Professional Documents

Culture Documents

Earth Rite RTR

Uploaded by

Cris0102 MontielOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Earth Rite RTR

Uploaded by

Cris0102 MontielCopyright:

Available Formats

Leading the way in hazardous area static control

Earth-Rite® RTR™

Static Grounding for Tank Trucks

IECEx SIL 2

ATEX

® ™

Precision and reliability is what the Earth-Rite RTR

provides to HAZLOC safety professionals and engineers

who are tasked with protecting personnel and plant assets

from the ignition hazards of static electricity during tank

truck loading and unloading operations.

Inquiry > Click here to submit a

product related query or a request

for quotation.

Earth-Rite RTR Road Tanker Grounding System

The loading and unloading of tank The Earth-Rite RTR utilises patented

trucks with large quantities of electronics called “Tri-Mode”

chemicals and powders generates technology (next page) to establish

static electricity which, if left to three key inputs that must be in

accumulate on a tank truck, could place before the loading/unloading

discharge electrostatic sparks with operation can commence. When the

energies far in excess of the three key inputs are met, only then

minimum ignition energies of a vast will the Earth-Rite RTR go permissive

range of combustible gases, vapours and energise its pair of dry change-

and dusts. The ignition of such over contacts to engage the pump,

The Earth-Rite RTR includes:

atmospheres by static electricity can or whatever equipment is interlocked

> Explosion Proof Control Enclosure

be prevented by ensuring the tank with the system, to control the flow of

incorporating Intrinsically Safe Static

truck is grounded. product to or from the tank truck.

Ground Monitoring Electronics.

Any static generated by the loading

Grounding ensures there can be no operation is transferred from the tank

build of static electricity on the tank truck via the Earth-Rite RTR to > Ground Connection Junction Box

and chassis of the tank truck and the ground, eliminating static electricity with Clamp Stowage Point and Quick

most reliable way of grounding your as a potential source of ignition. Release Connector.

tank trucks is to specify an

Earth-Rite RTR. With over 3,000 units > Heavy Duty Stainless Steel Universal

in the field the 2nd generation Grounding Clamp

Earth-Rite RTR is the most reliable with Hytrel™ Extendable Cable and

and precise method of grounding Quick Connectors.

tank trucks today.

Newson Gale | For over 30 years Newson Gale has been supplying the chemical and processing industry worldwide with its

market leading range of static control products ensuring people and plant are protected from static related fires and explosions.

www.newson-gale.com Page 1 of 13 Tri-Mode Technology >

Leading the way in hazardous area static control

Earth-Rite® RTR™ Static Grounding for Tank Trucks

GREEN LIGHT

Tri-Mode checks complete

Tri-Mode Technology RTR permits product transfer

MODE 1 |Tank Truck Recognition

In accordance with the recommendations of IEC 60079-32*, the Earth-Rite RTR

determines if the grounding clamp is connected to a tank truck. This ensures

the clamp is connected to the main body of the tank truck and cannot be

bypassed by connecting the clamp to the loading rack.

MODE 2 | Static Ground Verification

The Earth-Rite RTR ensures that it has a connection to the general mass of the

earth. This is a critical input as a connection to earth is the only means by

which the static electricity can be transferred from the tank truck, preventing

the accumulation of static electricity.

MODE 3 | Continuous Ground Loop Monitoring

In accordance with the key recommendations of IEC 60079-32* and

NFPA 77*, the Earth-Rite RTR ensures the resistance between the tank truck

and the verified grounding point at the loading rack never exceeds 10 ohms.

The Earth-Rite RTR achieves this by monitoring the resistance between the

RTR clamp’s connection to the tank truck and the RTR’s connection to the

verified grounding point for the duration of the transfer operation.

*IEC 60079-32, “Explosive atmospheres: electrostatic hazards, guidance”

*NFPA 77, “Recommended Practice on Static Electricity”.

Pulsing LEDs confirm

positive ground connection.

Compliant with The monitoring set-point of 10 ohms resistance is compliant

IEC 60079-32 with the standards for static control in hazardous areas: IEC

& NFPA 77 60079-32 & NFPA77.

Operator friendly Simple GO / NO GO indication informs operator when the Options

interface road tanker is connected to ground. When a positive RTR System Tester (ER2/CRT)

ground connection is made the pulsing hi-visibility indicators

are activated during the MODE 3| Continuous Ground Loop Mode Selector Keyswitch

Monitoring stage.

Self-Retracting Cable Reel

Control / Interlock The first output contact can be used to interlock with flow Explosion Proof Strobe Light

capability control devices (e.g. pumps, valves, PLCs) to ensure

(Two dry output product cannot flow unless the RTR has established a IEC/Cenelec (European) and NEC/CEC (North

contacts) ground path for the tanker truck. The second output contact American) versions available

can operate attention grabbing devices (e.g. strobe lights) to

warn personnel that a hazardous product transfer is Certification

underway.

Wide operating The RTR system can operate in extreme weather conditions IECEx SIL 2

temperature range without modifications or enhanced protection: -40°F to

+122°F.

Ingress Protection Temperature Range

Detachable Clamp & Quick Connect system provides flexible and easy removal of

Type 4X - IP 66 -40oF to +122oF - CSA

Cable grounding clamp and cable from the hazardous area for

(-40oC to +55oC -

maintenance.

ATEX / IECEx)

Universally Approved Suitable for installation in highest range of gas and vapour

Enclosure environments. Power Supply

Selectable 110/120 V or 220/240 V AC, 50-60 Hz

Selectable 12 V or 24 V DC

The Earth-Rite® RTR™ forms part of the Earth-Rite® range of Static

Grounding and Bonding Equipment available from Newson Gale Inc.

www.newson-gale.com Page 2 of 13 Technical Specification >

Leading the way in hazardous area static control

Earth-Rite® RTR™ Static Grounding for Tank Trucks

Technical Specification

)

m

5.5" (140mm)

7m

"(

XP (Class I, II, III - Div 1 Installations)

0.3

Ø

Newson

Gale

Monitoring unit

5.5" (140mm)

Power supply 110/120 V or 220/240 V AC, 50-60 Hz

12 V or 24 V DC

Power rating 10 watt

Ambient temperature range -13oF to +131oF

Ingress protection Type 4X, (IP 66)

7.5" (192mm) 5.2" (132mm)

Weight 9.9 lbs (4.5 kg) nett

ATEX certified / UL Approved copper free cast

Construction Copper-free cast aluminium aluminium enclosure - IP 66 / Type 4X

Monitoring Circuit Intrinsically Safe

Operational Series Ground Nominally ≤10 Ohm

Resistance 2 x Tungsten

Carbide Teeth

Retractable

Output Relay Contact Rating 2 off dry contacts, Hytrel Cable

250 V AC, 5 A, 500 VA max resistive Stainless Steel

Handles (304)

30 V DC, 2 A, 60 W max resistive

Cable Entries 7 x ¾" NPT (supplied with 4 stopper plugs)

Universal 9.3" (237mm)

Grip

ATEX certified / FM Approved 2 Pole stainless steel

grounding clamp fitted with one pair of tungsten carbide tips

Junction Box/Stowage Point

Enclosure Material GRP with carbon loading

3" (75mm)

Terminals 2 x AWG #14 conductor capacity

Stowage Device Insulated ¾" diameter pin

Cable Entries 1 x M20 2.2" (57mm)

Clamp Cable Connection Quick Connect

1.8" (45mm)

Grounding Clamp

Clamp Design 2 pole with tungsten carbide teeth

Body Stainless Steel 2.7" (68mm)

3.15" (80mm)

Approval FM Approved

Simple Apparatus GRP clamp

stowage box with grounding

clamp stowage pin

Spiral Cable

Cable Blue Cen-Stat Hytrel sheath (Static

dissipative, chemical & abrasion resistant)

Conductors 2 x AWG #18 copper

Length 32 ft. (10 m) extended, 3 ft. (1 m)

unextended (other lengths available -

please inquire)

www.newson-gale.com Page 3 of 13 Certification Data >

Leading the way in hazardous area static control

Earth-Rite® RTR™ Static Grounding for Tank Trucks

Hazardous Area Certication

Europe / International: North America:

IECEx NEC 500 / CEC (Class & Division)

Ex d[ia] IIC T6 Gb(Ga) (gas & vapour). Associated Equipment [Ex ia] for use in

Ex tb IIIC T80ºC IP66 Db (combustible dusts). Class I, Div. 1, Groups A, B, C, D;

Ta = -40ºC to +55ºC. Class II, Div. 1, Groups E, F, G;

IECEx SIR 09.0018 Class III, Div. 1,

IECEx certifying body: SIRA. Providing intrinsically safe circuits for

Class I, Div. 1, Groups A, B, C, D;

ATEX Class II, Div. 1, Groups E, F, G;

II 2(1)GD Class III, Div. 1,

Ex d[ia] IIC T6 Gb(Ga) When installed per Control Dwg;

Ex tb IIIC T80ºC IP66 Db ERII-Q-10110 cCSAus

Ta = -40ºC to +55ºC. Ta = -25°C to +50°C.

Sira 09ATEX2047 Ta = -13°F to +122°F.

ATEX Notified Body: SIRA.

OSHA recognised NRTL: CSA.

NEC 505 & 506 (Class & Zoning)

Class I, Zone 1 [0] AEx d[ia] IIC T6 Gb(Ga)

(gas & vapour).

Class II, Zone 21 [20] AEx tD [iaD] 21 T80oC

(combustible dusts).

CEC Section 18 (Class & Zoning)

Class I, Zone 1[0] Ex d[ia] IIC T6 Gb(Ga)

DIP A21, IP66, T80ºC

Additional Certication

Safety Integrity Level: SIL 2 (in accordance with IEC/EN 61508).

SIL assessment body: Exida

EMC Tested: to EN 61000-6-4, EN 61000-6-2

FCC - Part 15 (Class B)

IECEx SIL 2

ATEX

www.newson-gale.com Page 4 of 13 Technical Specification >

Leading the way in hazardous area static control

Earth-Rite® RTR™ Static Grounding for Tank Trucks

6.2" (160mm)

Technical Specification

GRP (Class I, II, III - Div 2 Installations)

6.2" (160mm)

Power Supply & Monitoring Unit

Power Supply 108/125 V or 216/250 V AC, 50-60 Hz

12 V or 24 V DC

Power Rating 10 watt

Ambient Temperature Range -13°F to +122°F

Ingress Protection IP 66

Earth-Rite RTR in Static Dissipative Enclosure consisting of ground loop

Weight 4.4 lbs (2 kgs) nett monitoring module and 230V/110V power supply for Zone 21& 22 dust

atmospheres installations. This system may also be installed in Zone 2

Construction Carbon-loaded GRP atmospheres. For Zone 1 installations the Earth-Rite RTR is supplied in a

universally approved Ex(d)/XP metal enclosure.

Monitoring Circuit Intrinsically safe

Operational Series Ground Nominally ≤10 Ohm

Resistance

1.8" (45mm)

3" (75mm)

Output Relay Contact Rating 2 off dry contacts,

250 V AC, 5 A, 500 VA max resistive

30 V DC, 2 A, 60 W max resistive

Cable Entries 7 x M20 (4 x plugged) 2.2" (57mm)

2.7" (68mm)

3.15" (80mm)

Junction Box/Stowage Point

2 x Tungsten

Enclosure Material GRP with carbon loading Carbide Teeth

Terminals 2 x AWG #14 conductor capacity

Stainless Steel

Handles (304)

Stowage Device Insulated 0.79" diameter pin

Cable Entries 1 x M20

9.3" (237mm)

Clamp Cable Connection Quick Connect

X90-IP - Static Grounding Clamp

Grounding Clamp

Stainless Steel

Clamp Design 2 pole with tungsten carbide teeth Handles (304)

2 x Tungsten

Carbide Teeth

Body Stainless steel

Certication Ex II 1 GD T6 4.7" (120mm)

Approval FM Approved X45-IP - Static Grounding Clamp

ATEX certified / FM Approved 2 Pole stainless steel grounding clamp

fitted with one pair of tungsten carbide tips.

Spiral Cable

Cable Blue Cen-Stat Hytrel sheath (Static dissipative,

chemical & abrasion resistant)

Conductors 2 x AWG #18 copper

Length 32 ft. (10 m) extended, 3 ft. (1 m) unextended

(other lengths available, please inquire)

www.newson-gale.com Page 5 of 13 Certification Data >

Leading the way in hazardous area static control

Earth-Rite® RTR™ Static Grounding for Tank Trucks

Hazardous Area Certication

Europe / International: North America:

IECEx NEC 500 / CEC (Class & Division)

Ex nA nC [ia] IIC T4 Gc(Ga) (gas & vapour). Associated Equipment [Ex ia] for use in

Ex tb IIIC T70ºC Db (combustible dusts). Class I, Div. 2, Groups A, B, C, D;

Ta = -40ºC to +55ºC. Class II, Div. 2, Groups E, F, G

IECEx SIR 09.0097 Class III, Div. 2,

IECEx certifying body: SIRA. Providing Intrinsically Safe circuits for

Class I, Div. 1, Groups A, B, C, D;

ATEX Class II, Div. 1, Groups E, F, G;

Class III, Div. 1;

II 3(1) G

When installed per Control Dwg;

Ex II 2D

ERII-Q-10165 cCSAus

Ex nA nC [ia] IIC T4 Gc(Ga)

Ta = -25°C to +55°C.

Ex tb IIIC T70ºC Db

Ta = -13°F to +131°F.

Ta = -40ºC to +55ºC.

Sira 09ATEX2247

OSHA recognised NRTL: CSA.

ATEX Notified Body: SIRA.

NEC 505 & 506 (Class & Zoning)

Class I, Zone 2, (Zone 0), AEx nA[ia] IIC T4

(gas & vapour).

Class II, Zone 21, AEx tD[iaD] 21, T70ºC,

(combustible dusts).

CEC Section 18 (Class & Zoning)

Class I, Zone 2 (Zone 0) Ex nA[ia] IIC T4

DIP A21, IP66, T70ºC

Additional Certication

Safety Integrity Level: SIL 2 (in accordance with IEC/EN 61508).

SIL assessment body: Exida

EMC Tested: to EN 61000-6-4, EN 61000-6-2

FCC - Part 15 (Class B)

IECEx SIL 2

ATEX

www.newson-gale.com Page 6 of 13 System Options >

Leading the way in hazardous area static control

Earth-Rite® RTR™ Static Grounding for Tank Trucks

System options

Newson Gale supplies a range of product options that enhance the control and

general safety of transfer processes and aid engineers with system installations

and routine system service checks. Contact Newson Gale or your local Newson

Gale representative for more information on the range of options available.

Hazardous Area Strobe Light

The strobe light is mounted in an elevated position and when the equipment

is correctly grounded, flashes continuously informing personnel that a

transfer process is underway and is protected from the static hazard. The

strobe light can be used in conjunction with the Earth-Rite RTR and

Earth-Rite PLUS.

> ATEX and Class/Div approved versions.

> 115 V / 230 V AC and 24 V / 48 V DC options.

Hazardous Area Strobe Light

> Amber, Green & Red strobe colour options.

Product Code: VESI/33U (Class/Div)

Inquire for color and mounting

options

RTR Tester

The RTR Tester is designed to have the same electrical characteristics as a

road tanker and provides engineers with a means of checking that the RTR

undergoing installation is permissive when it detects these characteristics.

The Tester is connected to the RTR system and it’s grounding point, and

when activated, the RTR’s LED indicators change from red to green,

confirming that the Road Tanker Recognition and Static Ground Verification

checks are functioning as intended.

> Ideal for system commissioning and routine service checks.

> Easy to use with simple PASS / FAIL condition. RTR Tester

Product Code: ER2/CRT.

www.newson-gale.com Page 7 of 13 System Options >

Leading the way in hazardous area static control

Earth-Rite® RTR™ Static Grounding for Tank Trucks

VESM02 Retractable Cable Reel

The VESM02 Retractable Cable Reel is supplied for grounding system

installations where customers want to ensure the grounding clamp and

cable are returned to the static grounding system by operators and drivers on

completion of the product transfer process. The VESM02 Reel can be used

in conjunction with the Earth-Rite RTR, Earth-Rite MGV and

Earth-Rite PLUS.

> Certified for ATEX Zone 1 and 21 hazardous areas.

> Self-retracting with up to 15 m (50 ft.) of Hytrel® protected cable.

VESM02 Retractable

> Silver plated ultra low resistance slip ring contacts. Cable Reel

Product Code: VESM02.

Sun Shield

Designed for operating environments subject to intense sunlight, the ERII Sun

Shield prevents direct sunlight hitting the indicators on the Earth-Rite RTR

and Earth-Rite PLUS static grounding systems.

The Sun Shield casts a shadow over the indicators during peak sun light

hours so that operators can easily view the ground status indicators. The

shield is constructed from stainless steel and can be fitted to any installation

Sun Shield

in a matter of minutes.

Product Code: ER2/SH

www.newson-gale.com Page 8 of 13 Application Spotlight >

Leading the way in hazardous area static control

Earth-Rite® RTR™ Static Grounding for Tank Trucks

Inquiry > Click here to submit a

product related query or a request

for quotation.

Application Spotlight Tank Truck static grounding protection.

As the product (liquid or powder) moves through the transfer system and interacts with pumps, valves,

filters meshes and pipe walls, the product will be building up the amount of electrostatic charge it carries. In

electrical terms this is commonly described as static charge accumulation. When the charged product is

transferred into the tank truck, the tank truck will become electrified and be subjected to a rising voltage.

When a typical tank truck is being filled A truck with capacitance as little as 1000 To counteract this risk, it is important to

with a liquid at recommended flow rates, pico-farads, that has been electrified to ensure that the tank truck does not have

but has no static grounding protection in 30,000 volts, has approximately 450 milli- the capacity to accumulate static

place, it could have its voltage raised to joules of potential spark energy waiting to electricity. The most practical and

between 10,000 volts and 30,000 volts be discharged in the form of a spark. comprehensive way of achieving this is to

within 10 to 50 seconds. This voltage Given that most hydrocarbon vapors and make sure that the tank truck is at “ground

range is very capable of discharging a high gases have MIEs of less than 1 milli-joule potential”, especially before the transfer

energy electrostatic spark towards objects and most combustible dusts have MIEs of process starts. When we describe “ground

at a lower voltage potential, especially less than 200 milli-joules, it’s easy to see potential” we mean that the tank truck is

anything at ground potential. Examples of why tank trucks that do not have static connected to the general mass of the

objects at ground potential could be grounding protection in place can be a Earth, which is commonly referred to, in

operators working in the vicinity of the major ignition source in a hazardous electrical terms, as “True Earth”.

truck, or the filling pipe situated in the location.

hatch on top of the tank truck.

It is possible to estimate the energy of

such sparks by combining the capacitance

of the tank truck with the voltage on the The surface of the road tanker Increased charge accumulation on

tank truck at the time the spark is takes up the charges (in red) the surface of the road tanker leads

of the charged liquid. to an increase in the voltage of the

discharged. road tanker.

Capacitance is a measure of how much

charge can accumulate on the outer

surface of the tank truck. Because tank

trucks have a very large surface area, they

can accumulate very large amounts of

charge, which in turn, creates the presence

of very high voltages on the surface of the

tank truck.

General mass of Earth

1. Electrostatically charged road tanker (electrified road tanker).

www.newson-gale.com Page 9 of 13 Application Spotlight >

Leading the way in hazardous area static control

Earth-Rite® RTR™ Static Grounding for Tank Trucks

Application Spotlight Tank Truck static grounding protection.

This is because the general mass of the Earth

has an infinite capacity to pull static charges

from the tank truck, which in turn eliminates the

generation and presence of voltages on the

tank truck.

Typical spark discharge territory

The Earth-Rite RTR performs three critical k

uc

er tr

functions which ensures the fire and explosion nk

Voltage (KV)

a

dt

risk of an ignition caused by static electricity is roa

on

eliminated. The first function the Earth-Rite nt

rese

RTR performs is in determining if the driver or ep

ag

volt

operator has made a secure connection to the ing Potential spark energy = 0.5 CV

2

Ris

body of the tank truck. Potential spark energy at 30 KV = 450 mJ

This minimises the risk of the driver obtaining a

permissive condition for the static grounding Charging Time (secs)

system by connecting to metal objects like the

loading rack, or objects on the tank truck that

could be isolated from the main body of the 2. Voltage build-up on charged tank truck.

tank truck (e.g. wheel nuts), as this would

defeat the objective of passing electrostatic

charges from the tank truck to ground.

Potential spark gap

between surface of charged

tank truck and grounded

filling pipe.

3. Example of potential spark gap during road tanker loading operation.

www.newson-gale.com Page 10 of 13 Application Spotlight >

Leading the way in hazardous area static control

® ™

Earth-Rite® RTR™ Static Grounding for Tank Trucks

Application Spotlight Tank Truck static grounding protection.

The Earth-Rite RTR then verifies if it …the Earth-Rite RTR will then If the resistance is not more than 10

has a low resistance connection to True establish and continuously monitor the ohms the Earth-Rite RTR will indicate

Earth via the structure to which it is connection resistance between the tank that the tank truck is connected to

connected, e.g. the loading rack. truck and the verified earth ground is ground and indicate this via its ground

10 ohms or less. status indicators, a cluster of green

As any static charges generated by LEDs that pulse continuously.

tank truck loading (unloading) process 10 ohms is the benchmark requirement

will travel to ground via the Earth-Rite repeated in several international Codes

RTR, it is important to ensure the of Practice, the most prominent of

Earth-Rite RTR itself has a low which is the National Fire Protection

resistance connection to True earth. Associations’s NFPA 77

When both of these conditions are “Recommended Practice on Static

positive, i.e.: Electricity” and the IEC’s 60079-32-1

“Explosive Atmspheres: Electrostatic

1. The Earth-Rite RTR knows it is Hazards - Guidance”.

connected to a tank truck.

2. The Earth-Rite RTR knows it is

connected to a verified earth

ground.

1 Earth-Rite RTR ensures it is connected to a

3 Earth-Rite RTR ensures the

tank truck by assessing the electrical characteristic resistance between the tank truck and

of the tank truck. the verified earth grounding point is

10 ohms or less. This is monitored for

the duration of the product transfer

operation. The dry (volt free) contacts

are energised to engage pumps,

valves or PLC controls.

0 volts on tank truck Newson

Gale

Relays to interlock with loading

rack equipment.

Objective: ensure

electrostatic charges have

a path to earth via a

General mass of Earth verified ground connection

for the duration of the

product transfer operation.

2 Earth-Rite RTR ensures the resistance of the loading rack structure to ground

is low enough to safely pass static charges off the tank truck to earth. In this

example the RTR verifies that loading rack structure will function as a True earth

grounding point. The shaded area represents the “concentric shells” of

resistance between the mass of the Earth and the desired grounding point (e.g.

loading rack structure).

4. How the Earth-Rite RTR ensures static electricity cannot build-up on the tank truck.

www.newson-gale.com Page 11 of 13 Application Spotlight >

Leading the way in hazardous area static control

Earth-Rite® RTR™ Static Grounding for Tank Trucks

Application Spotlight Tank Truck static grounding protection.

The LEDs pulse continuously to If the Earth-Rite RTR determines that

indicate that the RTR is continuously the tank truck has lost its connection

monitoring the static grounding to ground, the volt free contacts can

circuit between the tank truck and be used to halt the transfer process.

the verified earth grounding point The benefit of halting the transfer

(e.g. loading rack) for the duration of process removes the charging

the product transfer process. If the mechanism that would otherwise

resistance of the tank truck’s charge up the tank truck while it has

connection to the verified earth no active static grounding protection

ground ever rises above 10 ohms, in place.

the Earth-Rite RTR will go non-

permissive. * “earthing”: the equivalent term is

“grounding”.

Both of the Codes of Practice listed

above recommend that interlocks

controlling the flow of product to or

from the tank truck are provided by 5. The Earth-Rite RTR in a permissive condition.

the static grounding system. To

comply with this requirement, the

Earth-Rite RTR has two dry contacts

that can interface with control circuits IEC 60079-32-1, section 7.3.2.3.3, part c, states:

for pumps, valves and PLCs.

“It is recommended that the earth cable required

in b) be part of a static earth monitoring system

that continuously monitors the resistance

between the truck and a designated earthing

point on the gantry and activates interlocks to

prevent loading when this resistance exceeds 10

Ω. It is further recommended that the static earth

monitoring system should be capable of

differentiating between connection to the truck’s

tank (or earth connection point) and other metal

objects. This type of system will prevent operators

from connecting the earthing system to objects

(e.g. the mudguards) that may be electrically

isolated from the truck’s container.”

www.newson-gale.com Page 12 of 13 Product Ordering Codes >

Leading the way in hazardous area static control

Earth-Rite® RTR™ Static Grounding for Tank Trucks

Contact Us > Your inquiry will be processed

rapidly via our webform enquiry service. If you

would prefer to call us, or e-mail us, please use

the contact details provided below.

Product Ordering Codes * Additional Options Available

Ordering Code Product Description

RTRMUA1A3* Earth-Rite RTR Static Grounding System, Selectable 110/120 V

AC or 220/240 V AC including Heavy Duty grounding clamp,32

ft. (10 m) retractable spiral cable and GRP clamp stowage box

RTRP1UA1A3* Earth-Rite RTR Static Grounding System, GRP Enclosure,

Selectable 110/120 V AC or 220/240 V AC including Heavy Duty

grounding clamp, 32 ft. (10 m) retractable spiral cable and GRP

clamp stowage box

RTRP1UA4A7* Earth-Rite RTR Static Grounding System, GRP Enclosure,

Selectable 110/120 V AC or 220/240 V AC including Heavy Duty

grounding clamp, 50 ft. (15.2 m) retractable M02 cable reel

VESM02 VESM02 Retractable Cable reel with 50 ft. (15 m) of 2 conductor

Hytrel protected static grounding cable

ER2/CRT RTR Tester for RTR System installation commissioning and

servicing

ER2/SH Earth-Rite Sun Shield

ER/VESS60 SoundEx, XP Electronic Sounder

VESI/33U Explosion Proof Strobe Light (colour options amber, clear, blue,

green and red) - Please enquire for more details

* Alternative clamp, cable length and reel options upon request.

Contact your local sales office or distributor with your requirements.

United States United Kingdom Deutschland South East Asia

Newson Gale Inc Newson Gale Ltd Newson Gale GmbH Newson Gale S.E.A. Pte Ltd

NG US RTR 300616 R7

460 Faraday Avenue Omega House Ruhrallee 185 136 Joo Seng Road

Bldg C Private Road 8 45136 Essen #03-01

Jackson, NJ 08527 Colwick, Nottingham Deutschland Singapore

USA NG4 2JX, UK 368360

+1 732 961 7610 +44 (0)115 940 7500 +49 (0)201 89 45 245 +65 6704 9461

groundit@newson-gale.com groundit@newson-gale.co.uk erdung@newson-gale.de ngsea@newson-gale.com www.newson-gale.com

You might also like

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- O & M of Sub StationDocument94 pagesO & M of Sub StationAlbert Sekar100% (2)

- Offshore Electrical Engineering ManualFrom EverandOffshore Electrical Engineering ManualRating: 4 out of 5 stars4/5 (9)

- D 01aDocument40 pagesD 01aذوالفقار حبيبNo ratings yet

- Cascadia PrtPak 09AUG13Document44 pagesCascadia PrtPak 09AUG13Raul LunaNo ratings yet

- Load Bank Operating InstructionsDocument194 pagesLoad Bank Operating InstructionsJonathan Javier Ceballos Bonilla0% (1)

- T Proc Notices Notices 040 K Notice Doc 39826 154073019 PDFDocument281 pagesT Proc Notices Notices 040 K Notice Doc 39826 154073019 PDFabbastceNo ratings yet

- Triconex TrainingDocument38 pagesTriconex Trainingvenkatsubbu0% (1)

- Resistance Grounded Systems: PurposeDocument6 pagesResistance Grounded Systems: PurposeranjuNo ratings yet

- SICON-4000MZi in English (Rev1 8) PDFDocument116 pagesSICON-4000MZi in English (Rev1 8) PDFAdjie89% (9)

- One Word AnsDocument65 pagesOne Word Ansss_chinniNo ratings yet

- Resistance Grounded Systems: PurposeDocument6 pagesResistance Grounded Systems: Purposerenjithas2005No ratings yet

- TwingoDocument26 pagesTwingoDumitru-Lucian PurcaruNo ratings yet

- Worldpremium: AC-250M/156-60S AC-255M/156-60S AC-260M/156-60SDocument2 pagesWorldpremium: AC-250M/156-60S AC-255M/156-60S AC-260M/156-60SSeptimiu BotaNo ratings yet

- Sugar ManufacturingDocument55 pagesSugar Manufacturingamrialifa100% (3)

- Thin Film Deposition MethodsDocument14 pagesThin Film Deposition MethodsoktavNo ratings yet

- T e C H N I C A L S P e C I F I C A T I o N o F 3 3 / 1 1 K V M o B I L e S U B - S T A T I o N 1 × 1 0 M V A 1 × 1 6 M V ADocument24 pagesT e C H N I C A L S P e C I F I C A T I o N o F 3 3 / 1 1 K V M o B I L e S U B - S T A T I o N 1 × 1 0 M V A 1 × 1 6 M V Aذوالفقار حبيبNo ratings yet

- Electrical Control SystemsDocument9 pagesElectrical Control SystemsM.IBRAHEEMNo ratings yet

- Electrostatic PrecipitatorDocument12 pagesElectrostatic PrecipitatorchandraNo ratings yet

- NG Uk RTR 0220 r15 PDFDocument9 pagesNG Uk RTR 0220 r15 PDFDuong Thai BinhNo ratings yet

- Us Earth Rite Plus Exd DatasheetDocument7 pagesUs Earth Rite Plus Exd DatasheetwlyskrdiNo ratings yet

- Earth Integrity MonitorDocument2 pagesEarth Integrity MonitorAmy PriceNo ratings yet

- Static Earthing Protection For Rail TankersDocument5 pagesStatic Earthing Protection For Rail Tankersisjavg_jesusNo ratings yet

- 33 KV Recloser SpecsDocument22 pages33 KV Recloser SpecsO P Sridharan PerumalNo ratings yet

- Product Sheet Securiterre Type 640Document4 pagesProduct Sheet Securiterre Type 640MOHAMED SHARKAWINo ratings yet

- Static Protection System Cat. No.: SPS 600: Installation & Operational ManualDocument12 pagesStatic Protection System Cat. No.: SPS 600: Installation & Operational ManualHITESH100% (1)

- Gigasense DatasheetDocument4 pagesGigasense DatasheetRoberto VieiraNo ratings yet

- Technical Specification OF 11&33 KV Indoor Type Switchgear For Consumer SubstationDocument12 pagesTechnical Specification OF 11&33 KV Indoor Type Switchgear For Consumer SubstationAhmed JwdhariNo ratings yet

- Product Data Sheet Rosemount Tgu 58 Tank Radar Gauge Parabolic Antenna en 182276Document6 pagesProduct Data Sheet Rosemount Tgu 58 Tank Radar Gauge Parabolic Antenna en 182276m azamNo ratings yet

- Manual 2Document0 pagesManual 2Rafat ThongNo ratings yet

- Brochure NGR HilkarDocument4 pagesBrochure NGR HilkarCandra BaswardaniNo ratings yet

- Power System Protection For ESE ProposeDocument93 pagesPower System Protection For ESE ProposeYe GyiiiNo ratings yet

- Generator Specifications: 1-GeneralDocument14 pagesGenerator Specifications: 1-Generalgetachew mengstieNo ratings yet

- Winding and InsulationDocument6 pagesWinding and InsulationRatilal M JadavNo ratings yet

- Emco Dcmt3 enDocument2 pagesEmco Dcmt3 enFerdaous Paradis Ouiriemmi100% (1)

- 1mrk509002-Ben A en Time-Overcurrent Relays and Protection Assemblies Rxidk 2h Raidk Rxidg 21h RaidgDocument24 pages1mrk509002-Ben A en Time-Overcurrent Relays and Protection Assemblies Rxidk 2h Raidk Rxidg 21h RaidgDimas BlNo ratings yet

- Teorija - Thyristor, Triacs - Objasnjenje Karakteristika, Ig I Tako To, OdlicnoDocument6 pagesTeorija - Thyristor, Triacs - Objasnjenje Karakteristika, Ig I Tako To, Odlicnozelko kovacevicNo ratings yet

- Emco DCMT3 en PDFDocument2 pagesEmco DCMT3 en PDFcherif yahyaoui100% (2)

- T e C H N I C A L S P e C I F I C A T I o N o F K I o S K T y P e 1 1 / 0 - 4 K V S U B - S T A T I o N 2 5 0, 4 0 0 & 6 3 0 K V ADocument14 pagesT e C H N I C A L S P e C I F I C A T I o N o F K I o S K T y P e 1 1 / 0 - 4 K V S U B - S T A T I o N 2 5 0, 4 0 0 & 6 3 0 K V AAhmed JaNo ratings yet

- TAPCON® XPA-I - External Paralleling Assistant: Operating Instructions BA 282/02Document24 pagesTAPCON® XPA-I - External Paralleling Assistant: Operating Instructions BA 282/02Mahmoud AbuziadNo ratings yet

- 3.42 Grounding Control Device EKX-4 (Earthing Monitor) - Technical DescriptionDocument10 pages3.42 Grounding Control Device EKX-4 (Earthing Monitor) - Technical Descriptionel misNo ratings yet

- 65 Bedded MCH-mongar-Technical Specification - Electrical and LV SystemDocument53 pages65 Bedded MCH-mongar-Technical Specification - Electrical and LV SystemJigme TenzinNo ratings yet

- C-100EP HRG Product Guide-SJAHDocument24 pagesC-100EP HRG Product Guide-SJAHSejahtra AbadiNo ratings yet

- Objectives-2 0Document2 pagesObjectives-2 0Jennymhel 5st6rTuazonNo ratings yet

- MFAC ManualDocument19 pagesMFAC ManualAlpesh PatelNo ratings yet

- 9.8 Inverter Transformer Station (ITS) : 9.8.1 EnclosureDocument7 pages9.8 Inverter Transformer Station (ITS) : 9.8.1 Enclosurekser82No ratings yet

- TK3 Proximity System Test KitDocument6 pagesTK3 Proximity System Test KitMustapha REZGANINo ratings yet

- 7PG15 - TR: Answers For EnergyDocument4 pages7PG15 - TR: Answers For Energyahmedmaged88No ratings yet

- NWFall08 GingrasDocument2 pagesNWFall08 GingrasumairbvsNo ratings yet

- Phalcon-2000 Zone1 PressurizedDocument2 pagesPhalcon-2000 Zone1 PressurizedAnonymous UCveMQNo ratings yet

- Provision of Export Terminal Tug-ChecklistDocument5 pagesProvision of Export Terminal Tug-ChecklistMathias OnosemuodeNo ratings yet

- RECLOSER-FARADAY-33KV Auto Recloser BrochureDocument9 pagesRECLOSER-FARADAY-33KV Auto Recloser BrochureJoel Alevxandr OsorttoNo ratings yet

- Sifter Static EliminatorDocument1 pageSifter Static EliminatorTj Saitej100% (1)

- Summary of Installation Requirements and Annual Maintenance ProcedureDocument18 pagesSummary of Installation Requirements and Annual Maintenance ProcedureJuan DuqueNo ratings yet

- Types: Mfac 14 Mfac 34Document17 pagesTypes: Mfac 14 Mfac 34JadSamiNo ratings yet

- RC48C Ground-Fault Ground-Continuity MonitorDocument7 pagesRC48C Ground-Fault Ground-Continuity MonitorJhann Oliva GalvezNo ratings yet

- How To Select The Proper Neutral-Grounding Resistor For A High-Resistance Grounded Electrical SystemDocument6 pagesHow To Select The Proper Neutral-Grounding Resistor For A High-Resistance Grounded Electrical Systemjhon_pardo_3No ratings yet

- Instructions For Type KT Thermal-Magnetic Trip Unit Installation and Operation With K-Frame Series C Circuit BreakersDocument4 pagesInstructions For Type KT Thermal-Magnetic Trip Unit Installation and Operation With K-Frame Series C Circuit BreakersJussel Villafuerte AnamariaNo ratings yet

- E11 Unified Requirements For Systems With Voltages Above 1 KV Up To 15 KV E11Document7 pagesE11 Unified Requirements For Systems With Voltages Above 1 KV Up To 15 KV E11beho2000No ratings yet

- CPT Cirprotec V OVERVOLTAGE AND SURGE PROTECTION PDFDocument44 pagesCPT Cirprotec V OVERVOLTAGE AND SURGE PROTECTION PDFSitiSaodahNo ratings yet

- 1mrk502003-Ben A en Generator Protection CombiflexDocument20 pages1mrk502003-Ben A en Generator Protection CombiflexHai LeNo ratings yet

- En RecloserDocument8 pagesEn Recloseranastasija08100% (1)

- Ta840 Tg-L1019eDocument5 pagesTa840 Tg-L1019eKaleem KhanNo ratings yet

- RAIDK ManualDocument24 pagesRAIDK ManualAhmed RagabNo ratings yet

- Eld E08405Document2 pagesEld E08405AndrewcaesarNo ratings yet

- Alliance HD 73 RotorDocument14 pagesAlliance HD 73 RotorKenburNo ratings yet

- EPIV ValvesDocument2 pagesEPIV ValvesstomakosNo ratings yet

- Tsurumi Cutter ImpellerDocument5 pagesTsurumi Cutter ImpellerJapril AgustinNo ratings yet

- SAPPHIRE® PLUS 70-BarDocument2 pagesSAPPHIRE® PLUS 70-BarAyhan ÖZKALNo ratings yet

- Mantenedor de Bateria LBC1206Document6 pagesMantenedor de Bateria LBC1206YERKO OVIEDONo ratings yet

- H1000e 6Document472 pagesH1000e 6GesNo ratings yet

- Fuel, Lubricants and Fluids: en-GBDocument59 pagesFuel, Lubricants and Fluids: en-GBRuanNo ratings yet

- Incini-Cone SelectionGuide 420Document8 pagesIncini-Cone SelectionGuide 420Thaiminh Vo100% (1)

- Introduction To Marine MachineriesDocument13 pagesIntroduction To Marine MachineriessrcattozziNo ratings yet

- Eurocode 8-1-3Document18 pagesEurocode 8-1-3joaoNo ratings yet

- Single Plane Balance 091401Document16 pagesSingle Plane Balance 091401ridzim4638No ratings yet

- MR-E-A-QW003 MR-E - AG-QW003: General-Purpose AC Servo Ezmotion Mr-E Super General-Purpose InterfaceDocument326 pagesMR-E-A-QW003 MR-E - AG-QW003: General-Purpose AC Servo Ezmotion Mr-E Super General-Purpose InterfaceKailas PardeshiNo ratings yet

- Technical Data Compressor: SC12CLDocument6 pagesTechnical Data Compressor: SC12CLKokoNo ratings yet

- Vista Vista Ar Tech Data Sheet MalarkeyDocument2 pagesVista Vista Ar Tech Data Sheet MalarkeyHoeNo ratings yet

- Think WoodDocument10 pagesThink WoodkusumoajiNo ratings yet

- Multistage and Multilevel Power Electronic Converter-Based Power Supply For Plasma DBD DevicesDocument4 pagesMultistage and Multilevel Power Electronic Converter-Based Power Supply For Plasma DBD DevicesBrightworld ProjectsNo ratings yet

- Interfacing of Flame Sensor With ArduinoDocument14 pagesInterfacing of Flame Sensor With Arduinotech agentNo ratings yet

- Datasheet - GPxxAxxKNX - ENGDocument1 pageDatasheet - GPxxAxxKNX - ENGVishal SuryawaniNo ratings yet

- 27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)Document8 pages27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)autocomtrucksNo ratings yet

- Detection of Power Grid Synchronization Failure On Sensing Frequency and Voltage Beyond Acceptable RangeDocument6 pagesDetection of Power Grid Synchronization Failure On Sensing Frequency and Voltage Beyond Acceptable RangeHari PrasadNo ratings yet

- OSI - Screen Vortex DesanderDocument3 pagesOSI - Screen Vortex DesanderCarlos Andres Portilla HernandezNo ratings yet

- Plate Heat Exchanger Model M15-MFG - ASTM B265 Gr1 TitaniumDocument1 pagePlate Heat Exchanger Model M15-MFG - ASTM B265 Gr1 TitaniumCardoso MalacaoNo ratings yet

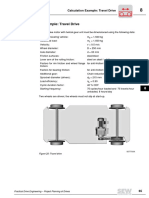

- Travel Drive ExampleDocument10 pagesTravel Drive Examplep-nicoNo ratings yet

- Catalog - Regent RSV Ed 3Document14 pagesCatalog - Regent RSV Ed 3Nyu123456No ratings yet

- 2-Wire Ac or DC Inductive SensorsDocument10 pages2-Wire Ac or DC Inductive SensorsCsaba VargaNo ratings yet