Professional Documents

Culture Documents

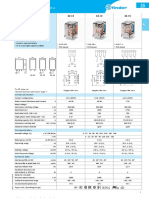

Model Number Structure: Enclosed Switch

Uploaded by

Muhamad PriyatnaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Model Number Structure: Enclosed Switch

Uploaded by

Muhamad PriyatnaCopyright:

Available Formats

Enclosed Switch

ZC-@55

Small, High-precision Enclosed Switch

• Employs a modified version of Z Basic Switch as built-in switch.

• Same mounting pitch as Z Basic Switch.

• Pre-wired molded terminal models are available.

• Requires less operating force than conventional limit switches.

• Long life expectancy and economical.

• Approved by EN, UL, CSA, and CCC (Chinese standard).

Model Number Structure

■ Model Number Legend

ZC-@55

1

1. Actuator

D: Plunger W: Short hinge lever

Q: Panel mount plunger W1: Hinge lever

Q22: Panel mount roller plunger W2: Short hinge roller lever

Q21: Panel mount crossroller plunger W21: Hinge roller lever

N22: Sealed roller plunger W3: One-way action short hinge roller lever

N21: Sealed crossroller plunger W31: One-way action hinge roller lever

Ordering Information

■ List of Models

Actuator Model Actuator Model

Plunger ZC-D55 Short hinge ZC-W55

lever

Panel mount ZC-Q55 Hinge lever ZC-W155

plunger

Panel mount ZC-Q2255 Short hinge ZC-W255

roller plunger roller lever

Panel mount ZC-Q2155 Hinge roller ZC-W2155

crossroller plunger lever

Sealed roller ZC-N2255 One-way action ZC-W355

plunger short hinge roller

lever

Sealed crossroller ZC-N2155 One-way action ZC-W3155

plunger hinge roller lever

Note: Use molded terminal models (refer to page 125) when using the Switch under one of the following conditions:

a) dusty, b) high amount of dripping oil, or c) high humidity.

Models are available with lead outlets in three positions: right-hand, left-hand, and underside.

Enclosed Switch ZC-@55 117

Terminal Protective Cover, Seal Rubber, and Rubber Packing

(The Switch is equipped with these 3 items as a standard.)

• ZC Terminal Cover

(Product code: ZC55-0002H)

Rubber packing

• ZC Seal Rubber

(Product code: SC-1404C)

• ZC Rubber Packing

(Product code: ZC55-0003F)

Terminal cover Seal rubber

Specifications

■ Approved Standards

(Except Molded Terminal Models and Operation Indicator-equipped Model)

Agency Standard File No.

UL UL508 E76675

CSA C22.2, No. 14 LR45258

TÜV Rheinland EN60947-1, EN60947-5-1 J9650089

CCC (CQC) GB14048.5 2003010303077620

Note: Ask your OMRON representative for information on approved models.

■ Approved Standard Ratings

UL/CSA

A300

Voltage Carry current Current Volt-amperes

Make Break Make Break

120 VAC 10 A 60 A 6A 7,200 VA 720 VA

240 VAC 30 A 3A

Microloads 0.1 A 125 VAC

0.1 A 30 VDC

TÜV Rheinland (EN60947-1, EN60947-5-1), CCC (GB14048.5)

Applicable category and ratings

AC-12 10 A/250 VAC

■ General Ratings

Rated voltage Non-inductive load Inductive load

Resistive load Lamp load Inductive load Motor load

NC NO NC NO NC NO NC NO

125 VAC 10 A 3A 1.5 A 10 A 5A 2.5 A

250 VAC 10 A 2.5 A 1.25 A 10 A 3A 1.5 A

8 VDC 10 A 3A 1.5 A 6A 5A 2.5 A

14 VDC 10 A 3A 1.5 A 6A 5A 2.5 A

30 VDC 6A 3A 1.5 A 5A 5A 2.5 A

125 VDC 0.5 A 0.4 A 0.4 A 0.05 A 0.05 A 0.05 A

250 VDC 0.25 A 0.2 A 0.2 A 0.03 A 0.03 A 0.03 A

Inrush current NC 30 A max.

NO 15 A max.

Note: 1. The above figures are for steady-state currents.

2. Inductive loads have a power factor of 0.4 min. (AC) and a time constant of 7 ms max. (DC).

3. Lamp load has an inrush current of 10 times the steady-state current.

4. Motor load has an inrush current of 6 times the steady-state current.

5. The above ratings were tested under the following conditions according.

Ambient temperature:20±2°C

Ambient humidity: 65±5%

Operating frequency: 20 operations/min

118 Enclosed Switch ZC-@55

■ Characteristics

Degree of protections IP67

Durability Mechanical: 10,000,000 operations min.

Electrical: 500,000 operations min.

Operating speed 0.05 mm to 0.5 m/s (at pin plunger)

Operating frequency Mechanical: 120 operations/min

Electrical: 20 operations/min

Insulation resistance 100 MΩ min. (at 500 VDC)

Contact resistance 15 mΩ max. (initial value)

Dielectric strength 1,000 VAC, 50/60 Hz for 1 min between non-continuous terminals

2,000 VAC, 50/60 Hz for 1 min between current-carrying metal part and ground, and between each terminal

and non-current-carrying metal parts

Rated insulation voltage (Ui) 1,000 VAC

Pollution degree 3 (IEC947-5-1)

(operating environment)

Short-circuit protective device 10 A-fuse type gG (IEC 269)

Protection against electric Class II

shock

PT1 (tracking characteristics) 175

Switch category D (IEC335)

Rated operating current (Ie) 10 A

Rated operating voltage (Ue) 250 VAC

Vibration resistance Malfunction: 10 to 55 Hz, 1.5-mm double amplitude (see note)

Shock resistance Destruction: 1,000 m/s2 max.

Malfunction: 300 m/s2 max. (at pin plunger) (see note)

Ambient temperature Operating: –10°C to 80°C (with no icing)

Ambient humidity Operating: 35% to 95%

Weight Approx. 92 g (in case of ZC-Q22(21)55)

Note: Less than 1 ms under a free state at the operating limits.

Connections

■ Contact Form

(COM) 1 2 (NC)

4 (NO)

Enclosed Switch ZC-@55 119

■ Operation Indicator-equipped Models (Not Approved by UL, CSA, or EN)

All the models can be equipped upon request with a operation indicator to facilitate maintenance and inspection.

Because the indicator is incorporated in the Terminal Protective Cover, the dimensions of the Limit Switch are not affected. In this model, the lead

wire is to be connected to the screw terminal. (A connecting washer is provided on the tip of the lead wire).

The lead wire can be connected to either the NC or NO terminal.

Operating characteristics are the same as the standard model from which the operation indicator equipped model is fabricated.

AC Operation DC Operation

The operating voltage range is from 90 to 250 VAC. The DC-operated is provided with an LED indicator.

The dimensions are the same as the standard type. The top of the There is no protective structure.

Terminal Protective Cover is transparent to allow checking the opera-

tion easily. Since a rectifier stack is incorporated into the unit to permit reversing

the polarity, this type can also operate on AC power source.

When placing your order for the indicator equipped, AC-operated

model, add suffix “L” to the end of the model number. The LED projects from the housing for easy visibility.

Example: When placing your order, add suffix “L2” or “L4” to the model number

Standard type: ZC-Q2255 of the standard type.

Indicator equipped type: ZC-Q2255-L

Example:

Standard type: ZC-Q2255

Indicator equipped type: ZC-Q2255-L2

Neon lamp position

Terminal Protective Cover (transparent)

Contact Circuit LED

NC terminal Type Voltage rating Leakage current Internal

Power supply

Neon lamp

resistance

R = 240 kΩ

L2 12 V Approx. 2.4 mA 4.3 kΩ

L4 24 V Approx. 1.2 mA 18 kΩ

Load

Contact Circuit

Built-in switch NC terminal

Power supply

NO terminal LED

Resistance

Power supply

Built-in switch

Load

Load

Load

Built-in switch

R = 240 kΩ NO terminal

Neon lamp Power supply

Built-in switch

Note: If the wiring is as shown above, the operation of the respective

parts will be as shown in the following table. The neon lamp is

Load

not wired when the Switch is delivered. Connect it as required.

Contact Neon lamp Load Actuator Resistance

NC ON Does not operate Operates LED

OFF Operates Does not operate

NO ON Does not operate Does not operate

Note: If the wiring is as shown above, the operation of the respective

OFF Operates Operates parts will be as shown in the following table. The LED terminals

are not wired when the Switch is delivered. Connect it as re-

quired.

Contact LED Load Actuator

NC ON Does not operate Operates

OFF Operates Does not operate

NO ON Does not operate Does not operate

OFF Operates Operates

120 Enclosed Switch ZC-@55

Nomenclature

Changing the Terminal Protective Cover around allows the cable to be pulled out from either the right or the left.

Roller

Plunger

Case

NC fixed contact

Moving contact

Switch

NO fixed contact

Packing Seal rubber

Terminal

Protective

Cover Common Normally

terminal Normally closed

(COM) open terminal

terminal (NC)

(NO)

Note: M4 binding head screws (with toothed washers) are used as the terminal screws.

Engineering Data

■ Mechanical Durability ■ Electrical Durability

(for ZC-Q55)

Operating temperature: 20±2°C

Operating humidity: 65±5%

No load

Operating frequency: 120 operations/min 125 VAC cosφ=1

Durability (x 104 operations)

Durability (x 104 operations)

125 VAC cosφ=0.4

250 VAC cosφ=1

250 VAC cosφ=0.4

Operating temperature: 20±2°C

Operating humidity: 65±5%

Operating frequency: 20 operations/min

OT (mm) Switching current (A)

Enclosed Switch ZC-@55 121

Dimensions

Note: 1. All units are in millimeters unless otherwise indicated.

2. Unless otherwise specified, a tolerance of ±0.4 mm applies to all dimensions.

Plunger Model ZC-D55

14 dia

ZC-D55 OF max. 11.8 N

7.8 dia. RF max. 4.90 N

(see note)

PT max. 1.5 mm

OT min. 2.4 mm

MD max. 0.2 mm

22 max.

OP 32.4±0.8 mm

15 (21 × 21) Note: Stainless steel plunger

Terminal Two, 4.3±0.1 dia. Seal rubber (NBR)

Protective mounting holes

Cover

Panel Mount Plunger 7.8 dia. Model ZC-Q55

ZC-Q55 (see note 1) OF max. 11.8 N

M14 × 1 mounting screw

RF max. 4.90 N

(See Two hexagon nuts

note 2) (thickness: 3 PT max. 1.5 mm

width: 17)

OT min. 3 mm

MD max. 0.2 mm

Note: 1. Stainless steel plunger OP 38.2±0.8 mm

22 max. 2. The length of the imperfect threads

is 1.5 mm maximum.

(15) (21 × 21) 3. Do not use the M14 mounting

screw and the case mounting hole

Terminal Two, 4.3±0.1 dia. Seal rubber (NBR) at the same time.

Protective mounting holes

Cover

Panel Mount Roller Plunger Model ZC-Q2255

ZC-Q2255 11 dia. × 4.7 OF max. 11.8 N

(see note 1)

Set position RF max. 4.90 N

indication line

Two hexagon nuts

PT max. 1.5 mm

(thickness: 3 OT min. 3 mm

(See width: 17)

note 2) M14 × 1 mounting MD max. 0.2 mm

screw

OP 47.4±0.8 mm

22 max.

Note: 1. Stainless sintered alloy roller

2. The length of the imperfect

15 (21 × 21) threads is 1.5 mm maximum.

3. Do not use the M14 mounting

Terminal Two, 4.3±0.1 dia. Seal rubber (NBR)

Protective screw and the case mounting

mounting holes hole at the same time.

Cover

Panel Mount Crossroller Plunger Model ZC-Q2155

ZC-Q2155 Set position 11 dia. × 4.7 OF max. 11.8 N

indication (see note 1)

line RF max. 4.90 N

M14 × 1 mounting

screw PT max. 1.5 mm

Two hexagon nuts

(thickness: 3 OT min. 3 mm

width: 17) MD max. 0.2 mm

Note: 1. Stainless sintered alloy roller

OP 47.4±0.8 mm

2. The length of the imperfect

threads is 1.5 mm maximum.

22 max. 3. Do not use the M14 mounting

screw and the case mounting

15 (21 × 21) hole at the same time.

Terminal Two, 4.3±0.1 dia. Seal rubber (NBR)

Protective mounting holes

Cover

122 Enclosed Switch ZC-@55

Sealed Roller Plunger Model ZC-N2255

9.5 dia. × 4.7

ZC-N2255 (see note) OF max. 6.86 N

Rubber boot RF max. 1.67 N

(chloroprene PT max. 1.5 mm

rubber)

OT min. 2.5 mm

MD max. 0.2 mm

OP 47.4±0.8 mm

22 max. Note: Stainless sintered alloy roller

15 (21 × 21)

Terminal Two, 4.3±0.1 dia. Seal rubber (NBR)

Protective mounting holes

Cover

Sealed Crossroller Plunger 9.5 dia. × 4.7

Model ZC-N2155

ZC-N2155 Rubber boot

(see note) OF max. 6.86 N

(chloroprene RF max. 1.67 N

rubber)

PT max. 1.5 mm

OT min. 2.5 mm

MD max. 0.2 mm

OP 47.4±0.8 mm

22 max.

15 (21 × 21) Note: Stainless sintered alloy roller

Seal rubber (NBR)

Terminal Two, 4.3±0.1 dia.

Protective mounting holes

Cover

Short Hinge Roller Lever Model ZC-W55

ZC-W55 t=1 OF max. 3.92 N

34.6

(see note) RF max. 0.78 N

50R

PT max. 6 mm

OT min. 1 mm

MD max. 28.5±1.2 mm

5 OP 34.7 mm

22 max.

15 (21 × 21) Note: Stainless steel lever

Terminal Two, 4.3±0.1 dia. Seal rubber (NBR)

Protective mounting holes

Cover

Hinge Lever Model ZC-W155

ZC-W155 t=1 34.6 OF max. 2.75 N

(see note)

70R RF max. 0.59 N

PT max. 8.4 mm

OT min. 1.4 mm

MD max. 28.5±1.2 mm

OP 36.7 mm

22 max.

Note: Stainless steel lever

15 (21 × 21)

Terminal Two, 4.3±0.1 dia.

Protective Seal rubber (NBR)

mounting holes

Cover

Enclosed Switch ZC-@55 123

Short Hinge Roller Lever Model ZC-W255

ZC-W255 12.7 dia. × 7.5 OF max. 3.92 N

34.6 (see note 2)

t=1 RF max. 0.78 N

(see note1)

50R PT max. 6 mm

OT min. 1 mm

MD max. 43±1.2 mm

OP 49.2 mm

Note: 1. Stainless steel lever

22 max. 2. Stainless steel roller

15 (21 × 21)

Terminal Seal rubber (NBR)

Two, 4.3±0.1 dia.

Protective

mounting holes

Cover

Hinge Roller Lever 12.7 dia. × 7.5

Model ZC-W2155

ZC-W2155 (see note 2) OF max. 2.75 N

34.6

t=1

(see note1) RF max. 0.59 N

70R

PT max. 8.4 mm

OT min. 1.4 mm

MD max. 43±1.2 mm

OP 51.3 mm

22 max.

Note: 1. Stainless steel lever

15 (21 × 21) 2. Stainless steel roller

Terminal Seal rubber (NBR)

Protective Two, 4.3±0.1 dia.

Cover mounting holes

One-way Action Short Hinge Roller Lever Model ZC-W355

ZC-W355 Operating OF max. 3.92 N

direction RF max. 0.78 N

12.7 dia. × 7.5 PT max. 6 mm

34.6

Angle of (see note 2)

roller OT min. 1 mm

swing:

t=1 90° 54R MD max. 53±1.2 mm

(see note1)

OP 59.2 mm

22 max. Note: 1. Stainless steel lever

2. Stainless steel roller

15 (21 × 21)

Terminal Two, 4.3±0.1 Seal rubber (NBR)

Protective dia. holes

Cover

One-way Action Hinge Roller Lever Model ZC-W3155

Operating

ZC-W3155 direction OF max. 2.75 N

12.7 dia. × 7.5 RF max. 0.59 N

34.6 (see note 2)

PT max. 8.4 mm

t=1 Angle of OT min. 1.4 mm

(see note1) 73R roller

swing:

90° MD max. 53±1.2 mm

OP 61.2 mm

22 max.

Note: 1. Stainless steel lever

15 (21 × 21) 2. Stainless steel roller

Terminal Two, 4.3±0.1 dia. Seal rubber (NBR)

Protective mounting holes

Cover

124 Enclosed Switch ZC-@55

Molded Terminal Models

■ Molded Terminal Model Note: When placing your order for the Switch, specify the required

length of V.C.T. cable in addition to the model number of the

Switch.

The molded-terminal model is available with right-hand, left-hand

and underside leads and is recommended for use where the Switch Example:

is exposed to dust, oil or moisture. Standard type: ZC-Q2255

Location of lead output: Right side

The molded-terminal model is not approved by UL, CSA, or EN.

Length of lead: 1 m (V.C.T. lead)

When placing your order for the above Switch, specify the model

number as ZC-Q2255-MR VCT 1M.

ML MR

MD

Suffix by Location of Lead Outlet

Location of lead output Model

COM, NC and NO

Right-hand ZC-@-MR

Left-hand ZC-@-ML

Underside ZC-@-MD

Lead Supplies

Leads Nominal Finished outside Terminal connections Standard length

cross-sectional area diameter

V.C.T. (vinyl cabtire cable) 1.25 mm 2 3 core: 10.5 dia. Black: COM 1, 3 m

White: NO

Red: NC

Enclosed Switch ZC-@55 125

Precautions

Refer to the “Precautions for General-purpose Limit Switches (Including Multiple Limit Switches, Mechanical Touch Switches, High-precision

Switches, Touch Switches, On-site Flexible Switches; Not Including Safety Switches)” on page 17.

■ Correct Use Incorrect Correct

Operating Environment

• Seal material may deteriorate if a Switch is used outdoor or where

subject to special cutting oils, solvents, or chemicals. Always

appraise performance under actual application conditions and set

suitable maintenance and replacement periods.

Rubber packing Rubber packing

• Install Switches where they will not be directly subject to cutting

chips, dust, or dirt. The Actuator and Switch must also be protected • A 8.5- to 10.5-dia. cable can be applied as seal rubber for the lead

from the accumulation of cutting chips or sludge. wire outlet. (Use two- or three-core cable of VCT1.25 mm2.)

• Use weather-proof rubber (chloroprene rubber) as seal rubber for

Not Suitable Suitable the ZC-N22(21)55.

Microload Models

Contact failure may occur is a General-purpose Switch is used to

switch a microload circuit. Use Switches within the areas shown in

• Constantly subjecting a Switch to vibration or shock can result in the following chart. Even when using Microload Switches within the

wear, which can lead to contact interference with contacts, opera- area shown below, contact wear will become more extreme with

tion failure, reduced durability, and other problems. Excessive loads that generate surge current when switching and durability will

vibration or shock can lead to false contact operation or damage. be adversely affected. If necessary, insert a contact protective circuit.

Install Switches in locations not subject to shock and vibration and Microloads are indicated by N standard reference values. This value

in orientations that will not produce resonance. represents the failure rate at a 60% (λ60) reliability level. (JIS C5003)

• The Switches have physical contacts. Using them in environments The equation λ60 = 0.5 x 10-6/operations indicates that a failure rate

containing silicon gas will result in the formation of silicon oxide of 1/2,000,000 operations can be expected at a reliability level of

(SiO2) due to arc energy. If silicon oxide accumulates on the con- 60%.

tacts, contact interference can occur. If silicon oil, silicon filling

agents, silicon cables, or other silicon products are present near 0.8 W

DC voltage (V)

the Switch, suppress arcing with contact protective circuits (surge

26 mA 100 mA

killers) or remove the source of silicon gas. 30

Dog Angle 24

When operating the roller type, be sure to set the dog angle to less

Applicable

than 30° (even when operating at a low speed). Operating the model Applicable area area

at a dog angle exceeding 30° will soon cause abrasion or damage. for Microload

Models

for General-

purpose

Do not apply a twisting force to the plunger. Set the OT to 70% to (ZC-@55-01) Models

100% of the specified value so that the actuator will not exceed the 12

(ZC-@55)

OT. Not

applicable

Handling 5

1 mA 100 mA 160 mA

When detaching the Terminal Protective Cover, insert a screwdriver 0

and apply a force in the opening direction. Do not use excess force to 0.1 1 10 100 1,000

remove the cover. Doing so may cause deformation in the fitting sec- Current (mA)

tion and reduce the holding force.

Model ZC-@55-01 ZC-@55

Minimum applicable load 5 VDC 1 mA 5 VDC 160 mA

Screwdriver

Mounting

• When mounting the Switch with screws on a side surface, fasten

the Switch with M4 screws and use washers, spring washers, etc.,

to ensure secure mounting.

Mounting Holes

Terminal Protective Cover

Two, 4.3-dia. or M4 screw holes

When mounting the Terminal Protective Cover to the case, align the

cover on the case and then press the cover down to mount it firmly. If

the cover is pressed down in an inclined position, rubber packing will

deform and thus affect the sealing capability. • When mounting the Panel Mount-type Enclosed Switch (ZC-Q55,

ZC-Q2255, or ZC-Q2155) with screws on a side surface, remove

the hexagonal nuts from the actuator.

126 Enclosed Switch ZC-@55

Mounting Hole Dimensions

14.5+0.2

0 dia.

Tightening Torque

A loose screw may result in a malfunction. Be sure to tighten each

screw to the proper tightening torque as shown below.

No. Type Torque

1 Terminal screw 0.78 to 1.18 N·m

2 Panel mounting screw 4.90 to 7.84 N·m

3 Side mounting screw 1.18 to 1.47 N·m

Operation

With the ZC-Q22(21)55, an appropriate OT line is marked on the

plunger. Set the OT so that it is between the two X-surface lines.

Appropriate OT line

X-surface

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. C025-E1-11 In the interest of product improvement, specifications are subject to change without notice.

Enclosed Switch ZC-@55 127

You might also like

- Integral As1000Document365 pagesIntegral As10000501196605285100% (3)

- Smart SYS S2301500R48 - DatesheetDocument2 pagesSmart SYS S2301500R48 - DatesheetWill F Alves0% (1)

- V3435CI - CI Programming and Front Cover Manual PDFDocument28 pagesV3435CI - CI Programming and Front Cover Manual PDFSergeiNo ratings yet

- PS48300-1800 Power Supply System User ManualDocument61 pagesPS48300-1800 Power Supply System User ManualSamuelNo ratings yet

- Model Number Structure: Enclosed SwitchDocument9 pagesModel Number Structure: Enclosed SwitchMuhamad PriyatnaNo ratings yet

- Model Number Structure: Enclosed SwitchDocument10 pagesModel Number Structure: Enclosed SwitchMuhamad PriyatnaNo ratings yet

- High-Capacity Switch Capable of Handling 20 A Loads With Large Inrush CurrentsDocument6 pagesHigh-Capacity Switch Capable of Handling 20 A Loads With Large Inrush CurrentsMuhammad Purbo SantosoNo ratings yet

- ZE, ZV, XE, XV EnclosedDocument12 pagesZE, ZV, XE, XV EnclosedMuhamad PriyatnaNo ratings yet

- General-Purpose Basic Switch XDocument8 pagesGeneral-Purpose Basic Switch XMuhamad PriyatnaNo ratings yet

- Sealed Miniature Basic Switch D2VWDocument6 pagesSealed Miniature Basic Switch D2VWMuhamad PriyatnaNo ratings yet

- b060 DZ Special-Purpose Basic Switch Datasheet enDocument6 pagesb060 DZ Special-Purpose Basic Switch Datasheet enKlan ZangoNo ratings yet

- High-capacity Switch Handles Large Inrush CurrentsDocument7 pagesHigh-capacity Switch Handles Large Inrush CurrentsMuhamad PriyatnaNo ratings yet

- General purpose relays for automation controlDocument18 pagesGeneral purpose relays for automation controlValerija SilinaNo ratings yet

- General Purpose Relays for Automation and ControlDocument18 pagesGeneral Purpose Relays for Automation and ControlMarcelino MoralesNo ratings yet

- Relay Finder 55 SeriesDocument18 pagesRelay Finder 55 SeriesBerlianiNo ratings yet

- 14pin Relay and BaseDocument16 pages14pin Relay and BaseNaveed AhmadNo ratings yet

- DZ-10G Basic Switch Controls Two Independent CircuitsDocument5 pagesDZ-10G Basic Switch Controls Two Independent CircuitsMuhamad PriyatnaNo ratings yet

- Finder-Industrialrelayseries5532 20160412120109Document16 pagesFinder-Industrialrelayseries5532 20160412120109pouya alizadehNo ratings yet

- Dra 051018Document5 pagesDra 051018MaximilianoAlvarezNo ratings yet

- Economical Miniature Limit Switch HL-5000 Boasting Rigid ConstructionDocument9 pagesEconomical Miniature Limit Switch HL-5000 Boasting Rigid ConstructionHlaing MyintNo ratings yet

- Miniature Basic Switch Provides Long Life of 2 Million OperationsDocument5 pagesMiniature Basic Switch Provides Long Life of 2 Million OperationsMuhamad PriyatnaNo ratings yet

- Osti Ia G Interlocks Hinge Pin v032113Document13 pagesOsti Ia G Interlocks Hinge Pin v032113EvaldoGualbertoNo ratings yet

- V3435CI - CI Programming ManualDocument28 pagesV3435CI - CI Programming ManualHerman StornebrinkNo ratings yet

- STNC Válvula Uwk e TeDocument1 pageSTNC Válvula Uwk e TeCOMPRESORES Y SOLUCIONES INDUSTRIALESNo ratings yet

- Din Time Delay RelaysDocument8 pagesDin Time Delay RelaysMohammad HosseinNo ratings yet

- Rele FinderDocument14 pagesRele FinderJosé marinNo ratings yet

- AE Bolted CB EnclosuresDocument6 pagesAE Bolted CB EnclosuresMuhamad PriyatnaNo ratings yet

- D4CC Miniature Limit SwitchDocument11 pagesD4CC Miniature Limit SwitchMuhamad PriyatnaNo ratings yet

- Miniature Basic Switch D2MVDocument7 pagesMiniature Basic Switch D2MVMuhamad PriyatnaNo ratings yet

- Ultra Subminiature Basic Switch JDocument6 pagesUltra Subminiature Basic Switch JMuhamad PriyatnaNo ratings yet

- Каталог Klr Переключатели EngDocument38 pagesКаталог Klr Переключатели Engkormakov1996No ratings yet

- Ca5x 10Document4 pagesCa5x 10Meezan BatchaNo ratings yet

- Evaluation and Finding of Isolated Flyback Converter: © 2016 ROHM Co.,LtdDocument29 pagesEvaluation and Finding of Isolated Flyback Converter: © 2016 ROHM Co.,LtdNhatNo ratings yet

- 1SBN010010R1010 Ca5 10Document5 pages1SBN010010R1010 Ca5 10Meezan BatchaNo ratings yet

- Features: 55 Series - General Purpose Relays 7 - 10 ADocument14 pagesFeatures: 55 Series - General Purpose Relays 7 - 10 AveeakumarNo ratings yet

- Model Number Structure: Enclosed SwitchDocument22 pagesModel Number Structure: Enclosed SwitchkoshkeNo ratings yet

- TA80DU-52 Thermal Overload RelayDocument4 pagesTA80DU-52 Thermal Overload RelayPower SolutionNo ratings yet

- v15 1 PDFDocument13 pagesv15 1 PDFHardik PanchalNo ratings yet

- D4NL 1189512 PDFDocument11 pagesD4NL 1189512 PDFLucas CardosoNo ratings yet

- Omron Gate Switch D4NL Catalog & WiringDocument10 pagesOmron Gate Switch D4NL Catalog & WiringDan SomervilleNo ratings yet

- HG-Series GuideDocument14 pagesHG-Series GuidesundewsNo ratings yet

- Model Number Structure: Enclosed SwitchDocument21 pagesModel Number Structure: Enclosed SwitchMuhamad PriyatnaNo ratings yet

- JVC kw-v820bt, kw-v820btm Exploded View Parts ListDocument41 pagesJVC kw-v820bt, kw-v820btm Exploded View Parts Listsamasca_serbanNo ratings yet

- High Efficiency 2ch LED Driver IC for LED Backlight - BL0200 SeriesDocument26 pagesHigh Efficiency 2ch LED Driver IC for LED Backlight - BL0200 SeriespopeyeNo ratings yet

- Miniature Basic Switch VXDocument7 pagesMiniature Basic Switch VXMuhamad PriyatnaNo ratings yet

- Emax-Air Circuit Breakers: E3 3200A Fixed and DrawoutDocument2 pagesEmax-Air Circuit Breakers: E3 3200A Fixed and DrawoutAishNo ratings yet

- Aq-G Relays: Features Typical ApplicationsDocument5 pagesAq-G Relays: Features Typical ApplicationsEduardoPassosNo ratings yet

- Crouzet Miniature V3D 8326Document10 pagesCrouzet Miniature V3D 8326wg0532No ratings yet

- ncv8518 - Regulador Voltaje Chevrolet Sonic BCMDocument12 pagesncv8518 - Regulador Voltaje Chevrolet Sonic BCMChristiam OrtegaNo ratings yet

- SI22 Solar Pump Inverter Manual: Setup, Operation and Troubleshooting GuideDocument6 pagesSI22 Solar Pump Inverter Manual: Setup, Operation and Troubleshooting GuideAldo Santiago VarasNo ratings yet

- AC/DC 225/125: Processes DescriptionDocument2 pagesAC/DC 225/125: Processes DescriptionHENRY MORALESNo ratings yet

- Detailed Characteristics For Each FunctionDocument1 pageDetailed Characteristics For Each FunctionRana Umar FarooqNo ratings yet

- MIP521A Application Note - Ver.2-5Document16 pagesMIP521A Application Note - Ver.2-5draNo ratings yet

- XGN15 Ring Main Unit User's ManualDocument21 pagesXGN15 Ring Main Unit User's ManualFrancisco VeraNo ratings yet

- 45W Ac-Dc Adapter With Standby Function: AN1134 Application NoteDocument9 pages45W Ac-Dc Adapter With Standby Function: AN1134 Application NoteGrzegorz WegnerNo ratings yet

- LED Drivers For LightingDocument20 pagesLED Drivers For LightingOmar BozziniNo ratings yet

- Addition of Lightning Surge ProtectorsDocument6 pagesAddition of Lightning Surge ProtectorsCarlos OrtegaNo ratings yet

- Annex Getting Started With ATV312: Short-Circuit Current Ratings (SCCR) and Branch Circuit ProtectionDocument4 pagesAnnex Getting Started With ATV312: Short-Circuit Current Ratings (SCCR) and Branch Circuit ProtectionTommy KhNo ratings yet

- Contactor Catalogue: According To CE, IEC 947, EN 60947Document20 pagesContactor Catalogue: According To CE, IEC 947, EN 60947Johanes Nugroho Adhi PrakosaNo ratings yet

- InertiaDynamics Controls SpecsheetDocument13 pagesInertiaDynamics Controls SpecsheetElectromateNo ratings yet

- Unisonic Technologies Co., LTD: Dual Equalizer Amplifier With AlcDocument6 pagesUnisonic Technologies Co., LTD: Dual Equalizer Amplifier With AlcDhanapal KuppusamyNo ratings yet

- Balanced Mains Filter SchematicDocument2 pagesBalanced Mains Filter SchematickosarobNo ratings yet

- Industrial Automation Catalog Section - U906: Switches & Pilot Devices AP Series Miniature Switches & Pilot DevicesDocument8 pagesIndustrial Automation Catalog Section - U906: Switches & Pilot Devices AP Series Miniature Switches & Pilot DevicesMuhamad PriyatnaNo ratings yet

- Relay Barriers: Intrinsically Safe Explosion ProtectionDocument8 pagesRelay Barriers: Intrinsically Safe Explosion ProtectionMuhamad PriyatnaNo ratings yet

- AS-Interface Devices: (Slave Modules)Document48 pagesAS-Interface Devices: (Slave Modules)Muhamad PriyatnaNo ratings yet

- EB3C & 3L - Sales ManualDocument10 pagesEB3C & 3L - Sales ManualMuhamad PriyatnaNo ratings yet

- FB Series Plastic Control Boxes provide IP65 protectionDocument8 pagesFB Series Plastic Control Boxes provide IP65 protectionMuhamad PriyatnaNo ratings yet

- EP1116-0 ControlUnits Relays 060217Document404 pagesEP1116-0 ControlUnits Relays 060217Muhamad PriyatnaNo ratings yet

- ø16mm and ø22mm Emergency Stop Switches - Compact Size, Safe Break ActionDocument20 pagesø16mm and ø22mm Emergency Stop Switches - Compact Size, Safe Break ActionMuhamad PriyatnaNo ratings yet

- A Series Miniature Control UnitsDocument44 pagesA Series Miniature Control UnitsMuhamad PriyatnaNo ratings yet

- Eb3C Eb3L: Relay Barriers Lamp BarriersDocument20 pagesEb3C Eb3L: Relay Barriers Lamp BarriersMuhamad PriyatnaNo ratings yet

- 30 MM XN Series Emergency Stop SwitchesDocument12 pages30 MM XN Series Emergency Stop SwitchesMuhamad PriyatnaNo ratings yet

- Power Supplies: Smart ProductsDocument6 pagesPower Supplies: Smart ProductsMuhamad PriyatnaNo ratings yet

- 16 MM XA Series & 22 MM HW, XW Series SEMI S2 Compliant EMODocument4 pages16 MM XA Series & 22 MM HW, XW Series SEMI S2 Compliant EMOMuhamad PriyatnaNo ratings yet

- PS5R-SB Switching Power Supplies Compact SizeDocument2 pagesPS5R-SB Switching Power Supplies Compact SizeMuhamad PriyatnaNo ratings yet

- Power Supplies BrochureDocument12 pagesPower Supplies BrochureMuhamad PriyatnaNo ratings yet

- 16 MM XA Series & 22 MM XW Series SEMI S2 Compliant EMO SwitDocument8 pages16 MM XA Series & 22 MM XW Series SEMI S2 Compliant EMO SwitMuhamad PriyatnaNo ratings yet

- 16 MM XA Series Emergency Stop Switches (Illuminated Type)Document4 pages16 MM XA Series Emergency Stop Switches (Illuminated Type)Muhamad PriyatnaNo ratings yet

- 8F Drains and Breathers: Application: ECD Type 4X''Document1 page8F Drains and Breathers: Application: ECD Type 4X''Muhamad PriyatnaNo ratings yet

- PLC, IO & Communications ProductsDocument46 pagesPLC, IO & Communications ProductsMuhamad PriyatnaNo ratings yet

- Photoelectric, Inductive & Capacitive SensorsDocument14 pagesPhotoelectric, Inductive & Capacitive SensorsMuhamad PriyatnaNo ratings yet

- Series: 611G 611V 611GE 611VE: Installation DrawingDocument1 pageSeries: 611G 611V 611GE 611VE: Installation DrawingMuhamad PriyatnaNo ratings yet

- ø16mm and ø22mm Emergency Stop Switches - Compact Size, Safe Break ActionDocument20 pagesø16mm and ø22mm Emergency Stop Switches - Compact Size, Safe Break ActionMuhamad PriyatnaNo ratings yet

- 1 Residual Current Circuit Breaker (RCCB) (ELCB)Document6 pages1 Residual Current Circuit Breaker (RCCB) (ELCB)Anirudh VN100% (1)

- 8F Drains and Breathers: Application: ECD Type 4X''Document1 page8F Drains and Breathers: Application: ECD Type 4X''Muhamad PriyatnaNo ratings yet

- Operator Interface ProductsDocument38 pagesOperator Interface ProductsMuhamad PriyatnaNo ratings yet

- Motor Control CentersDocument20 pagesMotor Control CentersMuhamad PriyatnaNo ratings yet

- NEMA Manual StartersDocument12 pagesNEMA Manual StartersMuhamad PriyatnaNo ratings yet

- Stacklights 46-1: February 2007Document12 pagesStacklights 46-1: February 2007Muhamad PriyatnaNo ratings yet

- Vacuum Contactors & StartersDocument32 pagesVacuum Contactors & StartersMuhamad PriyatnaNo ratings yet

- Medium Voltage Motor Control AssembliesDocument4 pagesMedium Voltage Motor Control AssembliesMuhamad PriyatnaNo ratings yet

- Cutler-Hammer: Standards Global Third Party CertificationDocument45 pagesCutler-Hammer: Standards Global Third Party Certificationmenendez2050100% (1)

- Datasheet - TR22AxxKNX - ENG - ITADocument2 pagesDatasheet - TR22AxxKNX - ENG - ITAVishal SuryawaniNo ratings yet

- IN-NT-PLUS-1.5 - Reference Guide PDFDocument90 pagesIN-NT-PLUS-1.5 - Reference Guide PDFDouglas SobralNo ratings yet

- Mitsubishi v500 VFD IB NA 0600135E-A FR-V560 Instruction Manaul-DetailedDocument243 pagesMitsubishi v500 VFD IB NA 0600135E-A FR-V560 Instruction Manaul-DetailedMROstop.comNo ratings yet

- Pagepro 1480MF SMDocument127 pagesPagepro 1480MF SMNorel AndreiNo ratings yet

- Battery Charger ManualDocument46 pagesBattery Charger ManualBrunitorodrigoNo ratings yet

- Complex System Vending MachineDocument31 pagesComplex System Vending MachineAbdul Razak Fatin NabilahNo ratings yet

- Infineon TLE6209R DS v03 02 enDocument30 pagesInfineon TLE6209R DS v03 02 enRoger SegoNo ratings yet

- Cpm2a Operation Manual W352-E1-07Document181 pagesCpm2a Operation Manual W352-E1-07Melchie Bob GunayanNo ratings yet

- RFC 430 450 Eth Ib Um e 6219 en 02Document128 pagesRFC 430 450 Eth Ib Um e 6219 en 02Aitor Larren0% (1)

- Introduction To The Personal Computer: IT Essentials 5.0Document53 pagesIntroduction To The Personal Computer: IT Essentials 5.0Daniel PerezNo ratings yet

- HVI1000 TechData-eDocument10 pagesHVI1000 TechData-eFiroze KhandakarNo ratings yet

- SG6105 Datasheet, Pinout, Application Circuits Power Supply Supervisor Regulator PWMDocument13 pagesSG6105 Datasheet, Pinout, Application Circuits Power Supply Supervisor Regulator PWMBeatrizEstevesNo ratings yet

- BO23 Brochure enDocument24 pagesBO23 Brochure enabhipankaj50% (2)

- Tea 1521 TDocument20 pagesTea 1521 TSamir Del CidNo ratings yet

- Controlling of AC Lamp Dimmer Through Mobile PhoneDocument2 pagesControlling of AC Lamp Dimmer Through Mobile PhoneMayank Kalra100% (1)

- صيانة الاجهزة والمعدات الطبيةDocument83 pagesصيانة الاجهزة والمعدات الطبيةSayed BadawyNo ratings yet

- Lab SI - Senzori InductiviDocument21 pagesLab SI - Senzori InductiviGeorge DragomirNo ratings yet

- Manual ATS022 1SDH000760R0002Document42 pagesManual ATS022 1SDH000760R0002Pasc ClaudiuNo ratings yet

- Twin Softener ManualDocument18 pagesTwin Softener ManualSanto ENo ratings yet

- Enhanced Base Transceiver System: TETRA - Revolutionising The Way The World CommunicatesDocument4 pagesEnhanced Base Transceiver System: TETRA - Revolutionising The Way The World CommunicatesLazni NalogNo ratings yet

- Akira 14hs9n 3y01Document15 pagesAkira 14hs9n 3y01Su BarkahNo ratings yet

- Wiring DiagramsDocument20 pagesWiring DiagramsIzzeldin ZakiNo ratings yet

- Alcatel-Lucent 9926 Bbuv2 (Base Band Unit) : Product DescriptionDocument30 pagesAlcatel-Lucent 9926 Bbuv2 (Base Band Unit) : Product DescriptioncuongNo ratings yet

- Ad2s99 3118552Document9 pagesAd2s99 3118552rROMULO MOREIRANo ratings yet

- Microondas LG Manual TécnicoDocument36 pagesMicroondas LG Manual TécnicoManualzNo ratings yet

- Medium Voltage SMC OEM Components - 10 15 KV Specifications: Technical DataDocument16 pagesMedium Voltage SMC OEM Components - 10 15 KV Specifications: Technical Dataahmed essamNo ratings yet

- G120C Op Instr 1020 en-USDocument500 pagesG120C Op Instr 1020 en-USAgnaldoNo ratings yet