Professional Documents

Culture Documents

Textile Quality01

Uploaded by

srini vasan0 ratings0% found this document useful (0 votes)

5 views1 pageOriginal Title

textile quality01

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views1 pageTextile Quality01

Uploaded by

srini vasanCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

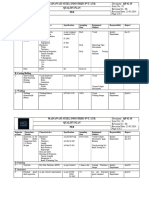

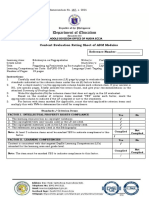

CUTTING DEPARTMENT

INTEGRATED QUALITY INSPECTION REPORT

Buyer Fabric Type Date

Order No Colour Check List Ok Not Ok

GSM Req Actual Fabric Bulk shade Approval

Descripton

Fabric Test Report

Fabnc Lot Dia Size Set Comments

Cad Approval

INITIAL PILOT RUN CUTTING AUDIT REPORT (MAXIMUM 500 Pattern Confirmation

PCS COVERING ALL SIZES)

Style Piece

(or) Available

BULK CUTING QUALITY AUDIT REPORT Comments

Q.A. Incharge CAD Cuting Incharge Sample Incharge

MAKER CONFIRMATION &AGAINST CAD PROGRAMME& LAYERING AUDIT REPORT

CHECK LIST OK NOT OK REMARKSS QUALITY AUDIT OBSERVATION AND COMMENTS

No. of Pieces

No. of Parts

Garment Direction

Ratio Conformation

Fabric Face side

Lay Length

Lay Height C.A.P. & P.A.P. (CORRECTIVE ACTION PREVENTIVE ACTION)

No of plys

table with/ Cuttable WTH

Spreading Method

Cut File Confirmation

On Machine

No. of Notches

Marker Setting Confimation EXECUTIVE CUTTING

Q.C. MICOPERATOR LAYERING

Shading SUPERVISOR INCHARGE

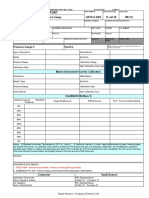

PATTERN AUDIT & SPEc CONFORMATION

CHECK LIST OK NOT OK REMARKS QUALITY AUDIT OBSERVATIONS AND COMMENTS

| Garment Shape (Body SLV, Others)|

Balancing Shade

Selvedge Visible

Half Cut Panel C.A. P.A:

Cut Raw Edges

Size Sticker conformation

Bundle Eveness Q.C.

BUNDLE VERIFICATION AUDIT REPORT LAY No TOTALBUNDLES

CHECK LIST BUNDLENo OKNOT OK REMARKS QUALITY AUDIT OBSERVATIONS AND COMMENTS

Lot No

Bundle No

Size

No of Pannel C.A. P.A

No of Pcs

Buyer

Style No. Q.C BUNDLE INCHARGE

You might also like

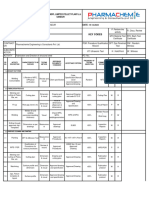

- Ultrasonic Laminations Test Report BatamDocument2 pagesUltrasonic Laminations Test Report Batamvinsensius rasaNo ratings yet

- Precision Equipments (Chennai) Pvt. LTD.: Ultrasonic Examination ReportDocument5 pagesPrecision Equipments (Chennai) Pvt. LTD.: Ultrasonic Examination ReportqaNo ratings yet

- Amc QapDocument8 pagesAmc QapSasanka SekharNo ratings yet

- Inspection MatrixDocument2 pagesInspection MatrixFabian BellNo ratings yet

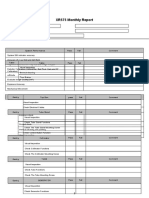

- DR-F Monthly ReportDocument3 pagesDR-F Monthly ReportarabNo ratings yet

- Form10 Shipment Report - Nov 2020Document1 pageForm10 Shipment Report - Nov 2020darithNo ratings yet

- Prds & Piping QapDocument2 pagesPrds & Piping QapPavul RajNo ratings yet

- Inspection Testing Plan (ITP)Document1 pageInspection Testing Plan (ITP)Kdown 99100% (1)

- Cable Continuity & Insulation Field Inspection ReportDocument1 pageCable Continuity & Insulation Field Inspection ReportHesham Helal100% (1)

- Client: Nlcil Subject: Quality Assurance Plan For Side Drain (Rev-00)Document2 pagesClient: Nlcil Subject: Quality Assurance Plan For Side Drain (Rev-00)Sasanka SekharNo ratings yet

- Quality Assurance PlanDocument4 pagesQuality Assurance PlanSasanka SekharNo ratings yet

- R Ew Ork M Inim IzationDocument58 pagesR Ew Ork M Inim IzationSaptarshi Bagchi100% (2)

- Saudi Aramco Test Report: Calibration Test Report - Pressure Recorder SATR-A-2004 24-Mar-16 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Pressure Recorder SATR-A-2004 24-Mar-16 MechSajid ShaikhNo ratings yet

- Condensate Collection Tank Qap 290722Document3 pagesCondensate Collection Tank Qap 290722Pavul RajNo ratings yet

- Trims InspectionDocument1 pageTrims InspectionprageethnirudakaNo ratings yet

- Simple LOS QAP FormatDocument1 pageSimple LOS QAP Formatmechdesign2k23No ratings yet

- Satr A 2002Document2 pagesSatr A 2002ramshad k aNo ratings yet

- QA-033 Outgoing Inspection Checklist Rev.GDocument1 pageQA-033 Outgoing Inspection Checklist Rev.GChoo Wei MingNo ratings yet

- Quality Assurance Plan For PEBDocument2 pagesQuality Assurance Plan For PEBBipin Vihari DasNo ratings yet

- Quality Assurance PlanDocument3 pagesQuality Assurance PlanNESTOR YUMULNo ratings yet

- Metallic Bellow QAPDocument2 pagesMetallic Bellow QAPPavul RajNo ratings yet

- QC Process Chart Template for Supplied PartDocument4 pagesQC Process Chart Template for Supplied Partbarja subarjaNo ratings yet

- QAP FormatDocument3 pagesQAP FormatSaravana Kumar100% (2)

- XR575 Monthly Report SummaryDocument2 pagesXR575 Monthly Report SummaryarabNo ratings yet

- Instrument Test SheetDocument2 pagesInstrument Test SheetMed CHNo ratings yet

- Instrument Test SheetDocument2 pagesInstrument Test SheetNsma AlaaNo ratings yet

- Check Sheet I QCDocument4 pagesCheck Sheet I QCEri ParihahNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 30-Apr-13 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 30-Apr-13 MechPradeepNo ratings yet

- Proposed QAP For Adani Internal CTR JobDocument2 pagesProposed QAP For Adani Internal CTR JobSasanka SekharNo ratings yet

- FAB Flow ChartDocument13 pagesFAB Flow ChartOCONER NORMAN - NCFSNo ratings yet

- SAIC-A-1015 Rev 8 HDPE Liner Receic Ving and Storage Insp Final.Document1 pageSAIC-A-1015 Rev 8 HDPE Liner Receic Ving and Storage Insp Final.Tito GarciaNo ratings yet

- Staircases & HandrailsDocument2 pagesStaircases & HandrailsPavul RajNo ratings yet

- Saudi Aramco Test Report: Mech-Calibration Test Report-Pressure Recorder SATR-A-2004 25-May-05Document1 pageSaudi Aramco Test Report: Mech-Calibration Test Report-Pressure Recorder SATR-A-2004 25-May-05Anonymous S9qBDVkyNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Pressure Recorder SATR-A-2004 22-Jan-18 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Pressure Recorder SATR-A-2004 22-Jan-18 MechaneeshNo ratings yet

- Vedanta Aluminium Plant Ltd. Quality Assurance Plan For Pot Line Maintenance Job (Rev-00)Document3 pagesVedanta Aluminium Plant Ltd. Quality Assurance Plan For Pot Line Maintenance Job (Rev-00)Sasanka SekharNo ratings yet

- Inspection Report: Khodiyar Spring IndustriesDocument1 pageInspection Report: Khodiyar Spring IndustriesVinay KumarNo ratings yet

- Testing and Commissioning Form For Suction/Booster Pumpset: Menajaya Oil Fats SDN BHDDocument1 pageTesting and Commissioning Form For Suction/Booster Pumpset: Menajaya Oil Fats SDN BHDMatthew WongNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 24-Mar-16 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 24-Mar-16 MechSajid ShaikhNo ratings yet

- Vedanta Aluminium Plant Ltd. Quality Assurance Plan For Buildinng Construction Job (Rev-00)Document4 pagesVedanta Aluminium Plant Ltd. Quality Assurance Plan For Buildinng Construction Job (Rev-00)Sasanka SekharNo ratings yet

- ENMAS EPC Quality Assurance Plan for Piping ComponentDocument2 pagesENMAS EPC Quality Assurance Plan for Piping ComponentPavul RajNo ratings yet

- American Bureau of Shipping: Application For Certification of Container Corner CastingsDocument3 pagesAmerican Bureau of Shipping: Application For Certification of Container Corner CastingsDarioNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 17-Mar-16 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 17-Mar-16 MechGOSP3 QC Mechanical100% (1)

- Quality Assurance Plan for Metallic Expansion Joint ManufacturingDocument1 pageQuality Assurance Plan for Metallic Expansion Joint Manufacturingdemas100% (1)

- IMTE RegisterDocument1 pageIMTE RegisterMomo Itachi100% (1)

- Saudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 22-Jan-18 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 22-Jan-18 MechaneeshNo ratings yet

- QAP1Document2 pagesQAP1akshaymehra2354No ratings yet

- Pressure Recorder Calibration Test ReportDocument2 pagesPressure Recorder Calibration Test ReportPradeepNo ratings yet

- Process Inspection ExampleDocument6 pagesProcess Inspection ExampleJayant Kumar JhaNo ratings yet

- Quality Assurance Plan for Steel Structure FabricationDocument1 pageQuality Assurance Plan for Steel Structure Fabricationvelmurug_balaNo ratings yet

- G030RWNYT0009Document1 pageG030RWNYT0009KarlaNo ratings yet

- PMO Office Building JobDocument3 pagesPMO Office Building JobSasanka SekharNo ratings yet

- SATR-A-2002Document2 pagesSATR-A-2002razzak.me.enggNo ratings yet

- Fireproofing Check List Quality Control and Inspection Report FormDocument1 pageFireproofing Check List Quality Control and Inspection Report FormAnonymous 4e7GNjzGWNo ratings yet

- Satr A 2002Document2 pagesSatr A 2002ansar aliNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 24-Jul-18 MechnadeemNo ratings yet

- 3) Qis (Sat)Document2 pages3) Qis (Sat)phutthawongdanchai041215No ratings yet

- TS-PTX-QUA-049-E-R03 Rotary Bushing Cat IIIDocument3 pagesTS-PTX-QUA-049-E-R03 Rotary Bushing Cat IIIict petrexNo ratings yet

- Quality Control PlanDocument13 pagesQuality Control Plandadz mingiNo ratings yet

- W.A.S.M.U.Widanaarachchi Postgraduate Institute of Science University of Peradeniya Peradeniya, Sri Lanka Csc2239@pgis - LKDocument7 pagesW.A.S.M.U.Widanaarachchi Postgraduate Institute of Science University of Peradeniya Peradeniya, Sri Lanka Csc2239@pgis - LKMalky WidanarachchiNo ratings yet

- ENC MSC 3 Unit Research LiteratureDocument24 pagesENC MSC 3 Unit Research Literatureenam professorNo ratings yet

- OJT RQMT MonitoringDocument4 pagesOJT RQMT MonitoringJerico VeranoNo ratings yet

- 52042-MariaPaulaMARTINEZ HERRERA-BSBRES411-CoverSheet-RESUBMISSION PDFDocument2 pages52042-MariaPaulaMARTINEZ HERRERA-BSBRES411-CoverSheet-RESUBMISSION PDFPaula MartinezNo ratings yet

- Sia Kelompok 10Document16 pagesSia Kelompok 10Desy manurungNo ratings yet

- Introducing HOIS - Nov 2020Document36 pagesIntroducing HOIS - Nov 2020David RodriguesNo ratings yet

- IT312 Systems Integration and Architecture PDFDocument55 pagesIT312 Systems Integration and Architecture PDFJayzon UmangayNo ratings yet

- CS2055 - Software Quality AssuranceDocument15 pagesCS2055 - Software Quality AssuranceHaripriya SridharanNo ratings yet

- Content Evaluation Rating Sheet of ADM ModulesDocument5 pagesContent Evaluation Rating Sheet of ADM ModulesJaycelyn BaduaNo ratings yet

- The Effect of Electronic Word of Mouth On Sales A Meta-Analytic Review of Platform Product and Metric FactorsDocument52 pagesThe Effect of Electronic Word of Mouth On Sales A Meta-Analytic Review of Platform Product and Metric FactorsHoda El HALABINo ratings yet

- Introduction To Dissertation WritingDocument29 pagesIntroduction To Dissertation WritingANDERSON ANTÔNIO DE LIMANo ratings yet

- Fi32BPP Course NotesDocument384 pagesFi32BPP Course NotesZ XNNo ratings yet

- Why Why Analysis Action PlanDocument1 pageWhy Why Analysis Action PlanDhileep KaippencheryNo ratings yet

- Strategy Planning and Execution From A To Z - Full BookDocument210 pagesStrategy Planning and Execution From A To Z - Full Booksalman aldoseri100% (2)

- Pmqa 3Document3 pagesPmqa 3YoushNo ratings yet

- Automation and Tax Compliance Empirical Evidence From Nigeria 2020Document10 pagesAutomation and Tax Compliance Empirical Evidence From Nigeria 2020Stalyn Celi BarreraNo ratings yet

- EQMS Integrated Internal Audit Checklist SampleDocument3 pagesEQMS Integrated Internal Audit Checklist SampleKishore RathodNo ratings yet

- Web-Based Thesis Evaluation System for CCS BiñanDocument17 pagesWeb-Based Thesis Evaluation System for CCS BiñanMan GeorgeNo ratings yet

- Four-Chapter Thesis Format GuideDocument11 pagesFour-Chapter Thesis Format GuideKrystelle EstradaNo ratings yet

- Evaluation Techniques: Human-Computer InteractionDocument22 pagesEvaluation Techniques: Human-Computer InteractionKristine Karylle NeveridaNo ratings yet

- Systematic Literature Review TemplateDocument8 pagesSystematic Literature Review Templateafduaciuf100% (1)

- Guide For The Classification of Drilling SystemsDocument234 pagesGuide For The Classification of Drilling SystemsFadil WimalaNo ratings yet

- Quiz 698Document30 pagesQuiz 698Raymond RamirezNo ratings yet

- Research10 1Document12 pagesResearch10 1Harlyn May Dumay EstradaNo ratings yet

- CIVE263 Group Design Project Brief 2019-20 v6Document15 pagesCIVE263 Group Design Project Brief 2019-20 v6Marvin ItolondoNo ratings yet

- Chapter 10 MDS and Correspondence AnalysisDocument49 pagesChapter 10 MDS and Correspondence AnalysisHasna SalmaNo ratings yet

- Eco Project-Ms Esl EflDocument6 pagesEco Project-Ms Esl Eflapi-524845185No ratings yet

- QA Plan Template BlankDocument31 pagesQA Plan Template Blankorawan_j100% (4)

- SEC - 14 - Security Project ManagementDocument38 pagesSEC - 14 - Security Project ManagementQamar Arif100% (4)

- Performance Management Plan PDFDocument12 pagesPerformance Management Plan PDFEnrique CuestaNo ratings yet