Professional Documents

Culture Documents

Modulo Q68adi

Uploaded by

jonathan leonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Modulo Q68adi

Uploaded by

jonathan leonCopyright:

Available Formats

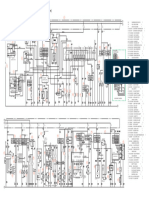

1. Overview 4.

Handling Precautions Setting

Switch 1 Input range setting Analog input range Input range setting value

Q64AD, Q68ADV, Q68ADI This manual explains specifications and the names of the components for the

Q64DA type analog digital module (hereafter Q64AD), the Q68ADV type A/D

(1) Do not drop the module or cause it to receive strong impact.

(2) Tighten the terminal screws for the module to the specified torque shown below. H

4 to 20 mA

0 to 20 mA

0 H *1

1H

A/D Converter Module converter module (hereafter Q68ADV) and the Q68ADI A/D converter module Insufficient tightening torque could result in shorts, failures or malfunction. CH4 CH3 CH2 CH1 1 to 5 V 2H

(hereafter Q68ADI), all of which are used in combination with the MELSEC-Q Switch 2 Input range setting 0 to 5 V 3H

Thank you for buying the Mitsubishi general-purpose programmable logic Screw location Tightening torque (M3 screw)

Series CPU module. In this manual, the Q64AD, Q68ADV and the Q68ADI are – 10 to 10 V 4H

controller MELSEC Q Series. referred to as A/D converter modules. Module mounting screw (M3 screw) 36 to 48 N · cm

H 0 to 10 V 5H

Terminal block terminal screw (M3 screw) 42 to 58 N · cm

Prior to use, please read both this manual and detailed manual thoroughly CH8 CH7 CH6 CH5 User range setting FH

and familiarize yourself with the product. 2. Specifications Terminal block mounting screw (M3.5 screw) 66 to 89 N · cm

Switch 3 Not used

Switch 4

The specifications for the A/D conversion module are shown in the following table. 5. Wiring H

User's Manual For general specifications for the A/D module, refer to the operation manual for the 00H : With temperature drift correction

01 to FFH (numeric value other than 00H)*: Without temperature drift correction

CPU module being used.

(Hardware) 5.1 Wiring precautions 0H : Normal resolution mode

1 to FH (numeric value other than 0H)*: High resolution mode

The mode setting method

Type Q64AD Q68ADV Q68ADI is different from that of the

Item (1) Use separate cables for the external output signal or external power supply for 0H : Normal mode (A/D conversion processing) function version A module.

MODEL Q-A/D-U-H Number of analog inputs 4 points (4 channels) 8 points (8 channels) 8 points (8 channels)

1 to FH (numeric value other than 0H)*: Offset/gain setting mode See point.

the AC and Q64AD, Q68ADV, Q68ADI converter modules. Take steps to

MODEL Analog input Voltage -10 to 10V DC (Input resistance 1 M Ω) ——— Switch 5 0 : Fixed

prevent the AC side from being affected by surge or inductance.

Number 13JQ51 Current 0 to 20 mA DC ——— 0 to 20 mA DC * Setting any value within the setting range will provide the same operation.

(Input resistance 250 Ω) (Input resistance 250 Ω) (2) Ground one point of the shield for shielded wires or shielded cables. When the setting range is 1 to FH, set 1 for example.

IB-0800034-E (0706) MEE Digital output 16-bit signed binary (normal resolution mode: –4096 to 4095,

high resolution mode:–12288 to 12287, –16384 to 16383) Depending on the type of module used, the settings for A/D unit input range are shown below.

©1999 MITSUBISHI ELECTRIC CORPORATION

I/O characteristics maximum 5.2 External wiring • Q64AD................... 0H to 5H, FH

Analog input range Normal resolution mode High resolution mode

resolution • Q68ADV ................ 0H, 2H to 5H, FH

Digital Maximum Digital output value Maximum (1) Q64AD

SAFETY PRECAUTIONS Voltage 0 to 10V

output value resolution

0 to 4000 2.5mV 0 to 16000

resolution

0.625mV (a) For voltage input

*1 When the setting is 0H, the input operating range will be 0 to 10 V.

• Q68ADI.................. 0H, 1H, FH

0 to 5 V 1.25 mV 0 to 12000 0.416 mV Signal source 0 to ± 10V *2

(Read these precautions before using.) 1 to 5 V 1.0 mV 0.333 mV + 15 V Point

When using Mitsubishi equipment, thoroughly read this manual and the associated – 10 to 10 V – 4000 to 2.5 mV – 16000 to 16000 0.625 mV 500k Ω Setting of the offset/gain setting mode differs for function version A and function version B.

Users range 4000 0.375 mV – 12000 to 12000 0.333 mV

manuals introduced in the manual. Also pay careful attention to safety and handle the V+ In the offset/gain setting mode, confirm that the RUN LED is flickering, and then set the offset/gain.

setting

module properly. Current 0 to 20 mA 0 to 4000 5µA 0 to 12000 1.66 µ A I+ If the RUN LED is not flickering, check whether switch 4 is set correctly.

4µA 1.33 µ A V–

6. External Dimensions

These precautions apply only to Mitsubishi equipment. Refer to the user’s manual of the 4 to 20 mA

Users range – 4000 to 1.37 µ A – 12000 to 12000 1.33 µ A 500k Ω – 15 V

CPU module to use for a description of the PLC system safety precautions. GND SLD

setting 4000

These SAFETY PRECAUTIONS classify the safety precautions into two categories: *1 Shielded

Accuracy Normal resolution mode High resolution mode

"DANGER" and "CAUTION". (Accuracy

Ambient temperature Ambient temperature

in respect Q6 AD

0 to 55°C 0 to 55°C RUN

Procedures which may lead to a dangerous condition and

to Analog input range With Without

Ambient

With Without

Ambient (b) For current input ERROR

maximum temperature temperature Signal source 0 to ± 20 mA *2 + 15 V

DANGER cause death or serious injury if not carried out properly. digital temperature temperature 25 ± 5 °C temperature temperature 25 ± 5 °C V+

output drift drift drift drift *3 500k Ω C V-

H

1

2

correction correction correction correction

1 I+

V+

3

Procedures which may lead to a dangerous condition and value) SLD

4

0 to 10V ±0.3% ±0.4% ±0.1%

V+

5

98 (3.36)

CAUTION I+

C V-

cause superficial to medium injury, or physical damage only, if

H 6

– 10 to 10 V (±48digit*) (±64digit*) (±16digit*) 250 Ω

2 I+

SLD

7

8

0 to 5 V V– V+

not carried out properly.

9

Voltage

C V-

500k Ω H

3 I+

10

1 to 5 V SLD – 15 V SLD

11

12

±0.3% ±0.4% ±0.1% GND

V+

Depending on circumstances, procedures indicated by CAUTION may also be linked Users range C V-

13

A.G.

H 14

setting (±12digit*) (±16digit*) (±48digit*) ±0.3% ±0.4% ±0.1%

4 I+

15

*1 Shielded

to serious results.

SLD

16

0 to 20 mA (±36digit*) (±48digit*) (±12digit*) FG

A.G.

(FG)

17

18

In any case, it is important to follow the directions for usage. *4 ANALOG GND

A/D

Current 4 to 20 mA

0-+10V

0-+@20mA

Store this manual in a safe place so that you can take it out and read it whenever Users range

setting *5 90 (3.54) 27.4(1.08)

necessary. Always forward it to the end user. * Digit indicates a digital value.

unit (mm (in.))

[DESIGN PRECAUTIONS]

Type Q64AD Q68ADV Q68ADI (2) Q68ADV

CAUTION Item Warranty

• Do not bunch the control wires or communication cables with the main circuit or power wires, or Conversion speed 80 µ s/ channel (When there is temperature drift, the time calculated by Mitsubishi Electric shall not be liable for any loss caused by reasons for which Mitsubishi is not held

install them close to each other. adding 160 µ s will be used regardless of the number of channels used) accountable, lost business opportunities or unrealized gain on the customer's side resulting from failure of the

They should be installed 100 mm (3.94 inch) or more from each other. *2

Absolute maximum input Voltage: ± 15 V Current: ± 30 mA + 15 V product, or any other damage, secondary disaster, accident, damage to equipment other than the product or

Not doing so could result in noise that may cause malfunction. Insulation method Between I/O terminal and PLC power supply: Photocoupler insulation disruption of other business operations arising out of special circumstances which may or may not have been

500k Ω

[INSTALLATION PRECAUTIONS] Between channels: Not insulated predicted at Mitsubishi.

V+

Number of occupied points 16 points

CAUTION V– For safe use of the product

Connecting terminals 18 points terminal block

500k Ω This product is manufactured as a general-purpose product intended for general industrial use only. It is not

• Use the PLC in an environment that meets the general specifications given in the User's Manual Applicable wire size 0.3 to 0.75 mm2 A.G.

GND designed nor manufactured for use in an equipment or system affecting human lives.

of the CPU module being used. Applicable solderless terminals R1.25 - 3 (A solderless terminals with sleeves cannot be used) FG

– 15 V

Using this PLC in an environment outside the range of the general specifications may cause If you are considering to use this product in equipment or systems for nuclear power generation, power

Internal current consumption 0.63 A 0.64 A 0.64 A *1 Shielded ANALOG GND

electric shock, fire, malfunction, and damage to or deterioration of the product. *4 generation, aerospace, medical or passenger transport applications, consult our sales representatives.

(5 V DC)

• When installing the module, securely insert the module fixing tabs into the mounting holes of the base This product is manufactured under our strict quality control system. However, if the product is used in the

Weight 0.18 kg 0.19 kg 0.19 kg *5 intended facility in such a way that a failure of the product may lead to serious accident or loss, incorporate

unit while pressing the installation lever located a t the bottom of the module downward.

Improper installation may result in malfunction , breakdown or the module coming loose and backup or fail-safe functions into the system design.

dropping. Securely fix the module with screws if it is subject to vibration during use.

• Tighten the screws within the range of specified torque.

3. Part Names (3) Q68ADI

If the screws are loose, it may cause the module to fallout, short circuits, or malfunction. This section explains the names of the components for the A/D conversion module. Country/Region Sales office/Tel Country/Region Sales office/Tel

If the screws are tightened too much, it may cause damage to the screw and/or the module, U.S.A Mitsubishi Electric Automation Inc. China Ryoden International Shanghai Ltd.

resulting in fallout, short circuits or malfunction. Terminal Signal name *2 250 Ω + 15 V 500 Corporate Woods Parkway Vernon 3F Block5 Building Automation

1) Q6 Hills, IL 60061

• Switch all phases of the external power supply off when mounting or removing the module.

AD Instrumentation Plaza 103 Cao Bao Rd.

RUN number Q64AD Q68ADV Q68ADI 500k Ω Tel : +1-847-478-2100 Shanghai 200233 China

Not doing so may cause damage to the module. ERROR Brazil MELCO-TEC Rep. Com.e Assessoria

1 CH1 V+ CH1 V+ CH1 I+ I+ Tel : +86-21-6475-3228

• Do not directly touch the conductive area or electronic components of the module. 2) Tecnica Ltda. Taiwan Setsuyo Enterprise Co., Ltd.

Doing so may cause malfunction or failure in the module. 2 V– V– I– I– Av. Rio Branco, 123-15 ,and S/1507, 6F., No.105 Wu-Kung 3rd.RD, Wu-Ku

500k Ω Rio de Janeiro, RJ CEP 20040-005, Hsiang, Taipei Hsine, Taiwan

[WIRING PRECAUTIONS] 3 I+ CH2 V+ CH2 I+ A.G. Brazil Tel : +886-2-2299-2499

1

4 SLD V– I– GND – 15 V Tel : +55-21-221-8343

Korea HAN NEUNG TECHNO CO.,LTD.

CAUTION 2 FG Germany Mitsubishi Electric Europe B.V. German

1F Dong Seo Game Channel Bldg.,

3 5 CH2 V+ CH3 V+ CH3 I+ *1 Shielded *4 ANALOG GND Branch

• Always ground the FG terminal for the PLC. 4 Gothaer Strasse 8 D-40880 Ratingen,

660-11, Deungchon-dong Kangsec-ku,

There is a risk of electric shock or malfunction. 6 V– V– I– GERMANY

Seoul, Korea

5 Tel : +82-2-3668-6567

• When turning on the power and operating the module after wiring is completed, always attach the 6 7 I+ CH4 V+ CH4 I+ *5 Tel : +49-2102-486-0

Singapore Mitsubishi Electric Asia Pte, Ltd.

U.K Mitsubishi Electric Europe B.V. UK

terminal cover that comes with the product. 7 8 SLD V– I– Branch 307 ALEXANDRA ROAD #05-01/02,

There is a risk of electric shock if the terminal cover is not attached. 8 Travellers Lane, Hatfield, Herts., AL10 MITSUBISHI ELECTRIC BUILDING

• Tighten the terminal screws within the range of specified torque. 9 CH3 V+ CH5 V+ CH5 I+ SINGAPORE 159943

9

*1 Use a twisted two core shielded wire for the power wire. 8XB,UK

Tel : +65-473-2480

If the terminal screws are loose, it may result in short circuits or malfunction. 10 10 V– V– I– Tel : +44-1707-276100

Thailand F. A. Tech Co.,Ltd.

If the terminal screws are tightened too much, it may cause damage to the screw and/or the 11

11 I+ CH6 V+ CH6 I+ *2 Shows input resistance. Italy Mitsubishi Electric Europe B.V. Italian

898/28,29,30 S.V.City Building,Office

module, resulting in short circuits or malfunction. 12 Branch

Tower 2,Floor 17-18 Rama 3 Road,

• Be careful not to let foreign matters such as sawdust or wire chips get inside the module. 13 12 SLD V– I– *3 If current input, always connect to (V+) and (I+) terminals. Centro Dir. Colleoni, Pal. Perseo - Ingr.2

Bangkpongpang, Yannawa,

Via Paracelso 12, 20041 Agrate B.,

These may cause fires, failure or malfunction. 14

13 CH4 V+ CH7 V+ CH7 I+ *4 "A.G." terminal does not normally require wiring. However, it can be used as Milano, Italy Bangkok 10120

Tel : +66-2-682-6522

• The top surface of the module is covered with protective film to prevent foreign objects such as 15

14 V– V– I– Tel:+39-039-60531

cable offcuts from entering the module when wiring.

IN 24VDC

16 GND for compatible equipment ground under the following conditions. Spain Mitsubishi Electric Europe B.V. Spanish

Indonesia P.T. Autoteknindo SUMBER MAKMUR

Jl. Muara Karang Selatan Block A Utara

Do not remove this film until the wiring is complete.

17

15 I+ CH8 V+ CH8 I+ Branch Carretera de Rubi 76-80

(FG) 18 (1) When there is a difference in polarity between "A.G" and "GND for 08190 - Sant Cugat del Valles, No.1 Kav. No.11 Kawasan Industri/

Before operating the system, be sure to remove the film to provide adequate heat ventilation. D/A 16 SLD V– I– Pergudangan Jakarta - Utara 14440

0- + 10V compatible equipment". Barcelona, Spain

Tel : +62-21-663-0833

About This Manual

0- + 20mA

17 A.G. (ANALOG GND) Tel:+34-935-653135

India Messung Systems Put,Ltd.

The following manuals are also related to this product. Order them if necessary. 18 FG

(2) As an alternative for 0V input when only the + side is open on a ± wire. South Africa Circuit Breaker Industries LTD.

Private Bag 2016, Isando 1600, Electronic Sadan NO:111 Unit No15,

M.I.D.C BHOSARI,PUNE-411026

Related Manual *5 Always use a ground. In addition, ground the FB of the power supply module. Johannesburg, South Africa

Tel : +27-11-928-2000 Tel : +91-20-7128927

Number Name Description Hong Kong Ryoden Automation Ltd. Australia Mitsubishi Electric Australia Pty. Ltd.

Manual Name Manual No. (Model code) 10th Floor, Manulife Tower, 169 Electric 348 Victoria Road, PostalBag, No 2,

SH-080055 1) RUN LED Displays the operating status of the A/D conversion module. Rydalmere, N.S.W 2116, Australia

A/D Converter Module User's Manual On : Normal operation 5.3 Switch setting for intelligent functional module Road, North Point, HongKong

Tel : +852-2887-8870 Tel : +61-2-9684-7777

(13JR03) Flashing : During offset/gain setting mode

Off : 5V power supply interrupted or watch dog timer error The settings for the intelligent function module are performed using the I/O allocation settings for

Conformation to the EMC Directive and Low Voltage Instruction the GX Developer. HEAD OFFICE : 1-8-12, OFFICE TOWER Z 14F HARUMI CHUO-KU 104-6212, JAPAN

2) ERROR LED Displays the error status of the A/D conversion module.

When complying with EMC Directives and Low-Voltage Directives by assembling a On : Error

NAGOYA WORKS : 1-14, YADA-MINAMI5, HIGASHI-KU, NAGOYA, JAPAN

Mitsubishi PLC compatible with EMC Directive and Low-Voltage Directives into the user Off : Normal operation

product, refer to Chapter 3 "EMC Directives and Low-Voltage Directives" in the User's Flashing : Error in switch settings When exported from Japan, this manual does not require application to the Ministry

Manual (Hardware Section) for the CPU module being used. The CE logo is printed on Switch No. 5 of the intelligent function module has of Economy, Trade and Industry for service transaction permission.

the rating plate on the main body of the PLC that conforms to the EMC directive and low been set to a value other than zero "0".

Specifications subject to change without notice.

voltage instruction. Printed in Japan on recycled paper.

You might also like

- Q64AD GH UserManual Hardware IB 0800223 BDocument1 pageQ64AD GH UserManual Hardware IB 0800223 BSebastián LozadaNo ratings yet

- Mif IiDocument4 pagesMif Iielectron13No ratings yet

- Wcenim2064 en AqDocument4 pagesWcenim2064 en AqaleNo ratings yet

- Innovance H2U Data SheetDocument2 pagesInnovance H2U Data SheetAmr samir ShahinNo ratings yet

- 2SB1587 PDFDocument1 page2SB1587 PDFisaiasvaNo ratings yet

- Godox LED6R 20210507Document1 pageGodox LED6R 20210507Ömer GezerNo ratings yet

- 300M Schematic DiagramDocument2 pages300M Schematic DiagramAdriano Andrade100% (3)

- High-Bay LED Lighting Fitting: Logistics/Warehouse AreaDocument1 pageHigh-Bay LED Lighting Fitting: Logistics/Warehouse AreaMatíasSosaNo ratings yet

- Datasheet PDFDocument1 pageDatasheet PDFRycky de la CruzNo ratings yet

- Plts Chemco Karawang 3.2 MWP: LegendDocument3 pagesPlts Chemco Karawang 3.2 MWP: LegendmuliamakmurNo ratings yet

- Silicon NPN Triple Diffused Planar Transistor: (High Voltage and High Speed Switchihg Transistor)Document1 pageSilicon NPN Triple Diffused Planar Transistor: (High Voltage and High Speed Switchihg Transistor)Angel Simo MoralesNo ratings yet

- 12AX7 Phono Tube Preamplifier User ManualDocument7 pages12AX7 Phono Tube Preamplifier User ManualmikelikespieNo ratings yet

- Darlington: Silicon PNP Epitaxial Planar Transistor (Complement To Type 2SD2439)Document1 pageDarlington: Silicon PNP Epitaxial Planar Transistor (Complement To Type 2SD2439)Elcio BrembattiNo ratings yet

- UntitledDocument20 pagesUntitledSteve RindNo ratings yet

- 19 Hilux: Remote ControlmirrorDocument1 page19 Hilux: Remote ControlmirrorautocomtrucksNo ratings yet

- 777D Off-Highway Truck Electrical System and 776D Tractor: Machine Harness Connector and Component LocationsDocument2 pages777D Off-Highway Truck Electrical System and 776D Tractor: Machine Harness Connector and Component LocationsNorman CoetzeeNo ratings yet

- HCD-ECL77BT - ECL99BT DiagramaDocument14 pagesHCD-ECL77BT - ECL99BT DiagramaAmin Santana100% (1)

- Vestel 17PW26 TM PDFDocument7 pagesVestel 17PW26 TM PDFBeáta Tapsonyi-DorosNo ratings yet

- V381 41 (2019090500017967) DecryptDocument37 pagesV381 41 (2019090500017967) DecryptgalicianmanNo ratings yet

- 2sc4140 Ds enDocument1 page2sc4140 Ds enAdah BumboneNo ratings yet

- Darlington: Silicon PNP Epitaxial Planar TransistorDocument1 pageDarlington: Silicon PNP Epitaxial Planar Transistormarcelo giussaniNo ratings yet

- CH 08 RFPDocument1 pageCH 08 RFPRUBEN DARIO SandovalNo ratings yet

- Silicon NPN Triple Diffused Planar Transistor: (Complement To Type 2SA1693)Document1 pageSilicon NPN Triple Diffused Planar Transistor: (Complement To Type 2SA1693)llargo007No ratings yet

- Manual DT50-P2113Document2 pagesManual DT50-P2113Alexandre FerreiraNo ratings yet

- V381 20 (2019090500017967) DecryptDocument37 pagesV381 20 (2019090500017967) DecrypttreweNo ratings yet

- PLC DiagramDocument18 pagesPLC DiagramStephen NideaNo ratings yet

- 2SC3263 en 10044835Document2 pages2SC3263 en 10044835Janos NagyNo ratings yet

- 2SA 1492 REMPLAZO de 2sa1244 Driver Turbo ToyotaDocument1 page2SA 1492 REMPLAZO de 2sa1244 Driver Turbo Toyotadavid silveiraNo ratings yet

- Empty Container Handlers: 6000 - 7000 KG at 1220 MM H6XM-12EC3 / H7XM-12EC4Document5 pagesEmpty Container Handlers: 6000 - 7000 KG at 1220 MM H6XM-12EC3 / H7XM-12EC4Wolf LordNo ratings yet

- Darlington: Silicon PNP Epitaxial Planar TransistorDocument1 pageDarlington: Silicon PNP Epitaxial Planar Transistorroberto carlos martinez narvaezNo ratings yet

- LDOV32011Document2 pagesLDOV32011georgeostNo ratings yet

- Manual de Instruccion 5kvaDocument1 pageManual de Instruccion 5kvaJuanca PiaNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- ACRD6XXP SchematicDocument2 pagesACRD6XXP SchematicMasab AnisNo ratings yet

- N9 and N10 With SCR (2014 - 2016) : Engine Wiring Diagram Engine Control Module (ECM)Document4 pagesN9 and N10 With SCR (2014 - 2016) : Engine Wiring Diagram Engine Control Module (ECM)Phil B.No ratings yet

- 65 93 PR Pid 01090 - 0001 - BDocument1 page65 93 PR Pid 01090 - 0001 - BgeocaustasNo ratings yet

- 1 Overview: STC8A8K64S4A12 Series ManualDocument18 pages1 Overview: STC8A8K64S4A12 Series Manualhossein gholamiNo ratings yet

- Silicon NPN Triple Diffused Planar Transistor (High Voltage Switchihg Transistor)Document1 pageSilicon NPN Triple Diffused Planar Transistor (High Voltage Switchihg Transistor)miloud1911No ratings yet

- KPN Manu EngDocument2 pagesKPN Manu Engserg minimeNo ratings yet

- W1 W3-B-C User ManualDocument1 pageW1 W3-B-C User Manualamad4youNo ratings yet

- Operation Manual: Fieldbus DeviceDocument1 pageOperation Manual: Fieldbus DeviceRodrigo CostaNo ratings yet

- LV300/H/Twin: Service Information Service InformationDocument8 pagesLV300/H/Twin: Service Information Service InformationCleber SantosNo ratings yet

- 300 WATTS: 12 V Prim 190 To 440 V + Active PFCDocument1 page300 WATTS: 12 V Prim 190 To 440 V + Active PFCGuillaume FoubertNo ratings yet

- Darlington: Silicon NPN Triple Diffused Planar Transistor (Complement To Type 2SB1559)Document1 pageDarlington: Silicon NPN Triple Diffused Planar Transistor (Complement To Type 2SB1559)Gilberto DiazNo ratings yet

- 3.7 Digital Input Module SM 321 DI 32 X DC 24 V (6ES7321-1BL00-0AA0)Document3 pages3.7 Digital Input Module SM 321 DI 32 X DC 24 V (6ES7321-1BL00-0AA0)LanreSKNo ratings yet

- Motorola Ming A1200Document3 pagesMotorola Ming A1200bassrivastava100% (2)

- EC55B Elec CircuitDocument1 pageEC55B Elec Circuitxiaojun liNo ratings yet

- Sharp Runtka611wjqz psd-0698 Psu SCHDocument2 pagesSharp Runtka611wjqz psd-0698 Psu SCHMarko VujinovićNo ratings yet

- G87 (C) A63 (A), A64 (B) G87 (C)Document1 pageG87 (C) A63 (A), A64 (B) G87 (C)Serg GarkushaNo ratings yet

- Interface Technology in Modular Housings: Your Global Automation PartnerDocument16 pagesInterface Technology in Modular Housings: Your Global Automation PartnerJorge_Andril_5370No ratings yet

- LCD InfDocument1 pageLCD Infkottee1977100% (2)

- Pre Tsa 420Document1 pagePre Tsa 420Antonio Fernandes de JesusNo ratings yet

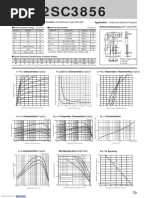

- 2SC3856 PDFDocument1 page2SC3856 PDFCarlos MejiaNo ratings yet

- Parts Catalogue DCD 250Document23 pagesParts Catalogue DCD 250Quốc Viêtj HuỳnhNo ratings yet

- DMDCMDocument2 pagesDMDCMSupuran RichardoNo ratings yet

- Inovance H1u PLC Product Note English 20 4 20 PDFDocument2 pagesInovance H1u PLC Product Note English 20 4 20 PDFMuthukumaresan ANo ratings yet

- 2 SB 1626Document1 page2 SB 1626wds657No ratings yet

- E50 (A), E52 (C), E61 (D)Document1 pageE50 (A), E52 (C), E61 (D)varenziaNo ratings yet

- Multidrop Link Guide: Normal Link Between PLC and Workstation (RS-232/RS-422/RS-485)Document7 pagesMultidrop Link Guide: Normal Link Between PLC and Workstation (RS-232/RS-422/RS-485)jonathan leonNo ratings yet

- Your User Manual Weg Cfw-10 EasydriveDocument2 pagesYour User Manual Weg Cfw-10 Easydrivejonathan leonNo ratings yet

- Simplificacion 1Document2 pagesSimplificacion 1jonathan leonNo ratings yet

- SIMPLIFICACION2Document2 pagesSIMPLIFICACION2jonathan leonNo ratings yet

- Simplificacion 1Document2 pagesSimplificacion 1jonathan leonNo ratings yet

- SIMPLIFICACION2Document2 pagesSIMPLIFICACION2jonathan leonNo ratings yet

- Fx2n 2ad Usersguide Jy992d74701 DDocument2 pagesFx2n 2ad Usersguide Jy992d74701 Djonathan leonNo ratings yet

- FX3U FLROM HardwareManual MemoryCassette JY997D12801 EDocument1 pageFX3U FLROM HardwareManual MemoryCassette JY997D12801 Ejonathan leonNo ratings yet

- GOT-A900series l08013cDocument1 pageGOT-A900series l08013cjonathan leonNo ratings yet

- DIN-Rail Mounted Power Supplies: DR Series 1.3 To 40 AmpsDocument3 pagesDIN-Rail Mounted Power Supplies: DR Series 1.3 To 40 Ampsjonathan leonNo ratings yet

- FX - 32BL Battery Hardware Manual: 1. Battery Life and Date of ManufactureDocument1 pageFX - 32BL Battery Hardware Manual: 1. Battery Life and Date of Manufacturejonathan leonNo ratings yet

- Yokogawa MW100Document13 pagesYokogawa MW100Jose Luis ColmenaresNo ratings yet

- Cambridge Assessment International Education: Computer Science 2210/13 October/November 2019Document14 pagesCambridge Assessment International Education: Computer Science 2210/13 October/November 2019Sarim JavedNo ratings yet

- Tiva C Series LaunchPadDocument152 pagesTiva C Series LaunchPadjan de la madridNo ratings yet

- Pic12Lf1840T48A Data Sheet: 8-Pin Flash Microcontroller With Nanowatt XLP TechnologyDocument372 pagesPic12Lf1840T48A Data Sheet: 8-Pin Flash Microcontroller With Nanowatt XLP Technologya5816No ratings yet

- LPC55S06 ManualDocument1,029 pagesLPC55S06 ManualSATISHREDDYNo ratings yet

- Bridge Type Sensor Measurements PDFDocument3 pagesBridge Type Sensor Measurements PDFSuvankar SasmalNo ratings yet

- Epac 3000 Rev2 Hardware Manual Rev 1.0Document33 pagesEpac 3000 Rev2 Hardware Manual Rev 1.0Anonymous ouFzvkzNo ratings yet

- Battery Charger - InoDocument15 pagesBattery Charger - InoDuraya IsmailNo ratings yet

- Microconverter 12-Bit Adcs and Dacs With Embedded High Speed 62-Kb Flash Mcu Aduc841/Aduc842/Aduc843Document88 pagesMicroconverter 12-Bit Adcs and Dacs With Embedded High Speed 62-Kb Flash Mcu Aduc841/Aduc842/Aduc843qhan90100% (1)

- Electronic System Design - ESD SyllabusDocument3 pagesElectronic System Design - ESD SyllabusAnoop MathewNo ratings yet

- Thomson Chassis Mt35Document89 pagesThomson Chassis Mt35ricardo_MassisNo ratings yet

- BQ 76952Document86 pagesBQ 76952Đạt Trần DoãnNo ratings yet

- Microelectronic PillDocument11 pagesMicroelectronic Pillheloparu100% (2)

- 18ECC203J - Unit 3 Session 1 - 3Document55 pages18ECC203J - Unit 3 Session 1 - 3Ankur JhaNo ratings yet

- DEWE-43 User ManualDocument37 pagesDEWE-43 User ManualyudiNo ratings yet

- RA8875 - Manual DatasheetDocument179 pagesRA8875 - Manual DatasheetPedro José Arjona GonzálezNo ratings yet

- Fuel Sensor: Electronic Systems LTDDocument32 pagesFuel Sensor: Electronic Systems LTDesoft7No ratings yet

- 06119397Document6 pages06119397bpd21No ratings yet

- Edwards ADC Active Digital Controller 3601 0196 01Document4 pagesEdwards ADC Active Digital Controller 3601 0196 01Michel León FrancoNo ratings yet

- Static Energy Meter Errors Caused by Conducted Electromagnetic InterferenceDocument7 pagesStatic Energy Meter Errors Caused by Conducted Electromagnetic InterferenceCerduardo Chanchisco Roga Rojas100% (1)

- PLC User's ManualDocument32 pagesPLC User's ManualAlex Porro Seclen33% (9)

- VI Dieu Khien Va Ung Dung - Nguyen Hong Quang - 2.introdspicDocument42 pagesVI Dieu Khien Va Ung Dung - Nguyen Hong Quang - 2.introdspicHùng NguyễnNo ratings yet

- FALLSEM2022-23 ECE4001 ETH VL2022230102368 Reference Material I 21-07-2022 Module - 1Document20 pagesFALLSEM2022-23 ECE4001 ETH VL2022230102368 Reference Material I 21-07-2022 Module - 1RISHABH PANDEYNo ratings yet

- Fortune' Properties For Reference Only: DatasheetDocument46 pagesFortune' Properties For Reference Only: DatasheetEL Picasesos TE VA PicarNo ratings yet

- Blue Eyes Technology IEEE+FORMATDocument18 pagesBlue Eyes Technology IEEE+FORMATBalaji King100% (2)

- LCD TV RepairDocument44 pagesLCD TV Repairbrotherg100% (11)

- The Z TransformDocument44 pagesThe Z Transformbrian mgabiNo ratings yet

- CIS Final ProjectDocument4 pagesCIS Final Project王柏勛No ratings yet

- Controledge Hc900 Io Modules Specifications: Universal AcDocument38 pagesControledge Hc900 Io Modules Specifications: Universal AcrahmadhaniNo ratings yet

- Maximizing The Capacity-Reach of 800G Generation Coherent: Baud Rates, Features, and Modem SNRDocument14 pagesMaximizing The Capacity-Reach of 800G Generation Coherent: Baud Rates, Features, and Modem SNRyunNo ratings yet