Professional Documents

Culture Documents

5 - MP Compressor

Uploaded by

imran niazOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5 - MP Compressor

Uploaded by

imran niazCopyright:

Available Formats

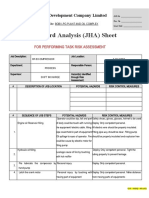

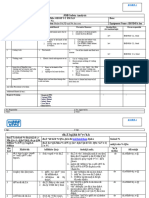

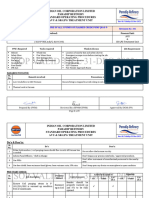

Oil & Gas Development Company Limited JHA No.

____________________

Rev. No. ____________________

Location / Site: BOBI LPG PLANT AND OIL COMPLEX

Issue Date: __________________

Job Hazard Analysis (JHA) Sheet

FOR PERFORMING TASK RISK ASSESSMENT

Job Description: Job Location:

MP COMPRESSOR AJAX AREA

Department: Responsible Person:

PROCESS AREA OPERATOR

Supervisor: Hazard(s) Identified

SHIFT INCHARGE through Risk

Assessment:

# DESCRIPTION OF JOB LOCATION POTENTIAL HAZARDS RISK CONTROL MEASURES

# SEQUENCE OF JOB STEPS POTENTIAL HAZARDS RISK CONTROL MEASURES

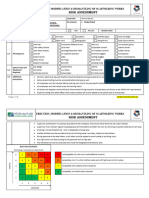

Engine oil Reservoir filling Operator could be slip; fall and part Safety shoes, gloves, glasses, helmet should be

of body could be touch with running were to the operator. Deploy Only competent

the equipment/ electric cable. filling personal.

1. pipe could hold in part of equipment All electric wire should be properly insulated.

Oil spillage to eyes of operator. Fire Filling pipe way should be clear. Filling pump

could be cause by electric motor for should be properly insulated and explosion free

filling pump

Hydraulic oil filling Deploy Only competent personal. Tight the

Leakage cause of fire by touching

2. tubing properly to insure leakage.

with hot muffler

Pre lubricate the compressor by Personal injury Deploy Only competent personal.

3.

hand pump

4. Latch the crank motor Personal injury by touching withDeploy Only competent personal. Make distance

moving part of equipment from moving parts of equipments

OGF – HSEQ – 003(02)

5. Open plant air Noise Wear ear muff

Adjust exhaust temperature of cylinder Deploy Only competent personal.

6. Electric shocks, burning Wear insulated gloves. Control the short circuit

sparking

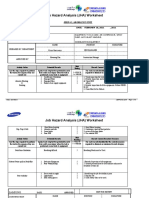

Open/close suction/discharge V/L Deploy Only competent personal.

7. Personal injury

Depressurize the compressor Off mobile phones, no lighter, Avoid spark, flame

electrical source, hot surface. Post area NO

SMOKING , NO OPEN FLAME

Training to be conducted

8. Fire due to open vent of gas

Only trained and experienced person is allowed

to perform

Gas mask to be used ,Follow wind socks

Fire extinguisher to be ready by an operator

During performing job Negligence in following SOP Proper training should be done.

9. causes fire, explosion, personal

injury or causality and damage of

equipment

Compressor in running mode Personal injury could be due to

damage of any part of equipment, Deploy Only competent personal.

10. fire or explosion possibility due to

leakages of gas or oil, excessive

pressure or heat.

11.House keeping Any incident or accident is possible

Proper house keeping should be done

due to improper house keeping

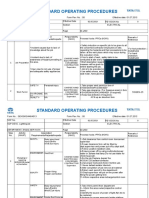

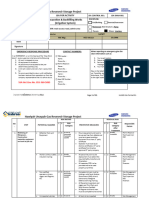

JOB SAFETY REQUIREMENTS YES/NO COMMENTS

SAFETY WATCH Yes Shell be the Trained Person

WORK CLEARANCE Yes Properly Depressurization

GAS DETECTOR Yes Calibrated[ REF: API RP 14C, API RP 14F & API RP 500]

PERSONAL PROTECTIVE EQUIPMENT YES/NO COMMENTS

Yes Eye protection, use clear glasses [REF: OSHA 1910.133 (a)

SAFETY GLASSES

(2)]

COVERALLS Yes Safe working [REF: OSHA 1910.134 (e)(5)(i)(D)]

HARD HAT Yes Use chin strap with Helmet. [ REF:OSHA 1910.135 (a) (1)]

EAR PLUG / EAR MUFF Yes with suitable noise reduction rating (NRR)

Prepared by: Reviewed by:

Signature

Signature

Date: Date:

Remarks:

OGF – HSEQ – 003(02)

Approved by:

Signature

Date:

OGF – HSEQ – 003(02)

You might also like

- 1 - Feed Gas CompressorDocument3 pages1 - Feed Gas Compressorimran niazNo ratings yet

- 3 - HP-B CompressorDocument3 pages3 - HP-B Compressorimran niazNo ratings yet

- Risk Assessment - Elie SabDocument8 pagesRisk Assessment - Elie SabMuhammad FaizalNo ratings yet

- Avu&Srlpg SopsDocument732 pagesAvu&Srlpg Sops00083583rfNo ratings yet

- Dokumen - Tips Hip For AramcoDocument5 pagesDokumen - Tips Hip For Aramcohamoud abdulazizNo ratings yet

- Jsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007Document30 pagesJsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007elmsm14No ratings yet

- 24 590 48 enDocument12 pages24 590 48 enspedet9919No ratings yet

- JHA - Gas Cutting For ReferenceDocument2 pagesJHA - Gas Cutting For ReferenceNarayanKavitakeNo ratings yet

- Grinding Operation JSA HSE ProfessionalsDocument1 pageGrinding Operation JSA HSE ProfessionalsSamadov 13No ratings yet

- Cable JointDocument1 pageCable Jointshonz georgeNo ratings yet

- JSA of CentrifugeDocument8 pagesJSA of CentrifugeGajanan NalegaonkarNo ratings yet

- Job Safety Analysis: Only Authorized Person Placed Lock and Tag. Disconnect Energy, A Circuit Breaker, A Line ValveDocument4 pagesJob Safety Analysis: Only Authorized Person Placed Lock and Tag. Disconnect Energy, A Circuit Breaker, A Line ValveAnonymous voA5Tb0No ratings yet

- Jsa Hot Work-Fabrication of Assembly BedDocument4 pagesJsa Hot Work-Fabrication of Assembly BedAbhi SandiNo ratings yet

- Job Safety Analysis For: Hcu & Lobs Revamp ProjectDocument6 pagesJob Safety Analysis For: Hcu & Lobs Revamp ProjectShilpiengg SafetyNo ratings yet

- Risk Assessment: Bunkering in GeneralDocument2 pagesRisk Assessment: Bunkering in Generaloto saviour0% (1)

- Packing Pumps New - FO-GL-HAL-HSE-0103FDocument4 pagesPacking Pumps New - FO-GL-HAL-HSE-0103FMohamed El-SawahNo ratings yet

- Job Safety Analysis: OperationDocument4 pagesJob Safety Analysis: OperationVi VekNo ratings yet

- 95 Fueling of Vehicles-JOB PROCEDUREDocument2 pages95 Fueling of Vehicles-JOB PROCEDURESKH CultureNo ratings yet

- ERECTION, MODIFICATION & DISMANTLING OF SCAFFOLDING WORKS - Risk Assessment - REV01Document10 pagesERECTION, MODIFICATION & DISMANTLING OF SCAFFOLDING WORKS - Risk Assessment - REV01SolimanNo ratings yet

- Risk Assessment WorksheetDocument2 pagesRisk Assessment WorksheetHergheligiu VasileNo ratings yet

- Grinding Operation JSA HSE ProfessionalsDocument4 pagesGrinding Operation JSA HSE ProfessionalsYogisopian HadiNo ratings yet

- Job Safety Analysis: Air Compressor OperationDocument2 pagesJob Safety Analysis: Air Compressor OperationVi VekNo ratings yet

- JSA9 - ABP OWS Manhole Sealant ProjectDocument9 pagesJSA9 - ABP OWS Manhole Sealant ProjectadeelkhanafeNo ratings yet

- JSA InsulationDocument8 pagesJSA InsulationOlavilam Prakash100% (3)

- Job Hazard Analysis (JHA) Worksheet: Sungchang & Al-Shaikh Contracting Co.,LtdDocument3 pagesJob Hazard Analysis (JHA) Worksheet: Sungchang & Al-Shaikh Contracting Co.,LtdTeodoro EsquilloNo ratings yet

- SOP For Lighting JobDocument3 pagesSOP For Lighting Jobgulam safi100% (1)

- JSA Fan Area InspectionDocument3 pagesJSA Fan Area InspectionavinashNo ratings yet

- Diesel Generator Operation JSADocument1 pageDiesel Generator Operation JSANoe Aranel100% (1)

- 3..hot Work ActivitiesDocument2 pages3..hot Work ActivitiesFrancis VinojNo ratings yet

- F.03-09 Job Safety Analysis - EMV MaintenanceDocument3 pagesF.03-09 Job Safety Analysis - EMV Maintenanceaqeel ahmedNo ratings yet

- 1.JSA-Mechanical Work Hydrant InstallationDocument9 pages1.JSA-Mechanical Work Hydrant InstallationMuhammad Umar GondalNo ratings yet

- F.03-09 Job Safety Analysis - Oil, Grease and Lubricant ChangeDocument3 pagesF.03-09 Job Safety Analysis - Oil, Grease and Lubricant Changeaqeel ahmedNo ratings yet

- Steam Turbine StartupDocument17 pagesSteam Turbine StartupRahul ChoubeyNo ratings yet

- Honda Em5000sDocument57 pagesHonda Em5000sdavidNo ratings yet

- JSA OF Fabrication and Installation Work ApproviedDocument3 pagesJSA OF Fabrication and Installation Work Approviedsakthi venkatNo ratings yet

- Standard Operating ProcedureDocument16 pagesStandard Operating ProcedureBhubanmohan NayakNo ratings yet

- CE03 Hydraulic Testing of Pressure VesselsDocument5 pagesCE03 Hydraulic Testing of Pressure VesselsTafireyi TeveraNo ratings yet

- 2 - JSA Hot WorkDocument9 pages2 - JSA Hot WorkAijaz AhmedNo ratings yet

- JSA Formet New Hot WorkDocument6 pagesJSA Formet New Hot Worksakthi venkat100% (1)

- HG34P I HG34e: Maintenance ManualDocument40 pagesHG34P I HG34e: Maintenance Manualcamilo obrasNo ratings yet

- JHA 58-A - CML & CIG 4,5 Pump Header & Water Line Modification - DIP2Document3 pagesJHA 58-A - CML & CIG 4,5 Pump Header & Water Line Modification - DIP2cmgent2022No ratings yet

- SIM ARABIA - JSA For Excavation and Backfilling Works (Irrigation System)Document11 pagesSIM ARABIA - JSA For Excavation and Backfilling Works (Irrigation System)Rana AhmedNo ratings yet

- JHA - DU ReplacementDocument9 pagesJHA - DU ReplacementSanthosh KumarNo ratings yet

- Retail Permit To Work System - Job Hazard AnalysisDocument7 pagesRetail Permit To Work System - Job Hazard AnalysisSanthosh Kumar100% (1)

- Jsa Grinding Welding Gas CuttingDocument3 pagesJsa Grinding Welding Gas CuttingWidodo D PrasetyoNo ratings yet

- JHA InstrumentationDocument8 pagesJHA Instrumentationசேகர் வேதாரண்யம்No ratings yet

- 3 Avu&Srlpg Sop P-003abc FailureDocument5 pages3 Avu&Srlpg Sop P-003abc Failure00083583rfNo ratings yet

- Risk Assessment/Management FormDocument4 pagesRisk Assessment/Management FormNazriNo ratings yet

- Job Safety Analysis: Nitrogen Plant OperationDocument2 pagesJob Safety Analysis: Nitrogen Plant OperationVi VekNo ratings yet

- Job Safety Analysis (Jsa) : Damage and Personal InjuryDocument2 pagesJob Safety Analysis (Jsa) : Damage and Personal InjuryReda Bouali100% (1)

- Steel Cutting, Bending, Welding and Grinding Work JsaDocument2 pagesSteel Cutting, Bending, Welding and Grinding Work JsaAKBAR ALINo ratings yet

- Instructions For Use: Réf. Constructeur: Réf. GPAO: 33502012701 Ind1Document40 pagesInstructions For Use: Réf. Constructeur: Réf. GPAO: 33502012701 Ind1Lionel AuclairNo ratings yet

- Sequence of Basic Job Steps Potential Hazards Safeguard/Controls To Be Put in Place ResponsibilityDocument6 pagesSequence of Basic Job Steps Potential Hazards Safeguard/Controls To Be Put in Place ResponsibilityAli AshfaqueNo ratings yet

- Jsa Removal Fixing InsulationDocument2 pagesJsa Removal Fixing InsulationAprilia Rizki Ardila63% (8)

- 18 - Maintenance of Skip HoistDocument5 pages18 - Maintenance of Skip Hoistgiet11aei010No ratings yet

- Gunitting Operation JSA HSE ProfessionalsDocument1 pageGunitting Operation JSA HSE ProfessionalsSamadov 13No ratings yet

- Gas Cutting Work JsaDocument2 pagesGas Cutting Work JsaAKBAR ALINo ratings yet

- Ewrc SHP Gen Hse Jsa 00040Document12 pagesEwrc SHP Gen Hse Jsa 00040Rickz CabaloNo ratings yet

- Operator's Manual: Model No. 580.752220Document56 pagesOperator's Manual: Model No. 580.752220Channing websterNo ratings yet

- NFC IEFR, FaisalabadDocument1 pageNFC IEFR, Faisalabadimran niazNo ratings yet

- LPG Vap Mass in LPG BulletDocument1 pageLPG Vap Mass in LPG Bulletimran niazNo ratings yet

- TST CMD BypassDocument1 pageTST CMD Bypassimran niazNo ratings yet

- LPG From Natural Gas: 4.85 MMSCFD Mol Wt. 7 Percent 44 LB/LB - Mol 0.6 Percent 58 LB/LB - Mol 0.4 Percent 58 LB/LB - MolDocument2 pagesLPG From Natural Gas: 4.85 MMSCFD Mol Wt. 7 Percent 44 LB/LB - Mol 0.6 Percent 58 LB/LB - Mol 0.4 Percent 58 LB/LB - Molimran niazNo ratings yet

- Volume in LPG BulletDocument1 pageVolume in LPG Bulletimran niazNo ratings yet

- John Donaldson: August 14, 2020Document1 pageJohn Donaldson: August 14, 2020imran niazNo ratings yet

- Program of Works - CapbuildDocument20 pagesProgram of Works - CapbuildJonnel CatadmanNo ratings yet

- Hdpe Statment Detail PDFDocument1 pageHdpe Statment Detail PDFshameemNo ratings yet

- Ww5000t-Led DC68-04206K-00 en ArDocument120 pagesWw5000t-Led DC68-04206K-00 en Aromar oduibatNo ratings yet

- (1-07) Spesifikasi TL Shortwave Diathermy + Complete AksesoriDocument2 pages(1-07) Spesifikasi TL Shortwave Diathermy + Complete AksesoriFardiyan SyafriNo ratings yet

- Mapping Standar Alat Labkesda Kab KotaDocument3 pagesMapping Standar Alat Labkesda Kab Kotacctb kabbogorNo ratings yet

- Presentation - Fleximag PlusDocument24 pagesPresentation - Fleximag PlusAlauddin SyahNo ratings yet

- PLC - s7300 - sm331 - Ai - 8x12 - Bit - Getting - Started - En-Us - En-Us - (Cuuduongthancong - Com)Document76 pagesPLC - s7300 - sm331 - Ai - 8x12 - Bit - Getting - Started - En-Us - En-Us - (Cuuduongthancong - Com)Cường TrầnNo ratings yet

- အေျခခံဓါတ္ပုံရုိက္နည္း စာစုမ်ား by ဓါတ္ပုံပညာ ေလ့လာရန္Document101 pagesအေျခခံဓါတ္ပုံရုိက္နည္း စာစုမ်ား by ဓါတ္ပုံပညာ ေလ့လာရန္Mg Thant AungNo ratings yet

- Relay Testing ProcedureDocument50 pagesRelay Testing Procedureunnikrish05No ratings yet

- DanfossDocument4 pagesDanfossAliKarimliNo ratings yet

- GE Lighting Systems HM-1000 High Mast Series Spec Sheet 3-70Document2 pagesGE Lighting Systems HM-1000 High Mast Series Spec Sheet 3-70Alan Masters100% (1)

- Shot List TemplateDocument4 pagesShot List TemplateCharlotte Heath0% (1)

- Aircraft Maintenance ManualDocument10 pagesAircraft Maintenance ManualPPC LINE9No ratings yet

- eTORK Digital Wrench InstructionsDocument8 pageseTORK Digital Wrench InstructionsJHON FREDY PEREZ ZAMUDIONo ratings yet

- DIY Thickness Sander - WoodArchivistDocument6 pagesDIY Thickness Sander - WoodArchivistEricsNo ratings yet

- TSP Manual Titan - Hoist Only - Ce 31-08-05Document11 pagesTSP Manual Titan - Hoist Only - Ce 31-08-05Eduardo ParraNo ratings yet

- Clamp Meter 2520TDocument1 pageClamp Meter 2520TwaytobhushanNo ratings yet

- Philips Tcw060Document11 pagesPhilips Tcw060Muhammad MakkihNo ratings yet

- DP-8060 / 8045 / 8035 For STD Version (Except USA)Document700 pagesDP-8060 / 8045 / 8035 For STD Version (Except USA)vladimir2426No ratings yet

- Relés NS1 Mors MittDocument28 pagesRelés NS1 Mors MittManuel Octavio Penroz CelisNo ratings yet

- Aurduino 12345Document4 pagesAurduino 12345adershNo ratings yet

- GN4 - Hand Tools and Power Tools - Heavy Equipment SafetyDocument123 pagesGN4 - Hand Tools and Power Tools - Heavy Equipment SafetyNavi AgeinNo ratings yet

- Alia AMF300 AliaMag FlowmeterDocument3 pagesAlia AMF300 AliaMag FlowmeterRexCrazyMindNo ratings yet

- Experiment 1: Uncontrolled Rectifier: Power ElectronicsDocument3 pagesExperiment 1: Uncontrolled Rectifier: Power ElectronicsYogesh khandelwalNo ratings yet

- Yamaha Nxamp4x4Document153 pagesYamaha Nxamp4x4gafesa electronicsNo ratings yet

- Different Kinds of MechanismsDocument31 pagesDifferent Kinds of Mechanismslockenload92% (13)

- Parker Dual-Bed Nitrogen Generation Systems: Installation, Operation, and Maintenance ManualDocument48 pagesParker Dual-Bed Nitrogen Generation Systems: Installation, Operation, and Maintenance ManualgokulNo ratings yet

- Solenoid Valves 3/2 327Document4 pagesSolenoid Valves 3/2 327ARTURO TZITZIHUA HERNANDEZNo ratings yet

- Diode Test and FamiliarizationDocument4 pagesDiode Test and Familiarizationcent carinoNo ratings yet

- 828 Series With 832 Series Add OnDocument9 pages828 Series With 832 Series Add Onsettar06No ratings yet