Professional Documents

Culture Documents

Tivar 88 PDS e 10022014

Uploaded by

EDDY PINOOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tivar 88 PDS e 10022014

Uploaded by

EDDY PINOCopyright:

Available Formats

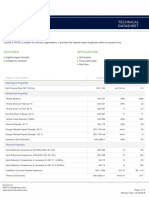

>> ULTRA HIGH MOLECULAR WEIGHT POLYETHYLENE [PE-UHMW + additives]

TIVAR® 88

PRODUCT DATA SHEET T

Due to its outstanding properties (low coefficient of friction and excellent wear resistance), TIVAR® 88 is the

preferred material for the lining of storage and transport containers.

Physical properties (indicative values g)

PROPERTIES Test methods Units VALUES Legend:

Colour - - Blue (1) This is the average molar mass of the PE-UHMW resins

(irrespective of any additives) used for the manufacture of

Average molar mass (average molecular weight) - (1) - 6

10 g/mol 9 this material. It is calculated by means of the Margolies-

equation

Density ISO 1183-1 g/cm³ 0.93

M = 5.37 x 104 x [η]1.49, with [η] being the intrinsic

Water absorption at saturation in water of 23 °C - % < 0.1 viscosity (Staudinger index) derived from a viscosity

Thermal Properties (2) measurement according to ISO 1628-3:2001, using

Melting temperature (DSC, 10 °C/min) ISO 11357-1/-3 °C 135 decahydronaphtalene as a solvent (concentration of

Thermal conductivity at 23 °C - W/(K.m) 0.4 0.0002 g/cm³).

(2) The figures given for these properties are for the most

Average coefficient of linear thermal expansion between 23 and 80 °C - m/(m.K) 200 x 10-6 part derived from raw material supplier data and other

Temperature of deflection under load: publications.

- method A: 1.8 MPa ISO 75-1/-2 °C 42 (3) Only for short time exposure (a few hours) in applications

Copyright 2014 The Quadrant group of companies. All rights reserved. - Date of issue / revision: February 10, 2014

Vicat softening temperature - VST/B50 ISO 306 °C 80 where no or only a very low load is applied to the

Max. allowable service temperature in air: material.

(4) Temperature resistance over a period of 20,000 hours.

- for short periods (3) - °C 90 After this period of time, there is a decrease in tensile

- continuously : for 20,000 h (4) - °C 80 strength – measured at 23 °C – of about 50 % as

Min. service temperature (5) - °C -200 compared with the original value. The temperature value

Flammability (6): given here is thus based on the thermal-oxidative

- "Oxygen Index" ISO 4589-1/-2 % < 20 degradation which takes place and causes a reduction in

properties. Note, however, that the maximum allowable

- according to UL 94 (6 mm thickness) - - HB service temperature depends in many cases essentially

Mechanical Properties at 23 °C (7) on the duration and the magnitude of the mechanical

Tension test (8): stresses to which the material is subjected.

- tensile stress at yield (9) ISO 527-1/-2 MPa 19 (5) Impact strength decreasing with decreasing temperature,

- tensile strain at yield (9) ISO 527-1/-2 % 21 the minimum allowable service temperature is practically

mainly determined by the extent to which the material is

- tensile strain at break (9) ISO 527-1/-2 % > 50 subjected to impact. The value given here is based on

- tensile modulus of elasticity (10) ISO 527-1/-2 MPa 790 unfavourable impact conditions and may consequently

Compression test (11): not be considered as being the absolute practical limit.

- compressive stress at 1 / 2 / 5 % nominal strain (10) ISO 604 MPa 7 / 10 / 16 (6) These estimated ratings, derived from raw material

supplier data and other publications, are not intended to

Charpy impact strength - unnotched (12) ISO 179-1/1eU kJ/m² no break

reflect hazards presented by the material under actual

Charpy impact strength - notched ISO 179-1/1eA kJ/m² 96 fire conditions. There is no ‘UL File Number’ available for

Charpy impact strength - notched (double 14° notch) - (13) ISO 11542-2 kJ/m² NT these stock shapes.

Ball indentation hardness (14) ISO 2039-1 N/mm² 29 (7) The figures given for these properties are average values

Shore hardness D (14) ISO 868 - 57 of tests run on test specimens machined out of 20 - 30

mm thick plates.

Relative volume loss during a wear test in "sand/water-slurry" ;

ISO 15527 - 80 (8) Test specimens: Type 1 B

TIVAR 1000 = 100 (9) Test speed: 50 mm/min

Electrical Properties at 23 °C (10) Test speed: 1 mm/min.

Electric strength (15) IEC 60243-1 kV/mm - (11) Test specimens: cylinders Ø 8 mm x 16 mm

Volume resistivity IEC 60093 Ohm.cm > 10 12 (12) Pendulum used: 15 J

(13) Pendulum used: 15 J

Surface resistivity IEC 60093 Ohm > 10 12 (14) Measured on 10 mm thick test specimens.

Relative permittivity εr : - at 100 Hz IEC 60250 - - (15) Electrode configuration: ∅ 25 / ∅ 75 mm coaxial

Relative permittivity εr : - at 1 MHz IEC 60250 - - cylinders ; in transformer oil according to IEC 60296 ; 1

Dielectric dissipation factor tan δ: - at 100 Hz IEC 60250 - - mm thick test specimens.

Dielectric dissipation factor tan δ: - at 1 MHz IEC 60250 - - g

This table, mainly to be used for comparison purposes, is

Comparative tracking index (CTI) IEC 60112 - -

a valuable help in the choice of a material. The data listed

Note: 1 g/cm³ = 1,000 kg/m³ ; 1 MPa = 1 N/mm² ; 1 kV/mm = 1 MV/m.; NT= not tested here fall within the normal range of product properties.

However, they are not guaranteed and they should

®

not be used to establish material specification limits

TIVAR is a registered trademark of the Quadrant Group. nor used alone as the basis of design.

This product data sheet and any data and specifications presented on our website shall provide promotional and general information about the Engineering Plastic Products (the "Products")

manufactured and offered by Quadrant Engineering Plastic Products ("Quadrant") and shall serve as a preliminary guide. All data and descriptions relating to the Products are of an indicative

nature only. Neither this data sheet nor any data and specifications presented on our website shall create or be implied to create any legal or contractual obligation.

Any illustration of the possible fields of application of the Products shall merely demonstrate the potential of these Products, but any such description does not constitute any kind of covenant

whatsoever. Irrespective of any tests that Quadrant may have carried out with respect to any Product, Quadrant does not possess expertise in evaluating the suitability of its materials or

Products for use in specific applications or products manufactured or offered by the customer respectively. The choice of the most suitable plastics material depends on available chemical

resistance data and practical experience, but often preliminary testing of the finished plastics part under actual service conditions (right chemical, concentration, temperature and contact time,

as well as other conditions) is required to assess its final suitability for the given application.

It thus remains the customer's sole responsibility to test and assess the suitability and compatibility of Quadrant's Products for its intended applications, processes and uses, and to choose

those Products which according to its assessment meet the requirements applicable to the specific use of the finished product. The customer undertakes all liability in respect of the ap-

plication, processing or use of the aforementioned information or product, or any consequence thereof, and shall verify its quality and other properties.

Quadrant Engineering Plastic Products global leader in engineering plastics for machining

www.quadrantplastics.com

You might also like

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- QuickSilver PDS E 0710Document1 pageQuickSilver PDS E 0710luisNo ratings yet

- Ertalon 6PLA-ENDocument1 pageErtalon 6PLA-ENEdwin TacoNo ratings yet

- ErtalyteDocument1 pageErtalyteFlavio BertolaNo ratings yet

- Scheda Tecnica Prodotto: Nylatron GSM Materiale Plastico 1317Document1 pageScheda Tecnica Prodotto: Nylatron GSM Materiale Plastico 1317wilderness_666No ratings yet

- Nylon 66 Technical Data SheetDocument1 pageNylon 66 Technical Data SheetRajeev BujjiNo ratings yet

- Ertalyte - TX Data SheetDocument1 pageErtalyte - TX Data Sheetjhax90No ratings yet

- Nylatron 66 SA FR PDS E 12072017Document1 pageNylatron 66 SA FR PDS E 12072017TasfikNo ratings yet

- Ketron 1000 PEEK PDS E 30032019 01Document1 pageKetron 1000 PEEK PDS E 30032019 01jorgepradaco1No ratings yet

- Murtfeldt TK Murlubric Datasheet enDocument1 pageMurtfeldt TK Murlubric Datasheet enPedro Henriques RamosNo ratings yet

- Polyethylene PE1000 - Natural & Blue: PAR Group LTD Technical Data SheetDocument2 pagesPolyethylene PE1000 - Natural & Blue: PAR Group LTD Technical Data SheetMaiquel Eduardo ErnNo ratings yet

- Duratron D7015 PI PDS E 30032019 02Document1 pageDuratron D7015 PI PDS E 30032019 02Andres BarriosNo ratings yet

- Nylatron GSM Technical Data SheetDocument1 pageNylatron GSM Technical Data SheetgovindsrNo ratings yet

- ABS Terlux 2802 TR - Fiche Technique enDocument2 pagesABS Terlux 2802 TR - Fiche Technique endamien_roule5728No ratings yet

- Glass Filled Nylon Technical Data SheetDocument1 pageGlass Filled Nylon Technical Data SheetSyed MoinNo ratings yet

- UltrasonS6010 IsoDocument2 pagesUltrasonS6010 IsoKablayialijanNo ratings yet

- Pa6 GF15 - Basf Ultramid B3eg3Document2 pagesPa6 GF15 - Basf Ultramid B3eg3armandoNo ratings yet

- Ultramid® B3S en SIDocument2 pagesUltramid® B3S en SImuamerNo ratings yet

- Pe1000 PDFDocument2 pagesPe1000 PDFrohitdakngNo ratings yet

- MDS102RG600x47 1Document2 pagesMDS102RG600x47 1Khawla BkNo ratings yet

- StyrolutionTDS400700190196 PDFDocument3 pagesStyrolutionTDS400700190196 PDFMirella FaresNo ratings yet

- Murtfeldt Material S Group Material-S-1000-Green Technical Data enDocument1 pageMurtfeldt Material S Group Material-S-1000-Green Technical Data enPedro Henriques RamosNo ratings yet

- Iso-Superior Glycols-Plain: Product Features & ApplicationsDocument1 pageIso-Superior Glycols-Plain: Product Features & ApplicationsEldiyar AzamatovNo ratings yet

- Styrolution PS 158N/L Heat Resistant GPPSDocument3 pagesStyrolution PS 158N/L Heat Resistant GPPSscribdichigoNo ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- ULTRAMID_sup_®️__sup_+B3WG6+BGVW+BLACK+00564 (1)Document2 pagesULTRAMID_sup_®️__sup_+B3WG6+BGVW+BLACK+00564 (1)Luis Enrique Ramos PérezNo ratings yet

- Luran S 778T: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 778T: Acrylonitrile Styrene Acrylate (ASA)jineshdmehtaNo ratings yet

- (Datasheet) Eriks - Ketron Peek-1000Document2 pages(Datasheet) Eriks - Ketron Peek-1000Carlos AlbertoNo ratings yet

- A3HG7 BlackDocument2 pagesA3HG7 BlackRanjan GnanaoliNo ratings yet

- Ultramid: Product Information ®Document2 pagesUltramid: Product Information ®muthuNo ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- Luran S 797se: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 797se: Acrylonitrile Styrene Acrylate (ASA)bobNo ratings yet

- HOSTAFORM® C 9021 TF-enDocument4 pagesHOSTAFORM® C 9021 TF-enshahin_723No ratings yet

- PEI_ULTEM__enDocument2 pagesPEI_ULTEM__ennhtan2020No ratings yet

- PBT GF30 enDocument1 pagePBT GF30 enSteven Rojas JerezNo ratings yet

- Styrolution TDS400900250546Document2 pagesStyrolution TDS400900250546prabhat singhNo ratings yet

- Nylon 66 30GF Technical Data Sheet 2Document1 pageNylon 66 30GF Technical Data Sheet 2N ANo ratings yet

- UHMWPE PE1000 Technical Data SheetDocument1 pageUHMWPE PE1000 Technical Data Sheetruvil alphaplusNo ratings yet

- Original Material "S" Green: Technical InformationDocument1 pageOriginal Material "S" Green: Technical InformationPedro Henriques RamosNo ratings yet

- Arkema PEKK kKepstan 8001 TDSDocument3 pagesArkema PEKK kKepstan 8001 TDSstartionlilNo ratings yet

- Styro Lution Tds 400900240714Document3 pagesStyro Lution Tds 400900240714vrjrNo ratings yet

- Terluran HI-10: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran HI-10: Acrylonitrile Butadiene Styrene (ABS)bobNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- Technical Datasheet LITEN BB 85 F - EngDocument2 pagesTechnical Datasheet LITEN BB 85 F - EngTo RaNo ratings yet

- Styrolution TDS401600170785Document3 pagesStyrolution TDS401600170785shahin_723No ratings yet

- Technical Data Sheet (ABS) - PlastimDocument1 pageTechnical Data Sheet (ABS) - PlastimKelvin Tai Wei LimNo ratings yet

- Main Characteristics Value Unit Test Method: ( ) Samples Conditioned 15 Days at 23°C - 50 % R.H. (C) Complete BreakDocument1 pageMain Characteristics Value Unit Test Method: ( ) Samples Conditioned 15 Days at 23°C - 50 % R.H. (C) Complete BreakAlan TsaiNo ratings yet

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrNo ratings yet

- TerluranGP-22Document5 pagesTerluranGP-22Chu ChuNo ratings yet

- Brayco Micronic™ SV/B: DescriptionDocument5 pagesBrayco Micronic™ SV/B: DescriptionAlfonsus W.M.No ratings yet

- Total 3645Document1 pageTotal 3645M. Kürşad ArslanNo ratings yet

- MCAM - 01609 - GEP - Ertalon 6PLA PA6 - Nylatron MC 907 PA6 - PDS - en-USDocument2 pagesMCAM - 01609 - GEP - Ertalon 6PLA PA6 - Nylatron MC 907 PA6 - PDS - en-USDiego RuedaNo ratings yet

- Ultradur® B 6550 LN en SI - Product DatasheetDocument2 pagesUltradur® B 6550 LN en SI - Product Datasheetnoto.sugiartoNo ratings yet

- TerluranGP35Document5 pagesTerluranGP35cristinamss33No ratings yet

- Luran S KR2868C: Acrylonitrile Styrene Acrylate / Polycarbonate (ASA/PC)Document3 pagesLuran S KR2868C: Acrylonitrile Styrene Acrylate / Polycarbonate (ASA/PC)rosebifNo ratings yet

- Atlac 590 002126 - 1520269898Document2 pagesAtlac 590 002126 - 1520269898Jainam ShahNo ratings yet

- Luran HH-120: Please SelectDocument3 pagesLuran HH-120: Please SelectDavid Costi da RosaNo ratings yet

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezNo ratings yet

- Maxguard GN NTRL HS A TN INDocument3 pagesMaxguard GN NTRL HS A TN INRakesh NnvNo ratings yet

- Epofine 556 - Finehard 22962Document5 pagesEpofine 556 - Finehard 22962Karishma PrabhuNo ratings yet

- 2164 086 5 003 0Document1 page2164 086 5 003 0EDDY PINONo ratings yet

- AU0087 MC Mill Circuit BrochureFINAL - v2 - LoresDocument8 pagesAU0087 MC Mill Circuit BrochureFINAL - v2 - Loreshiram89No ratings yet

- AU0087 MC Mill Circuit BrochureFINAL - v2 - LoresDocument8 pagesAU0087 MC Mill Circuit BrochureFINAL - v2 - LoresEDDY PINONo ratings yet

- MaterialData 20169Document1 pageMaterialData 20169EDDY PINONo ratings yet

- Tivar 88 PDS e 10022014Document1 pageTivar 88 PDS e 10022014EDDY PINONo ratings yet

- Tivar Uhmw-Pe Family of ProductsDocument2 pagesTivar Uhmw-Pe Family of ProductsEDDY PINONo ratings yet

- Tivar 88 PDS e 10022014Document1 pageTivar 88 PDS e 10022014EDDY PINONo ratings yet

- PDFDocument2 pagesPDFhatemNo ratings yet

- Title: Author: Rolando Efraín Hernández Ramírez: Luminescence Process of LuminolDocument2 pagesTitle: Author: Rolando Efraín Hernández Ramírez: Luminescence Process of LuminolEfraínNo ratings yet

- Gaalship Offshore Cables: SW4 (C) or SW2 (C) 150/250 VDocument2 pagesGaalship Offshore Cables: SW4 (C) or SW2 (C) 150/250 VHalenaBuanNo ratings yet

- New Developments in Pavement Design - Some IssuesDocument45 pagesNew Developments in Pavement Design - Some IssuesSalam FaithNo ratings yet

- Joint Model of PipesDocument28 pagesJoint Model of PipessandbadbahriNo ratings yet

- Z-ABS Material Safety Data Sheet-1 PDFDocument7 pagesZ-ABS Material Safety Data Sheet-1 PDFLaurentiu-Florin MosinoiuNo ratings yet

- Saic Q 1013Document5 pagesSaic Q 1013Hussain Nasser Al- NowiesserNo ratings yet

- Phenol-formaldehyde runaway reaction case study analyzedDocument6 pagesPhenol-formaldehyde runaway reaction case study analyzedMary Grace VelitarioNo ratings yet

- Specification For Hot and Cold Insulation WorkDocument13 pagesSpecification For Hot and Cold Insulation WorkchintanNo ratings yet

- Display PDFDocument8 pagesDisplay PDFberktorNo ratings yet

- UV-Curing Coatings: A Concise OverviewDocument10 pagesUV-Curing Coatings: A Concise OverviewIsmail BayraktarNo ratings yet

- Brosur Pt. Srirejeki Perdana Steel-1Document16 pagesBrosur Pt. Srirejeki Perdana Steel-1Agus SofiansyahNo ratings yet

- Energy Efficiency For Engineers and Technologists PDFDocument595 pagesEnergy Efficiency For Engineers and Technologists PDFVíctor50% (4)

- Angle Brackets For Buildings: Complete RangeDocument6 pagesAngle Brackets For Buildings: Complete RangeKenan AvdusinovicNo ratings yet

- Oxidation SS2 NOTE - 061442Document11 pagesOxidation SS2 NOTE - 061442ayomideadare13No ratings yet

- Iteh Standard Preview (Standards - Iteh.ai)Document12 pagesIteh Standard Preview (Standards - Iteh.ai)AnelNo ratings yet

- Angle Style, Pressure Relief Valves For Steam, Gas, and Liquid ServicesDocument14 pagesAngle Style, Pressure Relief Valves For Steam, Gas, and Liquid ServicesCHRISTIAN ZAVALANo ratings yet

- 4412 I E LocknutsDocument32 pages4412 I E LocknutsArdian20No ratings yet

- Debye Model - Wikipedia, The Free EncyclopediaDocument7 pagesDebye Model - Wikipedia, The Free EncyclopediaBenni WewokNo ratings yet

- Ultra-Soft Thermal Conductive Pad TG6050 Spec SheetDocument2 pagesUltra-Soft Thermal Conductive Pad TG6050 Spec SheetArunkumar PBNo ratings yet

- RACOLD Domestic Solar PresentationDocument14 pagesRACOLD Domestic Solar PresentationnagtummalaNo ratings yet

- FM Global Property Loss Prevention Data Sheets: List of FiguresDocument29 pagesFM Global Property Loss Prevention Data Sheets: List of FiguresYacila AlvaradoNo ratings yet

- (English) SDS PERTAMINA GRISKLINDocument13 pages(English) SDS PERTAMINA GRISKLINaudreyNo ratings yet

- Astm F 1852Document8 pagesAstm F 1852luis100% (1)

- Nano Select - 2021 - Anik - Gold Nanoparticles GNPs in Biomedical and Clinical Applications A ReviewDocument37 pagesNano Select - 2021 - Anik - Gold Nanoparticles GNPs in Biomedical and Clinical Applications A ReviewJavoxis Alonso Javo IrarrazabalNo ratings yet

- De SaltersDocument15 pagesDe SaltersMuhammad Arslaan100% (2)

- DS-1273ZJ-140 Datasheet 20230724Document1 pageDS-1273ZJ-140 Datasheet 20230724Klayton PiresNo ratings yet

- Phetrofigisg Pages 113 140Document28 pagesPhetrofigisg Pages 113 140UncabresNo ratings yet

- Gas Law Packet AnswersDocument6 pagesGas Law Packet Answersjerm655No ratings yet

- Engraving of Roller PrintingDocument24 pagesEngraving of Roller Printingapi-3817839100% (3)