Professional Documents

Culture Documents

Model Number Structure: Enclosed Switch

Uploaded by

Muhamad PriyatnaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Model Number Structure: Enclosed Switch

Uploaded by

Muhamad PriyatnaCopyright:

Available Formats

Enclosed Switch

D4MC

Economical, High Utility Enclosed Switch

• High precision and long life (10,000,000 mechanical operations)

through employment of the moving spring used in OMRON Z

Basic Switch.

• Sealed with gasket diaphragm to provide high sealing property

without use of any adhesive or pin.

• Suitable for applications demanding higher mechanical

strength, dustproof and drip-proof properties than those on ba-

sic switches.

• Panel mount versions have the same operating position as Z

Basic Switch.

• Resin molded terminal versions are available.

• Approved by UL, CSA, and CCC (Chinese standard).

Model Number Structure

■ Model Number Legend

D4MC-

1

1. Actuator

5000: Panel mount plunger

5020: Panel mount roller plunger

5040: Panel mount crossroller plunger

1020: Short hinge lever

1000: Hinge lever

2000: Hinge roller lever

2020: Short hinge roller lever

3030: One-way action short hinge roller lever

Enclosed Switch D4MC 151

Ordering Information

■ List of Models

Actuator Model

Panel mount plunger D4MC-5000

Panel mount roller plunger D4MC-5020

Panel mount crossroller plunger D4MC-5040

Short hinge lever D4MC-1020

Hinge lever D4MC-1000

Hinge roller lever D4MC-2000

Short hinge roller lever D4MC-2020

One-way action short hinge roller lever D4MC-3030

Note: Use molded terminal models (refer to page 158) when using the Switch under one of the following conditions:

a) dusty, b) high amount of dripping oil, or c) high humidity.

Models are available with the lead outlet in one of three locations: right-hand, left-hand, and underside.

■ Terminal Protective Cover, Seal Rubber, and Rubber Packing

(The Switch is equipped with these 3 items as a standard.)

• ZC Terminal Cover

(Product code: ZC55-0002H)

Rubber packing • ZC Seal Rubber

(Product code: SC-1404C)

• ZC Rubber Packing

(Product code: ZC55-0003F)

Terminal cover Seal rubber

152 Enclosed Switch D4MC

Specifications

■ Approved Standards

(Except Molded Terminal Models)

Agency Standard File No.

UL 508 E76675

CSA C22.2 No. 14 E45258

CCC (CQC) GB14048.5 2003010303077627

Note: Ask your OMRON representative for information on approved models.

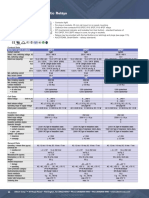

■ Approved Standard Ratings

UL/CSA

A300

Rated voltage Carry current Current Volt-amperes

Make Break Make Break

120 VAC 10 A 60 A 6A 7,200 VA 720 VA

240 VAC 30 A 3A

EN60947-1 and EN60947-5-1

250 V, 10 A (AC12) (Tested by ASTA)

CCC (GB14048.5)

Applicable category and ratings

AC-12 10 A/250 VAC

■ General Ratings

Rated voltage Non-inductive load Inductive load

Resistive load Lamp load Inductive load Motor load

NC NO NC NO NC NO NC NO

125 VAC 10 A 3A 1.5 A 10 A 5A 2.5 A

250 VAC 10 A 2.5 A 1.25 A 10 A 3A 1.5 A

480 VAC 3A 1.5 A 0.75 A 2.5 A 1.5 A 0.75 A

8 VDC 10 A 3A 1.5 A 6A 5A 2.5 A

14 VDC 10 A 3A 1.5 A 6A 5A 2.5 A

30 VDC 6A 3A 1.5 A 5A 5A 2.5 A

125 VDC 0.5 A 0.4 A 0.4 A 0.05 A 0.05 A 0.05 A

250 VDC 0.25 A 0.2 A 0.2 A 0.03 A 0.03 A 0.03 A

Inrush current NC 30 A max.

NO 15 A max.

Note: 1. The above figures are for steady-state currents.

2. Inductive loads have a power factor of 0.4 min. (AC) and a time constant of 7 ms max. (DC).

3. Lamp load has an inrush current of 10 times the steady-state current.

4. Motor load has an inrush current of 6 times the steady-state current.

5. The above ratings were tested under the following conditions.

Ambient temperature: 20±2°C

Ambient humidity: 65±5%

Operating frequency: 20 operations/min

Enclosed Switch D4MC 153

■ Characteristics

Degree of protection IP67

Durability Mechanical: 10,000,000 operations min.

Electrical: 500,000 operations min.

Operating speed 0.05 mm/s to 0.5 m/s (for plunger models)

Operating frequency Mechanical: 120 operations/min

Electrical: 20 operations/min

Rated frequency 50/60 Hz

Insulation resistance 100 MΩ min. (at 500 VDC)

Contact resistance 15 mΩ max. (initial value)

Dielectric strength 1,000 VAC, 50/60 Hz for 1 min between terminals of the same polarity

2,000 VAC, 50/60 Hz for 1 min between current-carrying metal parts and ground, and between each ter-

minal and non-current-carrying part

Rated insulation voltage (Ui) 1,000 VAC

Pollution degree 3 (IEC947-5-1)

(operating environment)

Protection against electric shock Class II

PTI (tracking characteristics) 175

Switch category D (IEC335)

Rated operating current (Ie) 10 A

Rated operating voltage (Ue) 250 VAC

Vibration resistance Malfunction: 10 to 55 Hz, 1.5-mm double amplitude (see note)

Shock resistance Destruction: 1,000 m/s2 min.

Malfunction: 100 m/s2 min. (for plunger models) (see note)

Ambient temperature Operating: –10°C to 80°C (with no icing)

Ambient humidity Operating: 35% to 95%

Weight Approx. 71 g (at panel mount plunger)

Note: Less than 1 ms under a free state at the operating limits.

Connections

■ Contact Form

(COM) 1 2 (NC)

4 (NO)

154 Enclosed Switch D4MC

Nomenclature

Changing the Terminal Protective Cover around allows the cable to be pulled out from either the right or the left.

Roller

Case

Pushbutton

Built-in switch

Seal rubber

Terminal

Protective

Cover

Common Normally

terminal Normally closed

(COM) open terminal

terminal (NC)

(NO)

Note: M4 binding head screws (with toothed washers) are used as the terminal screws.

Engineering Data

■ Mechanical Durability ■ Electrical Durability

(D4MC-5000)

10,000 10,000

Operating temperature: 20±2°C 7,000

Operating humidity: 65±5% 5,000

5,000 No load 125 VAC cosφ=1

Durability (x 104 operations)

Durability (x 104 operations)

Operating frequency: 120 operations/min 3,000

125 VAC cosφ=0.4

250 VAC cosφ=1

2,000 1,000

700 250 VAC cosφ=0.4

500

1,000

300

500

100

70

50

200

30 Operating temperature: 20±2°C

Operating humidity: 65±5%

100

0.01 0.02 0.05 0.1 0.2 0.5 1 2 5 10 Operating frequency: 20 operations/min

10

0 2 4 6 8 10 12

OT (mm)

Switching Current (A)

Enclosed Switch D4MC 155

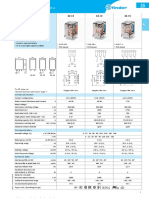

Dimensions

Note: 1. All units are in millimeters unless otherwise indicated.

2. Unless otherwise specified, a tolerance of ±0.4 mm applies to all dimensions.

Model D4MC-5000

Panel Mount Plunger

OF max. 5.88 N

D4MC-5000

RF min. 0.98 N

(See note 1)

M12 x 1 mounting screw PT max. 1.6 mm

Two hexagon nuts 8.4 dia.

(thickness: 33

(thickness: OT min. 5 mm

width:

width: 17)

17)

(See MD max. 0.2 mm

note 2) 16

16

dia.

dia. OP 21.8± 1.2 mm

FP max. ---

Note: 1. Stainless steel plunger

2. The length of the imperfect

22 max. threads is 1.5 mm maximum.

3. Do not use the M12 mounting

15

15 (21

(21 xx 21)

21) screw and the case mounting

Terminal

Terminal hole at the same time.

Seal rubber (NBR)

protective Two, 4.3±0.1 dia.

cover mounting holes

Model D4MC-5020

Panel Mount Roller Plunger

OF max. 5.88 N

D4MC-5020

RF min. 0.98 N

12.7 dia. × 5 (see note 1)

PT max. 1.6 mm

M12 x 1 mounting screw

Two hexagon nuts OT min. 5 mm

(thickness: 3

(See

MD max. 0.2 mm

width: 17)

note 2)

16

OP 33.4±1.2 mm

dia. FP max. ---

Note: 1. Stainless steel roller

22 max.

2. The length of the imperfect

threads is 1.5 mm maximum.

15 (21 x 21)

3. Do not use the M12

Terminal Seal rubber (NBR) mounting screw and the case

Two, 4.3±0.1 dia.

protective mounting hole at the same

mounting holes

cover time.

Model D4MC-5040

Panel Mount Crossroller Plunger

OF max. 5.88 N

D4MC-5040

RF min. 0.98 N

12.7 dia. × 5 PT max. 1.6 mm

M12 x 1 mounting screw (see note 1)

Two hexagon nuts OT min. 5 mm

(thickness: 3

MD max. 0.2 mm

(See width: 17)

note 2) 16

Note: 1. Stainless steel roller

OP 33.4±1.2 mm

dia.

2. The length of the imperfect FP max. ---

threads is 1.5 mm maximum.

3. Do not use the M12 mounting

screw and the case mounting

22 max. hole at the same time.

(21 x 21)

Terminal Seal rubber (NBR)

protective Two, 4.3±0.1 dia.

cover mounting holes

156 Enclosed Switch D4MC

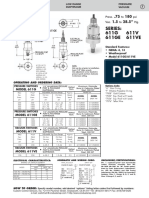

Model D4MC-1020

Short Hinge Lever

OF max. 2.55 N

D4MC-1020

RF min. 0.34 N

t = 1 (see note) PT max. ---

48.6R OT min. 2.5 mm

Note: Stainless steel lever

MD max. 1.7 mm

OP 25±1 mm

FP max. 33 mm

22 max.

15 (21 x 21)

Terminal Seal rubber (NBR)

Two, 4.3±0.1 dia.

protective

mounting holes

cover

Model D4MC-1000

Hinge Lever

OF max. 1.67 N

D4MC-1000

RF min. 0.25 N

t = 1 (see note)

72.7R

PT max. ---

OT min. 4 mm

MD max. 3 mm

OP 25±1 mm

FP max. 36 mm

22 max.

15 (21 x 21) Note: Stainless steel lever

Terminal Two, 4.3±0.1 dia. Seal rubber (NBR)

protective mounting holes

cover

Model D4MC-2000

Hinge Roller Lever

OF max. 1.96 N

D4MC-2000

RF min. 0.39 N

12.7 dia.× 7.5

t=1 (see note 2) PT max. ---

(see note 1)

OT min. 5 mm

63.7R

MD max. 3 mm

OP 40±1 mm

FP max. 51 mm

22 max.

Note: 1. Stainless steel lever

15 (21 x 21) 2. Plastic roller

Terminal Two, 4.3±0.1 dia. Seal rubber (NBR)

protective mounting holes

cover

Model D4MC-2020

Short Hinge Roller Lever

OF max. 2.94 N

D4MC-2020

12.7 dia.× 7.5

RF min. 0.39 N

t=1 (see note 2) PT max. ---

(see note 1)

OT min. 2 mm

41R

MD max. 1.5 mm

OP 40±1 mm

FP max. 47 mm

22 max. Note: 1. Stainless steel lever

2. Plastic roller

15 (21 x 21)

Terminal Two, 4.3±0.1 dia. Seal rubber (NBR)

protective mounting holes

cover

Enclosed Switch D4MC 157

Model D4MC-3030

One-way Action Short Hinge Roller Lever

OF max. 2.94 N

D4MC-3030

RF min. 0.39 N

12.7 dia.× 7.5

t=1 14 PT max. ---

Angle of roller (see note 2)

(see note 1)

swing: 90° OT min. 2 mm

46.6R MD max. 1.5 mm

OP 50±1 mm

Note: 1. Stainless steel lever FP max. 57.2 mm

2. Plastic roller

22 max.

15 (21 x 21)

Terminal Two, 4.3±0.1 dia. Seal rubber (NBR)

protective mounting holes

cover

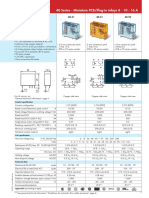

Molded Terminal Models

■ Molded Terminal Models (Not Approved by UL, CSA, or EN)

The molded terminal model is available with right-hand, left-hand and underside leads and is recommended for use where the Switch is exposed

to dust, oil, or moisture.

When placing your order for the Switch specify the required length of

V.C.T. cable in addition to the model number of the Switch

Example:

Standard type: D4MC-5020

Location of lead outlet: Underside

Length of lead: 1 m (V.C.T. lead)

When placing your order for the above Switch specify the model

number as D4MC-5023 VCT 1M

(2) (1)

Suffix by Location of Lead Outlet

Location of lead outlet Model

(3)

COM, NC, and NO

Right-hand D4MC-@@@1

Left-hand D4MC-@@@2

Underside D4MC-@@@3

Leads Supplied

Leads Nominal Finished outside diameter Terminal Standard length

cross-sectional area connections

V.C.T. (Vinyl cabtire cable) 1.25 mm2 3 core:10.5 mm dia. Black: COM 1, 3 m

White: NO

Red: NC

158 Enclosed Switch D4MC

Precautions

Refer to the “Precautions for General-purpose Limit Switches (Including Multiple Limit Switches, Mechanical Touch Switches, High-precision

Switches, Touch Switches, On-site Flexible Switches; Not Including Safety Switches)” on page 17.

■ Correct Use When mounting the Terminal Protective Cover to the case, align the

cover on the case and then press the cover down to mount it firmly. If

the cover is pressed down in an inclined position, rubber packing will

Operating Environment deform and thus affect the sealing capability.

• Seal material may deteriorate if a Switch is used outdoor or where

subject to special cutting oils, solvents, or chemicals. Always

appraise performance under actual application conditions and set Incorrect Correct

suitable maintenance and replacement periods.

• Install Switches where they will not be directly subject to cutting

chips, dust, or dirt. The Actuator and Switch must also be protected

from the accumulation of cutting chips or sludge.

v

Not Suitable Suitable

Rubber packing Rubber packing

Mounting

When mounting the Switch with screws on a side surface, fasten the

• Constantly subjecting a Switch to vibration or shock can result in Switch with M4 screws and use washers, spring washers, etc., to

wear, which can lead to contact interference with contacts, opera- ensure secure mounting.

tion failure, reduced durability, and other problems. Excessive

vibration or shock can lead to false contact operation or damage.

Install Switches in locations not subject to shock and vibration and Mounting Holes

in orientations that will not produce resonance. Two, 4.3-dia. or M4 screw holes

• The Switches have physical contacts. Using them in environments

containing silicon gas will result in the formation of silicon oxide

(SiO2) due to arc energy. If silicon oxide accumulates on the con-

tacts, contact interference can occur. If silicon oil, silicon filling

agents, silicon cables, or other silicon products are present near • When mounting the Panel Mount-type Switch (D4MC-5000, D4MC-

the Switch, suppress arcing with contact protective circuits (surge 5020, or D4MC-5040) with screws on a side surface, remove the

killers) or remove the source of silicon gas. hexagonal nuts from the actuator.

• When mounting the panel mount type on a panel, be careful not to

Operating tighten to an excessive torque. Tightening the screws to a torque

exceeding 4.91 N·m will cause the plunger to fail.

Excessive dog angle, operating speed, or overtravel (OT) may dam-

age the actuator. Check that OT has a sufficient margin. The actual Mounting Hole Dimensions

OT should be rated OT x 0.7 to 1.

D4MC-5000 D4MC-5020, D4MC5040

Handling 12.5+0.2

0 dia. 12.5+0.2

0 dia.

• Do not expose the Switch to water exceeding 60°C or use it in

steam. 5+0.2

0

• Do not use the Switch in oil or water.

• An 8.5- to 10.5-dia. cable can be applied as seal rubber for the lead

wire outlet. (Use two- or three-core cable of VCT1.25 mm2.)

13+0.2

0

• When detaching the Terminal Protective Cover, insert a screwdriver

and apply a force in the opening direction. Do not use excess force

to remove the cover. Doing so may cause deformation in the fitting Correct Tightening Torque

section and reduce the holding force.

A loose screw may cause malfunctions. Be sure to tighten each

screw to the proper tightening torque as shown in the table.

Screwdriver No. Type Torque

1 Terminal screw 0.78 to 1.18 N·m

2 Panel mounting screw 2.94 to 4.92 N·m

3 Side mounting screw 1.18 to 1.47 N·m

Terminal Protective Cover

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. C027-E1-10 In the interest of product improvement, specifications are subject to change without notice.

Enclosed Switch D4MC 159

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Caterpillar 966d Wheel Loader Service Manual SN 35s PDFDocument7 pagesCaterpillar 966d Wheel Loader Service Manual SN 35s PDFyudi0% (2)

- M01 Hibb0000 00 Se C16Document153 pagesM01 Hibb0000 00 Se C16luisloredoperez156No ratings yet

- Siremobil PartsDocument20 pagesSiremobil PartsOscar OcañoNo ratings yet

- DZ-10G Basic Switch Controls Two Independent CircuitsDocument5 pagesDZ-10G Basic Switch Controls Two Independent CircuitsMuhamad PriyatnaNo ratings yet

- b060 DZ Special-Purpose Basic Switch Datasheet enDocument6 pagesb060 DZ Special-Purpose Basic Switch Datasheet enKlan ZangoNo ratings yet

- Model Number Structure: Enclosed SwitchDocument11 pagesModel Number Structure: Enclosed SwitchMuhamad PriyatnaNo ratings yet

- High-capacity Switch Handles Large Inrush CurrentsDocument7 pagesHigh-capacity Switch Handles Large Inrush CurrentsMuhamad PriyatnaNo ratings yet

- Low-Torque Basic Switch D2MCDocument5 pagesLow-Torque Basic Switch D2MCMuhamad PriyatnaNo ratings yet

- Economical Miniature Limit Switch HL-5000 Boasting Rigid ConstructionDocument9 pagesEconomical Miniature Limit Switch HL-5000 Boasting Rigid ConstructionHlaing MyintNo ratings yet

- High-Capacity Switch Capable of Handling 20 A Loads With Large Inrush CurrentsDocument6 pagesHigh-Capacity Switch Capable of Handling 20 A Loads With Large Inrush CurrentsMuhammad Purbo SantosoNo ratings yet

- Miniature Basic Switch Provides Long Life of 2 Million OperationsDocument5 pagesMiniature Basic Switch Provides Long Life of 2 Million OperationsMuhamad PriyatnaNo ratings yet

- 6055 DB 1401Document6 pages6055 DB 1401Francisco MartinezNo ratings yet

- General-Purpose Basic Switch XDocument8 pagesGeneral-Purpose Basic Switch XMuhamad PriyatnaNo ratings yet

- Dra 051018Document5 pagesDra 051018MaximilianoAlvarezNo ratings yet

- Sla 12vdc SL A SongleDocument2 pagesSla 12vdc SL A SonglePrecila CanobidaNo ratings yet

- Sla 12vdc SL A SongleDocument2 pagesSla 12vdc SL A SongleAHMAD NUR IMAMNo ratings yet

- Sla 12vdc SL A SongleDocument2 pagesSla 12vdc SL A SongleAHMAD NUR IMAMNo ratings yet

- Relay SingleDocument2 pagesRelay Singlekrlos_adrianNo ratings yet

- Sla 24vdc S L A Songle RelayDocument2 pagesSla 24vdc S L A Songle Relayagus2kNo ratings yet

- Rele FinderDocument14 pagesRele FinderJosé marinNo ratings yet

- orman-Miniature Basic SwitchDocument5 pagesorman-Miniature Basic Switchmehdibagherpour.sNo ratings yet

- Ca5x 10Document4 pagesCa5x 10Meezan BatchaNo ratings yet

- R15 473564 PDFDocument7 pagesR15 473564 PDFHENDER VILLEGASNo ratings yet

- General Purpose Relays for Automation and ControlDocument18 pagesGeneral Purpose Relays for Automation and ControlMarcelino MoralesNo ratings yet

- General purpose relays for automation controlDocument18 pagesGeneral purpose relays for automation controlValerija SilinaNo ratings yet

- Miniature Basic Switch D2MVDocument7 pagesMiniature Basic Switch D2MVMuhamad PriyatnaNo ratings yet

- Ultra Subminiature Basic Switch JDocument6 pagesUltra Subminiature Basic Switch JMuhamad PriyatnaNo ratings yet

- HG-Series GuideDocument14 pagesHG-Series GuidesundewsNo ratings yet

- 1SBN010010R1010 Ca5 10Document5 pages1SBN010010R1010 Ca5 10Meezan BatchaNo ratings yet

- 30 Amp Heavy Duty Power RelayDocument2 pages30 Amp Heavy Duty Power Relaybaba jiNo ratings yet

- Relais FINDER - 4C.02Document8 pagesRelais FINDER - 4C.02Menet HenriNo ratings yet

- Relay Finder 55 SeriesDocument18 pagesRelay Finder 55 SeriesBerlianiNo ratings yet

- MSR125H/HP: DescriptionDocument3 pagesMSR125H/HP: DescriptionI SNo ratings yet

- Circuit Protector Cong Ty Co Phan Viet NguyenDocument6 pagesCircuit Protector Cong Ty Co Phan Viet NguyenTriều Nguyễn NgọcNo ratings yet

- 943 Series Relay: FeaturesDocument3 pages943 Series Relay: FeaturesFavian MartinezNo ratings yet

- Model Number Structure: Enclosed SwitchDocument10 pagesModel Number Structure: Enclosed SwitchMuhamad PriyatnaNo ratings yet

- Evaluation and Finding of Isolated Flyback Converter: © 2016 ROHM Co.,LtdDocument29 pagesEvaluation and Finding of Isolated Flyback Converter: © 2016 ROHM Co.,LtdNhatNo ratings yet

- HL-500 General-Purpose Limit SwitchDocument9 pagesHL-500 General-Purpose Limit SwitchMuhamad PriyatnaNo ratings yet

- Finder-Industrialrelayseries5532 20160412120109Document16 pagesFinder-Industrialrelayseries5532 20160412120109pouya alizadehNo ratings yet

- RELAY ISO9002 FEATURESDocument2 pagesRELAY ISO9002 FEATURESMarudhasalamMarudhaNo ratings yet

- Rele Finder - Serie 55Document4 pagesRele Finder - Serie 55José marinNo ratings yet

- DDR-120-SPECDocument10 pagesDDR-120-SPECJose Maria Salazar GarciaNo ratings yet

- Schrack Power PCB Relay U/UB (V23148) : General Purpose Relays PCB RelaysDocument3 pagesSchrack Power PCB Relay U/UB (V23148) : General Purpose Relays PCB Relaysremus popescuNo ratings yet

- Finder Catalogo 95.15.2SMA - Relay Socket, Through Hole, Through Hole, 8 PinsDocument16 pagesFinder Catalogo 95.15.2SMA - Relay Socket, Through Hole, Through Hole, 8 PinsJMSNo ratings yet

- DDR 120Document10 pagesDDR 120Jack HawkeNo ratings yet

- 14pin Relay and BaseDocument16 pages14pin Relay and BaseNaveed AhmadNo ratings yet

- S65ENDocument8 pagesS65ENRemy MendozaNo ratings yet

- CATEN - 58Series-Finder RelayDocument11 pagesCATEN - 58Series-Finder RelayjaneeshNo ratings yet

- Features: 55 Series - General Purpose Relays 7 - 10 ADocument6 pagesFeatures: 55 Series - General Purpose Relays 7 - 10 AAdetunji TaiwoNo ratings yet

- Okpac: Single Phase Solid State RelaysDocument2 pagesOkpac: Single Phase Solid State RelaysAnwar QahtanNo ratings yet

- Three Pole Contactors MNX PDFDocument10 pagesThree Pole Contactors MNX PDFEli SharmaNo ratings yet

- SFG Gas-insulated indoor switch disconnector technical overviewDocument4 pagesSFG Gas-insulated indoor switch disconnector technical overviewRazvan SasuNo ratings yet

- Multiple Pulse (MP) Disk Varistors, S10: HeadlineDocument4 pagesMultiple Pulse (MP) Disk Varistors, S10: HeadlineDaniel MesaNo ratings yet

- Model Number Structure: Relays With Forcibly Guided ContactsDocument22 pagesModel Number Structure: Relays With Forcibly Guided Contactselkin mezaNo ratings yet

- DatasheetDocument3 pagesDatasheetMatias FicaNo ratings yet

- WD-A-CC-087 Series Module SpecificationsDocument7 pagesWD-A-CC-087 Series Module SpecificationsMidhat MalikNo ratings yet

- DatasheetDocument2 pagesDatasheetSebas EcharteNo ratings yet

- 1209B-1221B RevDDocument2 pages1209B-1221B RevDSergio RecabarrenNo ratings yet

- TA80DU-52 Thermal Overload RelayDocument4 pagesTA80DU-52 Thermal Overload RelayPower SolutionNo ratings yet

- Catalogue Vitzro AtsDocument2 pagesCatalogue Vitzro Atsvhoa309No ratings yet

- D4NL 1189512 PDFDocument11 pagesD4NL 1189512 PDFLucas CardosoNo ratings yet

- Omron Gate Switch D4NL Catalog & WiringDocument10 pagesOmron Gate Switch D4NL Catalog & WiringDan SomervilleNo ratings yet

- EB3C & 3L - Sales ManualDocument10 pagesEB3C & 3L - Sales ManualMuhamad PriyatnaNo ratings yet

- A Series Miniature Control UnitsDocument44 pagesA Series Miniature Control UnitsMuhamad PriyatnaNo ratings yet

- Industrial Automation Catalog Section - U906: Switches & Pilot Devices AP Series Miniature Switches & Pilot DevicesDocument8 pagesIndustrial Automation Catalog Section - U906: Switches & Pilot Devices AP Series Miniature Switches & Pilot DevicesMuhamad PriyatnaNo ratings yet

- ø16mm and ø22mm Emergency Stop Switches - Compact Size, Safe Break ActionDocument20 pagesø16mm and ø22mm Emergency Stop Switches - Compact Size, Safe Break ActionMuhamad PriyatnaNo ratings yet

- FB Series Plastic Control Boxes provide IP65 protectionDocument8 pagesFB Series Plastic Control Boxes provide IP65 protectionMuhamad PriyatnaNo ratings yet

- Relay Barriers: Intrinsically Safe Explosion ProtectionDocument8 pagesRelay Barriers: Intrinsically Safe Explosion ProtectionMuhamad PriyatnaNo ratings yet

- Power Supplies: Smart ProductsDocument6 pagesPower Supplies: Smart ProductsMuhamad PriyatnaNo ratings yet

- PS5R-SB Switching Power Supplies Compact SizeDocument2 pagesPS5R-SB Switching Power Supplies Compact SizeMuhamad PriyatnaNo ratings yet

- EP1116-0 ControlUnits Relays 060217Document404 pagesEP1116-0 ControlUnits Relays 060217Muhamad PriyatnaNo ratings yet

- AS-Interface Devices: (Slave Modules)Document48 pagesAS-Interface Devices: (Slave Modules)Muhamad PriyatnaNo ratings yet

- 30 MM XN Series Emergency Stop SwitchesDocument12 pages30 MM XN Series Emergency Stop SwitchesMuhamad PriyatnaNo ratings yet

- Eb3C Eb3L: Relay Barriers Lamp BarriersDocument20 pagesEb3C Eb3L: Relay Barriers Lamp BarriersMuhamad PriyatnaNo ratings yet

- ø16mm and ø22mm Emergency Stop Switches - Compact Size, Safe Break ActionDocument20 pagesø16mm and ø22mm Emergency Stop Switches - Compact Size, Safe Break ActionMuhamad PriyatnaNo ratings yet

- Power Supplies BrochureDocument12 pagesPower Supplies BrochureMuhamad PriyatnaNo ratings yet

- 16 MM XA Series & 22 MM XW Series SEMI S2 Compliant EMO SwitDocument8 pages16 MM XA Series & 22 MM XW Series SEMI S2 Compliant EMO SwitMuhamad PriyatnaNo ratings yet

- Series: 611G 611V 611GE 611VE: Installation DrawingDocument1 pageSeries: 611G 611V 611GE 611VE: Installation DrawingMuhamad PriyatnaNo ratings yet

- Stacklights 46-1: February 2007Document12 pagesStacklights 46-1: February 2007Muhamad PriyatnaNo ratings yet

- 16 MM XA Series Emergency Stop Switches (Illuminated Type)Document4 pages16 MM XA Series Emergency Stop Switches (Illuminated Type)Muhamad PriyatnaNo ratings yet

- 8F Drains and Breathers: Application: ECD Type 4X''Document1 page8F Drains and Breathers: Application: ECD Type 4X''Muhamad PriyatnaNo ratings yet

- 8F Drains and Breathers: Application: ECD Type 4X''Document1 page8F Drains and Breathers: Application: ECD Type 4X''Muhamad PriyatnaNo ratings yet

- 16 MM XA Series & 22 MM HW, XW Series SEMI S2 Compliant EMODocument4 pages16 MM XA Series & 22 MM HW, XW Series SEMI S2 Compliant EMOMuhamad PriyatnaNo ratings yet

- Operator Interface ProductsDocument38 pagesOperator Interface ProductsMuhamad PriyatnaNo ratings yet

- PLC, IO & Communications ProductsDocument46 pagesPLC, IO & Communications ProductsMuhamad PriyatnaNo ratings yet

- Photoelectric, Inductive & Capacitive SensorsDocument14 pagesPhotoelectric, Inductive & Capacitive SensorsMuhamad PriyatnaNo ratings yet

- Motor Control CentersDocument20 pagesMotor Control CentersMuhamad PriyatnaNo ratings yet

- Vacuum Contactors & StartersDocument32 pagesVacuum Contactors & StartersMuhamad PriyatnaNo ratings yet

- 1 Residual Current Circuit Breaker (RCCB) (ELCB)Document6 pages1 Residual Current Circuit Breaker (RCCB) (ELCB)Anirudh VN100% (1)

- NEMA Manual StartersDocument12 pagesNEMA Manual StartersMuhamad PriyatnaNo ratings yet

- Cutler-Hammer: Standards Global Third Party CertificationDocument45 pagesCutler-Hammer: Standards Global Third Party Certificationmenendez2050100% (1)

- Medium Voltage Motor Control AssembliesDocument4 pagesMedium Voltage Motor Control AssembliesMuhamad PriyatnaNo ratings yet

- Chalwyn CE111Document20 pagesChalwyn CE111venks2kNo ratings yet

- PVT Behavior of Fluids: Dr. M. SubramanianDocument58 pagesPVT Behavior of Fluids: Dr. M. SubramanianRama GaurNo ratings yet

- Crown Saver Test Report GuidelinesDocument4 pagesCrown Saver Test Report GuidelinesAmirNo ratings yet

- Maythuykhi Tracnghiem CodapanDocument18 pagesMaythuykhi Tracnghiem CodapanLuan BuiNo ratings yet

- Steam Turbine Condenser: How it Works and TypesDocument33 pagesSteam Turbine Condenser: How it Works and TypesSatyam KumarNo ratings yet

- Practical Machinery Vibration Analysis and Predictive MaintenanceDocument3 pagesPractical Machinery Vibration Analysis and Predictive MaintenanceSafrul EfendiNo ratings yet

- Bab II Wa600Document17 pagesBab II Wa600abrisal03No ratings yet

- Bridge AerodynamicsDocument25 pagesBridge AerodynamicsJoseAngelFernandezOrtegaNo ratings yet

- सचू ना 2012 में EMDEC प्रणाली पर सूचनाDocument140 pagesसचू ना 2012 में EMDEC प्रणाली पर सूचनाHanuma Reddy100% (1)

- Performance Data: Curve 14.00 1BB065, 2BB065Document2 pagesPerformance Data: Curve 14.00 1BB065, 2BB065texwan_No ratings yet

- Module 3 Part 2 Shear Design in BeamsDocument7 pagesModule 3 Part 2 Shear Design in BeamsMichelle DangcalanNo ratings yet

- Calculate total pipe lengthDocument6 pagesCalculate total pipe lengthImtinan MohsinNo ratings yet

- Simulation and CFD Analysis of Various Combustion Chamber Geometry of A C.I Engine Using CFXDocument8 pagesSimulation and CFD Analysis of Various Combustion Chamber Geometry of A C.I Engine Using CFXZineddine AlicheNo ratings yet

- Control Valve Dx28 Solar III 20287132gDocument58 pagesControl Valve Dx28 Solar III 20287132gAlejandro Mayr100% (1)

- ET Diesel Locomotives DHD30 - tcm1106-2974304Document3 pagesET Diesel Locomotives DHD30 - tcm1106-2974304vivo por rossyNo ratings yet

- MEBS6006 Environmental Services I Psychrometric AnalysisDocument52 pagesMEBS6006 Environmental Services I Psychrometric Analysisahtin618100% (2)

- Wind Turbines Foundations1Document22 pagesWind Turbines Foundations1CristiNo ratings yet

- Crawler Tractor Delivers Powerful Performance and Low Operating CostsDocument24 pagesCrawler Tractor Delivers Powerful Performance and Low Operating CostsCristianoNo ratings yet

- Model ICB 100-800 HP Boilers: Table A4-9. Model ICB Steam Boiler Dimensions, 4-Pass and 3-PassDocument4 pagesModel ICB 100-800 HP Boilers: Table A4-9. Model ICB Steam Boiler Dimensions, 4-Pass and 3-PasssebaversaNo ratings yet

- John Ochoa: Atwater High School - WelderDocument1 pageJohn Ochoa: Atwater High School - Welderapi-458020956No ratings yet

- Hitachi Water Pump CatalogueDocument6 pagesHitachi Water Pump CatalogueRicky al ikhsaniNo ratings yet

- Diagnostic Test 819Document3 pagesDiagnostic Test 819Yhel Del Rosario BernardoNo ratings yet

- Parabolic Leaf Spring OptimizationDocument8 pagesParabolic Leaf Spring OptimizationRajaSekarsajjaNo ratings yet

- SOLTEQ Bench Cooling Tower TestDocument13 pagesSOLTEQ Bench Cooling Tower TestAlohaaSwezzNo ratings yet

- Mechanics of Materials SyllabusDocument3 pagesMechanics of Materials SyllabusgundulpNo ratings yet

- Economizer welding mapDocument22 pagesEconomizer welding mapMuhammad Fitransyah Syamsuar Putra100% (2)

- Open steam distillation column designDocument12 pagesOpen steam distillation column designTle SupawidNo ratings yet