Professional Documents

Culture Documents

Storing Corn From The 2010 Harvest - Aerate and Monitor

Uploaded by

troub X2Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Storing Corn From The 2010 Harvest - Aerate and Monitor

Uploaded by

troub X2Copyright:

Available Formats

Storing Corn from the 2010 Harvest: Aerate and Monitor – (Matt Roberts, Grain Quality Extension

Specialist and Richard Stroshine, Professor, Agricultural and Biological Engineering Department)

The 2010 corn harvest season has been almost the exact opposite of the season producers

experienced in 2009. In 2010 growers and researchers reported almost no field molds and harvest

moistures were considerably lower than in years past. Based on conversations with growers around the

state, some who started harvesting early had moistures around 25%, while the bulk of the corn was

harvested at moistures between 14% and 18%. Although grain drying was not much of a concern for

many producers this year, it is still important to minimize the chances of spoilage by applying the basic

principles of grain storage, which include aeration and monitoring. There have already been reports of

grain in storage going out of condition and in many cases this can be attributed to ignoring those

principles.

Aeration: Aeration of grain in storage helps to equalize not only temperature differences, but also

moisture differences throughout the grain mass. It is especially important to aerate grain that was taken

out of the field and placed directly into storage. While the field average may have been 14% or 15%

moisture, there may have been pockets of 16% or 18% moisture grain in the harvested corn. Aeration will

help to cool this corn and may move some of the moisture out of those wetter pockets.

This year the temperature of a large portion of the corn was put in the bin at temperatures between

70 and 80 degrees. At such high temperatures there is greater risk that the corn will spoil. Corn at 16%

moisture with a kernel temperature of 70 degrees can begin to spoil in approximately 30 days. Therefore

as soon as corn is placed in the bin, it should be aerated and, if it was above 70 degrees, the first cooling

cycle should begin when the average outside air temperature (average of the daily high and low

temperatures) drops by about 10 degrees. Cooling should continue in a stepwise process throughout the

fall months and into the winter. A new cooling front should be moved through the bin when the average

outside air temperature has dropped another 10 to 15 degrees. Ideally, corn should be cooled to just

above freezing using two or three aeration cycles. Grain temperature near the top surface of the grain

mass can be determined by placing a thermometer (such as a metallic oven thermometer with a long

stem) 1 to 1.5 to feet under the surface of the grain where it is left for about 5 minutes before the reading

is taken. If the cooling front has moved through the bin, the temperature of the grain below the upper

surface should be the average temperature when aeration was begun. Length of time for an aeration front

to move through a grain mass can vary greatly depending on bin and fan size. For a small bin with a large

fan it may take only a day for the cooling front to move through the bin. For a tall bin with a smaller fan it

may take several weeks for the cooling front to reach the top surface.

Air takes the path of least resistance. Therefore it is important to “core” the bin by pulling a load of the

grain out of the bin to level the top of the grain mass. Because of the lower harvest moistures and

particularly if combine cylinder speeds were higher than necessary, there may have been higher

percentages of broken kernels in the corn. Broken kernels tend to accumulate near the center of the bin

and reduce airflow through that part of the grain mass. Coring the bin removes the corn with higher fines.

In larger bins it may be necessary to take several loads from the bin to reduce the concentration of fines

in the center of the bin.

After aeration is completed for the year the fans should be covered to prevent entrance of outside air

and to keep out rodents and pets.

Monitoring: It is necessary to check a bin for signs of spoilage at least once every two weeks during

the winter and weekly in the fall and spring when the outside air temperatures are warmer. The suggested

way to do this is to climb to the eave door, look inside and smell for any signs of spoilage. Also, observe

the roof for any frost or current or past signs of condensation. Turning on the fans during this time will

assist in detecting musty odors associated with spoilage. If an observer is present it may also be useful to

enter the bin and walk around on the top of the grain to determine if grain has started to spoil and clump

together.

You might also like

- STORAGE: Aerating Stored GrainDocument4 pagesSTORAGE: Aerating Stored GrainMilling and Grain magazineNo ratings yet

- Grain and Soybean Drying On Georgia FarmsDocument13 pagesGrain and Soybean Drying On Georgia FarmsjimNo ratings yet

- Rice StorageDocument4 pagesRice StorageBechara Philip Assouad100% (3)

- Potato Storage Management Fact Sheet English FinalDocument9 pagesPotato Storage Management Fact Sheet English FinalDiego RuedaNo ratings yet

- Soybean Drying and Storage: Harvest Moisture Preparation For DryingDocument2 pagesSoybean Drying and Storage: Harvest Moisture Preparation For DryingAnonymous yPWi8p3KkANo ratings yet

- Seed DryingDocument10 pagesSeed DryingJack Ethan Dean B. CamiadorNo ratings yet

- Cultivation of Second Year Onion SetsDocument3 pagesCultivation of Second Year Onion SetsAleš FisterNo ratings yet

- Partial Scope and Delimitations of The StudyDocument4 pagesPartial Scope and Delimitations of The Studymestudent44444No ratings yet

- Basic Principles and Systems of Grain DryingDocument13 pagesBasic Principles and Systems of Grain DryingMary - Ann AndalNo ratings yet

- Lesson 6 Seed Drying, Processing and Handling - 101058Document34 pagesLesson 6 Seed Drying, Processing and Handling - 101058Zyrone EsguerraNo ratings yet

- Considerations For Artificial Drying of Soybeans 10-29-09Document2 pagesConsiderations For Artificial Drying of Soybeans 10-29-09Anonymous yPWi8p3KkANo ratings yet

- Solar Assisted Crop Dryers For Paddy, Flowers and Kenaf: Malaysian Agricultural Research & Development Institute (MARDI)Document22 pagesSolar Assisted Crop Dryers For Paddy, Flowers and Kenaf: Malaysian Agricultural Research & Development Institute (MARDI)Omphile MosuweNo ratings yet

- FinalDocument6 pagesFinalMarlene SambasNo ratings yet

- Lsu Drier DesignDocument10 pagesLsu Drier DesignKumaran ManiNo ratings yet

- Agaricus Bisporus OystersDocument3 pagesAgaricus Bisporus OystersWjekoslav WodopijaNo ratings yet

- Fundamentals of Grain DryingDocument2 pagesFundamentals of Grain Dryingmiguel_marshNo ratings yet

- Analysis of Plant and Livestock Weather RelationshipDocument10 pagesAnalysis of Plant and Livestock Weather RelationshipRondon LabosnogNo ratings yet

- DryingDocument19 pagesDryingEngr Muhammad Asif JavaidNo ratings yet

- Abiotic Factors Moisture Content: Stored Grain Deterioration by Biotic and Abiotic FactorsDocument5 pagesAbiotic Factors Moisture Content: Stored Grain Deterioration by Biotic and Abiotic FactorsMd IrfanNo ratings yet

- Guidelines For Formulation of Project Proposal For Mushroom FarmingDocument26 pagesGuidelines For Formulation of Project Proposal For Mushroom Farmingrbala9985% (20)

- WeatherDocument10 pagesWeatherRondon LabosnogNo ratings yet

- Grain Aeration: January 2012Document15 pagesGrain Aeration: January 2012Marie Cris Gajete MadridNo ratings yet

- Mashroom ProjectDocument19 pagesMashroom ProjectVinay100% (1)

- Cotton TalesDocument1 pageCotton TalesKwni KarfiNo ratings yet

- Chapter 16: Drying - Grain Drying, Types of Drying, Types of Dryers, Importance of DryingDocument10 pagesChapter 16: Drying - Grain Drying, Types of Drying, Types of Dryers, Importance of Drying9567592146No ratings yet

- Oyster Mushroom Cultivation - Unidad 2 PDFDocument14 pagesOyster Mushroom Cultivation - Unidad 2 PDFSandra Milena VelandiaNo ratings yet

- Lily Forcing GuideDocument29 pagesLily Forcing Guidenedela71No ratings yet

- HP Solar Food Dryer ArticleDocument11 pagesHP Solar Food Dryer ArticleBismi MaulizaNo ratings yet

- Mushroom Farming: Department of ArchitectureDocument7 pagesMushroom Farming: Department of ArchitectureHritika GurungNo ratings yet

- Agricultural Sciences Mushroom Cultivation (AGA - 453) B.Sc. (Hons.), B.Sc. Integrated MBADocument5 pagesAgricultural Sciences Mushroom Cultivation (AGA - 453) B.Sc. (Hons.), B.Sc. Integrated MBAMahendra paudel PaudelNo ratings yet

- Mushroom FarmingDocument11 pagesMushroom FarmingAltaf ShaikhNo ratings yet

- Seeddrying2 180213101315Document35 pagesSeeddrying2 180213101315Apolinar TabañeraNo ratings yet

- Grain StorageDocument26 pagesGrain StorageTarsem Mittal100% (1)

- 10 Chapter 8 Rice DryingDocument4 pages10 Chapter 8 Rice Dryinganisha francisNo ratings yet

- Year-Round Gardening: Growing Vegetables and Herbs, Inside or Outside, in Every SeasonFrom EverandYear-Round Gardening: Growing Vegetables and Herbs, Inside or Outside, in Every SeasonRating: 2 out of 5 stars2/5 (1)

- Greenhouse CucumbersDocument15 pagesGreenhouse Cucumbersnpotocnjak815100% (1)

- 34) Classification of DryersDocument27 pages34) Classification of Dryersalvin100% (1)

- Green TomaDocument4 pagesGreen TomaFarhat Abbas DurraniNo ratings yet

- Horticulture Vegetables 2010-01prDocument3 pagesHorticulture Vegetables 2010-01prAllison MorinNo ratings yet

- Seed Drying Principles and Types of DryersDocument21 pagesSeed Drying Principles and Types of DryersŇel DanNo ratings yet

- Home Composting: Getting StartedDocument5 pagesHome Composting: Getting StartedOliver ChildNo ratings yet

- Storage and Conditioning of Wheat To Maintain Its QualityDocument4 pagesStorage and Conditioning of Wheat To Maintain Its QualityAmalia IstighfarahNo ratings yet

- Lilium ManualDocument8 pagesLilium ManualVikas Bhandari100% (1)

- Guidelines For Formulation of Project Proposal For Mushroom FarmingDocument8 pagesGuidelines For Formulation of Project Proposal For Mushroom Farmingnuwan1987100% (2)

- Year-Round Edible Gardening: Growing Vegetables and Herbs, Inside or Outside, in Every SeasonFrom EverandYear-Round Edible Gardening: Growing Vegetables and Herbs, Inside or Outside, in Every SeasonNo ratings yet

- Automated Electronic Evaporative Cooling and Fogging System For MushroomDocument14 pagesAutomated Electronic Evaporative Cooling and Fogging System For MushroomElijahx San JoseNo ratings yet

- A Guide to Starting Early Vegetable and Flowering Plants in the HothouseFrom EverandA Guide to Starting Early Vegetable and Flowering Plants in the HothouseNo ratings yet

- Growing Information Alstroemeria Cut FlowerDocument6 pagesGrowing Information Alstroemeria Cut FlowerZineil BlackwoodNo ratings yet

- How To Increase Yields With Potato Growing BagsDocument5 pagesHow To Increase Yields With Potato Growing BagsKlaat KlaatNo ratings yet

- Rice Is A Hygroscopic MaterialDocument3 pagesRice Is A Hygroscopic MaterialShadab AliNo ratings yet

- Types of StorageDocument3 pagesTypes of StorageshindedattatriNo ratings yet

- Greenhouse Manual 2Document22 pagesGreenhouse Manual 2Kamlesh Prajapati0% (1)

- FAQ On White Button MushroomDocument2 pagesFAQ On White Button MushroomchampakNo ratings yet

- MushroomDocument12 pagesMushroomSonuNo ratings yet

- Bucklin Buildings Offers Cost Effective and Efficient Grain StorageDocument5 pagesBucklin Buildings Offers Cost Effective and Efficient Grain StorageMeiyarasi reddyNo ratings yet

- Dryer Types PDFDocument9 pagesDryer Types PDFShanmugapriyaNo ratings yet

- Potato StorageDocument3 pagesPotato StorageSanjeev Gautam100% (1)

- Horticulture for Beginners - With Information on Market-Gardening and Flower GardeningFrom EverandHorticulture for Beginners - With Information on Market-Gardening and Flower GardeningNo ratings yet

- Organic Gardening: The complete guide on everything you need to know for easy organic gardening from home!From EverandOrganic Gardening: The complete guide on everything you need to know for easy organic gardening from home!No ratings yet

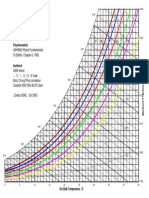

- Guide ERH Equilibrium-MC Charts Canada GrainsDocument4 pagesGuide ERH Equilibrium-MC Charts Canada Grainstroub X2No ratings yet

- Fan PerformanceDocument21 pagesFan Performancetroub X2No ratings yet

- Wheat and Barley StorageDocument1 pageWheat and Barley Storagetroub X2No ratings yet

- Resistance of Bulk Grain To AirflowDocument11 pagesResistance of Bulk Grain To Airflowtroub X2No ratings yet

- FGIS Registered Grain Exporters DirectoryDocument2 pagesFGIS Registered Grain Exporters Directorytroub X20% (1)

- Using Flat Buildings For Dry Grain StorageDocument2 pagesUsing Flat Buildings For Dry Grain Storagetroub X2No ratings yet

- Typical Angles of ReposeDocument1 pageTypical Angles of Reposetroub X2No ratings yet

- Flat StorageDocument1 pageFlat Storagetroub X2No ratings yet

- Psyc Chart WheatDocument1 pagePsyc Chart Wheattroub X2No ratings yet

- Planning Grain Drying, Handling, and Storage Facilities OKDocument4 pagesPlanning Grain Drying, Handling, and Storage Facilities OKEng Urimubenshi DonatNo ratings yet

- Arkansas Current - Grain - Warehouse - ListDocument2 pagesArkansas Current - Grain - Warehouse - Listtroub X2No ratings yet

- On-Farm Grain Storage CostsDocument2 pagesOn-Farm Grain Storage Coststroub X2No ratings yet

- Grain Storage TipsDocument2 pagesGrain Storage Tipstroub X2No ratings yet

- On-Farm Grain Storage CostsDocument2 pagesOn-Farm Grain Storage Coststroub X2No ratings yet

- Sahay 1926Document16 pagesSahay 1926Vitor Moura VisoniNo ratings yet

- Evaluation EssayDocument3 pagesEvaluation Essayapi-509662912No ratings yet

- Ananthi ThesisDocument24 pagesAnanthi ThesisYogananth NagarajanNo ratings yet

- Languagechimp Spanish-Vocabulary PDFDocument2 pagesLanguagechimp Spanish-Vocabulary PDFayooniaNo ratings yet

- Review Test 2 - SpeakingDocument4 pagesReview Test 2 - SpeakingNV TùngNo ratings yet

- LRF Details For CommunitiesDocument7 pagesLRF Details For CommunitiesKaran AnandNo ratings yet

- Loving YouDocument12 pagesLoving YouCain LNo ratings yet

- Summative Assessment: Food (Fish) ProcessingDocument4 pagesSummative Assessment: Food (Fish) ProcessingJon GraniadaNo ratings yet

- Full Term Test 8th FormDocument3 pagesFull Term Test 8th FormStarr BlueNo ratings yet

- English 4 3rd Periodical TestDocument7 pagesEnglish 4 3rd Periodical TestMich Berdan-Domingo100% (1)

- Sandwich Cookbook PDFDocument0 pagesSandwich Cookbook PDFgiftycms100% (1)

- Veg Manchurian - Marathi RecipeDocument3 pagesVeg Manchurian - Marathi RecipeOmkar JangamNo ratings yet

- History of RefrigerationDocument20 pagesHistory of RefrigerationCharene BernabeNo ratings yet

- Kinds & Characteristics of Restaurants & Their Owners LO1Document29 pagesKinds & Characteristics of Restaurants & Their Owners LO1Pawel KulonNo ratings yet

- The Stanford Daily - Intermission, Jan. 28, 2011Document8 pagesThe Stanford Daily - Intermission, Jan. 28, 2011coo9486No ratings yet

- Cae Open Cloze 1-21Document21 pagesCae Open Cloze 1-21inmaNo ratings yet

- October 2015 Question Paper 2 Tcm143 354031Document16 pagesOctober 2015 Question Paper 2 Tcm143 354031Dương Ngọc Cường33% (3)

- Experiment 4 - Effect of Enzyme Concentration On Enzyme ActivityDocument5 pagesExperiment 4 - Effect of Enzyme Concentration On Enzyme ActivityLinhNguyeNo ratings yet

- Ethiopia Commodity Exchange - Commodities PDFDocument3 pagesEthiopia Commodity Exchange - Commodities PDFSELUNo ratings yet

- Android Based Object Detection Application For Food ItemsDocument6 pagesAndroid Based Object Detection Application For Food ItemsHafza GhafoorNo ratings yet

- No. Cat. Code Product NameDocument4 pagesNo. Cat. Code Product NameRyan SevenfoldNo ratings yet

- Alii Palau (English)Document84 pagesAlii Palau (English)Charlie ChandraNo ratings yet

- Basic Lip Balm Recipe Basic Balm Recipe: IngredientsDocument1 pageBasic Lip Balm Recipe Basic Balm Recipe: IngredientsmolsimNo ratings yet

- Detailed Lesson Plan in MAPEH Health IIDocument8 pagesDetailed Lesson Plan in MAPEH Health IIMa Marisa Arbalate100% (3)

- Ragi Mudde: Slurpyplat T e R.blo Gspo T .InDocument5 pagesRagi Mudde: Slurpyplat T e R.blo Gspo T .Innemo3045No ratings yet

- Pathfinder Scout Rank Worksheet: Requirement 1Document8 pagesPathfinder Scout Rank Worksheet: Requirement 1Khen Ivan Emerzon GabatanNo ratings yet

- Ethiopia Land Policy Administration Assessment 2004 EN PDFDocument110 pagesEthiopia Land Policy Administration Assessment 2004 EN PDFMahedre ZenebeNo ratings yet

- The Girl Who CanDocument4 pagesThe Girl Who Can2026 GOKALDAS DevinaNo ratings yet

- Example of SpoofDocument6 pagesExample of SpoofAdi NugrahaNo ratings yet

- Farleigh Road Lunch MenuDocument8 pagesFarleigh Road Lunch MenuLizNelsonNo ratings yet