminal block definition of H2U-1616MR and H2U-1616MT T0 to T199, 200 points,100 [T246 to T249], [T250 to T255],

Timer (T) ms; Subprogram: T192 to T200

parameters Input ON

24 VDC power Y0

Output group 0 to T245,

Input current > 4.5 mA. Input current > 3.5 mA. Internal logic circuit COM0

Internal logic circuit

5 VDC power Y0

Output group 0 46 points,10 ms 4 points, 1 ms 6 points,100 ms

power supply

power supply COM0 S/S 0V 0V X0 X2 X4 X6 X10 X12 X14 X16 T199 (Note 3) (Note 3)

Input OFF Input current < 1.5 mA Input current < 1.5 mA. Y1

Output group 1 Y1

COM1

· Output group 1 16-bit Up C0 to C99, 100 points (general use) [C100 to C199], 100 points

X0 to X7 has digital filter function. The filter time should be · COM1

L N S/S 24V 24V X1 X3 X5 X7 X11 X13 X15 X17 Counter (Note 1)

Digital filter ·

Logic processing

·

Logic processing

· ·

Filter 0-60 msec. ·

·

· ·

(C) (storing), (Note 2)

Output drive circuit

Y4 · ·

circuit

circuit

function

Output drive circuit

Y4

Except X0 to X7, the other I/O terminals are hardware filter. 32 bit high-speed counting reversible,

Hardware filter Y0 Y1 Y2 Y4 Y6 Y10 Y12 Y14 Y16 32 bit reversible

The filter time is about 10 msec. Y5

Output group 3

Y5

Max.6 points

X0 to X5 can realize functions such as high-speed counting, Y6 Y6 Output group 3 COM0 COM1 COM2 Y3 COM3 Y5 COM4 Y7 COM5 Y11 Y13 COM6 Y15 Y17 [C220 to

interrupt and pluse capture. 32-bit C200 to [C235 to C245], [C246 to C250], [C251 to C255],

Maximum frequency of X0 and X1 is 100 kHz. (Maximum Counter C219, C234],

single-phase single-phase

Y7 Y7

frequency of H2U-XP is 60 kHz.)

COM3

·

COM3

·

◆◆ Terminal block definition of H2U-2416MR and H2U-2416MT (C) 20 points 15 points unidirectional bidirectional dual-phase

Hi-speed function Maximum frequency of X2 to X5 is 10 kHz (models of 40/60 ·

·

·

· Internal equivalent circuit of PLC

·

·

·

· (general use) (retentive at counting input counting input counting input

I/O terminals). Internal equivalent circuit of PLC · · S/S X1 X3 X5 X7 X11 X13 X15 X17 X21 X23 X25 (Note 1) power-down) (Note 2)

X27 (Note 2) (Note 2)

Maximum frequency of X2 to X5 is 100 kHz (models of (Note 2)

32/64/80/128 I/O terminals). (Maximum frequency of H2U-XP

For the inductive load in AC circuit, you need add an RC component instead, L N X0 X2 X4 X6 X10 X12 X14 X16 X20 X22 X24 X26 [D200 to

is 60 kHz.) and for the inductive load in DC circuit, you need add a freewheeling diode, as [D8000 to

Data D0 to D199, D511], [D512 to D7999], V0 to V7, Z0 to

Common connection terminal Only a common port S/S shown in the following figure. COM Y0 Y1 Y2 Y4 Y6 Y10 Y12 Y14 Y16

200 points

register (general use) 312 points 7488 points D8255], 256 Z7, 16 points

Figure 10 Inductive load absorption circuit D, V, Z (Note 2) (storing) (Note 3) points (special (indexing)

S/S connecting to 24V+ or COM determines the Sink or Source input mode. 24V COM0 COM1 COM2 Y3 COM3 Y5 Y7 COM4 Y11 Y13 COM5 Y15 Y17

(storing) use)

The connecting mode is effective to all input points of the PLC. 24V+ Y1 24V- (Note 2)

to N7, 8 P0 to P127, I00* to I50*, 6 I6** to 8**, 3 I010 to I060, 6

■ Output Specifications

Inductive load

◆◆ Terminal block definition of H2U-2416MTQ-F01 Nesting N0 128 points points (input points (timer points (counting

points (main

pointer control) (jump interrupt interrupt interrupt

The H2U series PLC has relay output and transistor output. Their parameters 24V+ Fly-wheel diode 1N4004 24V- S/S 0V 0V X0 X2 X4 X6 X10 X12 X14 X16 X20 X22 X24 X26

subprogram) pointers) pointers) pointers)

are quite differently. Please select the correct output type so as to avoid Y10

Inductive load L N 24V 24V X1 X3 X5 X7 X11 X13 X15 X17 X21 X23 X25 X27 32 bits (-2,147,483,648 to

misuse. Failure to comply may result in damage to the PLC. K (Decimal) 16 bits (-32,768 to 32,767) 2,147,483,647)

The current of transistor output terminals must be less than the allowable Fly-wheel diode 1N4004 Y0 Y2 Y3 Y4 Y5 Y6 COM5 Y11 Y13 Y14 Y16 Constants H (HEX) 16 bits (0 to FFFFH) 32 bits (0 to FFFFFFFFH)

AC-L

maximum current. If the output current of multiple transistor terminals is greater

AC- N

E (floating 32 bits (1175 x 10-41 to 3402 x

Y3 -

Inductive load

COM0 Y1 COM1 COM2 COM3 COM4 Y7 Y10 Y12 COM6 Y15 Y17

point) 1035)

than 100 mA, they should be evenly arranged but not be arranged adjacently,

convenient for heat dissipation. R C

R = 200 Ω, 2 W ◆◆ Terminal block definition of H2U-3624MR and H2U-3624MT The soft components within [ ] are the battery backup area.

C = 0.022 uF,250 VAC

It is suggested that the output points, which are set to ON simultaneously, do ■ Power Supply Specification S/S X1 X3 X5 X7 X11 X13 X15 X17 X21 X23 X25 X27 X31 X33 X35 X37 X41 X43 • Note 1: Non-battery backup area can be changed into battery backup area

not exceed 70% of total output points for long. L N X0 X2 X4 X6 X10 X12 X14 X16 X20 X22 X24 X26 X30 X32 X34 X36 X40 X42 via parameter setting.

Min. Typical Max.

Item Relay outputs Transistor outputs Item Unit Remark • Note 2: Battery backup area can be changed into non-battery backup area

Value Value Value

Circuit power voltage < 250 VAC, or < 30 VDC 5–24 VDC Rated operating voltage VAC 100 220 240 Normal startup and running range

COM Y0 Y1 Y2 Y4 Y6 Y10 Y12 Y14 Y16 Y20 Y22 Y24 Y26

via parameter setting.

Circuit insulation Relay mechanical insulation Opto-coupling insulation

Input voltage limit VAC 85 - 264

Derated in the range of 85–100 24V COM0 COM1 COM2 Y3 COM3 Y5 Y7 COM4 Y11 Y13 COM5 Y15 Y17 COM6 Y21 Y23 COM7 Y25 Y27

• Note 3: Such permanent battery backup area cannot be changed.

When the relay output contact VAC and 240–264 VAC

LED indicator closes, the LED indicator

When the opto-coupling is driven, the

Input current A - - 1 85 VAC input, full-load output ■ Programming requirements

becomes ON.

LED indicator becomes ON. ◆◆ Terminal block definition of H2U-3232MR and H2U-3232MT 1) One PC with Microsoft Windows XP or Windows 7 system

Input power W/VA - - 50/85 S/S 0V 0V X0 X2 X4 X6 X10 X12 X14 X16 X20 X22 X24 X26 X30 X32 X34 X36

Leakage current during 5V/GND V 4.75 5 5.25 Output 1 2) Inovance AutoShop (version 2.0 or above) for the purpose of writing and

- Less than 0.1 mA/30 VDC

open circuit L N 24V 24V X1 X3 X5 X7 X11 X13 X15 X17 X21 X23 X25 X27 X31 X33 X35 X37

Output 24VDD/GND V 21.6 24 26.4 Output 2 downloading user programs

Min. load 2 mA/5 VDC 5 mA (5–24 VDC) voltage 24VCC/COM V 21.6 24 26.4 Output 3 Y0 Y2 Y4 Y6 Y10 Y12 Y14 Y16 Y20 Y22 Y24 Y26 Y30 Y32 Y34 Y36 COM6 3) Inovance USB-mini DIN8 download cable or mouse head download cable

2A/1 point 0.5A/point

Resistive The sum of capacity load is the for PC with DB9-type RS232 port

8A/4 points common port 0.8A/4 points 5V/GND mA - - 900 COM1 Y1 Y3 COM2 Y5 Y7 COM3 Y11 Y13 COM4 Y15 Y17 COM5 Y21 Y23 Y25 Y27 Y31 Y33 Y35 Y37

load internal consumption and the

Max. 8A/8 points common port 1.6A/8 points

Output 24VDD/GND mA - - 500 expansion module.

output Inductive High speed terminal: 7.2 W/24 VDC current The maximum output power shall ◆◆ Terminal block definition of H2U-3232MTQ (same as that of H2U-3232MTP)

220 VAC, 80 VA

current load Others: 12 W/24 VDC be the sum of each full load.

High speed terminal: 0.9 W/24 VDC 24VCC/COM mA - - 500 Natural cooling is adopted. S/S 0V 0V X0 X2 X4 X6 X10 X12 X14 X16 X20 X22 X24 X26 X30 X32 X34 X36

Lamp Load 220 VAC, 100 W

Others: 12 W/24 VDC

L N 24V 24V X1 X3 X5 X7 X11 X13 X15 X17 X21 X23 X25 X27 X31 X33 X35 X37

ON response delay 20 ms (max.) High speed output: 10 μs

Output 3 applies power to sensor. It can also provide external power supply to

Others: 0.5 ms special function modules. Output 2 provides power supply to the main module

OFF response delay

High-speed output

20 ms (max.)

and the relay of I/Os of expansion module. Output1 provides power to all

Y0 Y2 Y3 Y4 Y5 Y6 COM5 Y11 Y13 Y14 Y16 COM7 Y21 Y23 Y24 Y26 Y30 Y32 Y34 Y36 COM9

Product Warranty Card

- 100 kHz per channel (max.) COM0 Y1 COM1 COM2 COM3 COM4 Y7 Y10 Y12 COM6 Y15 Y17 Y20 Y22 COM8 Y25 Y27 Y31 Y33 Y35 Y37

frequency modules. During system configuration, make sure that the demand of each

Output common port Each group shares a common port and the groups are isolated . power supply does not exceed its maximum capacity. Address:

◆◆ Terminal block definition of H2U-3232MTQ (same as that of H2U- Customer

Fuse protection Without fuse protection ■ Power Supply Capacitance and Expansion Capacity 3232MTP) information Contact person:

Company name:

■ Internal Equivalent Circuit The main module and active expansion module of PLC provide power supply to

Postcode:

expansion modules, extension cards and adapters. The I/O points of expansion Tel or Email:

PLC has a built-in power supply (24 VDC) to detect user switch status, so you S/S 0V 0V X0 X2 X4 X6 X10 X12 X14 X16 X20 X22 X24 X26 X30 X32 X34 X36

only need to connect input signals of dry contact. OC output type is needed if modules and the number of special function expansion modules must be within L N 24V 24V X1 X3 X5 X7 X11 X13 X15 X17 X21 X23 X25 X27 X31 X33 X35 X37 Product model:

you connect an active transistor or sensor. the power supply capacitance of the main module or active expansion module.

Y0 Y2 Y3 Y4 Y5 Y6 COM5 Y11 Y13 Y14 Y16 COM7 Y21 Y23 Y24 Y26 Y30 Y32 Y34 Y36 COM9

PLC signal input and internal equivalent circuit are shown as Figure 6 below. For calculation on power supply capacitance, take the following aspects into

Circuit of the user and the PLC internal circuit are connected by the terminal. considerations: COM0 Y1 COM1 COM2 COM3 COM4 Y7 Y10 Y12 COM6 Y15 Y17 Y20 Y22 COM8 Y25 Y27 Y31 Y33 Y35 Y37 Product Serial No (Attach here):

Figure 6 shows the SINK input mode, determined by short connection of the information

• Each power supply capacitance should be calculated independently.

terminal S/S and the terminal 24V. ◆◆ Terminal block definition of H2U-4040MR and H2U-4040MT

Figure 7 SOURCE input mode • The expansion capacity is decided by the smaller power supply Name of supplier who supplied you the unit:

Figure 6 SINK input mode User signal wiring

capacitance. S/S 0V 0V X0 X2 X4 X6 X10 X12 X14 X16 X20 X22 X24 X26 X30 X32 X34 X36 X40 X42 X44 X46

24V L N 24V 24V X1 X3 X5 X7 X11 X13 X15 X17 X21 X23 X25 X27 X31 X33 X35 X37 X41 X43 X45 X47

For example: 24VDD allows connection of six expansion modules, while +5V

User signal wiring

24V

24V+

COM

only allows connection of eight expansion modules. So the system can only be Y0 Y1 Y2 Y3 Y5 Y7 Y10 Y12 Y14 Y16 Y20 Y22 Y24 Y26 Y30 Y32 Y34 Y36 Y40 Y42 Y44 Y46 Failure

24 VDC

Auxiliary S/S

extended up to six expansion modules. Description

Various signal input devices

COM power COM0 COM1 COM2 COM3 Y4 Y6 COM4 Y11 Y13 COM5 Y15 Y17 COM6 Y21 Y23 Y25 Y27 COM7 Y31 Y33 Y35 Y37 COM8 Y41 Y43 Y45 Y47

24V-

Selection of Extension Device

Internal equivalent circuit of PLC

S/S

X0

■ (eg. Fault Maintenance personnel:

Sensor X0

When designing an H2U series PLC system, we must consider the following code)

aspects: ◆◆ Terminal block definition of H2U-6464MR and H2U-6464MT

Signal input device

Logic processing

X1

X1

X2

◆◆ Total I/Os should be within 256 for a main PLC system. ◆◆

circuit

◆◆ Power supply capacitance (see Power Supply Specification) S/S 0V 0V X0 X2 X4 X6 X10 X12 X14 X16 X20 X22 X24 X26 X30 X32 X34 X36 X40 X42 X44 X46 X50 X52 X54 X56 X60 X62 X64 X66 X70 X72 X74 X76

X2

24VDC

X2

◆◆ main modules and active expansion modules can provide 24 VDC and 5 L N 24V 24V X1 X3 X5 X7 X11 X13 X15 X17 X21 X23 X25 X27 X31 X33 X35 X37 X41 X43 X45 X47 X51 X53 X55 X57 X61 X63 X65 X67 X71 X73 X75 X77

VDC power supply to expansion modules and special modules. But total

For self-

powered

device

power consumption of all expansion units should be restricted within the Y0 Y2 COM2 Y5 Y7 Y10 Y12 COM4 Y15 Y17 Y20 Y22 Y24 Y26 COM6 Y31 Y33 Y35 Y37 Y40 Y42 Y44 Y46 COM8 Y51 Y53 Y55 Y57 Y60 Y62 Y64 Y66 COM10 Y71 Y73 Y75 Y77

power supply capacitance of main module or the active expansion module.

Xn

Xn

Internal equivalent COM1 Y1 Y3 Y4 Y6 COM3 Y11 Y13 Y14 Y16 COM5 Y21 Y23 Y25 Y27 Y30 Y32 Y34 Y36 COM7 Y41 Y43 Y45 Y47 Y50 Y52 Y54 Y56 COM9 Y61 Y63 Y65 Y67 Y70 Y72 Y74 Y76

circuit of PLC

◆◆ The H2U series PLC can be connected to maximum 8 special modules.

You might also like

- User Guide: NICE9000-V Series Integrated Villa Elevator Control CabinetDocument2 pagesUser Guide: NICE9000-V Series Integrated Villa Elevator Control CabinetyanlayNo ratings yet

- Nokia 6233 rm-145 6234 rm-123Document10 pagesNokia 6233 rm-145 6234 rm-123me academyNo ratings yet

- PWM DCDocument2 pagesPWM DCĐỗ Xuân BằngNo ratings yet

- User Guide: IT6000-IOT Series HMIDocument2 pagesUser Guide: IT6000-IOT Series HMINgọc NhấtNo ratings yet

- Electrical System 793D Off-Highway Truck: Harness and Wire Electrical Schematic SymbolsDocument4 pagesElectrical System 793D Off-Highway Truck: Harness and Wire Electrical Schematic SymbolsJose luis ConsuegraNo ratings yet

- Micro Atmel 3 CH AFE W DSP For 1p M90E26-ApplicationNoteDocument19 pagesMicro Atmel 3 CH AFE W DSP For 1p M90E26-ApplicationNoteshuvo hasanNo ratings yet

- SCADA Network ArchitectureDocument1 pageSCADA Network ArchitectureSlick72No ratings yet

- Silicon NPN Triple Diffused Planar Transistor: (High Voltage and High Speed Switchihg Transistor)Document1 pageSilicon NPN Triple Diffused Planar Transistor: (High Voltage and High Speed Switchihg Transistor)Angel Simo MoralesNo ratings yet

- Datasheet PDFDocument1 pageDatasheet PDFRycky de la CruzNo ratings yet

- 12AX7 Phono Tube Preamplifier User ManualDocument7 pages12AX7 Phono Tube Preamplifier User ManualmikelikespieNo ratings yet

- Operation Manual: Fieldbus DeviceDocument1 pageOperation Manual: Fieldbus DeviceRodrigo CostaNo ratings yet

- Instructions and Cautions For Safe Use of AC Servos: General-Purpose AC Servo CautionDocument1 pageInstructions and Cautions For Safe Use of AC Servos: General-Purpose AC Servo CautiontadyNo ratings yet

- Installation & Owner'S Manual: EnglishDocument8 pagesInstallation & Owner'S Manual: EnglishAdilen A. NadlorNo ratings yet

- Taae Rce 11 09 2022Document22 pagesTaae Rce 11 09 2022Orbenson TanNo ratings yet

- Vestax Vss PMC 280Document33 pagesVestax Vss PMC 280Diogo SilvaNo ratings yet

- Valbia Actuator SetupDocument1 pageValbia Actuator SetupkikinNo ratings yet

- KPN Manu EngDocument2 pagesKPN Manu Engserg minimeNo ratings yet

- Is 0405 A 00 MMDocument2 pagesIs 0405 A 00 MMsusanaNo ratings yet

- 机型:KDL42XS715UN: Konka Dtv Sch DesignDocument14 pages机型:KDL42XS715UN: Konka Dtv Sch DesignAlexis FloresNo ratings yet

- AGN 035 - Protect alternators from overloads and faultsDocument10 pagesAGN 035 - Protect alternators from overloads and faultsariwibowoNo ratings yet

- ms-aj1_eDocument2 pagesms-aj1_eAjay MayalNo ratings yet

- KT-502H en Tcd210202ab 20211221 Inst WDocument1 pageKT-502H en Tcd210202ab 20211221 Inst WGopal HegdeNo ratings yet

- Heat Detector Guide - UL Certified HD912 SeriesDocument1 pageHeat Detector Guide - UL Certified HD912 SeriesShahbaz AlamNo ratings yet

- Históricos de La PelonaDocument1 pageHistóricos de La Pelonaabel sanchezNo ratings yet

- Access Network Design Top Down ApproachDocument13 pagesAccess Network Design Top Down Approachmcclaink06No ratings yet

- LAYOUT of OT Shelter PDFDocument1 pageLAYOUT of OT Shelter PDFBalaji YNo ratings yet

- Construction Issue: General NotesDocument1 pageConstruction Issue: General NotesShokry AlkissyNo ratings yet

- Mitsubishi VRF Interior Mascat Tavan Pefy P Vma E3Document3 pagesMitsubishi VRF Interior Mascat Tavan Pefy P Vma E3Ilie-valentinGanciarovNo ratings yet

- Modulo Q68adiDocument1 pageModulo Q68adijonathan leonNo ratings yet

- SI 5NB0A 001 00 Eng - v1 - m56577569830747488Document1 pageSI 5NB0A 001 00 Eng - v1 - m56577569830747488brassoyNo ratings yet

- Detail Detail: Issued For Public CommentDocument1 pageDetail Detail: Issued For Public CommentChilakamarri SrikamalNo ratings yet

- 2SC3263 en 10044835Document2 pages2SC3263 en 10044835Janos NagyNo ratings yet

- PID - Lube Oil SkidDocument1 pagePID - Lube Oil SkidTalha AamirNo ratings yet

- 99MAA007ADocument2 pages99MAA007ARajib Kumar BarmonNo ratings yet

- 2sc4140 Ds enDocument1 page2sc4140 Ds enAdah BumboneNo ratings yet

- Ard D 01 en Ma Drw171437aa 20171220 He 20171227 PDFDocument1 pageArd D 01 en Ma Drw171437aa 20171220 He 20171227 PDFUus SuhadaNo ratings yet

- Schematics: Model Serial NumbersDocument5 pagesSchematics: Model Serial NumbersCoque de LunaNo ratings yet

- RM-74 RM-75 Schematics V2 0Document8 pagesRM-74 RM-75 Schematics V2 0Владимир КлюевNo ratings yet

- ALUMERO Installation Instruction RoofHook EnglishDocument18 pagesALUMERO Installation Instruction RoofHook EnglishIsaac Torres LoretoNo ratings yet

- LDOV32011Document2 pagesLDOV32011georgeostNo ratings yet

- Ib ST 24 Ai 4/I: Module No:2719629 Labelid:2719629 Operator:PhoenixDocument152 pagesIb ST 24 Ai 4/I: Module No:2719629 Labelid:2719629 Operator:PhoenixБагдатNo ratings yet

- DIGIT_Schematic_PSU sectionDocument1 pageDIGIT_Schematic_PSU sectionvs055707No ratings yet

- 2SC3856 PDFDocument1 page2SC3856 PDFCarlos MejiaNo ratings yet

- FBC9080 Fieldbus Converter Installation ManualDocument2 pagesFBC9080 Fieldbus Converter Installation ManualTHANGABALU RAJENDIRANNo ratings yet

- In Out SEL 787Document1 pageIn Out SEL 787Tosikur RahmanNo ratings yet

- Draw Wire EncoderDocument2 pagesDraw Wire EncoderdiewiesNo ratings yet

- Silicon PNP transistor specifications and data sheetDocument1 pageSilicon PNP transistor specifications and data sheetdavid silveiraNo ratings yet

- UC600 MANUAL DE INSTALACIONDocument2 pagesUC600 MANUAL DE INSTALACIONm.cortezNo ratings yet

- Product & Solutions Portfolio: Fortifying Your Network InfrastructureDocument45 pagesProduct & Solutions Portfolio: Fortifying Your Network Infrastructurerence_kioskNo ratings yet

- BB BB: Code and SpecificationsDocument1 pageBB BB: Code and SpecificationsandersonNo ratings yet

- QSG Outlier Air - Air SE WW Rev ADocument2 pagesQSG Outlier Air - Air SE WW Rev AChia SeNo ratings yet

- Idn27943 - SCN1200 F2.5 - Ga+alDocument2 pagesIdn27943 - SCN1200 F2.5 - Ga+alAbdul JabbarNo ratings yet

- General Specifications: Model SC42 High Pressure/high Temperature Small-Bore Conductivity SensorsDocument2 pagesGeneral Specifications: Model SC42 High Pressure/high Temperature Small-Bore Conductivity SensorsJuan Tapia SuarezNo ratings yet

- Si 6ngfa 004 EngDocument1 pageSi 6ngfa 004 EnglgsmartNo ratings yet

- B1.2 B2.1 B3 B2.2 B1.3 B1.1: Saddle Arrangement in Intermediate YardDocument1 pageB1.2 B2.1 B3 B2.2 B1.3 B1.1: Saddle Arrangement in Intermediate YarddeniNo ratings yet

- PV Single Line DiagramDocument1 pagePV Single Line DiagramMohammad ShayanNo ratings yet

- 3 Mps Building Dingras ElectricalDocument7 pages3 Mps Building Dingras ElectricalJuan MarcosNo ratings yet

- TABLE OF CONTENTS AND ELECTRICAL SCHEDULEDocument8 pagesTABLE OF CONTENTS AND ELECTRICAL SCHEDULEMarc LxmnNo ratings yet

- February Monthly Collection, Grade 5From EverandFebruary Monthly Collection, Grade 5Rating: 3 out of 5 stars3/5 (1)

- Eric Black PDH TutorialDocument9 pagesEric Black PDH TutorialliuleeNo ratings yet

- RC Phase Shift OscillatorDocument25 pagesRC Phase Shift Oscillatorahmed omarNo ratings yet

- Virtual Reality Augmented RealityDocument38 pagesVirtual Reality Augmented RealitySahil OberoiNo ratings yet

- 3K PDFDocument13 pages3K PDFFelipe QuindeNo ratings yet

- Counterfeit Integrated CircuitsDocument15 pagesCounterfeit Integrated CircuitsPudi PudaNo ratings yet

- Monitor LCD Samsung Gg15as 15as R 15L 15L R 15v 15v R 15e 15e RDocument43 pagesMonitor LCD Samsung Gg15as 15as R 15L 15L R 15v 15v R 15e 15e RvideosonNo ratings yet

- Interface - Brad Harrison Plug - 3-Pin For Single Solenoid - 5-Pin For Double SolenoidDocument1 pageInterface - Brad Harrison Plug - 3-Pin For Single Solenoid - 5-Pin For Double Solenoids bNo ratings yet

- Cse 320Document19 pagesCse 320Ayush BaiswarNo ratings yet

- Abap BDC Program To Load Output ConditionsDocument24 pagesAbap BDC Program To Load Output ConditionsSivaram NayakNo ratings yet

- Airpax PDFDocument46 pagesAirpax PDFvjNo ratings yet

- Understanding Frequencies Through Harmonics AssociationsDocument24 pagesUnderstanding Frequencies Through Harmonics Associations1aquila1100% (2)

- IMS Abend CodesDocument23 pagesIMS Abend Codesparvathy88No ratings yet

- PSG 2pro901Document97 pagesPSG 2pro901tecni suNo ratings yet

- Toyota Trouble Code Info: 96 & Later Are OBD2 Systems and Require A ScantoolDocument8 pagesToyota Trouble Code Info: 96 & Later Are OBD2 Systems and Require A ScantoolCesar Vega100% (1)

- Serially Interfaced, 8-Digit LED Display Drivers: General Description FeaturesDocument16 pagesSerially Interfaced, 8-Digit LED Display Drivers: General Description FeaturesHebertAlexMamaniSalomaNo ratings yet

- Ployphase DecompositionDocument29 pagesPloyphase DecompositionTechy GuyNo ratings yet

- NRF51 Series Reference Manual v3.0Document174 pagesNRF51 Series Reference Manual v3.0johan straussNo ratings yet

- WEG w22 Three Phase Electric MotorDocument44 pagesWEG w22 Three Phase Electric MotorMATIAS GODOYNo ratings yet

- 1N5712Document7 pages1N5712Jeetu AnjanaNo ratings yet

- 90209-1017DEE D-Series AS-Language Reference Manual PDFDocument474 pages90209-1017DEE D-Series AS-Language Reference Manual PDFelmacuarro5No ratings yet

- CT7TP em IndexDocument10 pagesCT7TP em IndexMichałNo ratings yet

- Sealed SRL Data SheetDocument4 pagesSealed SRL Data Sheetjpsingh823632No ratings yet

- BMP180 Barometric Pressure Sensor Specifications and CodeDocument34 pagesBMP180 Barometric Pressure Sensor Specifications and Codeabhilash100% (3)

- Low Smoke HalogenDocument17 pagesLow Smoke HalogenquycoctuNo ratings yet

- Chapter 2Document22 pagesChapter 2Sameer SharmaNo ratings yet

- Garage Door M Line Manual 8030628Document16 pagesGarage Door M Line Manual 8030628vijayNo ratings yet

- NPT-1200 IMM Viet NamDocument167 pagesNPT-1200 IMM Viet NamAnh Ba Lâm100% (1)

- EE 705: Experiment 1: 1 Describing Combinational Circuits in VHDLDocument3 pagesEE 705: Experiment 1: 1 Describing Combinational Circuits in VHDLkbkkrNo ratings yet

- DTU EE 4th Sem Midsem SyllabusDocument5 pagesDTU EE 4th Sem Midsem SyllabusHimanshu GuptaNo ratings yet

- Collision Avoidance SystemDocument47 pagesCollision Avoidance SystemAmeha GetachewNo ratings yet