Professional Documents

Culture Documents

Ketron 1000 PEEK PDS E 30032019 01

Uploaded by

jorgepradaco1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ketron 1000 PEEK PDS E 30032019 01

Uploaded by

jorgepradaco1Copyright:

Available Formats

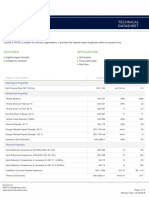

Poly-ether-ether-ketone

Ketron® 1000 PEEK

Ketron® 1000 PEEK stock shapes are produced from virgin polyetheretherketone resin and offer the highest toughness and

PRODUCT DATA SHEET T

impact strength of all Ketron® PEEK grades. Both Ketron® 1000 PEEK natural & black can be sterilised by all conventional

sterilisation methods (steam, dry heat, ethylene oxide and gamma irradiation).

Copyright 2019 The Mitsubishi Chemical Advanced Materials group of companies. All rights reserved. - Date of issue / revision: March 26, 2019

Physical properties (indicative values g)

PROPERTIES Test methods Units VALUES Legend:

Colour - - Tan, Black 1) According to method 1 of ISO 62 and done on discs Ø

50 mm x 3 mm.

2) The figures given for these properties are for the most

Density ISO 1183-1 g/cm³ 1.31 part derived from raw material supplier data and other

Water absorption: publications.

3) Values for this property are only given here for

- after 24 immersion in water of 23 °C (1) ISO 62 % 0.06 amorphous materials and for materials that do not show

- at saturation in water of 23 °C - % 0.45 a melting temperature (PBI, PAI, PI).

Thermal Properties (2) 4) Temperature resistance over a period of min. 20,000

hours. After this period of time, there is a decrease in

Melting temperature (DSC, 10 °C/min) ISO 11357-1/-3 °C 340 tensile strength – measured at 23 °C – of about 50 % as

Glass transition temperature (DSC, 20 °C/min) - (3) ISO 11357-1/-2 °C - compared with the original value. The temperature value

given here is thus based on the thermal-oxidative

Thermal conductivity at 23 °C - W/(K.m) 0.25 degradation which takes place and causes a reduction

Coefficient of linear thermal expansion: in properties. Note, however, that the maximum

- average value between 23 and 100 °C - m/(m.K) 50 x 10-6 allowable service temperature depends in many cases

essentially on the duration and the magnitude of the

- average value between 23 and 150 °C - m/(m.K) 55 x 10-6 mechanical stresses to which the material is subjected.

- average value above 150 °C - m/(m.K) 130 x 10-6 5) Impact strength decreasing with decreasing

temperature, the minimum allowable service

Temperature of deflection under load: temperature is practically mainly determined by the

- method A: 1.8 MPa ISO 75-1/-2 °C 160

extent to which the material is subjected to impact. The

value given here is based on unfavourable impact

Max. allowable service temperature in air: conditions and may consequently not be considered as

being the absolute practical limit.

- continuously : for min. 20,000 h (4) - °C 250 6) These estimated ratings, derived from raw material

Min. service temperature (5) - °C -50 supplier data and other publications, are not intended to

Flammability (6): reflect hazards presented by the material under actual

fire conditions. There is no ‘UL File Number’ available

- according to UL 94 (3 mm thickness) - - V-0 for these stock shapes.

Mechanical Properties at 23 °C (7) 40 x 10-6 7) Most of the figures given for these mechanical

properties of the materials are average values of tests

Tension test (8): run on dry test specimens machined either out of plate

- tensile strength (9) ISO 527-1/-2 MPa 115 15-20 mm thick or rod diameter 40-50mm, the test

- tensile strain at yield(9) ISO 527-1/-2 % 5 specimens were then taken from the stock shape with

their length in longitudinal direction (parallel to the

- tensile strain at break (9) ISO 527-1/-2 % 17 extrusion direction).

- tensile modulus of elasticity (10) ISO 527-1/-2 MPa 4300 8) Test specimens: Type 1 B

9) Test speed: either 5 or 50 mm/min [chosen acc. to ISO

Compression test (11):

10350-1 as a function of the ductile behaviour of the

- compressive stress at 1 / 2 / 5 % nominal strain (10) ISO 604 MPa 38 / 75 / 140 material (tough or brittle)]

Flexural test (12): 10) Test speed: 1 mm/min.

11) Test specimens: cylinders Ø 8 mm x 16 mm

- flexural strength ISO 178 MPa 170 12) Test specimens: bars 4 mm (thickness) x 10 mm x 80

- flexural modulus of elasticity ISO 178 MPa mm ; test speed: 2 mm/min ; span: 64 mm.

Charpy impact strength - unnotched (13) ISO 179-1/1eU kJ/m² no break 13) Pendulum used: 4 J.

14) Measured on 10 mm thick test specimens.

Charpy impact strength - notched ISO 179-1/1eA kJ/m² 3.5 15) Test procedure similar to Test Method A: “Pin-on-disk”

Rockwell M-hardness (14) ISO 2039-2 - 105 as described in ISO 7148-2, Load 3MPa, sliding

velocity= 0,33 m/s, mating plate steel Ra= 0.7-0.9 μm,

Dynamic Coefficient of Friction (-) ISO 7148-2 (15) - 0.3-0.5

tested at 23°C, 50%RH.

Wear rate ISO 7148-2 (15) µm/km 28 16) Electrode configuration: ∅ 25 mm / ∅ 75 mm coaxial

Electrical Properties at 23 °C 0 cylinders ; in transformer oil according to IEC 60296 ; 1

Electric strength (16) IEC 60243-1 kV/mm 24 mm thick test specimens.

Volume resistivity IEC 60093 Ohm.cm >10E 14 this table is a valuable help in the choice of a material. The

Surface resistivity ANSI/ESD STM 11.11 Ohm/sq. >10E13 data listed here fall within the normal range of product

Relative permittivity εr : - at 1 MHz IEC 60250 - 3.2 properties of dry material. However, they are not guaranteed

and they should not be used to establish material specification

Dielectric dissipation factor tan δ: - at 1 MHz IEC 60250 - 0.002 limits nor used alone as the basis of design.

Note: 1 g/cm³ = 1,000 kg/m³ ; 1 MPa = 1 N/mm² ; 1 kV/mm = 1 MV/m.

It has to be noted that reinforced and filled material shows an

anisotropic behaviour (properties differ when measured

® parallel and perpendicular to the manufacturing direction).

Ketron is a registered trademark of Mitsubishi Chemical Advanced Materials.

This product data sheet and any data and specifications presented on our website shall provide promotional and general information about the Engineering Plastic Products (the "Products") manufactured and

offered by Mitsubishi Chemical Advanced Materials and shall serve as a preliminary guide. All data and descriptions relating to the Products are of an indicative nature only. Neither this data sheet nor any data

and specifications presented on our website shall create or be implied to create any legal or contractual obligation.

Any illustration of the possible fields of application of the Products shall merely demonstrate the potential of these Products, but any such description does not constitute any kind of covenant whatsoever.

Irrespective of any tests that Mitsubishi Chemical Advanced Materials may have carried out with respect to any Product, Mitsubishi Chemical Advanced Materials does not possess expertise in evaluating the

suitability of its materials or Products for use in specific applications or products manufactured or offered by the customer respectively. The choice of the most suitable plastics material depends on available

chemical resistance data and practical experience, but often preliminary testing of the finished plastics part under actual service conditions (right chemical, concentration, temperature and contact time, as well

as other conditions) is required to assess its final suitability for the given application.

It thus remains the customer's sole responsibility to test and assess the suitability and compatibility of Mitsubishi Chemical Advanced Materials' Products for its intended applications, processes and uses, and to

choose those Products which according to its assessment meet the requirements applicable to the specific use of the finished product. The customer undertakes all liability in respect of the application,

processing or use of the aforementioned information or product, or any consequence thereof, and shall verify its quality and other properties.

You might also like

- TWIML - PODCAST - First NotesDocument3 pagesTWIML - PODCAST - First NotesKhim DV100% (2)

- TOPNOTCH DIGITAL HANDOUT - BIOCHEMISTRY Juan Dela CruzDocument2 pagesTOPNOTCH DIGITAL HANDOUT - BIOCHEMISTRY Juan Dela CruzJoy Fucanan100% (1)

- ME 554 Problem Set-04 Nozzle Theory-Part-2Document1 pageME 554 Problem Set-04 Nozzle Theory-Part-2rahul prakashNo ratings yet

- Edited Sourcebook For Providing TA On PopDev Integration PDFDocument60 pagesEdited Sourcebook For Providing TA On PopDev Integration PDFIbrahim Jade De AsisNo ratings yet

- Duratron D7015 PI PDS E 30032019 02Document1 pageDuratron D7015 PI PDS E 30032019 02Andres BarriosNo ratings yet

- Ertalon 6PLA-ENDocument1 pageErtalon 6PLA-ENEdwin TacoNo ratings yet

- Nylatron 66 SA FR PDS E 12072017Document1 pageNylatron 66 SA FR PDS E 12072017TasfikNo ratings yet

- Glass Filled Nylon Technical Data SheetDocument1 pageGlass Filled Nylon Technical Data SheetSyed MoinNo ratings yet

- QuickSilver PDS E 0710Document1 pageQuickSilver PDS E 0710luisNo ratings yet

- Ertalyte - TX Data SheetDocument1 pageErtalyte - TX Data Sheetjhax90No ratings yet

- Nylon 66 Technical Data SheetDocument1 pageNylon 66 Technical Data SheetRajeev BujjiNo ratings yet

- Scheda Tecnica Prodotto: Nylatron GSM Materiale Plastico 1317Document1 pageScheda Tecnica Prodotto: Nylatron GSM Materiale Plastico 1317wilderness_666No ratings yet

- ErtalyteDocument1 pageErtalyteFlavio BertolaNo ratings yet

- Tivar 88 PDS e 10022014Document1 pageTivar 88 PDS e 10022014EDDY PINONo ratings yet

- Nylatron GSM Technical Data SheetDocument1 pageNylatron GSM Technical Data SheetgovindsrNo ratings yet

- (Datasheet) Eriks - Ketron Peek-1000Document2 pages(Datasheet) Eriks - Ketron Peek-1000Carlos AlbertoNo ratings yet

- Pe1000 PDFDocument2 pagesPe1000 PDFrohitdakngNo ratings yet

- Original Material "S" Green: Technical InformationDocument1 pageOriginal Material "S" Green: Technical InformationPedro Henriques RamosNo ratings yet

- PBT GF30 enDocument1 pagePBT GF30 enSteven Rojas JerezNo ratings yet

- Murtfeldt Material S Group Material-S-1000-Green Technical Data enDocument1 pageMurtfeldt Material S Group Material-S-1000-Green Technical Data enPedro Henriques RamosNo ratings yet

- Technical Data Sheet (ABS) - PlastimDocument1 pageTechnical Data Sheet (ABS) - PlastimKelvin Tai Wei LimNo ratings yet

- Polyethylene PE1000 - Natural & Blue: PAR Group LTD Technical Data SheetDocument2 pagesPolyethylene PE1000 - Natural & Blue: PAR Group LTD Technical Data SheetMaiquel Eduardo ErnNo ratings yet

- PEI_ULTEM__enDocument2 pagesPEI_ULTEM__ennhtan2020No ratings yet

- UHMWPE PE1000 Technical Data SheetDocument1 pageUHMWPE PE1000 Technical Data Sheetruvil alphaplusNo ratings yet

- Murtfeldt TK Murlubric Datasheet enDocument1 pageMurtfeldt TK Murlubric Datasheet enPedro Henriques RamosNo ratings yet

- ABS Terlux 2802 TR - Fiche Technique enDocument2 pagesABS Terlux 2802 TR - Fiche Technique endamien_roule5728No ratings yet

- Nylon 66 30GF Technical Data Sheet 2Document1 pageNylon 66 30GF Technical Data Sheet 2N ANo ratings yet

- HOSTAFORM® C 9021 TF-enDocument4 pagesHOSTAFORM® C 9021 TF-enshahin_723No ratings yet

- Luran S 797se: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 797se: Acrylonitrile Styrene Acrylate (ASA)bobNo ratings yet

- Luran S 778T: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 778T: Acrylonitrile Styrene Acrylate (ASA)jineshdmehtaNo ratings yet

- Ketron Peek - 1000 Data SheetDocument1 pageKetron Peek - 1000 Data Sheetjhax90No ratings yet

- HDPE - Technical Data SheetDocument1 pageHDPE - Technical Data SheetDhinakar RajamanickamNo ratings yet

- UPVC Technical Data SheetDocument1 pageUPVC Technical Data SheetRND KencanaNo ratings yet

- StyrolutionTDS400700190196 PDFDocument3 pagesStyrolutionTDS400700190196 PDFMirella FaresNo ratings yet

- Ultradur B2520Document2 pagesUltradur B2520Phung LucNo ratings yet

- Mc-Blue: PropertiesDocument1 pageMc-Blue: PropertiesChung LêNo ratings yet

- Styrolution PS 158N/L Heat Resistant GPPSDocument3 pagesStyrolution PS 158N/L Heat Resistant GPPSscribdichigoNo ratings yet

- MDS102RG600x47 1Document2 pagesMDS102RG600x47 1Khawla BkNo ratings yet

- Ultramid: Product Information ®Document2 pagesUltramid: Product Information ®muthuNo ratings yet

- Terluran HI-10: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran HI-10: Acrylonitrile Butadiene Styrene (ABS)bobNo ratings yet

- Ultradur® B 6550 LN en SI - Product DatasheetDocument2 pagesUltradur® B 6550 LN en SI - Product Datasheetnoto.sugiartoNo ratings yet

- Celanex 3316Document5 pagesCelanex 3316klausoshoNo ratings yet

- Ultramid® B3S en SIDocument2 pagesUltramid® B3S en SImuamerNo ratings yet

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrNo ratings yet

- Lexan™ Exell™ D - Sheet DatasheetDocument3 pagesLexan™ Exell™ D - Sheet DatasheetAmritraj CharlesNo ratings yet

- Tecasint 1011 Natural 0Document1 pageTecasint 1011 Natural 0Suraj_73No ratings yet

- Styrolution TDS401600170785Document3 pagesStyrolution TDS401600170785shahin_723No ratings yet

- Pe-Uhmw Technical Data SheetDocument1 pagePe-Uhmw Technical Data SheetPrashant MalikNo ratings yet

- UltrasonS6010 IsoDocument2 pagesUltrasonS6010 IsoKablayialijanNo ratings yet

- Luran HH-120: Please SelectDocument3 pagesLuran HH-120: Please SelectDavid Costi da RosaNo ratings yet

- Pa6 GF15 - Basf Ultramid B3eg3Document2 pagesPa6 GF15 - Basf Ultramid B3eg3armandoNo ratings yet

- High-Temp PI Stock ShapesDocument2 pagesHigh-Temp PI Stock ShapesGreeshmaNo ratings yet

- Styrolution PS 485N: High Impact Polystyrene (HIPS)Document2 pagesStyrolution PS 485N: High Impact Polystyrene (HIPS)Inês MorgadoNo ratings yet

- Ultrason® E 2010 G6 UN en SI - Product DatasheetDocument2 pagesUltrason® E 2010 G6 UN en SI - Product Datasheetshahin_723No ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- Makrolon Solid Flame Retardant Polycarbonate Sheet: Your BenefitsDocument2 pagesMakrolon Solid Flame Retardant Polycarbonate Sheet: Your BenefitsAbdelmajid HmNo ratings yet

- TerluranGP-22Document5 pagesTerluranGP-22Chu ChuNo ratings yet

- PP Compound - PP15T1020Document2 pagesPP Compound - PP15T1020Chaimae HanynyNo ratings yet

- uPVC Pipe PropertiesDocument5 pagesuPVC Pipe PropertiesAntoNo ratings yet

- 1000 MM PolytheleneDocument1 page1000 MM PolytheleneJaokNo ratings yet

- Luran 368R: Technical DatasheetDocument3 pagesLuran 368R: Technical DatasheetVictor PuertoNo ratings yet

- Datasheet Sustarin C ENDocument2 pagesDatasheet Sustarin C ENazwar1105No ratings yet

- Ultramid A3X2G5 Crni PDFDocument2 pagesUltramid A3X2G5 Crni PDFOvidiu ChertesNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Sep. Gravimetrica - CromitaDocument13 pagesSep. Gravimetrica - Cromitaemerson sennaNo ratings yet

- Cce RF Cce RR: RevisedDocument12 pagesCce RF Cce RR: Revisedvedanth rajNo ratings yet

- Statistics For Biology and Health: M. Gail K. Krickeberg J. M. Samet A. Tsiatis W. WongDocument579 pagesStatistics For Biology and Health: M. Gail K. Krickeberg J. M. Samet A. Tsiatis W. WongViníciusSeixasNo ratings yet

- 105 Cau Hoi Trac Nghiem Tieng Anh Lop 12 Co Dap An Va Loi Giai Chi Tiet 2023Document15 pages105 Cau Hoi Trac Nghiem Tieng Anh Lop 12 Co Dap An Va Loi Giai Chi Tiet 2023UnknownNo ratings yet

- CP3 Assignment1Document2 pagesCP3 Assignment1Rea Dominique CabanillaNo ratings yet

- Development of Science and Technology Throughout HistoryDocument198 pagesDevelopment of Science and Technology Throughout HistoryBenjie GuereroNo ratings yet

- PK Mitomycin C in LCMSDocument13 pagesPK Mitomycin C in LCMSRuthNo ratings yet

- Laboratory Activity 1: Do and See The Surface Tension: 1. Describe The Shape of The Water On Top of The Coin. (5 Points)Document3 pagesLaboratory Activity 1: Do and See The Surface Tension: 1. Describe The Shape of The Water On Top of The Coin. (5 Points)Clarence Bautista100% (2)

- Glue Blender: Main FeaturesDocument2 pagesGlue Blender: Main FeaturesCarlos Maduro BuendíaNo ratings yet

- đề 20Document5 pagesđề 20duongnguyenthithuy2008No ratings yet

- SE-409 Aluminium Enclosure SE-409-0-0-A-0-11284: RevisionDocument1 pageSE-409 Aluminium Enclosure SE-409-0-0-A-0-11284: RevisionAhmet MehmetNo ratings yet

- Algorithms to calculate, compare, and determine valuesDocument3 pagesAlgorithms to calculate, compare, and determine valuesLee Anne AngelesNo ratings yet

- AI Unit 1 PDFDocument51 pagesAI Unit 1 PDFAshishNo ratings yet

- Unit 1Document25 pagesUnit 1ragavaharish463No ratings yet

- Questions of Reliability Centered MaintenanceDocument15 pagesQuestions of Reliability Centered Maintenancemariana100% (1)

- UROP Proceedings 2015-16Document95 pagesUROP Proceedings 2015-16alex61937No ratings yet

- Properties and Reactions of Acids and BasesDocument46 pagesProperties and Reactions of Acids and Basesaliefyan4769No ratings yet

- PRINCIPLES OF DETERMINING WATER'S FORMULADocument1 pagePRINCIPLES OF DETERMINING WATER'S FORMULAMominul HaqueNo ratings yet

- Probability TheoryDocument9 pagesProbability TheoryAlamin AhmadNo ratings yet

- Pengaruh Etika Kepemimpinan, Fungsi Badan Pengawas, Tingkat Pemahaman Akuntansi Terhadap Kualitas Pelaporan Keuangan LPD Di Kota DenpasarDocument12 pagesPengaruh Etika Kepemimpinan, Fungsi Badan Pengawas, Tingkat Pemahaman Akuntansi Terhadap Kualitas Pelaporan Keuangan LPD Di Kota DenpasarNaufal Kamil FauziNo ratings yet

- Final CBoW 2020 (Dilnesaw)Document267 pagesFinal CBoW 2020 (Dilnesaw)dilnesaw teshomeNo ratings yet

- Architect's Professional Practice 2Document48 pagesArchitect's Professional Practice 2Joshua CorpuzNo ratings yet

- SABIC-SUPEER™ mLLDPE-7118LA-Regulatory Data Sheet (RDS) - GlobalDocument13 pagesSABIC-SUPEER™ mLLDPE-7118LA-Regulatory Data Sheet (RDS) - Globalalnair coronaNo ratings yet

- SDD GROUP (Zuhaira, Zikry, Athirah, Ariff, Aiman)Document11 pagesSDD GROUP (Zuhaira, Zikry, Athirah, Ariff, Aiman)MUHAMMAD HARITH IKHWAN ROSMAEININo ratings yet

- Power AdministrationDocument17 pagesPower AdministrationWaseem KhanNo ratings yet

- Bai Giang - CT361 - Chuong 4 (PDF - Io)Document18 pagesBai Giang - CT361 - Chuong 4 (PDF - Io)Nghiệp Nguyễn ThànhNo ratings yet