Professional Documents

Culture Documents

C. Chemistry 1 L2 Quality Management Lecture

Uploaded by

Chelze Faith DizonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

C. Chemistry 1 L2 Quality Management Lecture

Uploaded by

Chelze Faith DizonCopyright:

Available Formats

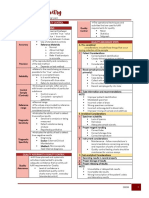

LESSON 2

• It reflects the ability of the method to detect true-

negatives with very few false-positive.

• System of ensuring accuracy and precision in

the laboratory by reagents (quality control) in

KINDS OF QUALITY CONTROL

every series of measurement

• Process of ensuring that analytical results are INTRALAB (Internal QC)

correct by testing known samples (control • Involves the analysis of control samples together

solution) that resembles patient samples with patient specimens.

• Involves the process of monitoring the • Important for the daily monitoring of accuracy

characteristics of the analytical processes and and precision of anlytical methods.

detects analytical errors during testing • Detects both random and systemic error.

• It is one component of the quality assurance

system. INTERLAB (External QC)

• Involves proficiency testing programs that

1. SENSITIVITY periodically provide samples of unknown

• The ability of an analytical method to measure concentration of analytes to participating

the smallest concentration of the analyte of laboratories

interest. • Important in maintaining long term accuracy of

2. SPECIFICITY the analytical method

• Difference of >2 in the results indicates that a

• Is the ability of an analytical method to measure

laboratory is not in agreement with the rest of the

only the analyte of interest.

laboratories included in the program.

3. ACCURACY

• Nearness or closeness of the assayed value to OBJECTIVES OF QUALITY CONTROL

the true or target value. 1. To check the stability of the machine

2. To check the quality of reagents

4. PRECISION OR REPRODUCIBILITY 3. To check technical errors

• Ability to give repeated results on the same

sample that agree with one another. CHARACTERISTICS OF AN IDEAL QC

MATERIAL

5. PRACTICABILITY

1. Resembles human sample

• Degree by which a method is easily repeated. 2. Inexpensive and stable for long periods

6. RELIABILITY 3. No communicable disease.

4. No matrix effects/known matrix effects.

• Ability of analytical method to maintain accuracy

5. With known analyte concentrations.

and precision over extended period of time

6. Convenient packaging for easy dispensing and

during which equipment, reagents and personnel

storage.

change.

7. DIAGNOSTIC SENSITIVITY NOTES TO REMEMBER

• Ability of the test to detect proportion of individual • Quality control materials should resemble human

with that disease who test positively with the test. sample and be available for a minimum of one

year (same lot number)

• Indicates the ability of the test to generate more

• Bovine control material – not the choice for

true-positive results and few false-negative

immunochemistry, dye-binding and certain

8. DIAGNOSTICS SPECIFICITY bilirubin assays.

• Control limits are calculated from the mean and

• Ability of the test to detect proportion of individual

standard deviation

with that disease who test negatively with the

test.

PASCUAL QUALITY MANAGEMENT | 5

POST-ANALYTICAL ERRORS

1. Unavailable or delayed laboratory results.

RANDOM ERROR

2. Incomplete laboratory results.

• Non repeating, occurs once 3. Wrong transcription of the patient’s data and

• The basis for varying differences between laboratory results.

repeated measurement - R

• It is due to instrument, operator, and

environmental conditions

o Pipeting errors, mislabeling of samples, • Is the science of gathering, analyzing,

temperature fluctuations, improper mixing of interpreting and presenting data.

sample and reagent.

MEAN

SYSTEMATIC ERROR • A measure of central tendency. It is associated

• Repeating, can be predicted with symmetrical or normal distribution.

• Often related to calibration problems,

deterioration of reagents and control materials, STANDARD DEVIATION

unstable and inadequate reagent blanks, • a measure of the dispersion of values from the

contaminated solutions, failing instrumentation mean.

and poorly written procedures. • It helps describe the normal curve.

• It is a measure of the agreement between the • A measure of the distribution range

measured quantity and the true value – A

COEFFICIENT OF VARIATION

a. Constant Error • A percentile expression of the mean

o refers to a difference between the target • Index of precision

value and the assay value.

o Independent of sample concentration VARIANCE

b. Proportional/Slope/Percent Error • Is called the standard deviation squared

o Results in greater deviation from the target • Measure of variability

value due to higher sample concentration.

TERMINOLOGIES

CLERICAL ERROR MEDIAN

• The highest frequency of clerical errors with the • Value of the observation that divides the

use of handwritten labels and request forms. observations into two groups, each containing

equal numbers of observation.

PRE-ANALYTIC ERRORS • It is a midpoint of distribution

1. Improper patient preparation. • 50th percentile

2. Mislabeled specimen.

MODE

3. Incorrect order of draw.

4. Incorrect patient identification • Is the most frequent observation

5. Wrong specimen container INFERENTIAL STATISTICS

6. Incorrect anticoagulant to blood ratio. • Are used to compare the means or standard

7. Improper mixing of sample and additives.

deviations of two groups of data.

8. Incorrect specimen preservation.

9. Incorrect used of tubes for blood collection. T-TEST

10. Mishandled specimen (transport and storage) • Is used to determine whether there is statistically

11. Missed or incorrectly interpreted laboratory significant difference between the means of two

requests. groups of data.

PASCUAL QUALITY MANAGEMENT | 6

F-TEST YOUDEN/TWIN PLOT

• Is used to determine whether there is statistically • It is used to compare results obtained on a high

significant difference between the standard and low control serum from different

deviations of two groups of data. laboratories.

• The points falling from a center but on the 45o

QUALITY CONTROL CHART line suggest a proportional error, and points

falling from the center but not on the 45 o line

GAUSSIAN CURVE

suggest a constant error.

• Bell-shaped curve

• It occurs when the data set can be accurately

described by the SD and mean

• It is obtained by plotting the values from multiple

analysis of a sample. Figure 2-3

• It occurs when the data elemnts are centered Youden/Twin

around the mean with most elements close to the Plot

mean.

• It focuses on the distribution of errors from the

analytical method rather than the values from a

healthy or patient population.

SHEWHART LEVEY-JENNING CHART

• Most widely used system in clinical laboratory

• Allows the laboratorians to apply multiple rules

Figure 2-1 without the aid of a computer

Gaussian Curve • A graphic representation of the acceptable limits

of variation in the results of an analytical method.

CUMULATIVE SUM GRAPH (CUSUM)

Figure 2-4

• It calculates the difference between QC results Levey-

and the target means. Jenning Chart

• V mask is the most common method – requires

computer implementation

• Identifies consistent bias problems.

• This plot will give the earliest indication of

systematic errors (trend)

• Results are out of control when the slope ERRORS WHICH CAN BE OBSERVED

exceeds 45o or a decision (+/- 2.7 SD) is a. Trend

exceeded. o Is formed by control values that either

increase or decrease for six consecutive

days.

o Main cause: deterioration of reagents

Figure 2-2

Cumulative Sum

Graph

Figure 2-5

Trends

PASCUAL QUALITY MANAGEMENT | 7

b. Shift

• Is formed by control values that distribute

• It recognized that the use of simple upper and

themselves on one side or either side of the

lower control limits are not enough to identify

mean for six consecutive days.

analytical problems.

• Shift in the reference range is due to transient

• Westgard used the term control rule to indicate if

instrument differences

the analytical process is out of control.

• Main cause: improper calibration of the

instrument.

CONTROL RULES

12s

• use as rejection or warning rule when one control

result exceeds the mean +/- 2SD; for screening

Figure 2-6

Shift

purposes.

c. Outliers

• Are control values thatt are far from the main

set of values.

• They are highly deviating values

• Cause by random or systematic errors

NOTES

• 95% confidence limit (+/- 2SD) – acceptable

range.

• Kurtosis- refers to the degree of flatness or Figure 2-7 12s Rule

sharpness in the peak of a set of values

having a gaussian distribution. 13s

• An analytical method is considered in • reject a run when one control result exceeds the

control when ther is symmetrical distribution mean +/- 3SD.

of control values about the mean and there

are few control values outside the 2s control

limits.

• If the analytical test results to control values

are not within the +/- 2SD confidence range,

run a new set of controls and repeat

specimen testing.

• A control value between 2s and 3s is a sign

of potential problem.

• A value outside 3s would require corrective

action.

• Continued QC failure requires more trouble

shooting – preparation of new reagents,

recalibration, instrument maintenance and

Figure 2-8 13s Rule

repair, and contacting the

dealer/manufacturer for technical support or

service.

PASCUAL QUALITY MANAGEMENT | 8

22s R4s

• reject a run when the last 2 control results (or 2 • reject a run if the range or difference between the

results from the same run); exceed either the highest and lowest control result within an

mean +/- 2SD. analytical run exceeds 4SD.

Figure 2-11 R4s Rule

10x

• reject a run when ten consecutive results are on

the same side of the target mean.

Figure 2-9 22s Rule

41s

• reject a run when the last four (or any four)

consecutive control results exceed either mean

+/- 1SD.

Figure 2-12 10x Rule

Figure 2-10 41s Rule

PASCUAL QUALITY MANAGEMENT | 9

TERMINOLOGIES

ANALYTICAL RUN

• a set of control and patient specimens

assayed, evaluated and reported together.

DELTA CHECK

• Is the most commonly used patient based-QC

technique

• It requires computerization of test data

• The difference between two consecutive

measurement of the same analytes on the same

individual.

POINT OF CARE TESTING

• Analytical testing performed outside the confines

of the central laboratory, usually by non

laboratorians personnel

• Use of portable whole blood glucose meters for

the management of patients with diabetes- most

commonly used POCT

• Other names: near-patient testing, decentralized

testing, bedside testing, alternate site testing.

REFERENCE LIMIT / REFERENCE INTERVAL /

REFERENCE VALUE

• A value obtained by observation or

measurement of a particular type of quantity on

a reference individual.

• Usual values for a healthy population that

represents 95% central tendency.

FIVE FACTORS WHEN ESTABLISHING

REFERENCE INTERVALS:

1. The composition of reference population

2. The criteria of excluding and including

individuals from the reference population.

3. The physiologic and environmental conditions of

the reference population

4. Specimen collection procedure, preparation for

testing

5. Analytical method used

NOTES

• Atleast 120 individuals should be tested for each

age and sex category

• However 20 reference individual need to be

sampled for analysis on the test instrument (not

more than 2 out of 20)

• Reference values vary slightly depending upon

method and specimen type.

PASCUAL QUALITY MANAGEMENT | 10

You might also like

- National Plumbing Code of The Phil SummaryDocument24 pagesNational Plumbing Code of The Phil Summaryregina_staclara81% (16)

- Intro To AnachemDocument3 pagesIntro To AnachemJoanne RemolloNo ratings yet

- Plumbing Code SummaryDocument7 pagesPlumbing Code SummaryMon ResocoNo ratings yet

- ASTM D6307.2019 Determination of Asphalt Content by Ignition MethodDocument5 pagesASTM D6307.2019 Determination of Asphalt Content by Ignition Methodjitendra100% (1)

- Lemar CC 2020Document27 pagesLemar CC 2020TRIXIE CYRAH MIRANDA SALAVIANo ratings yet

- Iqc Midterms MolinaDocument4 pagesIqc Midterms MolinaJazyl TanNo ratings yet

- Quality Assurance & Quality ControlDocument5 pagesQuality Assurance & Quality ControlErica Mae Macabingkel100% (1)

- Quality ControlDocument10 pagesQuality Controlbunniecaronan113003No ratings yet

- Specificity 100 X No - of Dse Individual WithDocument4 pagesSpecificity 100 X No - of Dse Individual WithmarianNo ratings yet

- Quality Control - CHEMISTRYDocument3 pagesQuality Control - CHEMISTRYAllyssa AniNo ratings yet

- Quality Management: Prepared By: Mariela C. Ronq Uillo, RMTDocument36 pagesQuality Management: Prepared By: Mariela C. Ronq Uillo, RMTRena100% (1)

- Clinical Chemistry LectureDocument9 pagesClinical Chemistry LectureAngge Aquino OfficialNo ratings yet

- Anal Lec - TransesDocument5 pagesAnal Lec - TransesMikay GutierrezNo ratings yet

- Clinical Chemis-Wps OfficeDocument13 pagesClinical Chemis-Wps OfficeJeneva Liyaban100% (1)

- Quality Control NotesDocument4 pagesQuality Control NotesAngelo Jude CobachaNo ratings yet

- Methods Comparison 5th Sept'18 DR PriyaDocument65 pagesMethods Comparison 5th Sept'18 DR Priyaamit danielNo ratings yet

- CC Quality Control TransesDocument6 pagesCC Quality Control TransesJohanna Rose Cobacha SalvediaNo ratings yet

- Screenshot 2023-06-16 at 3.02.46 PMDocument51 pagesScreenshot 2023-06-16 at 3.02.46 PM7strd5q6cbNo ratings yet

- 6 CCHM Trans LecDocument4 pages6 CCHM Trans LecCRUZ, ANNA MARIELLENo ratings yet

- Quality ControlDocument19 pagesQuality ControlFrankenstein MelancholyNo ratings yet

- Unit IDocument9 pagesUnit ImasorNo ratings yet

- VAL 015 Method Validation Procedure Sample PDFDocument2 pagesVAL 015 Method Validation Procedure Sample PDFMubarak PatelNo ratings yet

- Errors in Chemical Analysis BPHTDocument22 pagesErrors in Chemical Analysis BPHTMaria FlorinaNo ratings yet

- Standard Test Procedures Manual PDFDocument31 pagesStandard Test Procedures Manual PDFIrfan chaudharyNo ratings yet

- Analytical Methods Validation FINALDocument10 pagesAnalytical Methods Validation FINALVassant KudchadkarNo ratings yet

- Quality ControlDocument1 pageQuality ControlJinky CorpuzNo ratings yet

- Calibration and Quality Control in The LaboratoryDocument15 pagesCalibration and Quality Control in The LaboratoryChrisarh NofuenteNo ratings yet

- Chapter 5Document21 pagesChapter 5FrancoNo ratings yet

- Iqc - (1 Online and 1 Onsite) PDFDocument7 pagesIqc - (1 Online and 1 Onsite) PDFMauii TejidorNo ratings yet

- Quality Assurance & Lab MathDocument6 pagesQuality Assurance & Lab MathMica BernardoNo ratings yet

- Tep by TEP Pproach To Valuation and Omparison OF Nalytical EthodsDocument54 pagesTep by TEP Pproach To Valuation and Omparison OF Nalytical EthodsMalliga SundareshanNo ratings yet

- Theory 3 - Results RecordingDocument32 pagesTheory 3 - Results RecordingNavoda ThathsaraniNo ratings yet

- Iqc - MidtermsDocument7 pagesIqc - MidtermsMauii TejidorNo ratings yet

- SopDocument6 pagesSopعبدالعزيز بدرNo ratings yet

- Chap4.2 Lecture Method ValidationDocument53 pagesChap4.2 Lecture Method ValidationLily ERc Peter100% (1)

- Analytical Method Development of Bulk DrugsDocument40 pagesAnalytical Method Development of Bulk Drugsrishabhpharma100% (1)

- NMKL KappaDocument17 pagesNMKL KappanilayNo ratings yet

- Quality Control and Assurance in BacteriologyDocument21 pagesQuality Control and Assurance in BacteriologyDayledaniel SorvetoNo ratings yet

- Calibration Verification & LinearityDocument22 pagesCalibration Verification & LinearitynikhilmajethiaNo ratings yet

- Bioanalytical Method Validation: Prof. Dr. Muhammad Rashedul IslamDocument35 pagesBioanalytical Method Validation: Prof. Dr. Muhammad Rashedul IslamKhandaker Nujhat TasnimNo ratings yet

- Lecture Method ValidationDocument46 pagesLecture Method Validationsarah575No ratings yet

- Virotrol Chagas: 00125 00125X 1 X 4 MLDocument12 pagesVirotrol Chagas: 00125 00125X 1 X 4 MLClauss RubiNo ratings yet

- Types of Clinical Study Designs PDFDocument21 pagesTypes of Clinical Study Designs PDFDrAnisha Patel100% (1)

- F13 2022 ValidationDocument55 pagesF13 2022 ValidationAbdirahman NurNo ratings yet

- Quality Control Management in Labortory Services.Document54 pagesQuality Control Management in Labortory Services.Bakhtawar Siddique MemonNo ratings yet

- Variations, Errors, and QualityDocument46 pagesVariations, Errors, and QualityJohn Reden RomeroNo ratings yet

- Quantitative Analysis (CHEM 201) What Do You Need?: Fall 2007, SH-C162 T &TH: 11:40 Am - 1 PMDocument11 pagesQuantitative Analysis (CHEM 201) What Do You Need?: Fall 2007, SH-C162 T &TH: 11:40 Am - 1 PMCheNo ratings yet

- Anallytica Methodd VaalidaationDocument65 pagesAnallytica Methodd Vaalidaationvaishali patelNo ratings yet

- Validation and Verification of Mol Biol AssayDocument39 pagesValidation and Verification of Mol Biol Assaybose_lowe11No ratings yet

- Quality Assaurance and Q ControlDocument13 pagesQuality Assaurance and Q Controlmzulqurnain imranNo ratings yet

- Analytical Method ValidationDocument24 pagesAnalytical Method ValidationShanePooleNo ratings yet

- Process control for qualitative and semiquantitative proceduresDocument11 pagesProcess control for qualitative and semiquantitative proceduresAzizNo ratings yet

- Analysis as a ProcessDocument17 pagesAnalysis as a ProcessNoh0% (1)

- Qualitative Analysis Element Inorganic Compound Functional Group Organic CompoundDocument8 pagesQualitative Analysis Element Inorganic Compound Functional Group Organic CompoundJohn Henry G. Gabriel IVNo ratings yet

- QC 3Document32 pagesQC 3Fatma HamaadNo ratings yet

- Clinical Chemistry v1.2Document30 pagesClinical Chemistry v1.2Kervy Jay Agraviador100% (1)

- Lab Math Lec (Prelims)Document7 pagesLab Math Lec (Prelims)Merra VenzuelaNo ratings yet

- Analytical Method ValidationDocument30 pagesAnalytical Method ValidationEmad EmadNo ratings yet

- Validation of Analytical Method: Ashok Suthar Regulatory Associate Regulatory Affairs Amneal PharmaceuticalsDocument40 pagesValidation of Analytical Method: Ashok Suthar Regulatory Associate Regulatory Affairs Amneal Pharmaceuticalsshashank786No ratings yet

- Interferences in ImmunoassaysDocument27 pagesInterferences in ImmunoassaysAlfaina WahyuniNo ratings yet

- NordVal-protocol-No-2_Chem_Sept-2017Document15 pagesNordVal-protocol-No-2_Chem_Sept-2017ERICK MARTIN AGUILAR CRUZNo ratings yet

- Mirobial DiagnosisDocument4 pagesMirobial Diagnosiswishvish_scribdNo ratings yet

- Sa1 BusinessDocument19 pagesSa1 BusinessChelze Faith DizonNo ratings yet

- ItemDocument2 pagesItemChelze Faith DizonNo ratings yet

- Connection DetailsDocument1 pageConnection DetailsChelze Faith DizonNo ratings yet

- ComputationsDocument2 pagesComputationsChelze Faith DizonNo ratings yet

- Animal Shelter GuidebookDocument111 pagesAnimal Shelter GuidebookChelze Faith DizonNo ratings yet

- Table - GOAL OBJETIVE SOLUTION PROBLEM QUESTION..Document2 pagesTable - GOAL OBJETIVE SOLUTION PROBLEM QUESTION..Chelze Faith DizonNo ratings yet

- C. Bacteriology L6 Antimicrobial Agents and Resistance LaboratoryDocument6 pagesC. Bacteriology L6 Antimicrobial Agents and Resistance LaboratoryChelze Faith DizonNo ratings yet

- C. Bacteriology L6 Antimicrobial Susceptibility Testing LectureDocument5 pagesC. Bacteriology L6 Antimicrobial Susceptibility Testing LectureChelze Faith DizonNo ratings yet

- Assembling ComponentsDocument5 pagesAssembling ComponentsChelze Faith DizonNo ratings yet

- Major ProblemDocument1 pageMajor ProblemChelze Faith DizonNo ratings yet

- Hematology 1 L3 Erythrocytes LectureDocument3 pagesHematology 1 L3 Erythrocytes LectureChelze Faith DizonNo ratings yet

- Dalig, Antipolo City - Data AnalysisDocument8 pagesDalig, Antipolo City - Data Analysismaddieanne100% (1)

- Fa5 DizonDocument5 pagesFa5 DizonChelze Faith DizonNo ratings yet

- Hematology 1 L2 Hematopoiesis LectureDocument4 pagesHematology 1 L2 Hematopoiesis LectureChelze Faith DizonNo ratings yet

- Fa7 DizonDocument5 pagesFa7 DizonChelze Faith DizonNo ratings yet

- Fa7 DizonDocument5 pagesFa7 DizonChelze Faith DizonNo ratings yet

- Dizon FA3 PLNINGDocument1 pageDizon FA3 PLNINGChelze Faith DizonNo ratings yet

- Hematology 1 L1 Introduction To Hematology 1 LectureDocument2 pagesHematology 1 L1 Introduction To Hematology 1 LectureChelze Faith DizonNo ratings yet

- Fa6 DizonDocument2 pagesFa6 DizonChelze Faith DizonNo ratings yet

- Dizon FA4 PLNING132Document1 pageDizon FA4 PLNING132Chelze Faith DizonNo ratings yet

- FA2 DizonDocument2 pagesFA2 DizonChelze Faith DizonNo ratings yet

- Dizon FA1Document4 pagesDizon FA1Chelze Faith DizonNo ratings yet

- Formative Assessment 1 Development Controls Design PhilosophyDocument2 pagesFormative Assessment 1 Development Controls Design PhilosophyChelze Faith DizonNo ratings yet

- Far Eastern University Institute of Architecture and Fine Arts FORMATIVE ASSESSMENT 2Document15 pagesFar Eastern University Institute of Architecture and Fine Arts FORMATIVE ASSESSMENT 2Chelze Faith DizonNo ratings yet

- Summary Plumbing Code DONEDocument3 pagesSummary Plumbing Code DONERap PinedaNo ratings yet

- Designing A Community in Partnership With Nature Through Architecture.Document7 pagesDesigning A Community in Partnership With Nature Through Architecture.Chelze Faith DizonNo ratings yet

- FA2Document2 pagesFA2Chelze Faith DizonNo ratings yet

- Testing The Difference Between Means, Variances, and ProportionsDocument53 pagesTesting The Difference Between Means, Variances, and ProportionsaswardiNo ratings yet

- Quantitative AnalysisDocument47 pagesQuantitative AnalysisPhương TrinhNo ratings yet

- Credit Loss and Systematic LGD Frye Jacobs 100611 PDFDocument31 pagesCredit Loss and Systematic LGD Frye Jacobs 100611 PDFsgjatharNo ratings yet

- S-Mat 25P-Statistical Methods of Research in Physics: Vision-MissionDocument5 pagesS-Mat 25P-Statistical Methods of Research in Physics: Vision-MissionJun PontiverosNo ratings yet

- E2617-10 Standard Practice For Validation of Empirically Derived Multivariate CalibrationsDocument11 pagesE2617-10 Standard Practice For Validation of Empirically Derived Multivariate CalibrationsislamakthamNo ratings yet

- Vishal Sood 1Document11 pagesVishal Sood 1Anonymous CwJeBCAXpNo ratings yet

- BasicStatistics IDocument90 pagesBasicStatistics ISivanesh KumarNo ratings yet

- Business Statistic BBA-IDocument48 pagesBusiness Statistic BBA-IAnkur BhattNo ratings yet

- F2020STAT213: Answer(s) Submitted: - 18 - 2 - 60 - 12 - 68 - 12Document3 pagesF2020STAT213: Answer(s) Submitted: - 18 - 2 - 60 - 12 - 68 - 12Mayankjot SinghNo ratings yet

- Stanley Lawie 2008 Large Sample THMethodDocument11 pagesStanley Lawie 2008 Large Sample THMethodErik EstradaNo ratings yet

- Ml4t NotesDocument95 pagesMl4t NotesEricko Marvin KweknotoNo ratings yet

- Beniga Ma 102 Pre-Test ExamDocument6 pagesBeniga Ma 102 Pre-Test ExamRowena Beniga0% (1)

- Unit 6 Business Decision Making Assignment Statistical MethodDocument33 pagesUnit 6 Business Decision Making Assignment Statistical MethodAnas100% (1)

- Senior General Physics 1 q1 Module 1Document20 pagesSenior General Physics 1 q1 Module 1Coulline DamoNo ratings yet

- Week 15.2 - Six Sigma CalculationsDocument13 pagesWeek 15.2 - Six Sigma CalculationsHanzla ZubairNo ratings yet

- Expt-1: Introduction To Measurement and Statistical Error: Measurement of Different ShapesDocument12 pagesExpt-1: Introduction To Measurement and Statistical Error: Measurement of Different ShapesMahmudul Hasan 1610942630No ratings yet

- Peer Asses MentDocument3 pagesPeer Asses MentSudhanshu SahooNo ratings yet

- JmhurstDocument42 pagesJmhurstmehmetonb100% (6)

- Surveying-Lesson-1 FinishedDocument16 pagesSurveying-Lesson-1 FinishedJerick CosiñeroNo ratings yet

- Assignment 2 - Update YektiDocument2 pagesAssignment 2 - Update YektiPutri Ayuningtyas KusumawatiNo ratings yet

- DM GTU Study Material Presentations Unit-2 17032021053028AMDocument60 pagesDM GTU Study Material Presentations Unit-2 17032021053028AMmuhammad Shoaib janjuaNo ratings yet

- R & R Traditional ExplanationDocument29 pagesR & R Traditional ExplanationBiopharmaNo ratings yet

- Jurnal Gender 3Document22 pagesJurnal Gender 3chaeworldNo ratings yet

- Lean Six Sigma PHD ThesisDocument4 pagesLean Six Sigma PHD Thesissandrawilleyelpaso100% (2)

- Learning Objectives: What Is Descriptive Statistics? - Examples & Concept Lesson QuizDocument3 pagesLearning Objectives: What Is Descriptive Statistics? - Examples & Concept Lesson QuizEdwinNo ratings yet

- Teaching Models Designing Instruction For 21st Century Struction Titles - Clare R. Kilbane-144-177 PDFDocument16 pagesTeaching Models Designing Instruction For 21st Century Struction Titles - Clare R. Kilbane-144-177 PDFDian SugiantoroNo ratings yet

- SIEVE Plus-Latest VersionDocument10 pagesSIEVE Plus-Latest VersionSebastian Zarate VilelaNo ratings yet

- Rationale of The SIM-geneticsDocument15 pagesRationale of The SIM-geneticsglemarNo ratings yet

- Introduction to the Normal Distribution (Bell CurveDocument9 pagesIntroduction to the Normal Distribution (Bell CurveZeeshan AkhtarNo ratings yet