Professional Documents

Culture Documents

Littelfuse Fuse 215 Datasheet PDF

Uploaded by

Alexis GEMEHLOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Littelfuse Fuse 215 Datasheet PDF

Uploaded by

Alexis GEMEHLCopyright:

Available Formats

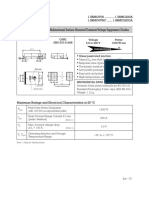

Axial Lead & Cartridge Fuses

5×20 mm > Time-Lag > 215 Series

215 Series, 5×20 mm, Time-Lag Fuse RoHS Pb PS

E

Description

5×20mm Time-Lag surge withstand ceramic body cartridge

fuse designed to IEC specification

Features

• Designed to International • Meets the IEC 60127-2,

(IEC ) Standards for use Sheet 5 specification for

globally Time-Lag fuses

• High breaking capacity • RoHS compliant and

lead-free

Agency Approvals Applications

Agency Agency File Number Ampere Range

Used as supplementary protection in appliance or

utilization equipment to provide individual protection for

Cartridge:

NBK080205-E10480A

1A – 5A components or internal circuits.

6.3A – 15A

NBK250702-E10480E

16A – 20A

NBK100408-JP1021A

PS

E

Leaded: Additional Information

1A – 5A

NBK080205-E10480B

6.3A – 15A

NBK250702-E10480F

16A – 20A

NBK100408-JP1021B

. 2005010207145714 1A – 6.3A

CQC07012021808 8A – 10A Datasheet Resources Samples

SU05001-2011B 1A – 2.5A

SU05001-10001 3.15A – 6.3A

SU05001-10002 8A

SU05001-2012B 4A - 10A

E10480 0.125A - 20A Electrical Characteristics for Series

29862 0.5A – 12A

% of Ampere

0.125A-12A Ampere Rating Opening Time

1517218 Rating

15A*, 16A*, 20A*

0.2A – 8A 0.125A – 0.800A 60 minutes, Minimum

40013521

*10A

40016610 *12A 1A – 3.15A 60 minutes, Minimum

150%

KM41462 0.200A – 10A 4A – 6.3A 60 minutes, Minimum

J50258578 16A/20A 8A – 20A 30 minutes, Minimum

N/A 0.125A – 20A 0.125A – 0.800A 30 minutes, Maximum

* Approved for cartridge versions only 1A – 3.15A 30 minutes, Maximum

210%

4A – 6.3A 30 minutes, Maximum

8A – 20A 30 minutes, Maximum

0.125A – 0.800A .25 sec. Min.; 80 secs. Max.

1A – 3.15A .75 sec. Min.; 80 secs. Max.

275%

4A – 6.3A .75 sec. Min.; 80 secs. Max.

8A – 20A .75 sec. Min.; 80 secs. Max.

0.125A – 0.800A .05 sec., Min.; 5 secs. Max.

1A – 3.15A .095 sec., Min.; 5 secs. Max.

400%

4A – 6.3A .150 sec., Min.; 5 secs. Max.

8A – 20A .150 sec., Min.; 5 secs. Max.

0.125A – 0.800A .005 sec., Min.; .150 sec. Max.

1A – 3.15A .010 sec., Min.; .150 sec. Max.

1000%

4A – 6.3A .010 sec., Min.; .150 sec. Max.

8A – 20A .010 sec., Min.; .150 sec. Max.

© 2019 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 08/05/19

Downloaded from Arrow.com.

Axial Lead & Cartridge Fuses

5×20 mm > Time-Lag > 215 Series

Electrical Characteristic Specifications by Item

Maximum Agency Approvals

Maximum

Nominal Nominal Voltage

Voltage Power

Amp Amp Interrupting Cold Melting Drop at

Rating Dissipation

Code Rating Rating Resistance I2t Rated PS

(V) at 1.5ln E

(Ohms) (A2 sec) Current

(W)

(mV)

.125 0.125 250 11.4455 0.0330 2600 1.6 x x x

.160 0.16 250 7.1000 0.0465 2400 1.6 x x x

.200 0.2 250 1.8400 0.340 2100 1.6 x x x x x

.250 0.25 250 1.2400 0.545 1500 1.6 x x x x x

.315 0.315 250 0.8800 0.975 1100 1.6 x x x x x

.400 0.4 250 0.5825 1.325 1000 1.6 x x x x x

.500 0.5 250 1.1675 0.420 850 1.6 x x x x x x

.630 0.63 250 0.7200 0.635 650 1.6 x x x x x x

.800 0.8 250 0.4675 0.975 500 1.6 x x x x x x

001. 1 250 0.1515 1.520 350 2.5 x x x x x x x x x

1500 A @

1.25 1.25 250 0.1074 3.200 300 2.5 x x x x x x x x x

250 VAC

01.6 1.6 250 0.0707 6.830 200 2.5 x x x x x x x x x

002. 2 250 0.0566 11.680 190 2.5 x x x x x x x x x

02.5 2.5 250 0.0386 22.290 180 2.5 x x x x x x x x x

3.15 3.15 250 0.0283 43.255 140 4 x x x x x x x x x

004. 4 250 0.0185 46.960 100 4 x x x x x x x x x

005. 5 250 0.0153 66.095 100 4 x x x x x x x x x

06.3 6.3 250 0.0108 128.750 100 4 x x x x x x x x x

008. 8 250 0.0092 209.880 100 4 x x x x x x x x x

010. 10 250 0.0066 333.565 100 4 x x x x x x x* x x

012. 12 250 0.0061 515.500 100 4 x x x x x* x

015. 15 250 500 A @ 0.0033 1237.0 N/A** N/A** x x x* x

016. 16 250 250Vac 0.0031 1408.0 N/A** N/A** x x x* x x

400 A @

020. 20 250 0.0023 2600.0 N/A** N/A** x x x* x x

250Vac

X* Approval for cartridge versions only

N/A** - Please contact Littelfuse for details on these parameters

1A to 2A have an IR : 100A@500VAC, 4A to 6-3A have the IR : 100A@305 VAC and 1000A@72VDC

I2t test at 10x rated current.

10A have an IR:1000A@300Vac for cURus

Temperature Re-rating Curve Product Characteristics

Body: Ceramic

Materials Cap: Nickel–plated Brass

Leads: Tin–plated Copper

Terminal

MIL-STD-202, Method 211, Test Condition A

Strength

Solderability MIL-STD-202 Method 208

Cap 1: Brand logo, current and voltage ratings

Product Marking

Cap 2: Agency approval markings

Operating

–55ºC to +125ºC

Temperature

MIL-STD-202, Method 107, Test Condition B (5 cycles,

Thermal Shock

–65ºC to +125ºC)

Vibration MIL-STD-202, Method 201

MIL-STD-202, Method 103, Test Condition A (High RH

Humidity

(95%) and elevated temp (40ºC) for 240 hours)

Salt Spray MIL-STD-202, Method 101, Test Condition B

© 2019 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 08/05/19

Downloaded from Arrow.com.

Axial Lead & Cartridge Fuses

5×20 mm > Time-Lag > 215 Series

Average Time Current Curves

T-C Curves for 125mA to 800mA only T-C Curves for 1A to 20A only

A

A

A

A

8.00 A

5.00 A

A

A

20.0 A

A

A

15.0 A

A

5.00 A

12.0 A

20.0 A

6.30 A

12.0 A

15.0 A

16.0 A

.200 A

A

1.00 A

.400 A

.800 A

.500 A

.800 A

16.0 A

2.00 A

A

.630 A

1.25 A

1.60 A

.125 A

.160 A

A

.500 A

.630 A

2.50 A

3.15 A

.250 A

.315 A

4.00

2.00

4.00

8.00

2.50

6.30

3.15

10.0

.200

.400

10.0

1.00

.250

1.25

1.60

.125

.160

.315

10000 10000 10000 10000

1000 1000 1000 1000

100 100 100 100

TIME IN SECONDS

TIME IN SECONDS

TIME IN SECONDS

TIME IN SECONDS

10 10 10 10

1 1

0.1 0.1 0.1 0.1

0.01 0.01 0.01 0.01

0.001 0.001 0.001 0.001

0.1 0.1 1 1 10 10 100 100 1000 1000 0.1 0.1 1 1 10 10 100 100 1000 1000

CURRENT IN AMPERES

CURRENT IN AMPERES CURRENT IN AMPERES

CURRENT IN AMPERES

Soldering Parameters - Wave Soldering

300

Recommended Process Parameters:

280 Wave Parameter Lead-Free Recommendation

Temperature (°C) - Measured on bottom side of board

260

240

Preheat:

220 (Depends on Flux Activation Temperature) (Typical Industry Recommendation)

200

Temperature Minimum: 100° C

180

Temperature Maximum: 150° C

160

140 Preheat Time: 60-180 seconds

120

100 Solder Pot Temperature: 260° C Maximum

80

Solder Dwell Time: 2-5 seconds

60

40

20

Recommended Hand-Solder Parameters:

0 Solder Iron Temperature: 350° C +/- 5°C

100

110

120

130

140

150

160

170

180

190

200

210

220

230

240

Heating Time: 5 seconds max.

10

20

30

40

50

60

70

80

90

0

Time (Seconds)

Note: These devices are not recommended for IR or Convection

Preheat Time Cooling Time

Reflow process.

Dwell Time

Different values of A and B available, please contact the

Littelfuse sales representative in your region:

For the pigtailed fuse, please follow the recommendations below for

A B

axial lead forming and mounting into PCB:

C Lead forming:

The distance C between cap flat surface and axial lead shall be

greater than 1.0 mm.

C PCB mounting:

A

The distance between PCB and fuse cap is recommended to be a

minimum of 1.5 mm.

B

© 2019 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 08/05/19

Downloaded from Arrow.com.

Axial Lead & Cartridge Fuses

5×20 mm > Time-Lag > 215 Series

Dimensions Part Numbering System

All dimensions in mm

0215 xxxx M X E/G P

20±0.5

0215.125P +0.1

5.2 −0.2

to Series

0215020P

5.1±0.6 5.1±0.6 Amp Code

Refer to Amp Code column of

5.6±0.4

Electrical Characteristics Table

40±1.0 21.5±1.0

0215.125XEP

to Quantity Code

0215.800XEP M = 1000

0.65±0.05

H = 100

Packaging Code

5.5±0.3 X = Filler

40±1.0 21.5±1.0

0215001.XEP

to Option Codes

0215020.XEP Blank : Cartidge Type Fuse

0.65±0.05*

E : Axial Lead Fuse

G : Color Coding

Notes:

* Ratings above 6.3 A have 0.8 ± 0.05 diameter lead; Lead-free

* Ratings above 12 A have 1.2 ± 0.05 diameter lead.

Packaging

Quantity &

Packaging Option Packaging Specification Quantity Taping Width

Packaging Code

215 Series

Bulk N/A 1000 MX N/A

Bulk N/A 1000 MXE N/A

Reel and Tape N/A 1000 MRET1 T1=53mm (2.087”)

Bulk and Color Coding N/A 1000 MXG N/A

Bulk N/A 1000 MXB N/A

Bulk N/A 100 HX N/A

Disclaimer Notice - Information furnished is believed to be accurate and reliable. However, users should independently evaluate the suitability of and test each

product selected for their own applications. Littelfuse products are not designed for, and may not be used in, all applications. Read complete Disclaimer Notice at:

www.littelfuse.com/disclaimer-electronics.

© 2019 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 08/05/19

Downloaded from Arrow.com.

You might also like

- Littelfuse Fuse 216 Datasheet pdf-310019Document5 pagesLittelfuse Fuse 216 Datasheet pdf-310019A. A.G.No ratings yet

- 0215005.MXP - Fusible, Cartucho, Fusión Lenta, 5 A, 250 V, 5mm X 20mm, 0.2 X 0.79, Serie Slo-Blo 215Document4 pages0215005.MXP - Fusible, Cartucho, Fusión Lenta, 5 A, 250 V, 5mm X 20mm, 0.2 X 0.79, Serie Slo-Blo 215Jose Luis Montejano GarciaNo ratings yet

- 217 Series: 5 × 20 MM, Fast-Acting FuseDocument4 pages217 Series: 5 × 20 MM, Fast-Acting FuseKhaled BellegdyNo ratings yet

- TE5 Time-Lag 392 SeriesDocument3 pagesTE5 Time-Lag 392 Seriesanand shekhawatNo ratings yet

- CSII N-Series SwitchesDocument10 pagesCSII N-Series Switchespaul reyesNo ratings yet

- En Acs550flyerrevfDocument2 pagesEn Acs550flyerrevfSơn Lê CaoNo ratings yet

- 220kv Greenko Feeder-2 Eqipment DetailsDocument34 pages220kv Greenko Feeder-2 Eqipment DetailsVeera ChaitanyaNo ratings yet

- Nano SMD 462 Series FuseDocument3 pagesNano SMD 462 Series Fuseedgar_dauzonNo ratings yet

- Benshaw Contactors Brochure PDFDocument14 pagesBenshaw Contactors Brochure PDFcristianNo ratings yet

- CONTACTORDocument3 pagesCONTACTORPHUC NGUYENNo ratings yet

- Bus Elx Ds 4395 GMCDocument2 pagesBus Elx Ds 4395 GMCRudyXPNo ratings yet

- TL 5903 Fev F 0420Document2 pagesTL 5903 Fev F 0420pepiNo ratings yet

- Baldor DC MotorsDocument58 pagesBaldor DC MotorstarraffNo ratings yet

- Fuses & Fuseholders: 6.3x25mm ( "x1") Glass & British Plug Top FusesDocument1 pageFuses & Fuseholders: 6.3x25mm ( "x1") Glass & British Plug Top Fusessyamsudin4077No ratings yet

- Power Relay F4: Automotive Relays Plug-In Mini ISO RelaysDocument5 pagesPower Relay F4: Automotive Relays Plug-In Mini ISO RelaysS MNo ratings yet

- Schrack Slimline PCB Relay SNR: General Purpose Relays PCB RelaysDocument3 pagesSchrack Slimline PCB Relay SNR: General Purpose Relays PCB RelaysJadi PurwonoNo ratings yet

- Cv77u036a06-76 TsDocument1 pageCv77u036a06-76 TsMarcelo Ricardo Garrido MarchantNo ratings yet

- 1.5SMC100 To 1.5SMC220CADocument7 pages1.5SMC100 To 1.5SMC220CAZoulou77No ratings yet

- Ficha Técnica Batería Solar 200AH GEL SunbattDocument2 pagesFicha Técnica Batería Solar 200AH GEL SunbattJhon AltamarNo ratings yet

- TYCO - Relés OEG SRET 103DP y Otros de PotenciaDocument4 pagesTYCO - Relés OEG SRET 103DP y Otros de PotenciaNestor Dino DominiciNo ratings yet

- 234 Series,: 5×20 MM Medium-Acting 234 SeriesDocument3 pages234 Series,: 5×20 MM Medium-Acting 234 SeriesalexanderNo ratings yet

- Sla 24vdc S L A Songle RelayDocument2 pagesSla 24vdc S L A Songle Relayagus2kNo ratings yet

- Relay SingleDocument2 pagesRelay Singlekrlos_adrianNo ratings yet

- Sla 12vdc SL A SongleDocument2 pagesSla 12vdc SL A SongleAHMAD NUR IMAMNo ratings yet

- Sla 12vdc SL A SongleDocument2 pagesSla 12vdc SL A SonglePrecila CanobidaNo ratings yet

- Sla 12vdc SL A SongleDocument2 pagesSla 12vdc SL A SongleAHMAD NUR IMAMNo ratings yet

- Benshaw ContactorsDocument13 pagesBenshaw ContactorsDione SilvaNo ratings yet

- Littelfuse LFPCN41226Document10 pagesLittelfuse LFPCN41226Miguel VenzNo ratings yet

- Model Number Structure: Enclosed SwitchDocument9 pagesModel Number Structure: Enclosed SwitchMuhamad PriyatnaNo ratings yet

- Relay Iso9002: SLA XX VDC S L CDocument2 pagesRelay Iso9002: SLA XX VDC S L CMarudhasalamMarudhaNo ratings yet

- Subminiature FuseDocument14 pagesSubminiature FuseGautham VenkatNo ratings yet

- Control Products CatalogDocument50 pagesControl Products Catalogmk saravananNo ratings yet

- DOL - SD Starter LeafletDocument2 pagesDOL - SD Starter Leafletoneops techNo ratings yet

- AmparoDocument9 pagesAmparorubicsNo ratings yet

- 213 Series: 5×20 MM, Time-Lag FuseDocument3 pages213 Series: 5×20 MM, Time-Lag Fuse원모양No ratings yet

- TE Connectivity AMP-3-1393118-4-datasheet PDFDocument5 pagesTE Connectivity AMP-3-1393118-4-datasheet PDFCajun LeBeauNo ratings yet

- Ct2000pro Manual PDFDocument71 pagesCt2000pro Manual PDFmajid aliNo ratings yet

- Littelfuse MEGA DatasheetDocument2 pagesLittelfuse MEGA DatasheetVIKASNo ratings yet

- 1.5KE Series: Silicon Avalanche DiodesDocument4 pages1.5KE Series: Silicon Avalanche DiodesPsyplant PsytranceNo ratings yet

- Fuses Glasses and CeramicDocument5 pagesFuses Glasses and CeramicAbhijit JanaNo ratings yet

- Multiple Pulse (MP) Disk Varistors, S10: HeadlineDocument4 pagesMultiple Pulse (MP) Disk Varistors, S10: HeadlineDaniel MesaNo ratings yet

- Uf 5400Document4 pagesUf 5400jesus cautivoNo ratings yet

- Terasaki Ecoplus 06 I81ecatalogueDocument19 pagesTerasaki Ecoplus 06 I81ecatalogueYasir JamilNo ratings yet

- Rotary Cam Switches: Advantages N N NDocument7 pagesRotary Cam Switches: Advantages N N NNedelescu MihaelaNo ratings yet

- Subfractional Permanent Magnet DC Motor - TENV, Rigid BaseDocument58 pagesSubfractional Permanent Magnet DC Motor - TENV, Rigid Baseduc minhNo ratings yet

- Sungrow Smart Energy Meter Application GuideDocument2 pagesSungrow Smart Energy Meter Application GuidegNo ratings yet

- 5 MM X 20 MM Time-Delay Glass Tube Fuses: Technical Data 4332Document2 pages5 MM X 20 MM Time-Delay Glass Tube Fuses: Technical Data 4332LXCNo ratings yet

- CNN - E / CNN / CNL Series Lift Truck Fuses: Powr-Gard Fuse DatasheetDocument1 pageCNN - E / CNN / CNL Series Lift Truck Fuses: Powr-Gard Fuse Datasheetpo truongNo ratings yet

- Dust Collector Main Pulse Valves: FeaturesDocument4 pagesDust Collector Main Pulse Valves: FeaturesQuân TrịnhNo ratings yet

- Mks Series 10Document25 pagesMks Series 10Kamatsho BarcelonaNo ratings yet

- GP15A, GP15B, GP15D, GP15G, GP15J, GP15K, GP15M: Vishay General SemiconductorDocument5 pagesGP15A, GP15B, GP15D, GP15G, GP15J, GP15K, GP15M: Vishay General SemiconductorJuan ChoNo ratings yet

- Power Relay F4: Automotive Relays Plug-In Mini ISO RelaysDocument4 pagesPower Relay F4: Automotive Relays Plug-In Mini ISO RelaysJorge CalcaneoNo ratings yet

- Cod280S ENDocument24 pagesCod280S ENpabloNo ratings yet

- Industrial Batteries / Network Power: Sonnenschein A600Document16 pagesIndustrial Batteries / Network Power: Sonnenschein A600iamlpNo ratings yet

- Carrier SSS - Littelfuse Fuse 370 Datasheet PDF-357362Document4 pagesCarrier SSS - Littelfuse Fuse 370 Datasheet PDF-357362Fabio Moacir KorndoerferNo ratings yet

- User Manual 1374484Document12 pagesUser Manual 1374484gutierkNo ratings yet

- Alstom ContactorsDocument8 pagesAlstom Contactorshassan karimiNo ratings yet

- A. T. S. - Switching Line BoardDocument6 pagesA. T. S. - Switching Line BoardAsif ShahNo ratings yet

- Nano Very Fast Acting Fuse 456 SeriesDocument3 pagesNano Very Fast Acting Fuse 456 Seriesm3y54mNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Kia Picanto SA 2004 2011 Workshop Service Repair ManualDocument1,478 pagesKia Picanto SA 2004 2011 Workshop Service Repair ManualJan Peterka100% (1)

- Metson Power AsiaDocument34 pagesMetson Power AsiatanniayulianaNo ratings yet

- Financial Times Europe - 26.05.23Document18 pagesFinancial Times Europe - 26.05.23Paulo4255No ratings yet

- Specifications: 2806C-E18TA, 2806D-E18TA and 2806D-E18TTA Industrial EnginesDocument70 pagesSpecifications: 2806C-E18TA, 2806D-E18TA and 2806D-E18TTA Industrial EnginesDaniel Ricardo Quintero SuavitaNo ratings yet

- Unit 3 MCQDocument11 pagesUnit 3 MCQNarendra ModiNo ratings yet

- Ecosystems: The High Peaks Wilderness Area in The Adirondack Park Is An Example of A Diverse EcosystemDocument16 pagesEcosystems: The High Peaks Wilderness Area in The Adirondack Park Is An Example of A Diverse EcosystemPranav67% (9)

- Why Do Airplanes With Turbofan Engines Have To Fly Higher Than The Ones With Turboprop - QuoraDocument4 pagesWhy Do Airplanes With Turbofan Engines Have To Fly Higher Than The Ones With Turboprop - QuoraAmir BahramiNo ratings yet

- YT-1200H-S-O3 GAS DETECTOR - SafegasDocument12 pagesYT-1200H-S-O3 GAS DETECTOR - SafegasdernivaljrNo ratings yet

- Mitsubishi Engine 6g72 ManualDocument10 pagesMitsubishi Engine 6g72 Manualmohammad98% (51)

- Hitachi Zw310 Technical Manual Operational PrincipleDocument20 pagesHitachi Zw310 Technical Manual Operational Principlemelody100% (40)

- Technology: 110 TRANSFORMERS MAGAZINE - Special Edition Substations - 2019Document6 pagesTechnology: 110 TRANSFORMERS MAGAZINE - Special Edition Substations - 2019hugoNo ratings yet

- STIHL HS 46, 56: Instruction Manual Notice D'emploiDocument64 pagesSTIHL HS 46, 56: Instruction Manual Notice D'emploikhoerul anamNo ratings yet

- ĐỀ THI THỬ SỐ 23 (2019-2020) lyDocument6 pagesĐỀ THI THỬ SỐ 23 (2019-2020) lyLy KhánhNo ratings yet

- Europass CV DMDocument2 pagesEuropass CV DMerdhirajmandalNo ratings yet

- 3.3 Understanding Gas PressureDocument4 pages3.3 Understanding Gas PressurepedNo ratings yet

- Electrical Component LocatorDocument47 pagesElectrical Component Locatorgentiles mdqNo ratings yet

- Tall Building Design - NotesDocument60 pagesTall Building Design - NotesHaHa WaNo ratings yet

- Mines in IndiaDocument2 pagesMines in Indiadharan511No ratings yet

- BatchpurWWTP2022 ADocument8 pagesBatchpurWWTP2022 AKshitiz MittalNo ratings yet

- 2 MW Product BrochurepdfDocument12 pages2 MW Product BrochurepdfaskagiNo ratings yet

- Hydrotest and Pneumatic Test of Piping Systems-Hydrotest Vs Pneumatic TestDocument11 pagesHydrotest and Pneumatic Test of Piping Systems-Hydrotest Vs Pneumatic TestAzher ANo ratings yet

- PT S1 Genap 2021-2022 Week 4 - Generalized Equation of Change For Isothermal SystemDocument54 pagesPT S1 Genap 2021-2022 Week 4 - Generalized Equation of Change For Isothermal SystemMuhammad Yuzer IrosoneriNo ratings yet

- Terminating, Connecting and Testing Electrical Wirings and Electronic CircuitsDocument4 pagesTerminating, Connecting and Testing Electrical Wirings and Electronic CircuitsCyril Joy N. Fernando50% (2)

- Rem 545 RelayDocument89 pagesRem 545 RelayVivek Devakumar100% (1)

- Transmission Lines and TowersDocument23 pagesTransmission Lines and Towersसुबास अधिकारीNo ratings yet

- List of Power Project in IndiaDocument30 pagesList of Power Project in IndiaInder RatheeNo ratings yet

- Project Final YearDocument73 pagesProject Final Yearprincepawan369No ratings yet

- Electrical SectionDocument142 pagesElectrical Sectionclaudiux78No ratings yet

- Power Upgrade Material - MTO-RFQDocument21 pagesPower Upgrade Material - MTO-RFQcybervolt securitiesNo ratings yet

- Preliminary Welding Procedure Specification Pwps PDF FreeDocument1 pagePreliminary Welding Procedure Specification Pwps PDF FreeFirozNo ratings yet